Your Guide to a Bulletproof FA20 Built Engine

Share

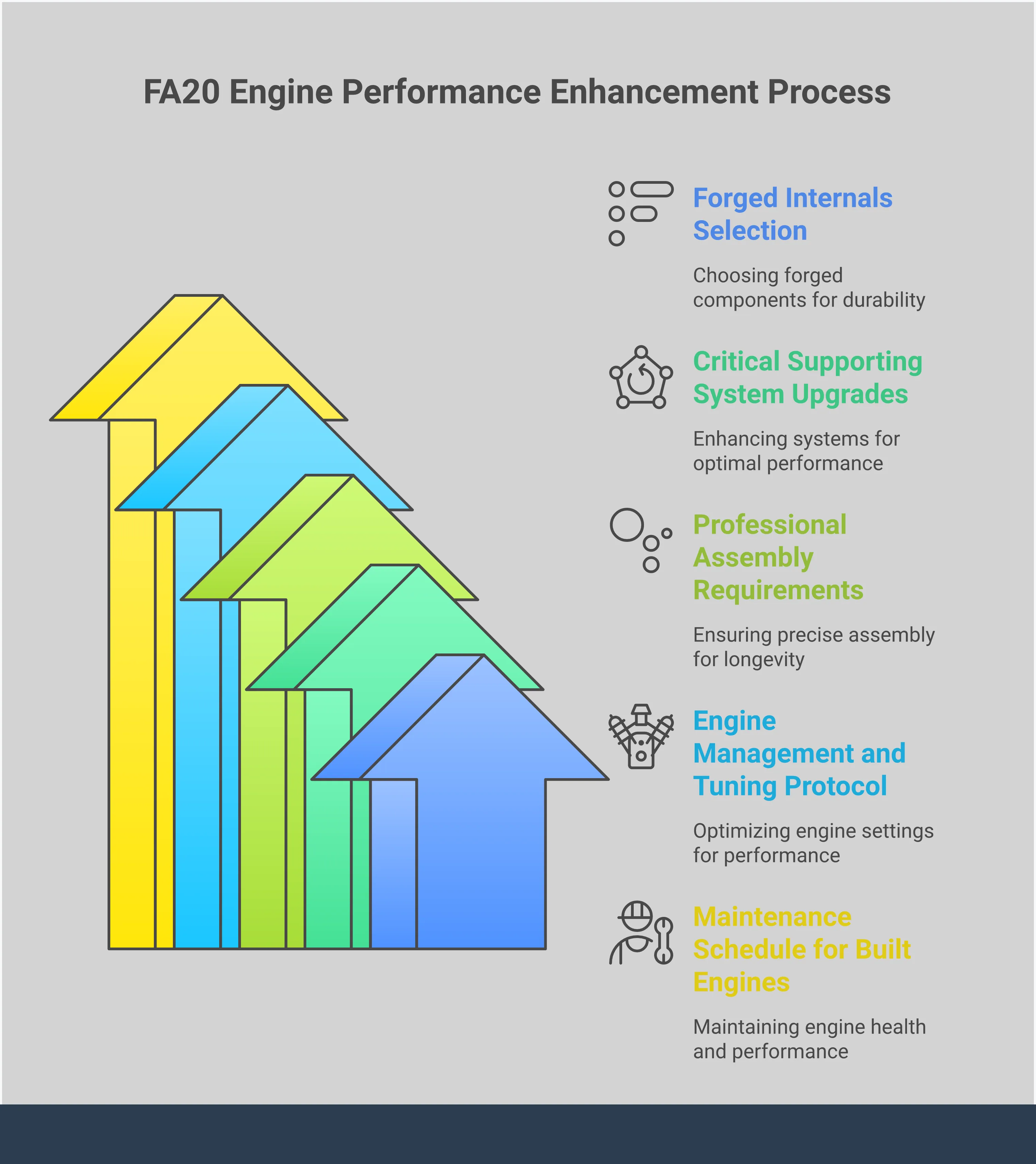

Chasing big horsepower is exciting. But nothing kills the fun faster than a catastrophic engine failure. The stock FA20 is a great platform, but pushing it past factory limits without the right reinforcements is a gamble. A successful build isn't just about making power—it's about making reliable power. This guide is all about creating a durable FA20 built engine by tackling its known weak points head-on. We'll cover the essential upgrades, from forged internals and better cooling to oil management and tuning, so you can push your Subaru with confidence.

Key Takeaways

- Know Your Limits and Build Accordingly: The stock FA20 internals are reliable up to about 400 HP. To safely push for more power, you must upgrade to a built short block with forged components designed to handle the increased stress.

- Prioritize Supporting Mods and Professional Tuning: Power-adding parts are ineffective without the right support. A robust cooling system, an upgraded fuel system, and proper oil management are essential for reliability, while a professional tune is required to make all your new components work together safely.

- Plan for the Entire Project, Not Just the Parts: A successful build requires a realistic budget that includes professional labor and tuning, not just the cost of components. After the build, a strict maintenance schedule and diligent engine monitoring are crucial for protecting your investment.

FA20 Engine 101: What You Need to Know

Before you start planning your build, it’s important to understand the engine you’re working with. The FA20 is the modern 2.0-liter, four-cylinder boxer engine found in Subaru models like the WRX (2015+) and BRZ (2013+). It succeeded the long-running EJ series, bringing with it new technologies like direct injection (on the WRX’s FA20DIT version) and a higher compression ratio.

From the factory, the FA20 is a solid performer that responds well to basic modifications. However, its stock components have their limits. A "built" engine replaces key internal parts with stronger, forged components designed to handle the increased stress that comes with significant power gains. Understanding the difference between a stock setup and a built one is the first step toward creating a reliable, high-performance machine that matches your driving ambitions.

Stock vs. Built: What's the Real Difference?

At its core, the FA20 is a "boxer" engine, which means its pistons move horizontally, like a boxer throwing punches. This design gives your Subaru a low center of gravity, which is a huge advantage for handling and stability. In its stock form, the engine uses components that are mass-produced to meet a balance of performance, reliability, and cost for the average driver.

A "built" engine, on the other hand, is one that has been disassembled and reassembled with upgraded, high-performance internal parts. This typically includes forged pistons, connecting rods, and a strengthened crankshaft. The goal is to create a much stronger foundation that can safely handle the higher cylinder pressures and rotational forces that come from a bigger turbo, aggressive tuning, and more fuel.

Performance Benchmarks of a Built Engine

Let's talk numbers, because that's what really matters in a performance build. A stock FA20 engine is impressive off the line, but its internal components have a well-documented ceiling. Most experienced tuners agree that the stock internals are reliable up to about 400 horsepower. Pushing beyond this on a stock block is a serious gamble, as the factory-cast pistons and connecting rods simply weren't designed to handle that level of stress and heat. To safely make more power and protect your investment, you have to upgrade to stronger, forged components that can withstand the increased cylinder pressures from an aggressive setup.

Once you upgrade, the performance potential increases dramatically. A properly constructed built short block can handle power levels well over 600 horsepower, transforming your Subaru into a true track or street weapon. However, achieving these numbers reliably requires more than just a strong foundation. It demands a holistic approach that includes a robust fuel system, an efficient cooling setup, and a precise professional tune to make everything work in harmony. While some see a 500+ horsepower FA20 as a daunting goal, it's entirely achievable with a well-planned build that prioritizes quality parts and expert assembly from the very beginning.

How Much Power Can a Stock FA20 Handle?

The stock FA20DIT engine found in the WRX is quite capable and can be easily modified to produce around 350 wheel horsepower (WHP) with some basic bolt-on parts and a good tune. This is often considered the safe limit for the stock engine internals. If your goal is to push past 450 WHP, you’ll need to build the engine.

Getting into the 500+ WHP range requires a purpose-built short block, a more robust fuel system, and a larger turbocharger. While the FA20 can achieve these numbers, it takes a carefully planned combination of performance parts to do so reliably. Without reinforcing the engine's core, you risk catastrophic failure when pushing for that next level of power.

What Are the FA20's Weakest Links?

When you start adding significant power to a stock FA20, you expose its inherent weak points. The most common failure points are the connecting rods, which can bend or break under high torque and cylinder pressure. This often leads to rod knock and catastrophic bearing failure, which can destroy the entire engine block.

Another issue to watch for is increased oil consumption, especially when the engine is driven hard. Some owners report using as much as a quart of oil every few hundred miles. This can be made worse by the increased heat and pressure from performance modifications. Addressing these vulnerabilities with stronger internals and supporting Subaru WRX upgrades is essential for building a powerful engine that lasts.

Your FA20 Built Engine Shopping List

Building a high-performance FA20 engine starts with selecting a solid foundation of core components. The stock parts in your Subaru are designed for daily driving, but when you start pushing for serious power, they become the weakest link. Upgrading these essential parts isn’t just about adding horsepower; it’s about creating a reliable engine that can handle the stress of increased performance without failing. Think of it as assembling a team of all-stars—each component must be strong enough to support the others. From the rotating assembly deep inside the block to the fuel system that feeds it, every part plays a critical role in achieving your power goals safely. Let's walk through the non-negotiable upgrades you'll need to consider for your build.

Why You Need Forged Internals

The moment your power goals exceed the 450 horsepower mark, the stock cast pistons and connecting rods are living on borrowed time. This is where forged internals come in. Forging involves shaping metal under extreme pressure, creating a much denser and stronger component than casting. Upgrading to forged pistons and rods provides the durability needed to handle higher cylinder pressures and temperatures from increased boost. This is the single most important step in fortifying your engine's bottom end for reliability. Investing in a quality set of performance parts here prevents catastrophic failure down the road, ensuring your engine can take the abuse you intend to give it.

Upgrade Your Cylinder Head and Block

Your engine block and cylinder heads are the foundation of your entire build. While the stock FA20 block is decent, it has its limits. For high-horsepower applications, reinforcing the block and upgrading the cylinder heads is crucial for managing the increased stress and improving airflow. Upgraded heads with better porting, stronger valve springs, and more aggressive camshafts allow the engine to breathe more efficiently at higher RPMs. Some builders even opt for complete, reinforced long blocks designed specifically for forced induction. These upgrades ensure your engine’s core structure is strong enough to contain the power you’re making, preventing cracks and other major failures.

Advanced Block Strengthening Techniques

For those aiming for the highest levels of performance, simply adding forged internals isn't enough. The engine block itself needs reinforcement to prevent the cylinder walls from flexing or cracking under extreme boost and pressure. This is where advanced techniques like "closed-decking" come into play. A closed-deck conversion involves inserting a strong metal plate into the open areas around the cylinders at the top of the block, creating a much more rigid structure. This modification provides critical support to the cylinder walls, ensuring they remain stable and round, which is essential for proper piston ring seal and preventing catastrophic failure. It’s a serious step for a serious build, turning the stock block into a foundation capable of supporting immense power reliably.

Increasing Displacement (Stroking)

There's an old saying in the performance world: "there's no replacement for displacement." While a turbo adds power by forcing more air into the engine, you can also make more power by physically increasing the engine's size. This is done by "stroking" the motor, which involves installing a crankshaft with a longer throw. This pushes the pistons further up and down in the cylinders, increasing the total volume of air and fuel the engine can burn per cycle. The result is a significant bump in torque across the entire RPM range, making the car feel more responsive and powerful even before the turbo fully kicks in. It’s a comprehensive upgrade that transforms the character of the FA20, providing a broader powerband with the right performance parts for both track and street driving.

Fueling Your Power: Upgrading the Fuel System

More air and more boost demand more fuel. The stock fuel system in your WRX or BRZ is only designed to support factory power levels. As you add performance parts, you'll quickly outpace its capabilities, leading to a lean air-fuel mixture that can cause detonation and destroy your engine. To prevent this, you'll need to upgrade your fuel pump, fuel injectors, and potentially the fuel rails and lines. For those chasing maximum power, switching to a higher-octane fuel like E85 is a popular choice, but it requires a fuel system that can handle its corrosive properties and deliver about 30% more volume than standard gasoline.

Choosing the Right ECU: Engine Management Options

All these new hardware upgrades are useless without a way to control them. An engine management system is the brain of your operation, and a professional tune is what makes it all work together in harmony. The stock ECU is not programmed to handle aftermarket parts. A standalone ECU or a piggyback device like the Cobb Accessport allows a tuner to adjust critical parameters like fuel delivery, ignition timing, and boost pressure. This is not a step to skip or cut corners on. Proper engine tuning services are essential to unlock the full potential of your build while maintaining a safe operating window for your new engine.

Understanding Pre-Built Engine Stages

When you start looking at pre-built engines, you'll notice they're often categorized into "stages," like Stage 1, 2, or 3. It's really important to understand that these labels aren't universal; what one builder calls a Stage 2 might be completely different from another's. However, a Stage 1 built short block generally serves as the entry point for anyone looking to push past the stock engine's limits, which is typically around the 400-450 horsepower mark. This first step involves replacing the most vulnerable factory parts—the cast pistons and connecting rods—with much stronger forged components. This upgrade is the essential foundation for a reliable engine that can handle the increased cylinder pressure from more boost and aggressive tuning. Higher stages then build upon this, adding things like upgraded crankshafts, improved bearings, and cylinder head work to support even more extreme power goals. Ultimately, choosing the right stage is all about aligning the engine's capabilities with your specific horsepower targets and how you plan to drive your car.

Define Your Goal: Building for Street or Track

Before you buy a single part, you need a clear destination for your build. Are you aiming for a spirited daily driver or a dedicated track machine? Your horsepower goals will dictate your budget, parts list, and timeline. Defining your target clarifies the path forward and helps you build an engine that’s powerful, reliable, and perfectly suited to your driving style.

Street Warrior: Your Recipe for 350-400HP

For many Subaru owners, the 350-400 horsepower range is the sweet spot for street performance. It offers a thrilling increase in power without sacrificing daily drivability. The good news is that the FA20DIT engine responds very well to basic modifications. With a few quality bolt-on performance parts, reaching 350 wheel horsepower (WHP) is a very achievable goal. This level of tuning provides a significant performance gain that you can feel every time you get behind the wheel, transforming your car into a much more responsive and exciting ride.

Track Monster: Your Blueprint for 400-500HP

If you have your sights set on track days and competitive driving, pushing past 400 HP is where the real work begins. Reaching 500+ horsepower with an FA20 is absolutely possible, but it requires a more serious commitment and a bigger budget. This is where a fully built engine with strong, high-performance internals becomes essential. You’ll need to invest in extensive modifications to handle the increased stress and heat. While it's a more challenging path, the payoff is a car with incredible track capabilities and the power to match.

The Community View on Reaching 500HP

Spend any time on enthusiast forums, and you'll find a healthy debate about the FA20's true potential. The general consensus is that achieving a reliable 500 horsepower is a significant challenge, both technically and financially. Many builders argue that the cost and effort required to fortify the FA20 to that level make other options more appealing. However, it's far from impossible. Several high-profile builds have proven that with a meticulous approach—including a fully built short block, a massive turbo, and a robust fuel system—the FA20 can deliver incredible power. The key takeaway from the community is that this isn't a goal for the faint of heart; it requires a no-compromise approach to selecting performance parts and a deep understanding of the platform's limits.

Alternative Engine Swaps for High Horsepower

When the goal is huge power and the challenges of building an FA20 seem daunting, many enthusiasts turn to engine swaps. This path involves replacing the stock Subaru engine with a different one known for its strength and power potential. The Honda K-series (K-swap) is a popular choice, valued for its high-revving nature and extensive aftermarket support, offering a well-documented route to 500HP. For those craving V8 torque and sound, an LS swap is another common alternative. More recently, some builders are opting to use the newer FA24 engine from the second-generation BRZ/GR86, which offers a stronger starting point while staying within the Subaru family. Each engine swap presents its own set of complexities, but for many, it's the most practical route to achieving extreme performance goals.

Beyond the Engine: Essential Supporting Mods

Power is nothing without reliability. Before you start chasing big horsepower numbers, it’s critical to address the FA20’s known weak points. Certain supporting modifications are essential for keeping your engine healthy under pressure. At a minimum, you should install an Air-Oil Separator (AOS) to prevent oil contamination and upgrade your cooling system to manage higher temperatures. As you push toward 500 HP, you’ll need to make further improvements to the oil system, internal components, and fuel system to ensure your engine remains reliable.

Putting the Power Down: Drivetrain and Brakes

Once your engine is built and the new parts are installed, your job isn’t over. A modified engine operates under greater stress, so you have to be diligent about maintenance. This means more frequent oil changes, using only high-quality fluids, and performing regular engine health checks. Most importantly, professional tuning is not optional. Every time you add a new performance part, your engine needs a new tune to optimize its performance and safety. Proper engine tuning services ensure all your components work together harmoniously, protecting your investment for the long haul.

Making Your FA20 Built Engine Bulletproof

Building a high-horsepower FA20 engine is an exciting project, but power is only half the equation. To protect your investment and enjoy your build for years to come, you need to focus on reliability. A powerful engine that can’t handle the stress is a ticking time bomb. By addressing a few key areas, you can ensure your engine is not only strong but also durable enough to handle whatever you throw at it, whether on the track or a remote trail. These upgrades are the foundation of a solid build, giving you the confidence to push your Subaru to its limits safely.

Choosing the Right Rods and Pistons

The stock internals of the FA20 are great for daily driving, but they have their limits. When you start chasing higher horsepower figures, the factory rods and pistons become a significant weak point. To handle the increased cylinder pressure and stress from a larger turbo or more boost, you'll need to upgrade to stronger internal parts like forged rods and pistons. Forged components are denser and more resilient than their cast counterparts, providing the strength necessary to prevent catastrophic failure. This upgrade is the cornerstone of any serious engine build and is essential for ensuring long-term durability under high-performance conditions.

Component Materials and Design Details

When you're building an engine for serious performance, the materials you choose are just as important as the design itself. The factory uses cast components because they're cost-effective for mass production, but they simply can't handle the stress of high boost. This is why a proper build relies on high-performance internal parts made from superior materials. Forging, a process that shapes metal under immense pressure, creates components that are significantly denser and stronger than their cast counterparts. Upgrading to forged pistons and connecting rods is the most critical step in fortifying your engine's bottom end. This provides the durability needed to safely handle the intense cylinder pressures and temperatures that come with aggressive tuning and a larger turbo, forming the reliable foundation your build needs.

Setting the Right Compression Ratio

Your engine's compression ratio—the ratio of the cylinder volume at the bottom of the stroke to the volume at the top—is a critical factor in a forced induction build. While the stock FA20 has a relatively high compression ratio for efficiency, this becomes a liability when you add significant boost, increasing the risk of detonation or "knock." For a high-horsepower turbo build, the solution is to use low-compression pistons. These pistons are specifically designed to lower the compression ratio, creating a safer environment for higher boost levels. The ideal ratio depends on your power goals, turbo size, and choice of fuel, but getting it right is essential for engine longevity and requires careful planning and professional tuning to optimize performance safely.

Keeping it Cool: Essential Cooling Upgrades

More power generates more heat, and your stock cooling system can quickly become overwhelmed. Consistently high engine temperatures put immense stress on every component, increasing wear and the risk of failure. Upgrading your radiator, thermostat, or adding an oil cooler helps keep engine temperatures stable, reducing stress on critical parts. A high-capacity radiator improves heat dissipation, while an oil cooler helps maintain optimal oil viscosity, ensuring proper lubrication. A robust cooling system is non-negotiable for track days or spirited driving, as it prevents overheating and protects your engine from damage.

Preventing Oil Starvation: Key Upgrades

Proper oil management is one of the most critical reliability mods you can make. The FA20 engine is prone to oil blow-by, where oily vapor from the crankcase gets into your engine's intake. This leads to carbon buildup on your intake valves and lowers your fuel's effective octane rating, which can cause detonation and serious engine damage. Installing a high-quality Air/Oil Separator (AOS) is the solution. It captures this oily vapor, returning clean oil to the crankcase and ensuring only clean air enters the intake. This simple addition keeps your engine running cleaner and safer.

Why Professional Tuning is a Must

After you install new performance parts, you absolutely need a professional tune. Think of it as giving your engine a new set of instructions so all the parts can work together safely and efficiently. A tune adjusts critical parameters like fuel delivery, ignition timing, and boost levels to match your new hardware. Skipping this step can lead to a lean air-fuel ratio, detonation, and other issues that can destroy your new engine in an instant. Professional engine tuning services ensure your build is not only powerful but also reliable for the long haul.

How to Assemble Your FA20 Engine Correctly

You’ve selected the best components for your FA20 build, but high-quality parts are only half the equation. The assembly process is where your project comes to life, and precision is everything. A meticulous, professional approach to building your engine ensures that every component works together seamlessly to deliver the power and reliability you expect. Rushing this stage or cutting corners can undermine your entire investment, leading to premature failure and costly repairs. Taking the time to assemble your engine correctly is the most critical step in achieving your performance goals. Whether you’re a seasoned builder or handing the job to a trusted mechanic, understanding the key steps of a professional assembly will set you up for success on the street and the track.

Your Assembly Toolkit: What You'll Need

Building an engine requires more than just a standard socket set. To do the job right, you need specialized tools like a high-quality torque wrench, an engine stand, piston ring compressors, and precision measuring instruments like micrometers and feeler gauges. These tools aren't just nice to have; they're essential for ensuring every bolt is tightened to spec and every clearance is perfect. Just as important as the tools are the parts themselves. Always choose performance parts from trusted brands known for excellent engineering. Using cheap, unproven components is a gamble that can cause catastrophic engine failure down the road, undoing all your hard work and investment.

Our Proven FA20 Assembly Checklist

A successful engine build follows a systematic and clean process. Start by ensuring your workspace is spotless to prevent any contaminants from entering the engine. As you assemble, meticulously follow the manufacturer's instructions and torque specifications for every single component. Even the best part can fail if it's installed incorrectly. If you’re new to engine building, it’s wise to have an experienced mechanic handle the assembly. Once the engine is built and installed, a professional tune is non-negotiable. Installing new performance parts changes how your engine needs to operate, and our engine tuning services provide the new instructions it needs to run safely and efficiently.

Using a Short Block Installation Kit

Nothing stalls an engine build faster than discovering you're missing a crucial gasket or seal mid-assembly. When you're investing in a built short block, this is precisely why a dedicated installation kit is invaluable. These kits bundle all the necessary supporting components for a smooth and correct installation, saving you the headache of tracking down dozens of individual part numbers. You get everything in one box, including the correct gaskets, seals, and often the specific break-in oil required to properly seat your new engine's components. This approach removes the guesswork and ensures you're using fresh, high-quality parts to support your new engine—a critical step in protecting your investment in high-end performance parts.

The First Start: How to Break In Your Built Engine

Your engine’s first moments are critical for its long-term health. The break-in period allows components like piston rings to seat properly against the cylinder walls. Follow a specific break-in procedure, which typically involves running the engine at varying RPMs without putting it under heavy load. After the initial break-in, a dynamometer (dyno) test is the best way to verify your build. A dyno session shows you exactly how much horsepower and torque your car is making and, more importantly, allows a tuner to fine-tune the engine mapping to ensure everything is working together safely and optimally. This isn't just about chasing numbers; it's about confirming the health and reliability of your new powerhouse.

Don't Skip These Final Quality Checks

Quality control doesn't end once the last bolt is tightened. It’s an ongoing process that starts during assembly and continues after the first startup. Double-check your work at every stage, ensuring all fasteners are torqued and all connections are secure. Once the engine is running, perform a thorough inspection for any fluid leaks—oil, coolant, or fuel. Listen carefully for any unusual sounds that could indicate a problem. Following instructions carefully is paramount, as a small mistake can have big consequences. These final checks ensure that your investment in top-tier Subaru WRX upgrades and other components pays off with a reliable, high-performing engine you can count on.

Maintain Your Built Engine for Longevity

Building a high-performance FA20 engine is a significant investment of time and money. To protect that investment and enjoy years of reliable power, you need to adopt a proactive maintenance mindset. A built engine operates under much higher stress than a stock one, so the factory service schedule simply won’t cut it. Consistent, careful maintenance is the key to keeping your Subaru running strong, whether you’re on the track or the street. Think of it as an essential part of the build itself—the final step that ensures everything you’ve worked for lasts.

What's the Right Service Schedule for a Built Engine?

A modified engine works harder, which means its components and fluids wear out faster. Your first step in long-term care is to establish a more aggressive service schedule. This starts with more frequent oil changes using high-quality synthetic oil that can handle the increased heat and pressure. Don’t forget other critical fluids like coolant and transmission fluid, as they also play a vital role in your engine's health. Regularly checking for leaks, worn belts, and other signs of wear can help you catch small issues before they escalate into major, costly failures. Sticking to a strict schedule is the most effective way to preserve the integrity of your build.

What to Watch: Monitoring Your Engine's Health

You wouldn't push your body to its limits without checking your heart rate, and the same logic applies to your engine. Using a tool like a Cobb Accessport or dedicated gauges to monitor key parameters in real-time is non-negotiable for a built motor. Keep a close eye on your air-fuel ratio (AFR), boost pressure, and oil and coolant temperatures. These metrics are your engine’s vital signs. Learning what’s normal for your specific setup allows you to spot deviations immediately. Catching an issue like a lean AFR or creeping coolant temps early can be the difference between a minor adjustment and a complete engine rebuild. This data is crucial for both you and your tuner to ensure your engine tuning remains optimized and safe.

How to Prevent Common Built Engine Issues

The reliability of your built engine depends heavily on the quality of every single component working together. Always choose performance parts from trusted brands known for their engineering and manufacturing standards. While budget-friendly parts can be tempting, they often lack the durability to withstand the demands of a high-horsepower build and can become the weak link that causes a catastrophic failure. Preventive care also means listening to your car. Pay attention to new sounds, vibrations, or changes in performance. Addressing these subtle cues promptly is a form of preventive maintenance that can save you from significant trouble down the road.

Why Carbon Cleaning is Still Important

The FA20 engine uses a direct-injection fuel system, which is great for performance but has one notable drawback: carbon buildup. Over time, carbon deposits accumulate on the intake valves, which can restrict airflow, hurt performance, and reduce efficiency. Because fuel is injected directly into the cylinder, it never washes over the valves to clean them. To keep your engine breathing freely, you should schedule a professional carbon cleaning service, like walnut blasting, every 40,000 to 60,000 miles. This process safely removes the hardened deposits and restores your engine’s performance, making it an essential long-term maintenance task for any FA20 owner.

How Much Does an FA20 Built Engine Cost?

Building a high-performance FA20 engine is a serious investment, and a solid plan is your best tool for success. Before you buy a single part, it’s crucial to map out your budget. This isn’t just about adding up the cost of components; it’s about creating a realistic financial picture that includes parts, labor, and a buffer for the unexpected. A well-structured budget helps you prioritize upgrades, avoid cutting corners, and ensure you can see the project through to completion without financial stress.

Think of your budget as the blueprint for your build. It guides your decisions and keeps your performance goals aligned with what you can realistically afford. By planning ahead, you can focus on sourcing the right performance parts from the start, rather than making compromises later that could affect your engine’s power and reliability. We’ll break down the key financial aspects to consider so you can build with confidence.

Breaking Down the Costs: Parts and Labor

First, let’s talk about the parts themselves. The cost of your build will directly reflect your horsepower goals. If you’re aiming for over 450 horsepower, you’ll need to invest in stronger internals like forged short blocks, which are designed to handle the increased stress. Make a detailed list of every component you need and research the prices. Keep in mind that high-demand parts can sometimes have lead times, so check availability early. A part being listed as "sold out" might just mean you need to order it and wait, so factor that timeline into your project plan. This initial research prevents surprises and helps you create an accurate cost estimate from day one.

Core Fees and Lead Times

Beyond the price of the parts themselves, you need to account for labor, tuning, and two other important factors: core fees and lead times. A "core fee" is common when you buy a major component like a built short block. Think of it as a refundable deposit. You pay the fee upfront, and when you send your old, usable engine block back to the supplier, you get that money back. This process ensures manufacturers have a steady supply of cores to build for future customers. Lead times are just as crucial for your project plan. High-quality performance parts are often built to order and aren't always sitting on a shelf. Be sure to ask about current wait times before you finalize your schedule, as this can impact when your build is completed.

DIY vs. Pro Install: Factoring in Labor Costs

Unless you’re a seasoned engine builder with a fully equipped garage, you’ll need to budget for professional installation. Even the highest-quality part can fail if it’s not installed correctly, potentially destroying your entire investment. Find a reputable shop with proven experience building Subaru engines and get a quote for the labor. This cost is just as important as the parts themselves. Professional assembly and engine tuning services ensure every component works together perfectly, giving you a reliable engine that performs as expected. Don’t treat labor as an afterthought; it’s a critical piece of your build’s success.

Budgeting for a Pre-Built Short Block

For those aiming for serious power, a pre-built short block is often the most reliable path forward. It eliminates the guesswork of bottom-end assembly and provides a professionally built foundation ready to handle significant stress. A purpose-built short block designed for forced induction can cost between $5,000 and $6,000. This price typically includes forged pistons and rods installed in a prepared engine block, engineered to support well over 600 horsepower. When budgeting, look for options that don’t require a core charge, as this can save you the hassle and expense of shipping your old engine. This upfront investment is the single most important step in building a durable engine that can safely handle the power levels you’re targeting.

However, the cost of the short block is just the starting point. To protect your investment, you must also budget for the necessary supporting modifications and professional tuning. A high-performance engine requires a more robust cooling system, an upgraded fuel system to deliver adequate fuel, and proper oil management to ensure everything stays lubricated under pressure. These components are not optional extras; they are essential for reliability. Factoring in the cost of professional engine tuning services is also critical. A proper tune ensures all your new performance parts work together safely, maximizing power while keeping your engine out of the danger zone.

Which Brands Can You Trust for Your Build?

When it comes to engine internals, this is not the place to bargain hunt. Always choose parts from trusted brands known for quality engineering and rigorous testing. Cheaper, unproven components are a huge gamble and often lead to catastrophic failures that will cost you far more in the long run. Brands with a long history in the Subaru community, like Crawford Performance, have spent decades figuring out what works and what doesn't. Investing in reputable Subaru WRX upgrades means you’re getting parts that have been designed, tested, and proven to perform under pressure, giving you confidence every time you turn the key.

Understanding Warranties on Performance Parts

A good warranty is more than just a piece of paper—it’s a manufacturer’s promise that they stand behind their product. When you’re investing thousands of dollars into a built engine, a warranty provides critical peace of mind. Look for components and built blocks that come with clear warranty terms. For example, the Crawford Performance Built Short Block includes a 12-month/12,000-mile warranty, which protects your investment against defects in materials or workmanship. This kind of backing is a strong indicator of quality and should be a key factor in your purchasing decision. It’s a safety net that lets you enjoy your new power without worry.

Finding the Right Shop for Your Build

Once you’ve selected your parts, the journey isn’t over. The assembly and support phase is where your build truly comes to life, and getting it right is non-negotiable. Proper installation, professional tuning, and a solid maintenance plan are what separate a powerful, reliable build from a costly headache. Even the highest-quality components can fail if they aren't installed and managed correctly. This is not the place to cut corners. Investing in professional support protects your engine and ensures you get the performance you paid for. Think of this phase as the bridge between your high-performance parts and the on-road experience you're aiming for. It requires precision, expertise, and a forward-thinking approach to care. The best parts in the world won't perform as a cohesive unit without an expert hand to assemble them and a custom tune to orchestrate their function. From meticulously documenting the build to creating a long-term maintenance strategy, these final steps are absolutely critical for the longevity and power of your FA20 engine. We'll walk through how to handle this crucial stage to safeguard your investment and enjoy your build for years to come.

Why You Should Document Your Engine Build

Keeping a detailed build journal is one of the smartest things you can do. This log should include every part you’ve installed, along with part numbers, specifications, and torque settings used during assembly. Take photos at each stage of the process. This documentation is invaluable for future maintenance, troubleshooting, or if you ever decide to sell the vehicle. It also provides a clear record for your tuner and any mechanic who works on your car, giving them the exact information they need to service it properly. A well-documented build is a sign of a meticulous owner and can make any future work much more straightforward.

Preparing for Your Professional Installation

The success of your build hinges on correct installation. Even the best performance parts can underperform or fail if installed improperly. Every component comes with specific instructions and tolerances that must be respected. If you’re handling the assembly yourself, follow the manufacturer’s guidelines to the letter and double-check your work. If you have any doubts, it’s always best to entrust the job to an experienced mechanic or a performance shop that specializes in Subaru engines. Their expertise ensures that every part fits and functions exactly as it was designed to, preventing catastrophic failures down the road.

What Happens After the Build? Planning for Support

After installing new performance parts, a professional tune is not optional—it's essential. A tune recalibrates your engine’s computer, providing it with new instructions so all the components work together safely and efficiently. A skilled tuner will optimize your air-fuel ratios, ignition timing, and boost levels to extract the most power your engine can safely handle, all while respecting the limits of your stock or built internals. This is where you can lean on professional engine tuning services to create a custom map for your specific setup, ensuring your engine runs smoothly and reliably under all conditions.

Creating Your Long-Term Maintenance Plan

A built FA20 engine requires more diligent care than a stock one. Your maintenance schedule needs to be adjusted to handle the increased stress and power. For a modified engine, plan to change your oil and filter every 3,000 to 4,000 miles using a high-quality full synthetic oil. Regularly check all your fluid levels, especially coolant, and inspect hoses and belts for any signs of wear or damage. Staying on top of this routine care is the best way to protect your investment, catch small issues before they become big problems, and keep your engine performing at its peak for years to come.

Related Articles

Frequently Asked Questions

How much power can I safely make on my stock FA20 engine before I need to build it? The stock FA20DIT engine in the WRX is quite capable, but its internal components have their limits. Generally, the safe ceiling for a stock block is around 350 wheel horsepower. Pushing beyond this number with just bolt-on parts and a tune puts significant stress on the factory connecting rods, which are the most common failure point. If your goals are north of 400 horsepower, investing in a built engine with forged internals is the only reliable path forward.

What are the first upgrades I should consider for reliability, even before chasing big power? Before you even think about adding a bigger turbo, focus on supporting modifications that address the FA20’s known weaknesses. The single most important reliability upgrade is a high-quality Air/Oil Separator (AOS). It prevents oil from contaminating your intake system, which protects against carbon buildup and potential engine knock. After that, consider improvements to your cooling system, like an upgraded radiator or oil cooler, to manage heat more effectively during spirited driving.

I've installed new performance parts. Do I really need a professional tune right away? Yes, absolutely. A professional tune is not an optional step; it's a critical part of the installation process. Your vehicle's factory computer is programmed to manage stock components. When you add new parts that change airflow or fuel delivery, the engine needs a new set of instructions to run safely and efficiently. Skipping a tune can lead to dangerous air-fuel ratios and detonation that can destroy your new parts and your entire engine.

What's the biggest difference in maintenance between a stock and a built FA20? A built engine operates under much greater stress, so your maintenance routine needs to become more rigorous. You'll need to perform oil changes more frequently, typically every 3,000 miles, using a high-quality synthetic oil. It also becomes essential to actively monitor your engine's health using gauges or a monitoring device to keep an eye on parameters like oil temperature and air-fuel ratios. You have to be more proactive in listening for new sounds and checking fluid levels to catch any potential issues early.

Why are forged internals so important for a high-horsepower build? The stock pistons and connecting rods in your FA20 are cast, a process that is fine for factory power levels but creates a component that is less dense and more brittle. Forged internals are created by shaping metal under extreme pressure, resulting in a much stronger and more durable part. This strength is necessary to handle the massive increase in cylinder pressure and heat that comes from running higher boost. Forging is what gives your engine the foundation it needs to reliably make and sustain big power without failing.