How to Built FA20 Engine

Share

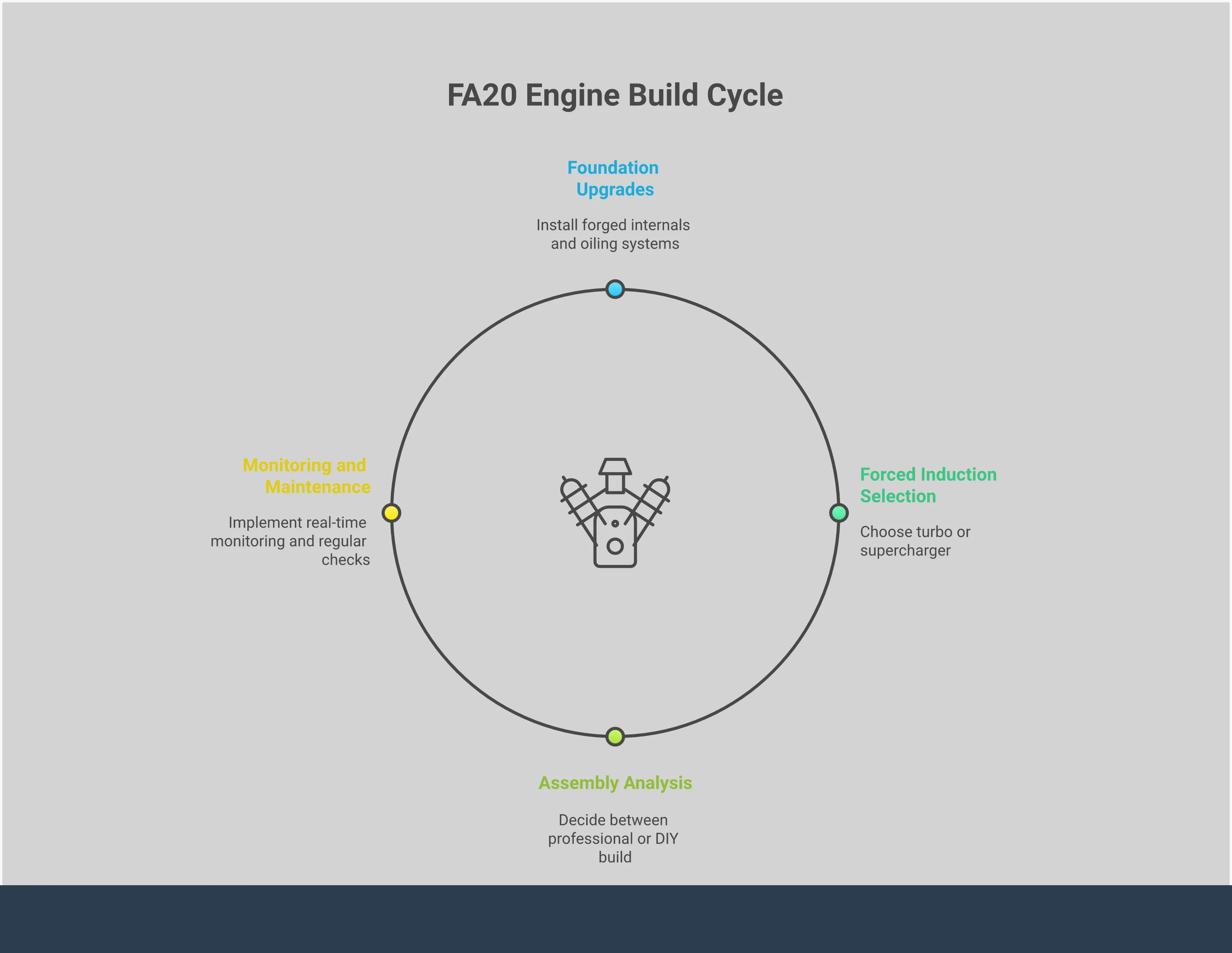

Adding more power brings every owner to a major crossroads: should you build the engine yourself or buy a professionally assembled short block? A custom build gives you total control, but a pre-built engine offers proven reliability and a warranty. There’s no single right answer, and making the right choice for you is crucial. This guide breaks down every part of the process, from the hidden costs of a DIY project to the benefits of expert assembly. We'll give you the clarity needed to choose your path and create the perfect built FA20 engine for your goals.

Key Takeaways

- Prioritize a Fortified Engine Core: Before chasing horsepower, address the FA20's known limitations. Upgrading to forged internals and improving the oiling and cooling systems are non-negotiable steps for building an engine that can reliably handle significant power.

- Forced Induction is a Package Deal: A turbo or supercharger doesn't work alone. To safely support the extra power, you must budget for essential supporting modifications, including an upgraded fuel system, an intercooler, and a comprehensive exhaust.

- Expert Assembly and Tuning are Your Best Insurance: The most reliable builds are assembled and tuned by professionals. Their experience prevents costly mistakes during assembly, and a proper tune is the only way to safely optimize your new hardware and protect your engine from damage.

The Stock FA20: What Are You Working With?

Before you start shopping for parts, it’s essential to understand the engine you’re working with. The FA20 is the heart of many modern Subarus, from the agile BRZ to the turbocharged WRX. It’s a capable platform with a ton of potential, but like any engine, it has its own unique strengths and weaknesses. Knowing what you’re starting with is the first step in building a reliable powerhouse that meets your performance goals. Whether you’re aiming for a responsive street car or a dedicated track machine, a solid grasp of the FA20’s characteristics will guide every decision you make.

A Look at the Stock FA20's Performance

The FA20 flat-four engine has been a Subaru staple since 2012 and comes in two primary versions. Your BRZ is equipped with the naturally aspirated FA20D, which produces about 200 horsepower from the factory. The other variant is the FA20DIT (Direct Injection Turbo), found in the WRX, which delivers a more potent 250 to 300 horsepower thanks to forced induction. While these figures make for an engaging drive, they are just the baseline. Consider the stock engine your blank canvas, ready for you to transform with carefully selected performance parts and a well-executed plan.

FA20 Engine: What Works and What Doesn't

One of the greatest assets of the FA20 is its surprisingly durable core. The stock internal components are remarkably strong, capable of handling over 500 wheel horsepower with the right supporting modifications. This inherent toughness makes the FA20 an excellent candidate for a high-performance build. However, this strength isn't a free pass to add endless power without consequence. To reach and sustain those higher outputs reliably, you need a comprehensive approach. This includes professional work from an engine tuning service to ensure all your new components work together safely and efficiently, protecting your investment for the long haul.

Understanding the D-4S Fuel System

The FA20 engine in your BRZ features a sophisticated D-4S fuel system, a hybrid setup that uses both direct and port fuel injectors. This dual approach is engineered to deliver the best of both worlds—optimizing power and efficiency across the entire rev range while tackling a common issue found in purely direct-injected engines. This smart design is a key reason the FA20 responds so well to modifications, but it's also something you need to understand to maintain its health and performance over the long term. The system intelligently switches between or combines injection methods based on engine load and RPM for a consistently responsive driving experience.

The biggest advantage of the D-4S system is its ability to prevent carbon buildup on the intake valves. In a standard direct-injection engine, fuel is sprayed directly into the cylinder, bypassing the valves entirely. Over time, this allows oil vapor and combustion byproducts to bake onto the valves, restricting airflow and robbing you of performance. The FA20’s port injectors solve this by spraying fuel over the intake valves, which acts as a constant cleaning agent. This self-cleaning feature is critical for maintaining engine efficiency and is a major factor in the FA20's long-term reliability, especially when you start adding new performance parts.

While the D-4S system is effective, it doesn't eliminate the need for proper maintenance, particularly on modified engines. For engines that see heavy use or have significant mileage, a professional cleaning service like walnut blasting every 40,000 to 60,000 miles is a smart preventative measure to ensure your intake ports and valves remain spotless. More importantly, when you upgrade components like the intake or exhaust, the fuel system's calibration must be adjusted. This is where professional engine tuning services become essential to safely optimize fuel delivery, maximize the benefits of your new hardware, and protect your investment.

Pinpointing the FA20's Weak Spots

No engine is perfect, and it’s important to know the FA20’s common issues before you build. Some owners report rough idling or stalling, which can often be linked to the factory ECU software or cam gears. A more significant concern, especially for performance driving, is the engine's tendency for high oil consumption. During aggressive maneuvers on the track, this can lead to oil starvation, risking major engine damage. Addressing these vulnerabilities with targeted Subaru WRX upgrades like an Air/Oil Separator is not just a good idea—it’s a critical step for ensuring your built engine remains reliable under pressure.

Common Failure Points and Power Limits

The FA20’s greatest asset is its surprisingly durable core. The stock internal components are remarkably strong and can handle over 500 wheel horsepower with the right combination of supporting modifications. However, this strength isn't a free pass to add endless power without consequence. Reaching and sustaining those higher outputs reliably requires a comprehensive approach. Simply adding a turbocharger won't cut it; you need to build a balanced system where every component works in harmony. This includes professional work from an engine tuning service to ensure all your new hardware operates safely and efficiently, protecting your investment for the long haul.

Known Issues and Recalls

Every engine has its quirks, and it’s important to know the FA20’s common issues before you start your build. Some owners report rough idling or stalling, which can often be traced back to the factory ECU software or cam gears. A more significant concern, especially for performance driving, is the engine's tendency for high oil consumption. During aggressive cornering on the track, this can lead to oil starvation and risk major engine damage. Addressing these vulnerabilities with targeted performance parts, like an Air/Oil Separator, isn’t just a good idea—it’s a critical step for ensuring your built engine remains reliable under pressure.

Key Performance Upgrades for Your FA20

Building a powerful and reliable FA20 engine is all about creating a strong foundation. Before you even think about adding a turbo or supercharger, you need to address the engine's internal weaknesses. The stock components were designed for factory output, and pushing them far beyond that limit without proper reinforcement is a recipe for disaster. By strategically upgrading key systems, you ensure your engine can handle the increased stress, heat, and power you plan to throw at it.

These upgrades aren't just for track-day heroes; they're essential for anyone looking to create a dependable, high-performance build that lasts. Focusing on the engine's core strength, oiling, cooling, and fuel delivery first will save you from costly failures down the road. Think of it as building a house—you wouldn't put up the walls without first pouring a solid foundation. Each of these modifications works together to create a balanced and robust system ready for whatever power goals you have in mind.

Building the Foundation: Forged Pistons and Rods

The heart of any high-horsepower build is a fortified rotating assembly. The factory FA20 pistons and connecting rods are cast, which is fine for daily driving at stock power levels. However, when you introduce the higher cylinder pressures and heat from forced induction, these components become the primary failure point. Upgrading to forged internals—specifically forged pistons and connecting rods—is non-negotiable for reliability. Forged parts are created under immense pressure, resulting in a denser grain structure that is significantly stronger and more resistant to detonation. This single upgrade is what allows your engine to safely handle the demands of serious power.

Reinforcing the Block with Stronger Hardware

While forged internals handle the direct forces of combustion, the engine block itself must endure the immense stress of added power. The stock head bolts, for instance, were never designed for high boost and can stretch under pressure. This leads to head gasket failure, a messy and expensive repair that can sideline your project. To create a truly robust foundation, you need to reinforce the block with superior hardware. This means replacing the factory bolts with high-strength head studs and main studs, which provide far more accurate and consistent clamping force.

This upgrade is crucial for preventing the cylinder heads from lifting and keeping the crankshaft securely in place under extreme loads. By investing in these essential performance parts, you are effectively creating a rigid and stable core that won't flex or fail when you push the engine hard. It’s a non-negotiable step for ensuring the long-term reliability of your high-horsepower FA20 build.

Securing Your Top End: Valvetrain and Head Studs

As you increase power and RPM, you put immense strain on the cylinder heads and valvetrain. The stock head bolts can stretch under high cylinder pressures, potentially leading to a head gasket failure. Swapping them for stronger head studs provides superior clamping force, ensuring a tight seal between the head and the block. At the same time, upgrading the valve springs, retainers, and valves prevents "valve float," a condition where the valves don't close fast enough at high RPMs. This can cause a catastrophic loss of compression and severe engine damage. A properly built valvetrain ensures your engine can breathe efficiently and safely at its new, higher redline.

Why an Oiling System Upgrade is Non-Negotiable

Proper lubrication is the lifeblood of your engine, and the FA20's stock oiling system can struggle under the G-forces of hard cornering on a track. This can lead to oil starvation, where the oil pickup momentarily sucks in air instead of oil, causing critical damage to bearings and other components. To prevent this, installing a baffled oil pan or an oil accumulator is a smart move. An upgraded oil pickup tube offers extra insurance against failure. For builds that will see track time, adding an external oil cooler is also essential for keeping oil temperatures in a safe range and maintaining consistent lubrication under extreme conditions.

How to Prevent Overheating with Cooling Upgrades

More power generates more heat—it's a simple fact. The factory radiator is designed to manage the thermal load of a stock engine, and it can quickly become overwhelmed when you add forced induction or spend time at high RPMs. An overworked cooling system can lead to overheating, which can warp heads and cause major engine damage. Installing a larger, high-performance aluminum radiator is one of the most effective ways to improve heat dissipation. This upgrade provides greater cooling capacity, ensuring your engine's temperatures remain stable and predictable, whether you're sitting in traffic or pushing it hard on the track.

Upgrading Your Fuel System for More Power

To make more power, your engine needs more air and more fuel. Once you’ve handled the airflow with a turbo or supercharger, the stock fuel system will quickly become a bottleneck. The factory fuel pump and injectors simply can't supply the volume of fuel required for a high-power setup, leading to a lean air-fuel ratio that can melt pistons. Upgrading to a higher-flow fuel pump and larger injectors is necessary to provide adequate fueling. For those aiming for maximum performance with fuels like E85, a robust fuel system is even more critical. Proper engine tuning services are essential to calibrate the new components and create a safe, powerful map.

Fueling for Higher Horsepower with E85

E85 is the go-to fuel for many enthusiasts looking to extract maximum power from their build. This ethanol-blend fuel offers a significantly higher octane rating and powerful cooling properties, which are invaluable for managing the intense heat generated by a turbo or supercharger. However, you can't simply pour it in and go. E85 requires about 30% more fuel volume than regular gasoline, and the stock fuel system isn't equipped to handle that demand. To run it safely, you'll need to install a higher-flow fuel pump and larger injectors. Without these upgrades, your engine will run dangerously lean, risking catastrophic damage. Once the hardware is in place, it's essential to get a professional engine tuning service to recalibrate your ECU for the new fuel and create a map that safely optimizes performance.

Forced Induction: Choosing Your Path to Power

Once you’ve built a solid foundation with forged internals and supporting upgrades, it’s time to think about adding serious power. This is where forced induction—using a turbocharger or supercharger to force more air into the engine—comes into play. More air means you can burn more fuel, which creates a bigger bang and, ultimately, more horsepower. But before you start shopping for the biggest turbo you can find, it’s important to have a clear plan. Your power goals will dictate your choice of components, your budget, and the supporting modifications you’ll need to make it all work reliably. Let’s walk through how to approach this exciting next step.

How to Set Realistic Power Targets

It’s easy to get caught up in chasing huge horsepower numbers, but setting realistic targets is the key to a successful and enjoyable build. While pushing an FA20 to 500 horsepower is technically possible, it’s an incredibly expensive and difficult goal that often sacrifices long-term reliability. A more practical approach is to define what you want to do with the car. Are you building a daily driver with some extra punch, a weekend track car, or a dedicated race machine? For most street and track builds, a target between 350 and 450 wheel horsepower offers a thrilling driving experience without completely compromising the engine’s lifespan or emptying your bank account. Be honest about your budget and how you’ll use the car to set a goal that makes sense for you.

Choosing a Turbocharger System

Turbochargers are the go-to choice for many FA20 owners looking for significant power gains. A turbo uses exhaust gases to spin a turbine, which in turn spins a compressor to force dense, pressurized air into the engine. This results in a dramatic increase in power, especially in the mid-to-high RPM range. A well-chosen turbo kit can transform your car’s performance. For example, some popular aftermarket turbos can push a stock FA20 block to over 400 wheel horsepower. On a fully built engine, that number can climb even higher. When selecting a turbo, consider its size and flow characteristics to match your power goals and desired driving feel.

The Supercharger Route: Pros and Cons

If you prefer a more linear and predictable power delivery, a supercharger might be the right choice for you. Unlike a turbo, which has a slight delay (or "lag") while it builds pressure, a supercharger is driven directly by the engine’s crankshaft via a belt. This means it delivers boost instantly, providing a smooth surge of power across the entire RPM range. Supercharger kits are a fantastic way to get a significant performance increase, often adding enough power to reach the 280-300 horsepower range on stock engine internals. This makes them a great option for those who want a simpler, highly responsive setup for their daily driver or canyon carver.

Don't Forget These Supporting Mods

Forced induction doesn't work in a vacuum. To handle the extra power safely and efficiently, you need a full suite of supporting performance parts. Think of it as building a complete system. Key upgrades include a larger front-mount intercooler (FMIC) to cool the compressed air, a high-flow cold air intake, and a less restrictive exhaust system to help the engine breathe. You’ll also need to upgrade your fuel system with a higher-capacity fuel pump and potentially larger injectors to meet the increased demand. Finally, none of this works without a proper tune. Professional engine tuning services are essential to recalibrate the ECU, optimize performance, and ensure your engine runs safely with the new hardware.

Essential Reliability Modifications

Building a powerful FA20 isn't just about adding horsepower; it's about making sure the engine can handle the increased demands without sacrificing reliability. Before you chase bigger numbers, it's crucial to address the engine's known limitations. This all starts with fortifying the engine's core. Upgrading to forged internals—specifically forged pistons and connecting rods—is non-negotiable. The stock components simply weren't designed for the stress of forced induction. Equally critical is the oiling system. To prevent oil starvation during hard driving, installing a baffled oil pan or an oil accumulator is a smart move. These performance parts ensure your engine receives consistent lubrication, protecting it from the kind of catastrophic failure that can end a track day early.

With the engine's core and lubrication handled, you can turn your attention to managing heat and fuel. More power generates more heat, and installing a larger, high-performance aluminum radiator is one of the most effective ways to improve heat dissipation and keep temperatures stable. At the same time, your fuel system needs to keep pace. The stock pump and injectors will quickly be outmatched, risking a lean air-fuel mixture that can destroy your engine. Upgrading to a higher-flow fuel pump and larger injectors is necessary to provide adequate fueling for your new power level. By focusing on these essential reliability modifications, you create a robust foundation that not only meets your performance goals but also ensures long-term durability, all fine-tuned through professional engine tuning services.

Don't Forget Your Transmission

All the horsepower in the world is useless if you can’t transfer it to the wheels. The stock transmission in FA20-powered cars is a known weak point, especially when you start adding significant torque from a turbo or supercharger. Before you finalize your power goals, create a plan to address your drivetrain. For moderate power increases, an upgraded clutch might be sufficient. However, for more ambitious builds aiming for high horsepower, you’ll need to consider strengthening the transmission itself with upgraded gear sets or other reinforcements. Ignoring the drivetrain is a common mistake that can lead to a very expensive failure, so be sure to factor these necessary upgrades into your overall budget.

How to Select the Best Parts for Your FA20 Build

Once you have a clear vision for your FA20 build, the next step is selecting the components to make it happen. The aftermarket is filled with options, and the quality of the parts you choose will directly impact your engine's performance and longevity. Investing in well-engineered components from reputable manufacturers is the surest way to build a reliable powerhouse. This isn't the place to cut corners; a single failed part can jeopardize your entire investment. Think of each component as a link in a chain—the final result is only as strong as its weakest link.

Which Aftermarket Brands Can You Trust?

When you're building an engine, brand reputation is more than just a name; it's a promise of quality, research, and proven results. Established brands invest heavily in engineering and testing to ensure their parts can withstand the stress of high-performance applications. Choosing proven performance parts means you're getting components that have been tested on the track and refined over time. This significantly reduces the risk of premature failure and gives you peace of mind. While it might be tempting to go with a lesser-known or cheaper option, sticking with top-tier brands that specialize in Subaru performance is a smart investment in your engine's future.

How to Choose the Right Short Block

For those aiming for significant power gains, a built short block is often the best foundation. A short block typically includes the engine block, crankshaft, connecting rods, and pistons, all assembled and ready to go. Companies offer these in various stages, often rated for specific horsepower levels, like 600 or 800 horsepower. This allows you to choose a core that directly matches your power goals. When comparing options, look at the specific components used—forged pistons and rods are a must for high-boost applications. A well-built short block from a reputable builder provides a solid, reliable base for the rest of your build.

Advanced Engine Building Techniques

Building a truly robust FA20 requires more than just adding power; it demands a focus on creating an unshakable foundation. The stock internal components were engineered for factory output, and pushing them far beyond that limit without reinforcement is asking for trouble. The absolute first step in any serious build is upgrading to forged internals. The factory cast pistons and connecting rods are the primary failure points under the increased heat and cylinder pressure of forced induction. Swapping them for stronger, forged performance parts is the single most important investment you can make in your engine's long-term health and ability to handle significant power reliably.

Technical Specs: Displacement, Compression, and Cams

For those looking to fundamentally alter the engine's character, changing its core specifications is the next frontier. A popular route is a stroker kit, which increases engine displacement. For example, some kits increase the FA20 from its stock 1,998cc to 2,116cc by using a slightly larger bore and longer stroke. This change results in more torque across the powerband. These kits often pair the increased displacement with a specific compression ratio, like 10.4:1, to optimize performance for forced induction. To complement this, high-angle camshafts are used to improve airflow at higher engine speeds, allowing the engine to breathe more efficiently. Altering these specs requires precise engine tuning services to ensure all components work in harmony.

Choosing Your Engine Management System (ECU)

All the high-performance hardware in the world won't do you any good without a way to control it. Your factory ECU is programmed for stock power levels, and it can't properly manage the demands of a modified engine. After installing major upgrades like a turbocharger or forged internals, a professional tune is absolutely essential. An effective engine management system allows a tuner to adjust fuel delivery, ignition timing, and boost levels to optimize performance and ensure the engine operates safely. Professional engine tuning services are critical for extracting power reliably and protecting your new engine from damage.

How to Choose Parts That Work Together

A successful engine build is about creating a balanced system where all components work in harmony. As you add power, you also need to upgrade the supporting systems. For example, if you install a larger turbo, you'll need a more robust fuel system to supply enough fuel and an upgraded cooling system to manage the extra heat. Consider adding an aftermarket radiator and a larger intercooler, especially for aggressive track use. Don't forget about the exhaust system, which needs to be able to flow the increased volume of gases efficiently. Planning your Subaru WRX upgrades as a complete package ensures no single system becomes a bottleneck.

What to Know About Installation

Building a high-performance engine is a complex and precise task. It's far more involved than simply swapping out parts. The process requires specialized tools, a clean environment, and a deep understanding of engine mechanics, from setting bearing clearances to torquing bolts in the correct sequence. Even a small mistake during assembly can lead to catastrophic failure down the road. Be honest about your own mechanical skill and the tools you have available. While a DIY build can be incredibly rewarding, for many, the smart choice is to trust the installation to a professional with experience building high-performance Subaru engines.

To Build or To Buy? Pre-Built vs. Custom

One of the biggest decisions you'll face when planning your FA20 project is whether to build the engine yourself or buy a professionally assembled short block. A custom, hands-on build offers a deeply personal experience, giving you total control to select every single component and learn the intricate details of your engine. It’s a rewarding path for those who love the process as much as the result. On the other hand, a pre-built engine from a trusted builder provides a proven, turnkey solution engineered for a specific performance level. There’s no single right answer, as the best choice depends entirely on your goals, resources, and timeline. Weighing the key factors—cost, time, warranty, and the value of professional expertise—will help you decide which path is right for you.

What's the Real Cost of a Built FA20 Engine?

Building a high-horsepower FA20 is a serious financial commitment, and a DIY approach can be deceptive. While sourcing parts yourself might seem cheaper initially, costs can quickly spiral out of control. Pushing for ambitious goals like 500 HP requires premium forged internals, specialized machine work, and tools you may not own. Unexpected issues, like a stripped bolt or a mis-measured clearance, can lead to buying parts twice, adding significantly to the final bill. A pre-built engine has a higher upfront price, but it’s a fixed cost. You’re paying for a complete, tested package of performance parts without the risk of surprise expenses, making it much easier to budget for your project.

Don't Underestimate the Time Commitment

Your time is one of your most valuable resources. A custom engine build is not a weekend project; it can easily consume weeks or even months of meticulous work, research, and troubleshooting. This means significant time spent in the garage and, more importantly, your car being off the road. You'll spend countless hours sourcing components, waiting for machine shop services, and carefully assembling everything to precise specifications. If your main goal is to get back behind the wheel and enjoy your car's new power as quickly as possible, a pre-built engine is the clear winner. It drastically reduces downtime, letting you move on to the installation and tuning phases much sooner.

Understanding Lead Times for Built Engines

When you decide on a professionally assembled short block, it’s important to plan for the build time. These aren't off-the-shelf items; high-quality, custom-built engines are typically assembled to order and can take anywhere from two to four weeks to be ready. This lead time isn't just a delay—it's a crucial period where expert technicians meticulously assemble and verify every component to precise specifications. While this might seem like a long wait, it's often significantly shorter and more predictable than the timeline for a DIY build, which can be derailed by backordered parts, machine shop delays, and unforeseen complications. Factoring in this professional build time allows you to create a reliable schedule for the rest of your installation and tuning, turning a major variable into a fixed point in your project plan.

What Kind of Warranty Can You Expect?

For many owners, this is the deciding factor. When you build an engine yourself, you are the warranty. If a part fails or a small assembly error causes catastrophic damage down the line, the responsibility—and the cost of the repair—falls entirely on you. This is a high-stakes gamble, especially with an engine built to handle significant power. In contrast, a professionally built engine from a reputable company like Crawford Performance comes with a warranty. Our 12-month/12,000-mile warranty on engine builds provides critical peace of mind, protecting your investment and ensuring you can push your car with confidence, knowing it's backed by experts.

Factory Warranty Risks vs. Builder Guarantees

Once you begin modifying your engine with performance parts, your original factory warranty becomes a thing of the past. At this point, you’re faced with a new reality regarding who covers potential failures. If you choose the DIY route, you assume 100% of the risk. A single assembly error or a faulty component can lead to catastrophic engine damage, and the financial burden to fix it rests entirely on your shoulders. In contrast, a professional builder provides a guarantee on their work. This isn't a factory warranty, but a builder's promise that the engine was assembled correctly using quality components. This guarantee is your safety net, ensuring your significant investment is protected against defects in workmanship and giving you the confidence to use the power you paid for.

Why Professional Assembly is Worth It

There is simply no substitute for experience. Professional engine builders have assembled hundreds of motors, refining their processes and learning the specific quirks of platforms like the FA20. They work in clean, controlled environments with calibrated, high-precision tools that most home mechanics don't have access to. This expertise minimizes the risk of common assembly errors that can lead to premature wear or catastrophic failure. A professionally built engine isn't just a collection of quality parts; it's a balanced, blueprinted system where every component works in perfect harmony. Paired with professional engine tuning services, it ensures you get reliable, repeatable power you can count on.

FA20 Build vs. Engine Swap: The Breakdown

One of the biggest decisions you'll face when chasing serious power is whether to build your car's original FA20 engine or swap it for something entirely different. This is a classic debate in the BRZ/FR-S/86 community, and the right answer depends entirely on your goals, budget, and how much time you want to spend in the garage versus on the road. An engine swap can open doors to different power characteristics, but it also introduces a world of complexity.

Building the FA20, on the other hand, means working with the platform you already know and love. It’s about refining and strengthening the engine designed specifically for your chassis. With the right approach and high-quality components, a built FA20 can deliver incredible performance that feels perfectly integrated with your car. Let's break down the key factors to help you decide which path is the right one for your build.

Popular Engine Swap Options

If you decide an engine swap is the right path, two Subaru-based options stand out for their proven results. The most common choice is swapping in the turbocharged FA20DIT from the WRX. This route delivers a factory-engineered turbo setup and a significant power increase, typically landing you in the 250-300 horsepower range. It’s a well-documented swap, but it requires a comprehensive list of supporting performance parts, including an intercooler, a robust fuel system, and custom wiring. Another increasingly popular option is the newer 2.4-liter FA24 engine. This swap provides a major advantage in displacement, offering a substantial torque increase across the powerband right from the start. With available plug-and-play harnesses, the FA24 integration is becoming more streamlined, making it an excellent choice for a modern, powerful, and responsive build.

Which Option Makes More Power?

Let’s be clear: a professionally built FA20 is no slouch. With a fortified bottom end and the right forced induction setup, these engines can reliably handle upwards of 600 horsepower. This is more than enough power to dominate on the track and create an exhilarating street car. While some engine swaps might offer a higher theoretical power ceiling for dedicated drag racing, the FA20 holds its own for almost every other application. The key is building it correctly with a solid plan from the start, ensuring your power goals are met without compromising the engine's integrity.

Which is Harder to Install?

Here’s where building the FA20 has a clear advantage. Since you’re working with the original engine, everything just fits. You won’t be wrestling with custom engine mounts, fabricating a new exhaust, or splicing together a complex wiring harness. An engine swap, however, is a major undertaking that requires extensive modification. You’ll need a specific swap kit, potential transmission adapters, and solutions for everything from the cooling system to the gauge cluster. Sticking with the FA20 eliminates these headaches, making the installation process far more straightforward and saving you significant time and effort.

Build vs. Swap: A Cost Comparison

At first glance, sourcing a used engine for a swap might seem cheaper than buying a list of high-end internal components. However, the total cost of a swap often exceeds a built motor once you factor everything in. Swap kits, custom driveshafts, specialized wiring, and the immense amount of labor required can quickly add up. When you invest in building your FA20, your money goes directly into robust performance parts and precision machine work, creating a solid foundation without the hidden costs of a complex conversion.

Which is More Reliable in the Long Run?

Reliability isn't about the engine you choose; it's about how well it's assembled and tuned. A common misconception is that built FA20s are fragile, but this is usually the result of cutting corners or an improper tune. A professionally assembled FA20 with quality internals and a meticulous tune is incredibly dependable for both daily driving and track abuse. An engine swap introduces more variables that can affect reliability, from custom wiring gremlins to component compatibility issues. A proper build combined with expert engine tuning services provides a proven formula for durable power.

Why Professional Assembly and Tuning Matter

Investing in high-quality performance parts is only half the battle. How those components are assembled and tuned is what transforms a collection of expensive metal into a reliable, high-output engine. Skipping the professional touch at this stage can undermine your entire build, leading to poor performance or catastrophic failure. Proper assembly ensures every clearance is perfect and every bolt is torqued to spec, while a professional tune makes all the new hardware work in harmony. This is where you protect your investment and ensure your FA20 build lives up to its full potential on the street or the track.

The Right Way to Assemble Your Engine

A successful engine build hinges on meticulous assembly. It’s about more than just putting parts together; it’s about implementing best practices that fortify the engine against the stresses of high performance. For the FA20, this means paying special attention to the oiling system. Upgrading the oil pickup, porting oil passages for better flow, and adding an oil cooler are critical steps to prevent oil starvation and maintain stable temperatures. These modifications ensure your engine receives consistent lubrication, which is vital for longevity, especially when you’re pushing for more power. Every detail, from bearing clearances to ring gaps, must be perfect to create a solid foundation for a dependable engine.

How to Properly Break In Your New Engine

Once your engine is assembled, the break-in period is the most critical time in its life. This process allows the piston rings to seat properly against the cylinder walls, creating a tight seal that is essential for compression and oil control. A careful break-in, following a specific procedure of varying engine loads and RPMs without excessive stress, ensures a longer, healthier lifespan for your build. Rushing this step can lead to issues like excessive oil consumption and reduced power down the road. Think of it as the final, crucial step of the assembly process—one that solidifies all the hard work and precision that went into the build itself.

Driving Habits for Engine Longevity

Your new engine's lifespan is now in your hands, and how you drive makes all the difference. Always let the engine warm up to operating temperature before applying heavy throttle; this simple habit prevents premature wear on cold components. For a modified engine, stick to a strict maintenance schedule, changing the oil and filter every 3,000 to 4,000 miles with high-quality synthetic oil. Keep a close eye on your engine’s vitals using gauges or a Cobb Accessport to monitor air-fuel ratios, boost, and temperatures. If you install new hardware, a professional tune is not optional—it's essential for safe operation. Finally, be aware that FA20s can consume oil, especially when driven hard. Check your oil level frequently to prevent oil starvation, which can quickly destroy even the most well-built engine.

What to Expect from a Professional Tune

Installing performance upgrades without a proper tune is like asking an orchestra to play without a conductor. Your car’s computer (ECU) is calibrated for factory components, and it has no idea how to manage a larger turbo or high-flow injectors on its own. Professional engine tuning services are essential to recalibrate the ECU, optimizing air-fuel ratios, ignition timing, and boost levels. This process ensures the engine runs efficiently and safely with its new modifications. A skilled tuner will maximize your power output while maintaining reliability, giving you a car that is both thrilling and dependable to drive.

The Role of a Dyno in Tuning

A dynamometer, or "dyno," is much more than a tool for getting a final horsepower number to show your friends. Think of it as a treadmill for your car, allowing a tuner to simulate real-world driving conditions in a safe, controlled setting. This is where the magic of a professional tune happens. On the dyno, a tuner can safely run your car through its full RPM range under load, carefully monitoring critical data like air-fuel ratios, boost pressure, and ignition timing in real-time. This data-driven approach allows them to make precise adjustments to the engine's map, ensuring every component of your build works together perfectly. It’s an indispensable tool for any serious performance build, providing the safe environment needed to maximize power while protecting your engine from potential damage. This is a critical part of any professional engine tuning service.

Why Safety Features in Your Tune are Crucial

A great tune does more than just make power; it builds in a safety net to protect your engine. Professional tuners set critical limits within the engine management system to prevent damage from issues like over-boosting or running too lean. This is especially important when you’ve installed a suite of supporting performance parts like a front-mount intercooler, a cold air intake, and an upgraded fuel pump. These components work together to support higher power levels, and the tune ensures they all operate within safe parameters. This proactive approach helps prevent catastrophic failures, giving you the confidence to use the power you’ve built.

Getting Your Car Ready for the Track

Taking your built FA20 to the track introduces a whole new level of stress on every component. The sustained high RPMs and extreme temperatures of track driving demand a build that is specifically prepared for that environment. This often means making different choices in parts and tuning strategies compared to a street-focused build. It’s important to have a realistic conversation with your builder and tuner about your track ambitions. They can help you understand the trade-offs between maximum power and on-track endurance, ensuring your car is not only fast but also reliable enough to handle lap after lap.

How to Maintain Your Built FA20 Engine

Once your FA20 engine is built and tuned, the work isn’t over. Protecting your investment means adopting a proactive approach to maintenance and monitoring. A high-performance engine operates under greater stress than a factory motor, so its needs are different. Think of it less like a daily commuter and more like a dedicated athlete—it requires specific care to perform at its peak consistently. Sticking to a disciplined routine will ensure your engine delivers reliable power for years, whether you’re on the street, track, or trail.

This means paying closer attention to fluid changes, keeping an eye on vital signs, and understanding how heat affects your setup. A little diligence goes a long way in preventing minor issues from turning into major failures. By staying on top of these key areas, you can enjoy the power you’ve built with confidence.

Creating a Maintenance Schedule for Your Built Engine

With a built engine, the factory maintenance schedule no longer applies. You’ll need to be much more frequent with your service intervals to keep everything in top shape. For oil changes, a good rule of thumb is every 3,000 to 6,000 miles, depending on how you drive. If you frequently track your car or drive it hard, stick to the lower end of that range. This regular service is your first line of defense, clearing out contaminants and ensuring all those high-performance internals are properly lubricated. Don’t forget to check other fluids like coolant and transmission fluid regularly, too.

Addressing Carbon Buildup

Carbon buildup is a known challenge with direct-injection engines like the FA20. Because fuel is sprayed directly into the cylinder, it never washes over the intake valves, allowing oily vapor from the crankcase ventilation system to bake onto them. Over time, these deposits can restrict airflow, hurt performance, and reduce efficiency. While periodic professional cleaning like walnut blasting can remove existing buildup, the best strategy for a built engine is prevention. Installing a high-quality Air/Oil Separator is one of the most effective modifications to combat this. An AOS intercepts and removes oil from the crankcase vapor before it enters your intake tract, keeping your valves clean and ensuring your engine breathes freely for consistent, reliable power.

How to Monitor Performance

You can’t protect what you can’t see. Installing a quality set of gauges is one of the smartest things you can do for a built motor. At a minimum, you should monitor oil pressure, oil temperature, and your air-fuel ratio (AFR). If you’re running forced induction, a boost gauge is also essential. These tools give you a real-time look at your engine's health and can help you spot a problem before it causes catastrophic damage. A sudden drop in oil pressure or a lean AFR reading is an immediate signal to shut things down and investigate. Proper engine tuning services will also establish safety parameters, but gauges are your daily check-in.

Best Practices for Oil Management

A high-performance engine is sensitive to what you put in it. Always use the highest-quality gasoline and engine oil you can find. Skimping here is not worth the risk. Your engine builder or tuner can recommend the ideal oil weight for your specific setup and intended use, as factors like bearing clearances and the addition of an oil cooler can change what’s required. It’s also a good practice to check your oil level frequently—at every other fuel fill-up is a good habit. High-revving and high-horsepower engines can sometimes consume a small amount of oil, and you never want to run it low.

Choosing the Right Oil for Your Build

A high-performance engine is sensitive to what you put in it, so always use the highest-quality gasoline and engine oil you can find. Skimping here is not worth the risk. Your engine builder or tuner can recommend the ideal oil weight for your specific setup and intended use, as factors like bearing clearances and the addition of an oil cooler can change what’s required. It’s also a good practice to check your oil level frequently—at every other fuel fill-up is a good habit. High-revving and high-horsepower engines can sometimes consume a small amount of oil, and you never want to run it low. This simple check is one of the most effective ways to protect your investment and ensure your engine has the lubrication it needs to handle the power you’ve built.

PCV System Maintenance

The Positive Crankcase Ventilation (PCV) system is designed to remove harmful vapors from the engine, but under the high cylinder pressures of a built motor, it can become a weak point. Increased blow-by can push oil vapor into your intake, lowering your fuel's octane rating and increasing the risk of detonation. This is where an Air/Oil Separator (AOS) becomes essential. An AOS intercepts these vapors, separating the oil and returning it to the crankcase while allowing clean air to pass through. Addressing these vulnerabilities with targeted performance parts like an Air/Oil Separator is not just a good idea—it’s a critical step for ensuring your built engine remains reliable under pressure.

How to Keep Engine Temperatures Down

Heat is the enemy of performance and reliability. As you make more power, you generate more heat, and the stock cooling system can quickly become overwhelmed. For spirited driving or track days, an upgraded aluminum radiator is a must-have modification. If you’re running a turbo or supercharger, a larger, more efficient intercooler is critical for keeping intake air temperatures down, which is key to making consistent power. For serious builds, an external oil cooler is also a wise addition to keep oil temperatures stable, protecting your bearings and other critical performance parts from premature wear.

Related Articles

- 4 Mods to Boost FA20 Engine Reliability

- Crawford Built FA20 Engine Price: A Full Breakdown

- The Ultimate Subaru Engine Upgrade Guide

Frequently Asked Questions

What's the very first upgrade I should make to my FA20 for reliability? Before you chase any power gains, your first move should be to address the engine's known oiling issues. Installing a high-quality Air/Oil Separator (AOS) is the single most important preventative modification you can make. It prevents oil from contaminating your intake system, which helps maintain fuel octane and reduces the risk of detonation. This simple upgrade protects your engine's health, even at stock power levels, and sets a solid foundation for everything that comes next.

How much power can the stock FA20 engine safely handle? This is a common question, and the answer depends heavily on the quality of your tune and supporting parts. Generally, the stock internals can handle around 300 to 350 wheel horsepower reliably. Pushing beyond this range on the stock pistons and connecting rods is a significant gamble. Once you have goals that exceed this threshold, it's time to seriously plan for forged internals to ensure your engine can handle the increased stress without failing.

Do I really need to upgrade my oiling and cooling systems for a street build? Absolutely. While track driving is the ultimate test, even spirited street driving can push your oil and coolant temperatures into unsafe territory. An upgraded radiator provides a crucial safety margin during hot days or even just sitting in traffic, while a baffled oil pan can prevent oil starvation during an aggressive turn on a back road. Think of these upgrades as insurance for your investment, ensuring your engine remains healthy and reliable no matter how you use it.

Is a turbocharger or a supercharger better for a daily driven car? This really comes down to personal preference and how you want your power delivered. A supercharger provides instant, linear power right from idle, making the car feel responsive and strong throughout the entire RPM range. A turbocharger typically delivers a bigger punch in the mid-range and top end, which can be incredibly exciting. For daily driving, many prefer the predictable nature of a supercharger, but a properly sized turbo can also be very manageable and fun.

Can I just buy parts and have my local mechanic install them? While a skilled general mechanic is great for routine maintenance, building a high-performance engine is a specialized craft. The process requires a deep understanding of the FA20 platform, access to precision measuring tools, and a meticulously clean environment to set clearances and tolerances correctly. A small mistake during assembly can lead to a catastrophic failure. For a reliable result, it's always best to trust the work to a professional with proven experience in building performance Subaru engines.