How Much Power Can a Built FA20 Engine Handle?

Share

Adding power to your FA20 before addressing its known weak points is a recipe for disaster. The platform's oiling system, in particular, struggles under the demands of track use—and ignoring it is the most common and costly mistake owners make. A properly built FA20 engine isn't just about chasing big power numbers; it's about creating a bulletproof foundation that can handle that power reliably. We'll walk you through the essential upgrades, from forged internals to a proper Air/Oil Separator, that are non-negotiable for protecting your investment and building an engine that lasts.

Key Takeaways

- Prioritize Forged Internals for Real Power: Before adding a turbo or an aggressive tune, you must replace the stock pistons and rods. Forged components are the non-negotiable foundation for building an FA20 that can safely handle significant horsepower without catastrophic failure.

- Address Supporting Systems for Long-Term Reliability: A strong short block is just one part of the equation. A successful build requires a complete system, including an upgraded oiling system (like an Air/Oil Separator), a robust fuel pump, and a professional tune to ensure all parts work together harmoniously.

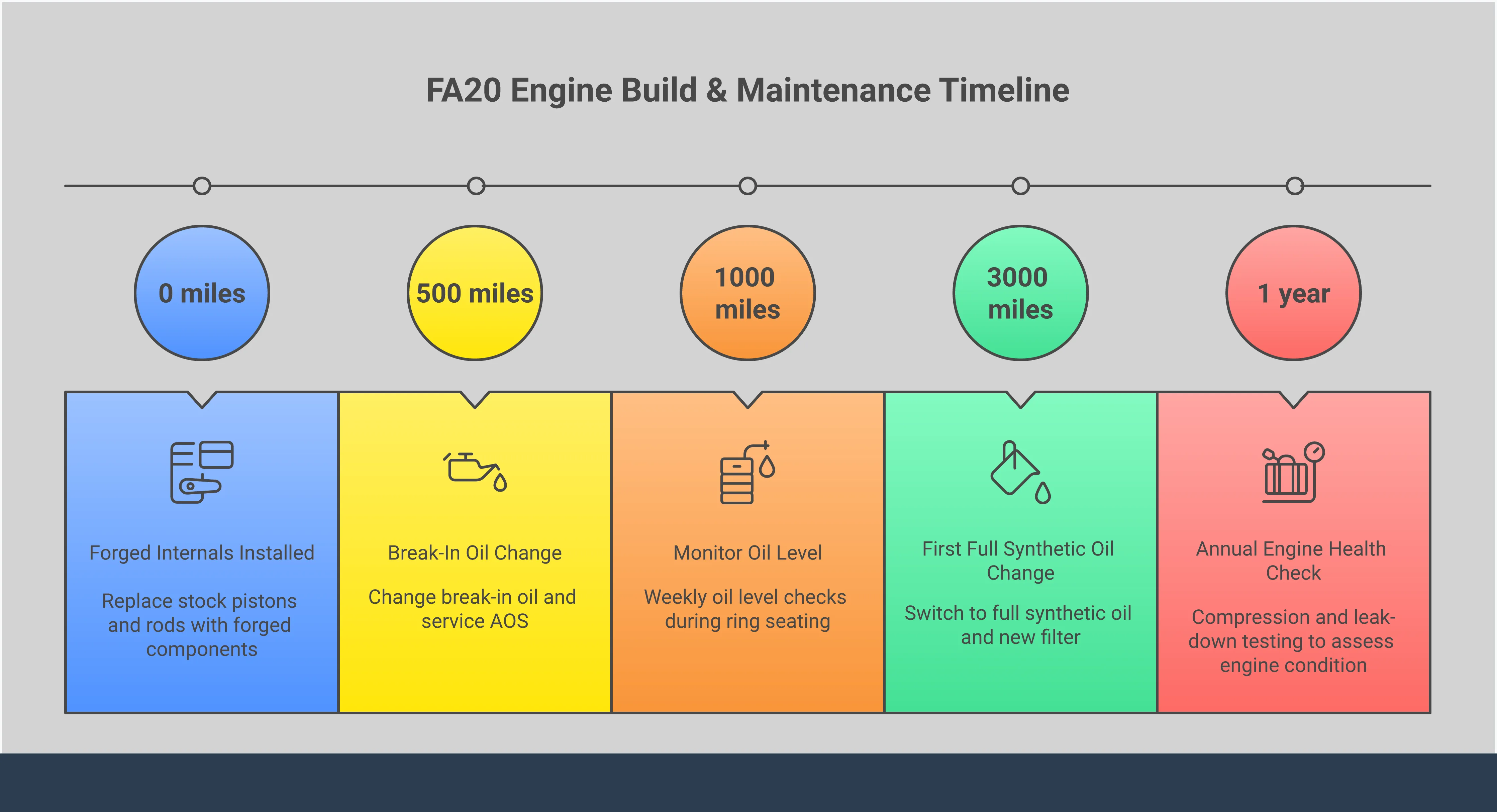

- Commit to a Strict Maintenance and Break-In Plan: A built engine demands more care than a stock one. Following a meticulous break-in procedure and adhering to a schedule of frequent, high-quality oil changes is essential for protecting your investment and ensuring its longevity.

What Is a Fully Built FA20 Engine?

When you hear the term "fully built FA20 engine," it means the engine has been completely overhauled with high-performance aftermarket parts. This isn't about adding a few bolt-on accessories; it's a comprehensive process where the engine is disassembled and reconstructed with components designed to handle significantly more power and stress than the original factory parts. The goal is to create a powerhouse that is not only stronger but also more reliable under the extreme conditions of track driving, overlanding, or aggressive street use. A built engine gives you the confidence to push your vehicle harder, knowing it has the foundation to support that performance.

Building a powerful FA20 isn't just about chasing higher horsepower numbers. It's about creating a balanced and durable system where every component works together in harmony. A stock engine is designed by Subaru to meet the needs of the average driver, balancing performance with fuel economy and emissions standards. A built engine, on the other hand, is engineered specifically for performance, reinforcing weak points and preparing the entire assembly to withstand the demands of professional engine tuning services and forced induction. This transformation turns your Subaru WRX or BRZ into a machine capable of achieving its true performance potential without compromising its long-term health.

Stock vs. Built: What's the Difference?

The primary difference between a stock and a built FA20 lies in the strength of the internal components. Factory engines use parts, like cast pistons and connecting rods, that are perfectly adequate for daily driving but can become failure points when you start adding significant power. A built engine replaces these with much stronger forged internals that can handle higher cylinder pressures and temperatures without breaking a sweat.

This isn't just about adding horsepower; it's about ensuring the engine can manage the increased demands without sacrificing reliability. While a stock FA20 is a capable platform, pushing it far beyond its intended limits with aggressive tunes or larger turbos is a recipe for disaster. A built engine provides the robust foundation needed to support those performance parts and unlock serious power safely.

What Upgrades Define a Built Engine?

A proper FA20 build focuses on several key areas to create a reliable high-performance engine. The first and most critical step is upgrading to forged internals. Forged pistons and connecting rods are the heart of any built motor, providing the strength needed to handle increased boost and higher RPMs. Without this foundation, any other power-adding modifications are risky.

Beyond the internals, addressing the engine's support systems is non-negotiable. Upgraded oiling and cooling systems are essential for managing the extra heat generated by a more powerful engine. A critical component for engine longevity is an Air/Oil Separator (AOS), which prevents oil from contaminating the intake system—a common issue that can lead to detonation and engine damage. These targeted upgrades ensure your built engine remains reliable under pressure.

Understanding Common FA20 Engine Problems

Before you can build a stronger engine, you need to understand its inherent weaknesses. The FA20 is a fantastic platform, but it has a few well-known vulnerabilities, especially when subjected to the high stress of track days or aggressive driving. The most common and costly mistake owners make is adding power without first addressing these weak points. The factory oiling system, for instance, can struggle to keep up under high G-forces, leading to oil starvation. This single issue is often the root cause of many catastrophic failures, turning a fun track day into a very expensive tow home. Understanding these limitations is the first step toward building a reliable powerhouse.

Common Mechanical Failures

The most talked-about issues with the FA20 often trace back to its internal components. Under increased power, the stock connecting rods are a significant failure point, as they can only reliably handle so much torque before they give out. This often results in the dreaded "rod knock," which is essentially a death sentence for the engine block. Similarly, premature bearing wear is another common problem, frequently caused by oiling issues or the added stress from more aggressive engine tuning. These aren't just random occurrences; they are predictable outcomes when the engine is pushed beyond its factory design without the proper supporting modifications.

Significant oil consumption can also plague these engines, especially as they age or are driven hard. This isn't just an annoyance that requires you to top off your oil frequently; it can lead to lower oil levels that worsen the risk of oil starvation and bearing damage. Building a reliable FA20 means you have to address these core issues head-on. Investing in a set of robust performance parts, like forged rods and pistons, isn't just for making more power—it's for ensuring your engine can actually survive it.

Factory Recalls and Service Bulletins

Beyond the mechanical weak points, it's also crucial to be aware of any factory recalls or technical service bulletins (TSBs) that may apply to your specific vehicle. The most notable example for the FA20 platform was the valve spring recall that affected some early Subaru BRZ and Scion FR-S models from 2012-2013. An issue like this, if left unaddressed, could lead to engine failure regardless of what modifications you've made. It's a simple but essential step to check with your local dealership or search online for any open recalls for your VIN.

Think of it as ensuring your foundation is solid before you start building on it. Addressing any factory-identified issues ensures you aren't building on a flawed base. It also prevents a situation where a recall-related failure could be mistakenly blamed on your aftermarket parts, potentially complicating warranty claims or repairs. Taking care of these official service items is a responsible part of the modification process and sets your project up for long-term success and reliability on the road or track.

Anatomy of a Built FA20 Engine

A "fully built" engine isn't about a single magic component; it's a carefully selected system of upgraded parts designed to work in harmony. When you push the FA20 beyond its factory limits, certain stock components become weak points. A proper build addresses these vulnerabilities head-on, replacing them with robust parts that can handle the increased stress, heat, and power. This process transforms the engine from a reliable daily driver into a high-performance powerhouse capable of withstanding the demands of the track or trail.

The core of any build focuses on three critical areas: the rotating assembly (internals), the lubrication and cooling systems, and the fuel and air delivery systems. Each area is a piece of the puzzle, and neglecting one can compromise the entire engine, no matter how much you invest in the others. By strengthening the engine's foundation with forged internals, ensuring its longevity with better cooling, and supplying it with the fuel it needs, you create a balanced and reliable setup. These upgrades are what separate a weekend project from a professionally built engine designed for sustained performance.

Why Forged Internals Are Your First Upgrade

The heart of any high-horsepower engine is its rotating assembly—the pistons, connecting rods, and crankshaft. Stock FA20 internals are designed for factory power levels, but they can fail under the immense pressure of increased boost and cylinder pressures. This is where forged components come in. Unlike cast stock parts, forged internals are manufactured under extreme pressure, creating a denser and stronger grain structure. Upgrading to forged internals is a non-negotiable step for building an engine that can reliably handle significant power. These parts provide the strength needed to prevent catastrophic failure, making them the true foundation of your built FA20.

Don't Skip These Oiling and Cooling Upgrades

Building a powerful FA20 isn't just about adding horsepower; it's about making sure the engine can handle the increased demands without sacrificing reliability. More power generates more heat, and the stock oiling and cooling systems can quickly become overwhelmed. The FA20, in particular, can experience oil starvation during high-G cornering. Addressing these vulnerabilities with targeted performance parts like an Air/Oil Separator is not just a good idea—it’s a critical step for ensuring your built engine remains reliable under pressure. An AOS prevents oil from contaminating your intake and helps manage crankcase pressure, protecting your engine when it matters most.

Essential Fuel and Valvetrain Modifications

To make more power, your engine needs more air and fuel. The stock fuel system can only supply so much, creating a ceiling on your horsepower goals. Upgrading to higher-flow fuel injectors and a more robust fuel pump is essential to prevent leaning out the engine, which can cause detonation and severe damage. While some worry about the FA20’s direct injection system and carbon build-up, a professional tune can manage this effectively. Proper engine tuning services ensure the entire system works together, optimizing fuel delivery and ignition timing for your specific setup and power goals.

Who Builds the Best FA20 Engines?

When you’re ready to invest in a built engine, choosing the right builder is one of the most critical decisions you'll make. The "best" builder often depends on your specific goals, budget, and how you plan to use your car. Are you looking for a reliable daily driver with more punch, or are you building a dedicated track machine? Different builders specialize in different areas, from short blocks designed for custom projects to complete, drop-in engine solutions.

Look for a builder with a proven track record, transparent communication, and a deep understanding of the FA20 platform's unique characteristics. A reputable builder won't just sell you an engine; they'll offer guidance on the supporting modifications and tuning required to make it run safely and reliably. They should be able to explain their component choices and assembly process clearly. We’ll cover a few of the top names in the industry to help you understand the different approaches to building a high-performance FA20.

Our Approach to Building a Bulletproof FA20 Short Block

With over two decades of experience, we’ve dedicated ourselves to finding the most durable components for Subaru engines. Our approach centers on meticulously engineered built short blocks that serve as the foundation for a powerful and reliable build. We use our own proprietary parts, including CrawfordSPEC JE Forged Pistons and CrawfordSPEC Pauter Billet Rods, which are the result of years of in-house testing. Our unique piston design helps the engine run smoother and make more power at the same boost level. To ensure a successful installation, we also offer a Short Block Installation Kit that includes all the necessary components and even specialized break-in oil.

HKS: The All-in-One Engine Package

HKS is a legendary name in the tuning world, known for its high-quality, comprehensive solutions. Their approach is to offer a complete FA20 engine built specifically for forced induction applications. These engines are assembled with top-tier components like ARP main bolts and forged I-beam connecting rods, designed to handle significant power increases right out of the crate. HKS offers different build levels, or "steps," allowing customers to choose an engine that matches their power goals. This makes them a strong choice for those who want a proven, ready-to-install package from a single, reputable manufacturer.

HKS 2.2L Technical Specifications

HKS takes a comprehensive approach with its stroked 2.2L engine, increasing displacement from the stock 1,998 cc to 2,116 cc. This is done by increasing both the cylinder bore to 86.5mm and the piston stroke to 90.0mm. A longer stroke means the piston travels farther down the cylinder, pulling in more air and fuel with each revolution—a key factor for making more power, especially with forced induction. HKS also sets the compression ratio at 10.4, creating a balance that works well for boosted applications. These complete engines come in different stages, or "STEPs," so you can choose a build that matches your performance goals.

Advanced Features of HKS Builds

Beyond the larger displacement, HKS engines are built with a suite of high-performance components designed for durability under pressure. They include stronger forged pistons, connecting rods, and crankshafts, plus upgraded bearings and gaskets to handle the stress of high horsepower. Key features include added oil jets to cool the pistons and high-angle camshafts that improve power delivery at high RPMs. The more advanced STEP 2 engine takes it a step further with a "closed deck" block for superior cylinder wall strength, special copper and bronze valve seats for better heat dissipation, and hand-ported intake and exhaust ports to maximize airflow. These upgrades result in a robust engine ready for the track.

Other Reputable Builders to Consider

Building a powerful FA20 isn't just about assembling strong internal parts; it's about creating a balanced system that can handle the stress. A reliable build addresses the platform's known vulnerabilities from the start. When researching builders, ask how they handle potential oiling and cooling issues under high load. The inclusion of targeted performance parts like an Air/Oil Separator is a great sign that a builder is focused on long-term reliability, not just peak horsepower numbers. A truly great engine is one that you can depend on, whether you're on the street or at the track.

What Power Can a Built FA20 Handle?

The stock FA20 engine is a capable performer right out of the box, but its true potential is unlocked with a proper build. When you start upgrading components, the question quickly becomes: how much power can it really handle? The answer isn't a single number—it's a range that depends entirely on the quality of the build, the supporting modifications, and the final tune. A well-built FA20 can transform your Subaru from a fun daily driver into a serious track or off-road machine.

Building a powerful FA20 isn't just about chasing a peak horsepower figure; it's about creating a reliable engine that can handle the increased demands without compromising its longevity. The goal is to achieve a balance where power, torque, and durability work together. With the right combination of parts and expert engine tuning services, you can push the FA20 platform to impressive levels, whether you're aiming for a responsive street car or a high-output competition build. The key is a strategic approach that addresses the engine's weak points and strengthens it for the power you intend to make.

How Much Power Can You Expect at Each Stage?

Your power goals will dictate the necessary build stage. For moderate gains, basic bolt-ons might suffice, but for anything significant, you need to strengthen the engine's core. Upgrading to forged internals and improving the oiling and cooling systems are non-negotiable steps for building an engine that can reliably handle a serious power increase. These foundational upgrades ensure the engine can withstand the higher cylinder pressures and temperatures that come with forced induction and aggressive tuning.

With a professional build, the FA20 can support substantial power. For example, a Crawford Performance Built Short Block is designed to handle up to 660 horsepower. It's important to remember that figures like these represent the maximum these parts can handle when the car is properly maintained and tuned. Reaching these levels requires a complete ecosystem of supporting performance parts, including an upgraded fuel system, a robust drivetrain, and a well-designed turbo or supercharger kit.

Stock Engine Limitations and Tuning Factors

Before you can build a powerful engine, you need to understand the limitations of the stock setup. The factory FA20 is engineered for a specific balance of performance, efficiency, and reliability under normal driving conditions. When you start demanding more, you quickly run into mechanical and logistical ceilings. Key factors like the physical strength of the stock internals, the capacity of the fuel system, and even the type of fuel you use will dictate how much power you can safely make. A professional tune can work wonders, but it can't defy the laws of physics—at some point, hardware upgrades become essential.

Power Limits of the Stock FA20

The stock FA20 engine is a solid performer for daily driving, but its internal components were not designed for high-horsepower applications. The connecting rods are widely considered the primary weak point and are often the first components to fail when boost levels are increased significantly. While there's no exact horsepower number where the stock engine will let go, most experienced tuners agree that pushing much beyond 300-350 wheel horsepower on a stock block is entering a high-risk zone. This limit is heavily influenced by the quality of the tune, the fuel used, and how the car is driven. For reliable power, upgrading to a built short block with forged performance parts is the only way to create a durable foundation.

The Role of Fuel Type in Power Output

Making more power requires a precise mixture of more air and more fuel. The stock fuel system is designed to meet the engine's factory demands, but it quickly becomes a bottleneck with performance upgrades. If the fuel pump and injectors can't supply enough fuel, the engine will run lean, causing a spike in cylinder temperatures that can lead to detonation and catastrophic engine damage. Furthermore, the type of fuel you use plays a massive role. Higher-octane fuels like 93 or E85 are more resistant to knock, which allows a tuner to advance ignition timing and increase boost safely. This is why professional engine tuning services are critical for optimizing your setup for the fuel you have available.

Understanding Dyno Variations

Many owners get fixated on hitting a specific horsepower number on a dynamometer, but these figures can be misleading. A dyno is first and foremost a tuning tool, not a definitive measure of power. Different types of dynos, such as a DynoJet versus a Mustang dyno, will produce different readings for the exact same car due to how they calculate load and resistance. Environmental factors like air temperature and humidity also impact the results. Instead of chasing a number, it's more productive to focus on the power gains achieved and the overall health of the tune. A smooth power curve and a reliable engine are far more valuable than a high number on a printout from a single dyno session.

Should You Add Displacement or Forced Induction?

To make big power, an engine needs to move more air. Beyond strengthening the internals, the two primary ways to achieve this are by increasing displacement or adding forced induction. Many builders opt for both. Increasing displacement, often by "stroking" the engine, gives you a larger combustion chamber, which naturally produces more torque and horsepower. For instance, some aftermarket solutions increase the FA20 from its stock 2.0 liters to 2.1 or 2.2 liters.

This extra displacement is especially effective when paired with a turbocharger or supercharger. A larger, stronger engine is better equipped to handle the immense pressure and airflow from a forced induction system. Engines like the HKS FA20 2.2L are specifically engineered for this purpose, featuring specialized parts designed to manage the stress. Whether you're building a high-revving track car or a torque-focused overlanding rig, combining a built bottom end with the right forced induction setup is the proven path to unlocking the FA20's maximum potential.

How Much Does a Fully Built FA20 Cost?

Planning your budget is one of the most critical steps in any engine build. The total cost for a fully built FA20 can vary widely based on your power goals, the parts you choose, and whether you handle the installation yourself. It’s important to look at the full picture, from the engine block itself to all the necessary supporting components and labor, to get a realistic idea of the investment required.

The Price Difference: Complete Engines vs. Short Blocks

When you start pricing out a built FA20, you'll find two main paths: complete crate engines and built short blocks. A complete engine, like the HKS FA20 2.2L, arrives fully assembled with high-performance components. It's a premium, drop-in solution for those seeking maximum power with minimal guesswork, but it comes with a significant price tag. The more common and flexible route is starting with a built short block. Our Crawford Performance Built Short Block FA20 provides a robust foundation with forged internals, ready to handle serious power. This approach allows you to customize the rest of the build to your specific goals and budget.

The Hidden Costs: Installation and Supporting Mods

The cost of the engine or short block is just the starting point. To get your car running safely and powerfully, you have to budget for installation and a host of supporting modifications. Labor costs for an engine swap can vary depending on your chosen shop's rates and the complexity of your build. Beyond that, a built engine requires more fuel, better cooling, and freer-flowing exhaust to perform correctly. You'll need to invest in an upgraded fuel system, a high-performance exhaust, and potentially a new radiator or oil cooler. Finally, professional engine tuning services are non-negotiable to ensure all the new components work together harmoniously and reliably.

Upgrading Your Drivetrain to Match Your Power

Adding a ton of horsepower to your engine is exciting, but that power is useless if you can't transfer it to the wheels reliably. The stock transmission and clutch in your Subaru are engineered for factory output, and they can quickly become a weak point when dealing with a significant power increase. The last thing you want is to invest in a built engine only to have your clutch slip or your transmission fail. For this reason, a high-performance clutch is an essential upgrade to handle the extra torque. For more extreme builds, you may need to go further by strengthening the transmission itself. Building a powerful car is about creating a balanced system, and these performance parts provide the durability needed to put your power down confidently.

Common Supporting Mods: EGR & TGV Deletes

On the FA20 engine, the Exhaust Gas Recirculation (EGR) and Tumble Generator Valve (TGV) systems are designed to help with emissions, but they can become a source of problems on a modified engine. Over time, these systems can contribute to significant carbon buildup in the intake manifold, restricting airflow and hurting performance. Removing these components helps keep your engine's intake air cleaner and cooler, which is beneficial for making consistent power. However, this isn't a simple bolt-off modification. The EGR and TGV systems are integrated into the ECU, and removing them without a proper tune will trigger a check engine light and cause poor performance. This is why professional engine tuning services are required to recalibrate the software, ensuring your engine runs smoothly while taking full advantage of the cleaner airflow.

Which Subaru Models Use the FA20 Engine?

The FA20 is a 2.0-liter flat-four boxer engine that became a staple in Subaru's modern lineup, most notably powering the Subaru WRX from 2015 to 2021. However, its most famous application is the lightweight, rear-wheel-drive sports car platform developed jointly by Subaru and Toyota.

This collaboration resulted in the Subaru BRZ, Scion FR-S, and Toyota 86—a trio of cars celebrated for their exceptional balance and handling. The FA20 was the heart of these vehicles, specifically engineered to sit low in the chassis to maintain an optimal center of gravity. While the engine is most associated with these models, understanding its compatibility and what’s required for an installation or swap is key before starting any project. Whether you're looking to build a high-horsepower track car or simply get more from your daily driver, knowing the platform's foundation is the first step.

Confirming Fitment for BRZ, FR-S, and GT86

The FA20 engine is the original power plant for the Subaru BRZ, Scion FR-S, and Toyota 86. These cars were designed around this specific engine, making it a perfect fit right from the factory. The FA20’s compact, flat design allows it to be mounted low in the chassis, which is a major reason these cars are praised for their sharp handling and balanced feel. Because the engine and chassis were developed together, the stock compatibility is seamless. This inherent design synergy means that when you decide to build upon the stock block, you’re working with a platform that was meant to be a cohesive unit from day one.

Installation Needs and Required Systems

If you're considering an engine swap or installing a fully built FA20, there are several critical systems to address. For instance, swapping in a turbocharged FA20DIT from a WRX requires significant modifications. You'll need to account for the entire turbo system, an intercooler, and an upgraded fuel system to support the increased power. The engine management system will also need a professional engine tuning service to function correctly.

Even when swapping a like-for-like FA20, details matter. Installing a newer model year FA20 into an older BRZ or GT86 can present challenges with wiring harnesses, engine mounts, and transmission compatibility. It's essential to verify that all your performance parts and factory components will work together before you begin the installation.

Avoiding Common Pitfalls in Your FA20 Build

Building a high-performance FA20 engine is an exciting project, but it comes with its own set of hurdles. It’s more than just adding a turbo and calling it a day; a successful build requires a thoughtful approach to creating a balanced and durable powertrain. The FA20 is a capable platform, but pushing it far beyond its factory limits exposes inherent weaknesses that must be addressed to avoid catastrophic failure.

The primary challenges revolve around three key areas. First, ensuring the engine remains reliable as you increase horsepower and torque. Second, managing the budget, which can quickly escalate and lead some to consider engine swaps as a more practical alternative. Finally, you must overcome the platform’s known heat and oiling issues right from the start. Addressing these potential problems with the right performance parts and a solid plan is the key to building an FA20 that delivers thrilling power without sacrificing peace of mind.

Can a High-Power FA20 Still Be Reliable?

Adding significant horsepower puts immense stress on an engine’s internal components. The factory pistons, connecting rods, and bearings in the FA20 were designed for stock power levels, and they simply can't withstand the increased cylinder pressures and heat from forced induction or aggressive tuning. This is why upgrading to forged internals is a non-negotiable step for any serious build.

True reliability, however, goes beyond just the short block. It’s about creating a cohesive system where every part supports your power goals. This includes a robust cooling system to manage heat, an efficient oiling system to ensure proper lubrication, and precise engine tuning services to keep everything operating safely. A well-built engine isn’t just powerful; it’s engineered to handle that power consistently, lap after lap or mile after mile.

Sticking to Your Budget: Build vs. Swap

Let’s be direct: building a reliable, high-horsepower FA20 can be expensive. As you push toward goals of 400 or 500 horsepower, the cost of the necessary components, machine work, and labor adds up. For some enthusiasts, the investment required to make the FA20 bulletproof reaches a point where other options become more attractive.

This is why engine swaps like the LS, K-series, or even Subaru’s own EJ series are popular alternatives. These platforms often have a larger aftermarket, a simpler path to making big power, and in some cases, a lower overall cost for achieving a specific horsepower target. Deciding between building the FA20 and swapping in a different motor comes down to your ultimate goals, your budget, and your personal preference for keeping the car’s original heart.

DIY vs. Pre-Built Engines: A Cost and Time Comparison

One of the first major decisions you'll face is whether to build the engine yourself or purchase a pre-built short block. The DIY route can seem like the more affordable option, but hidden costs add up quickly. You'll need specialized tools, and you'll almost certainly need to pay for professional machine work. If something goes wrong, the cost of replacing damaged parts falls on you. A pre-built engine from a reputable shop offers a fixed cost and often includes a warranty, giving you peace of mind. It also dramatically reduces your car's downtime from weeks or months to just the time it takes for the swap, getting you back on the road or track much faster.

High-Horsepower Alternatives: Common Engine Swaps

When the goal is extreme horsepower, some builders find that swapping to a different engine platform is a more direct path. While a built FA20 is incredibly capable, engine swaps like the GM LS-series, Honda K-series, or even Subaru's own EJ series are popular for a reason. These engines often have a larger aftermarket for high-power applications and can sometimes be a more cost-effective way to reliably reach 500+ horsepower. The decision to swap comes down to your budget, power goals, and whether you want to retain the original Subaru boxer engine. It's a trade-off between the unique character of the FA20 and the raw potential of other proven platforms supported by a vast array of performance parts.

How to Fix Common Heat and Oiling Issues

Before you even think about adding power, you need to address the FA20’s most well-known vulnerability: its oiling system. Under high-G cornering on the track or even during spirited driving, the stock system can struggle to prevent oil starvation, leading to premature wear and potential engine failure. This is why installing a high-quality Air/Oil Separator (AOS) is one of the first and most critical modifications for any FA20.

An AOS prevents oil from contaminating the intake system and helps manage crankcase pressure, ensuring your engine is lubricated properly under load. Paired with an upgraded oil cooler, you can effectively manage the two biggest threats to your built motor—heat and oil pressure loss. Addressing these foundational issues first provides the stable platform you need for all future Subaru WRX upgrades.

How to Choose the Right FA20 Build for You

Choosing the right FA20 build comes down to being honest about your goals, budget, and how you plan to use your car. There’s no single "best" build—the ideal setup for a daily driver hitting the occasional track day is very different from a dedicated race car. Before you start buying parts, it’s crucial to map out your entire plan, from the engine internals to the final tune. This approach ensures all your components work together harmoniously and helps you avoid costly mistakes down the road. Let's break down the key factors you need to consider.

Power vs. Reliability: How to Choose

It’s easy to get caught up in chasing big horsepower numbers, but a truly successful build balances power with durability. Building a powerful FA20 isn't just about adding horsepower; it's about making sure the engine can handle the increased demands without sacrificing reliability. Pushing the limits of your stock block might be fun for a little while, but it’s a quick way to end up with a blown engine. For any build aiming for significant power gains, upgrading to forged internals and improving the oiling and cooling systems are non-negotiable steps. These core performance parts create a foundation that can reliably handle the stress of added boost and higher RPMs, giving you peace of mind on the street and the track.

Matching Your Tune and Fuel System to Your Build

Your built engine is only one piece of the puzzle. To get the most out of your investment, you need a solid plan for your fuel system and a professional tune. To get the best advice, you should share more information about your current engine parts, like your valves, springs, cams, pistons, and connecting rods. A larger turbo and forged pistons won’t perform correctly without enough fuel, so upgrades like high-flow injectors and a robust fuel pump are essential. Using high-quality fuel like E85 can also make a huge difference, but it requires a compatible system. A professional engine tuning service will tie everything together, ensuring your engine runs safely and efficiently while delivering the power you paid for.

Does a Built Engine Come with a Warranty?

Investing in a fully built engine is a major decision, and it’s natural to wonder how it affects your vehicle’s warranty. While the manufacturer won’t cover your new high-performance engine, a reputable builder will stand behind their work. Understanding the difference between factory and builder warranties will give you the confidence to move forward with your project.

A common myth is that installing any aftermarket part instantly voids your entire vehicle warranty. While federal law offers some protection, replacing a core component like the engine shifts the responsibility from the manufacturer to the builder. That’s why choosing a builder who offers a solid warranty is critical—it’s a direct reflection of their confidence in their craftsmanship.

What Does a Standard Engine Warranty Cover?

When you modify your Subaru, it’s helpful to know your rights. The Magnuson-Moss Warranty Act ensures that a manufacturer cannot void your entire vehicle warranty just because you’ve installed aftermarket performance parts. For a warranty claim to be denied, the dealer must demonstrate that the aftermarket part was the direct cause of the necessary repair.

For example, if you install a built short block and your car’s navigation system fails, the dealer cannot blame the engine modification. The warranty for the electronics should still be honored. However, the factory warranty will no longer cover the engine itself or any components directly affected by its installation and increased power output. This is where the builder’s own warranty becomes essential.

The Crawford Performance 12-Month/12,000-Mile Warranty

We stand behind every engine we build. That’s why our built FA20 short blocks come with a comprehensive 12-month/12,000-mile warranty. This coverage gives you peace of mind, knowing your investment is protected against defects in materials and workmanship. We build our engines to handle immense power reliably, and our warranty reflects our confidence in the final product.

When you purchase a built engine component from us, you receive a brand-new part. You don’t need to return your old engine block, which means there are no core fees to worry about. This straightforward process, combined with our expert engine tuning services, ensures you get reliable performance from day one. Our warranty is our promise of quality.

How to Maintain Your Built FA20 Engine

Investing in a built FA20 engine is a serious commitment to performance, and protecting that investment requires a dedicated maintenance plan. Unlike a stock motor, a built engine operates under much higher stress and tighter tolerances. Proper care from day one is the single most important factor in ensuring its longevity and reliability. The process starts with a meticulous break-in period, followed by a consistent long-term maintenance schedule. Getting this right means you can enjoy all that extra power with confidence, whether you're on the track or a winding back road.

Think of it this way: you wouldn't run a marathon without warming up first. The break-in is your engine's warm-up, setting the stage for a long and healthy life. After that, it's all about staying vigilant with monitoring and fluid changes to keep it running at its peak.

The Critical First Miles: Your Engine Break-In Guide

The first 500 to 1,000 miles are the most critical for your new engine. This is when the piston rings seat against the cylinder walls, bearings settle, and all the new components learn to work together. Rushing this process is the fastest way to undo all the hard work and investment. Your engine builder will provide specific instructions, and you should follow them exactly. Generally, this involves varying the engine speed, avoiding constant RPMs (like on the highway), and staying out of high-load situations. Before you even think about chasing power, it's essential to address the FA20's known oiling issues with the right performance parts to ensure everything is properly lubricated from the start.

How to Monitor and Maintain Your Built Engine

Once your engine is broken in, the focus shifts to consistent, preventative care. A built engine is less forgiving of neglect than a stock one. Use high-quality oil and change it more frequently than the factory recommends—many owners opt for intervals between 3,000 and 5,000 miles. Pay close attention to your engine's health by monitoring oil pressure and temperature. One of the biggest risks to these engines is low-speed pre-ignition (LSPI), which can occur when you apply heavy throttle at low RPMs. A professional tune is your best defense, as it optimizes fuel and ignition timing to prevent this dangerous knock. Proper engine tuning services will help you safely access your engine's full potential while maintaining reliability for years to come.

Related Articles

- Best Built FA20 Engine for BRZ: A Complete Guide

- FA20 Engine Price: A Breakdown of the Total Cost

- 4 Mods to Boost FA20 Engine Reliability

Frequently Asked Questions

Do I really need a fully built engine for my daily driver? For most daily driving with basic bolt-on parts, your stock FA20 engine is perfectly capable. However, if your goal is to add a turbocharger, supercharger, or push for significant horsepower gains, a built engine stops being a luxury and becomes a necessity for reliability. Think of it as building a strong foundation before you build the house—it ensures your engine can safely handle the extra power you plan to add without risking catastrophic failure.

Why is an Air/Oil Separator (AOS) mentioned so often for the FA20? The FA20 is known to have oiling system vulnerabilities, especially during aggressive driving or track use. An AOS is a critical supporting part that prevents oil from entering your intake system, which can lower your fuel's octane and lead to a dangerous condition called detonation. Installing a quality AOS is one of the most important preventative measures you can take to protect your engine, whether it's stock or fully built.

Can I just add a turbo or supercharger to my stock FA20 without building the internals? While it's technically possible to add forced induction to a stock FA20, it's an extremely risky path. The factory pistons and connecting rods were not designed to handle the increased cylinder pressure and heat that come with significant boost. Pushing a stock block this way often leads to engine failure. A proper build replaces these weak points with forged internals, giving you a durable foundation that can safely manage the power.

How long can I expect a built FA20 engine to last? A professionally built and properly maintained FA20 can be incredibly durable, often lasting as long as a stock engine, even under high-performance conditions. The key factors determining its lifespan are the quality of the components, the precision of the assembly, a conservative and professional tune, and your commitment to the break-in procedure and regular maintenance. Its longevity is truly in your hands after the build is complete.

Is a professional tune absolutely necessary after the build? Yes, a professional tune is a non-negotiable final step. A built engine is a complex system of new, high-performance components that need to be calibrated to work together perfectly. The tune optimizes air-fuel ratios, ignition timing, and boost levels for your specific setup. Skipping this step not only leaves power on the table but also puts your entire investment at risk of severe damage.

Essential Monitoring Tools

A built engine communicates its health differently than a stock one, and the factory dashboard won't tell you the whole story. To protect your investment, you need to see what's happening in real-time. Pay close attention to your engine's health by monitoring oil pressure and temperature with dedicated aftermarket gauges. These tools provide precise readings that can alert you to a potential problem, like dropping oil pressure during a hard corner, long before it becomes a catastrophic failure. An air/fuel ratio (AFR) gauge is another smart addition, as it helps you ensure your engine isn't running dangerously lean. Think of these gauges as your engine's vital signs monitor—they're essential performance parts for preventative care.

Advanced Maintenance Schedule

Forget the factory-recommended service intervals; your built engine lives by a new set of rules. A professionally built and properly maintained FA20 can be incredibly durable, but its lifespan depends on your commitment to regular maintenance. This starts with more frequent oil changes using high-quality synthetic oil, typically every 3,000 to 5,000 miles, or even sooner if you frequent the track. Beyond oil, you should regularly inspect spark plugs for signs of wear or improper combustion, check all fluid levels, and keep an eye out for any potential leaks. This proactive schedule, combined with a professional tune from expert engine tuning services, is what ensures your high-performance engine remains healthy for the long haul.

The Importance of Proper Warm-Up Procedures

Patience after a cold start is one of the most effective ways to preserve your built engine. When your engine is cold, the oil is thick and hasn't fully circulated, meaning your high-performance components aren't properly lubricated. Forged pistons, for example, expand at a different rate than the cylinder walls, and driving hard before everything reaches operating temperature can cause premature wear. The best practice is to drive gently, keeping RPMs low until your oil temperature gauge indicates the engine is fully warmed up. This simple habit ensures that all the precision parts in your engine are protected, which is crucial for anyone with serious Subaru Crosstrek upgrades.