The Ultimate Guide to EJ25 Forged Pistons & Rods Specs

Share

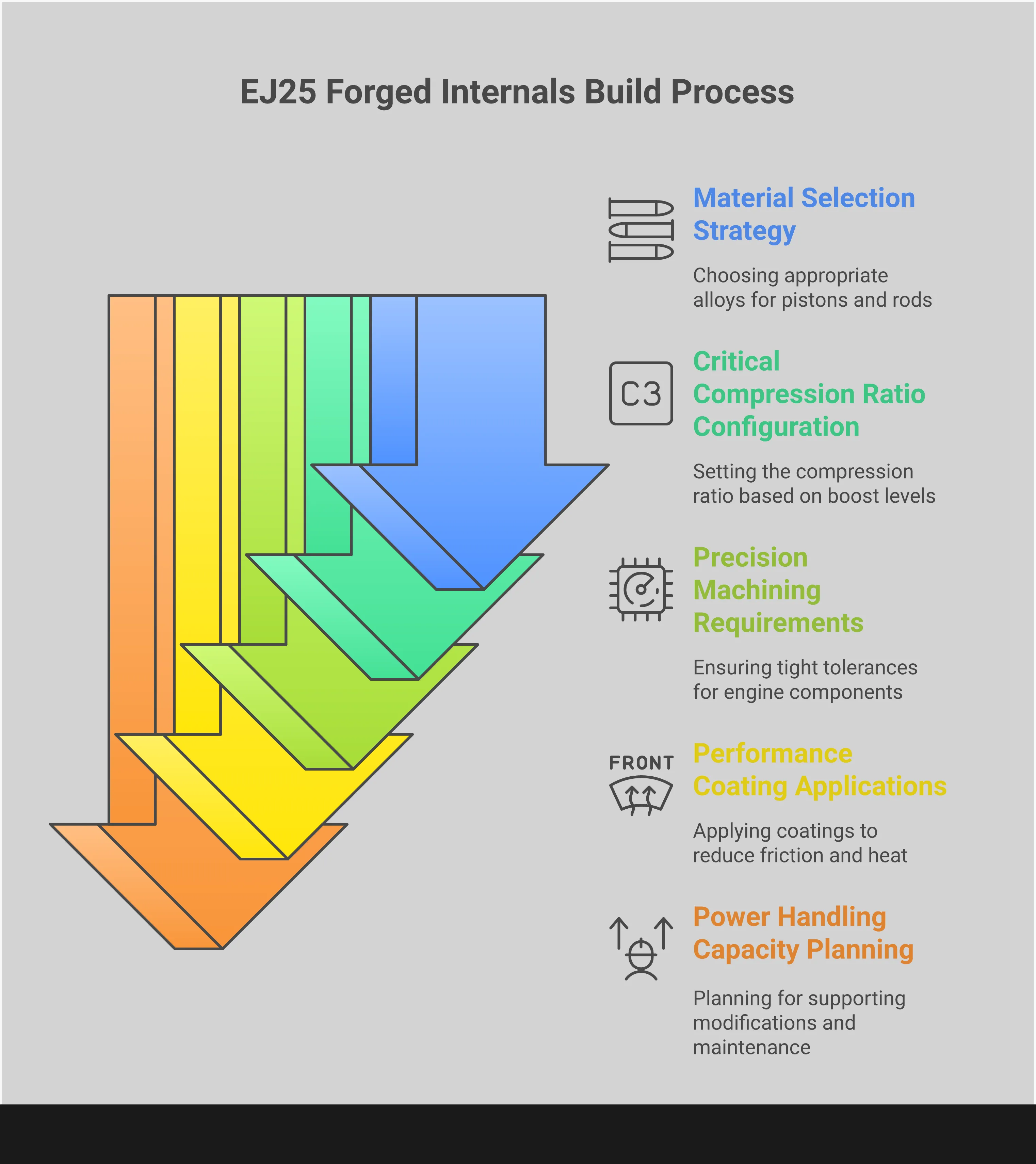

What’s the goal for your Subaru? Are you building a responsive 400-horsepower daily driver or a dedicated track machine that lives at high RPMs? The answer determines which internal components are right for you. A part that excels in one application might not be ideal for another. The key is to match the components to your specific performance goals. This starts with a deep understanding of the engineering and design choices that go into these critical parts. We’ll explore the different ej25 forged pistons and rods specs available, helping you select the perfect combination to bring your vision for your car to life.

Key Takeaways

- Reinforce Your Engine's Core First: Forged internals are not about instant horsepower; they are about creating a durable foundation. This upgrade prepares your EJ25 to safely handle the significant power you'll add from other modifications like a larger turbo and increased boost.

- Select Internals Based on Your Build's Purpose: The right components depend entirely on your goals. A daily driver benefits from quieter 4032 alloy pistons, while a dedicated track car may require the superior strength of a 2618 alloy, making it crucial to match the parts to your intended use.

- Professional Assembly and Tuning Are Essential: High-quality parts are only half the battle. The performance and reliability of your built engine depend on precise installation by an experienced builder and a professional ECU tune to optimize fuel, timing, and boost for the new setup.

What Are EJ25 Forged Pistons and Rods?

When you start pushing your Subaru for more power, you quickly find the limits of its stock engine components. That’s where forged pistons and rods come in. Think of them as the heavy-duty foundation for a high-performance engine build. Unlike standard cast parts, which are made by pouring molten metal into a mold, forged pistons and rods are made from a solid piece of metal that is shaped under high pressure, making them stronger and more durable. This process creates a much denser and more uniform grain structure, resulting in components that can withstand the intense heat and cylinder pressures of a modified engine.

Upgrading to forged internals is a critical step for anyone serious about adding significant horsepower to their EJ25. Whether you're aiming for a reliable track car, a competitive rally build, or just a powerful street machine, these parts provide the strength and durability needed to handle increased boost and higher RPMs without failure. They are the key to transforming your engine from a capable factory unit into a robust powerhouse built for performance.

Forged vs. Cast: What's the Difference?

The primary difference between forged and cast components lies in their manufacturing process, which directly impacts their strength. Casting is like making an ice cube—you pour liquid into a mold and let it solidify. This can create microscopic pores and an inconsistent grain structure, making the final part more brittle. Forging, on the other hand, is like a blacksmith shaping metal with a hammer, forcing the material's internal grain to align and become incredibly dense.

Interestingly, all Subaru EJ motor crankshafts and connecting rods are made using forged steel, which is a testament to their strength from the factory. However, the weak link is often the stock cast pistons. They simply aren't designed for the stress of high-horsepower applications and are prone to cracking under high boost. This is why a piston upgrade is the most common first step in building a reliable EJ25 long block.

Which Subaru Models Use the EJ25 Engine?

The EJ25 is one of Subaru's most iconic boxer engines, powering a range of performance models for years. If you're driving a Subaru from 2002 to the present, there's a good chance you have one. The EJ25 engine is found in various Subaru models, including the WRX and WRX STI, and is known for its versatility. You'll find the 2.5-liter EJ25 in the Subaru WRX from 2006-2014 and the WRX STI from 2004-2021.

Other models like the Forester XT (2004-2013) and Legacy GT (2005-2012) also came equipped with turbocharged EJ25 variants. Because of its widespread use and massive aftermarket support, the EJ25 has become a favorite platform for tuners. Understanding the history of the Subaru EJ-series engines helps explain why it remains so popular for performance builds today.

Why Upgrade From Stock Internals?

The simple answer is power. The factory cast pistons and connecting rods in an EJ25 are not designed to handle significant power increases. They are perfectly adequate for stock power levels, but they become a major liability once you start adding boost and tuning for more horsepower. Under the higher cylinder pressures and temperatures of a modified engine, stock pistons can fail catastrophically, leading to complete engine destruction. This is especially true for the ringlands—the area between the piston rings—which are known to crack on stock EJ25 pistons.

By upgrading to forged pistons and rods, you are installing components designed to handle extreme stress. This allows you to safely run higher boost levels, make more power, and have peace of mind that your engine's core is strong enough to handle the abuse. It’s a foundational modification that supports nearly all other performance parts you might add later on.

Common Myths About Forged Internals

One of the most persistent myths is that forged pistons always require greater skirt-to-wall clearances, leading to noise when cold (a phenomenon known as "piston slap"). While this was true for older forging alloys, modern materials have changed the game. Many high-quality forged pistons today are made from advanced alloys that expand less when heated, allowing for tighter clearances similar to stock pistons.

This means you can get the strength of a forged piston without the cold-start noise or increased oil consumption that people used to associate with built engines. Proper engine care and warm-up procedures are still important, but the idea that a forged engine has to be loud and loose is outdated. Always follow the manufacturer's specific clearance recommendations to ensure a quiet, reliable, and powerful build.

Decoding the Specs: What to Look For in Forged Internals

When you decide to build your EJ25 engine, you’re faced with a sea of options for pistons and rods. It’s easy to get lost in the numbers and marketing terms. But understanding the key specifications is the most important step in choosing the right components for your goals. The specs aren’t just numbers on a page; they determine how your engine will perform, how reliable it will be, and how it will feel to drive. Whether you’re building a high-powered Subaru STI for the track or a torque-focused motor for your Subaru Forester, getting the internals right is everything.

Think of this as the blueprint for your engine's core. We'll walk through the most critical specs, from the raw materials to the final coatings. By the end, you'll know exactly what to look for and be able to select the perfect forged pistons and rods for your specific Subaru build. This knowledge will help you see past the brand names and focus on the engineering that truly matters, ensuring you invest in parts that will handle the power you want to make for years to come.

Materials and Alloys

The foundation of any good piston is the material it’s made from. You'll typically see two main aluminum alloys used for forged pistons: 4032 and 2618. A 4032 alloy has a higher silicon content, which means it expands less as it heats up. This allows for tighter piston-to-wall clearances, resulting in a quieter engine on cold starts and reduced oil consumption, making it an excellent choice for high-performance daily drivers. On the other hand, 2618 alloy has very little silicon, which makes it stronger and more resistant to detonation but causes it to expand more with heat. This requires larger clearances, so it can be a bit noisier when cold, but it’s the preferred material for all-out race applications where maximum strength is the top priority.

Bore Size and Compression Ratios

Two of the most important numbers you’ll choose are the bore size and compression ratio. The standard bore size for an EJ25 is 99.5mm. If your engine block's cylinder walls are being machined to correct for wear, your builder may use an "overbore" piston, such as 99.75mm or 100mm. The compression ratio (CR) dictates how much the air-fuel mixture is squeezed in the cylinder. A stock EJ257 has an 8.2:1 CR. Aftermarket performance parts offer options to change this. A slightly higher CR, like 8.5:1 or 8.9:1, can improve throttle response and power off-boost, while a lower CR is often used in very high-boost applications to reduce the risk of detonation.

Connecting Rod Strength and Design

Connecting rods are the critical link between your pistons and crankshaft, and the stock ones are a known weak point when you start adding significant power. Forged connecting rods are typically made from high-strength 4340 chromoly steel. When it comes to design, the H-beam style is the most popular and effective choice for EJ25 builds. It offers an excellent balance of strength, durability, and light weight, which is ideal for an engine that needs to rev quickly and reliably. You should also ensure any set of rods you consider includes high-quality ARP rod bolts, as they provide the clamping force needed to hold everything together under extreme stress.

The Importance of Precision Machining and Weight Matching

The best materials and design in the world don’t mean much without precision manufacturing. Forged pistons and rods must be machined to incredibly tight tolerances to ensure proper fit and function. Just as important is weight matching. Reputable manufacturers weigh and group their pistons and rods into balanced sets, often within a single gram of each other. This precision balancing is critical for creating a smooth-running engine, especially at high RPMs. An unbalanced rotating assembly creates harmful vibrations that can lead to premature bearing wear and, eventually, catastrophic engine failure. This attention to detail is a hallmark of expert engine tuning services and quality components.

Key Design Features and Required Clearances

There’s a common myth that all forged pistons are noisy and create "piston slap" when the engine is cold. While this was true years ago, modern piston design has largely solved this. Advanced skirt profiles and better alloys allow for tighter piston-to-wall clearances than ever before. It is absolutely essential that your engine builder follows the specific clearance recommendations provided by the piston manufacturer. This single measurement is one of the most critical aspects of a reliable engine build. Other design features to look for include thick-walled, heavy-duty wrist pins, which are essential for handling the high cylinder pressures of a turbocharged Subaru WRX.

Protective Coatings for Heat and Friction

Top-tier forged pistons often come with special coatings that enhance their performance and durability. You may see a thermal barrier coating on the crown (the top) of the piston. This ceramic-based layer helps reflect heat back into the combustion chamber instead of letting it soak into the piston, which protects the piston and improves thermal efficiency. Additionally, many pistons feature a dry-film lubricant coating on the skirts. This dark gray coating reduces friction between the piston and the cylinder wall, which helps minimize wear during break-in and throughout the engine's life. These coatings are functional upgrades that provide an extra layer of protection, especially for engines that will be pushed hard.

Who Makes the Best EJ25 Forged Pistons and Rods?

When you’re ready to build your EJ25, choosing the right forged internals can feel overwhelming. The market is full of excellent brands, and the "best" option really comes down to your specific power goals, driving style, and budget. Whether you're building a reliable daily driver that can handle more power or a dedicated track car for your Subaru WRX or STI, there’s a manufacturer out there with the perfect setup for you.

To help you make an informed decision, let's look at some of the most trusted names in the industry. We'll cover what makes each brand unique, from their design philosophy to the specific applications they excel in. This isn't about crowning a single winner, but about giving you the information you need to pick the right components for your engine build. We’ll explore options from specialists like Crawford Performance, CP-Carrillo, Tomei, and ZRP, each bringing something different to the table.

Crawford Performance

As Subaru engine specialists, we’ve spent decades perfecting our components specifically for the EJ25 platform. Our pistons are engineered to withstand the unique demands of turbocharged Subaru engines. Crawford pistons feature reinforced ring lands and optimized crown thickness to handle the pressure spikes inherent in forced induction systems. This design directly addresses common failure points in stock pistons, giving you the confidence to push for more power. By focusing on durability and precise engineering, our forged Subaru engine internals provide the strength needed for high-performance street and track applications, ensuring your engine remains reliable under pressure.

CP-Carrillo

CP-Carrillo is a name that consistently comes up in high-horsepower circles, and for good reason. They have a stellar reputation for producing incredibly strong and reliable components. CP-Carrillo offers high-performance forged pistons that are designed for strength and reliability, making them a popular choice among enthusiasts looking to push their EJ25 engines to higher power levels. If your goal is to build an engine that can handle significant boost and compete at a high level, their products are a fantastic option. Their commitment to quality materials and manufacturing makes them one of the best forged pistons for the Subaru STI and other EJ25 models.

Tomei

Hailing from Japan, Tomei brings a rich motorsport heritage to their product design. They are well-known for creating parts that balance strength with efficiency. Tomei's forged pistons are known for their lightweight design and high strength, making them suitable for high-performance applications in the EJ25 engine. A lighter rotating assembly allows the engine to rev more freely and respond quicker to throttle inputs. This makes Tomei forged pistons an excellent choice for drivers who prioritize sharp engine response for autocross, time attack, or spirited street driving, where every fraction of a second counts.

ZRP

ZRP strikes a great balance between performance and endurance, making their components a solid choice for a wide range of builds. Their Subaru EJ25 / EJ257 pistons are developed for mild to high tuning, mainly for road or club race cars that want to develop their engine for high mileage. This focus makes ZRP forged pistons ideal for enthusiasts building a powerful daily driver or a weekend track car that still needs to be dependable. If you're looking for a robust upgrade that won't compromise the engine's longevity, ZRP offers a reliable and well-engineered solution that can handle increased power without issue.

Comparing Prices and Complete Kits

One of the most convenient and cost-effective ways to buy forged internals is through a complete kit. These packages bundle everything you need, ensuring all components are perfectly matched and saving you the headache of sourcing parts individually. A typical kit includes 4 pistons, 4 piston pins, 8 pin locks, 4 piston rings, 4 connecting rods, and 8 bolts. Prices can vary significantly based on the brand, materials, and specific features. You can find quality kits starting around $800, with high-end options going up from there. Browsing a wide selection of performance parts will give you a clear idea of what fits your budget and build goals.

What Performance Gains Can You Expect?

Upgrading to forged pistons and rods isn't about instantly adding 50 horsepower. Instead, think of it as building a rock-solid foundation for your engine. The real performance gain comes from creating an engine that can reliably handle significantly more power from other modifications. Factory cast internals are a known weak point in the EJ25, especially when you start increasing boost or pushing the car on the track. By swapping them for forged components, you're removing that limitation and preparing your Subaru for serious power.

This upgrade is about unlocking your engine's true potential. It gives you the confidence to install a larger turbo, run higher boost, and tune your ECU for maximum output without worrying about catastrophic engine failure. The primary benefit is a massive increase in strength and durability, which in turn allows you to chase higher horsepower and torque figures safely. It’s the essential first step for anyone serious about transforming their Subaru WRX or STI into a high-performance machine.

Improve Engine Strength and Durability

The factory cast pistons and connecting rods in an EJ25 were never designed to handle significant power increases. They are the product of a faster, less expensive manufacturing process that can leave them brittle under high stress. Forged internals, on the other hand, are created from a solid billet of alloy that is heated and pressed into shape. This process creates a much denser, stronger component with a grain structure that resists the intense forces inside a high-output engine. This added strength is crucial for preventing failures like cracked pistons or bent rods, ensuring your engine remains reliable even when pushed to its limits.

Handle Higher Boost Levels Safely

More boost means more power, but it also means more pressure and heat inside your engine's cylinders. Stock pistons can fail under the pressure spikes that come with aggressive tuning and forced induction. High-quality forged pistons are engineered specifically for this environment. Features like reinforced ring lands and optimized crown thickness allow them to withstand intense pressure without failing. Many also include thermal barrier coatings to manage heat more effectively. This allows you to safely run higher boost levels, which is one of the most effective ways to get more power from your turbocharged EJ25 engine.

Increase Your Engine's Power Handling Capacity

With stock internals, you’re always limited by how much power the engine can safely make before a component gives up. Once you install a quality set of forged Subaru engine internals, that ceiling gets much higher. A properly built EJ25 with high-quality forged pistons and rods can reliably handle around 400 wheel horsepower (whp), and sometimes more depending on the rest of the build. At that point, the engine block itself often becomes the next limiting factor. This upgrade fundamentally changes what your engine is capable of, turning it from a respectable street engine into a platform ready for serious performance.

Supporting Mods to Maximize Performance

Forged internals are a foundational upgrade, but they don't work in a vacuum. To truly capitalize on their strength, you’ll need to pair them with other supporting modifications. Think of it as building a complete system. With a stronger bottom end, you can now add parts like a larger turbocharger, high-flow fuel injectors, an upgraded fuel pump, and a more efficient intercooler. These components work together to produce the power that your new internals are built to handle. A full exhaust system and an improved intake will also help the engine breathe better, maximizing the efficiency of your entire setup.

Installation and Tuning: Getting It Done Right

Installing forged pistons and rods is a precision job that requires expertise. Proper clearances, bearing tolerances, and torque specifications are absolutely critical to the life of your engine. This is not a typical DIY project and should be handled by an experienced engine builder. After the mechanical work is done, a professional tune is mandatory. Your engine's computer needs to be completely recalibrated to account for the new components and your performance goals. A skilled tuner will optimize fuel delivery, ignition timing, and boost pressure to create a powerful and reliable setup, ensuring you get the most out of your investment.

Related Articles

- Everything You Need to Know About Your Subaru Engine

- The Ultimate STI Forged Piston Kit Buyer's Guide

- EJ25 Short Block Reliability: A Complete Guide

- Expert Subaru Solutions: How to Fix EJ25 Short Block Issues

Frequently Asked Questions

Do I really need forged internals for my daily driver? If your Subaru is stock or only has minor modifications like a cat-back exhaust, you don't need to worry about this upgrade. The factory components are perfectly capable. However, if you plan to add significant power through a larger turbo, increased boost, or an aggressive tune, then yes, forged internals become essential. They provide the strength needed to keep your engine reliable once you start pushing past its original design limits.

How much power can my EJ25 handle with forged internals? A professionally built EJ25 with quality forged pistons and rods can typically handle around 400 wheel horsepower reliably. The exact number depends heavily on the quality of the tune, the supporting modifications, and how the car is driven. Once you reach this level, the engine block itself often becomes the next limiting factor. The goal of this upgrade is to create a strong foundation that allows you to safely achieve your power goals.

Will a built engine with forged pistons be loud and burn oil? This is a common concern based on older technology, but it's largely a myth today. Modern forged pistons, especially those made from 4032 alloy, are designed to run with clearances very similar to stock parts. When installed and machined correctly by a skilled engine builder, a modern built engine should be just as quiet and reliable as a factory one, without excessive noise or oil consumption.

Should I upgrade the pistons and rods at the same time? Yes, it is highly recommended. While the stock cast pistons are usually the first component to fail, the factory connecting rods also have a power limit. Since building an engine requires a complete teardown, replacing both the pistons and rods at the same time is the most logical and cost-effective approach. This ensures your entire rotating assembly is strong enough to handle future power increases.

What's the difference between 4032 and 2618 alloy pistons, and which is right for me? The main difference is the silicon content, which affects how much the piston expands when it gets hot. 4032 alloy has more silicon, so it expands less, allowing for tighter clearances. This makes it the ideal choice for a high-performance street car because it's quieter on cold starts. 2618 alloy is stronger and more resistant to detonation, but it expands more, requiring looser clearances. This makes it the go-to option for dedicated race cars where maximum strength is the absolute priority.