Built FA20 Engine: The Ultimate Buyer's Guide

Share

You wouldn't build a skyscraper on a foundation meant for a single-family home. The same logic applies to your car’s engine. While bolt-on parts like exhausts and intakes offer a great performance bump, they only get you so far. To make truly significant power, you need to strengthen the engine from the inside out. A built FA20 engine is that reinforced foundation. It involves swapping stock pistons and rods for high-strength, forged parts designed to handle immense pressure and heat. This process transforms your engine into a durable powerhouse, giving you the confidence to chase your ultimate performance vision.

Key Takeaways

- Build Your Engine's Core for Serious Power: A built FA20 swaps factory internals for forged components, creating a durable foundation that can safely manage the intense pressure from significant horsepower and torque gains.

- Treat Your Build as a Complete System: A built engine requires a team of supporting parts to perform reliably; upgrades to your fuel system, intercooler, and oil management are just as critical as the engine itself.

- Budget Beyond the Block: The final cost includes more than just the engine—factor in professional installation, essential supporting modifications, and a professional tune to create a balanced and durable performance setup.

What is a Built FA20 Engine?

If you’re looking to get serious power out of your Subaru, you’ve probably heard the term “built engine.” A built FA20 engine is a stock engine that has been disassembled and reassembled with stronger, higher-performance internal components. This process transforms the engine from a reliable daily driver into a powerhouse capable of handling significant increases in horsepower and torque. It’s the foundation for any ambitious performance project, whether you’re aiming for the track or just want a more responsive and powerful street car. Think of it as reinforcing the engine’s core so you can safely add more power without risking catastrophic failure.

The Stock FA20: A Quick Primer

The FA20 is a 2.0-liter four-cylinder boxer engine that Subaru introduced as a successor to the popular EJ series. You’ll find two main versions in modern Subarus. The naturally aspirated FA20, producing around 200 horsepower, powers the Subaru BRZ and its Toyota 86 counterpart. The more powerful, turbocharged version is the FA20DIT (Direct Injection Turbo), which comes in the 2015 and newer Subaru WRX models, putting out about 268 horsepower from the factory. While both are solid platforms, the FA20DIT is especially popular for modifications due to its forced induction setup, which provides a great starting point for substantial power gains.

Common Weaknesses and Power Limits

While the FA20 is a capable engine right out of the box, it has a few well-known weak spots that can become major issues when you start adding serious power. The stock internals can generally handle up to about 400 horsepower and 350 ft-lbs of torque. Pushing beyond these numbers puts immense stress on the factory components, with the connecting rods often being the first to fail. Other common problems that can arise, especially on modified or hard-driven cars, include rod knock, premature bearing failure, and high oil consumption. Addressing these potential failure points is crucial for anyone planning significant performance upgrades, as it ensures your build is both powerful and reliable for the long haul.

Built vs. Stock: What's the Difference?

The key difference between a built and a stock engine lies in the internal components. A stock FA20 is designed for factory power levels and everyday reliability. A built engine, on the other hand, replaces critical stock parts with aftermarket upgrades designed to withstand much greater stress. This typically includes forged pistons and connecting rods, a stronger crankshaft, and upgraded bearings. Many builders also improve airflow by porting the cylinder heads and installing an upgraded valvetrain. These performance parts create a much more robust engine that can safely handle the increased cylinder pressures from higher boost and aggressive tuning.

Defining Your Build: Street, Track, or Both?

Building an FA20 engine isn’t a one-size-fits-all process; the specific components you choose depend entirely on your goals. Are you building a high-revving track car or a torque-heavy street machine? For example, a build intended for high boost levels might use lower compression pistons to maximize power safely. A street-focused build might prioritize a balance of power and reliability. A proper build can cost anywhere from $5,000 to over $10,000, so it’s important to have a clear plan. The final step is always a professional tune, as expert engine tuning services are required to optimize all the new components and achieve your desired performance.

Who Builds the Best FA20 Engines?

Once you decide to build your FA20, the next critical step is choosing the right builder. This decision will shape your car’s performance, reliability, and overall character. The market is filled with talented engineers, but each shop has its own philosophy and area of expertise. Some specialize in creating robust short blocks designed to handle immense pressure from forced induction, while others offer complete, turn-key crate engines ready for installation.

Your performance goals will guide you to the right builder. Are you aiming for a high-horsepower track monster or a reliable street car with a significant power increase? Understanding what you want to achieve is key to finding a partner who can deliver. To help you make an informed choice, let’s look at some of the most respected names in the FA20 engine building community. Each of these builders has a proven track record of transforming Subaru engines into high-performance powerhouses.

A Closer Look: Crawford Performance

With over 20 years of experience testing and developing high-performance Subaru parts, we’ve poured our expertise into creating a truly formidable engine. Our Built Short Block FA20 is specifically engineered for boosted applications, capable of handling up to 660 horsepower. We use custom-designed pistons and rods to ensure the engine can withstand the extreme pressures of forced induction while delivering consistent, reliable power. This block is the foundation for a serious performance build, giving you the confidence to push your Subaru to its limits on the street or the track.

A Closer Look: HKS

HKS is another leading name in the performance world, known for its precision engineering and comprehensive engine solutions. The company offers an FA20 2.2L complete engine designed as a drop-in solution for enthusiasts seeking a significant upgrade. HKS focuses on enhancing durability for turbocharged or supercharged setups by incorporating stronger internal components, such as upgraded bolts and connecting rods. Their engines are built to handle increased power levels effectively, making them a popular choice for those who want a fully assembled and proven package from a globally recognized brand.

Other Builders to Watch

The FA20 building community is home to several other skilled specialists. Shops like IAG Performance have demonstrated the FA20DIT’s impressive potential, noting that owners can achieve up to 350WHP with just basic bolt-on modifications. Many high-level builds from various tuners also incorporate ported cylinder heads and an upgraded valvetrain to improve airflow and unlock even more power. Exploring the work of these builders can provide valuable insights into different build philosophies and help you identify the best approach for your specific performance goals.

How to Compare Built FA20 Engines

When you start shopping for a built FA20, you'll see a lot of different numbers and specs. It’s easy to get lost in the details, but focusing on a few key areas will help you make a smart decision. Comparing engines isn't just about finding the biggest horsepower number; it's about understanding how that power is made and whether the engine is built to last. Let's break down the three most important factors: power output, internal components, and core engine specs.

Decoding Horsepower and Torque Specs

First, let's set a baseline. The naturally aspirated FA20 in the BRZ produces around 200 horsepower, while the turbocharged FA20DIT in the WRX comes in at about 268 horsepower. A built engine is designed to push far beyond those factory limits. When comparing builders, look at their advertised power ratings, but also consider how that power is achieved. A well-built engine focuses on efficient airflow. Upgrades like ported cylinder heads and an enhanced valvetrain allow the engine to breathe better, which is essential for making more power reliably. Think about your own performance goals and choose a build rated to handle your target horsepower with room to spare.

What's Inside? Key Internal Components

The real magic of a built engine happens on the inside. The stock pistons, rods, and bearings in an FA20 were not designed for the stress of high-horsepower applications. This is why a quality build uses superior performance parts made from stronger, forged materials that can withstand intense heat and pressure. Some high-end builds are rated to handle over 550 horsepower, a testament to the strength of their internals. The FA20 also has a "square" design, meaning its bore and stroke dimensions are equal (86mm x 86mm). A good builder knows how to select components that work in harmony with this design for a smooth and responsive feel.

Strengthening the Block and Heads

The core of any built engine project is reinforcing the engine block and cylinder heads. Think of the stock FA20 as a well-built structure designed for a specific load. When you start adding significant power through a turbocharger or aggressive tuning, you're drastically increasing that load. The factory cast pistons and connecting rods simply aren't engineered to handle the intense heat and cylinder pressures of a high-performance setup. A proper build replaces these with high-strength, forged components. This process transforms the engine's core into a durable foundation, giving you the structural integrity needed to safely pursue higher horsepower without worrying about catastrophic failure.

Upgrading the Oiling System

A powerful engine is useless if it can't stay lubricated under pressure. Building a strong engine is only half the battle; you also need to ensure its supporting systems are up to the task. The oiling system is one of the most critical. Increased G-forces from hard cornering on the track or navigating steep angles while overlanding can cause oil to slosh away from the pickup, momentarily starving the engine. This is where an upgraded oil management system, like an Air/Oil Separator (AOS), becomes essential. An AOS prevents oil from entering the intake system and ensures a consistent supply of lubrication, protecting your investment and keeping your high-performance engine running reliably under demanding conditions.

The Technical Specs: Compression, Bore, and Stroke

Diving a bit deeper, the compression ratio (CR) is a critical number to check. Many built FA20 engines, especially those intended for forced induction, use a lower compression ratio than stock. Lowering the CR allows you to run higher boost levels more safely, which is key to making significant power with a turbocharger. While it might slightly reduce off-boost responsiveness, it's a necessary trade-off for a high-powered, reliable build. The FA20's square 86mm bore and stroke is an excellent platform, allowing the engine to rev freely and efficiently. This design is a major reason the engine can achieve an impressive 100 horsepower per liter, a characteristic that expert engine tuning services can fully exploit.

What Performance Gains Can You Expect?

A built FA20 engine completely transforms your driving experience. It's not just about achieving a higher number on a dyno sheet; it's about creating a more powerful, reliable, and responsive machine that aligns with your specific goals. Whether you're building a spirited daily driver, a dedicated track car, or a capable overlanding rig, a built motor fundamentally changes the engine's character. The right combination of forged internals, supporting modifications, and expert tuning creates a synergy that a stock engine simply can't match. You'll feel the difference every time you press the accelerator. A stock engine is designed to meet broad consumer needs and manufacturing budgets, which means compromises are made. A built engine removes those compromises, replacing them with components chosen specifically for strength and performance. This allows you to safely push the limits and tailor the car's behavior to your exact preferences. Let's look at the specific improvements you can anticipate when you upgrade your Subaru WRX with a built FA20.

How Much More Power Will You Make?

A built FA20 is your ticket to significant power increases. By replacing stock internals with forged components and improving airflow, you create a foundation that can handle much more horsepower and torque. A built FA20 often includes ported cylinder heads to improve airflow, along with an upgraded valvetrain. These modifications allow the engine to breathe more efficiently, which is essential for making more power. When paired with the right turbo, fuel system, and a professional tune, these engines can push well beyond the limits of the factory setup. The exact gains will depend on your specific build and supporting performance parts, but the potential for a truly high-output machine is unlocked.

Can a Built Engine Be More Reliable?

More power is exciting, but it's meaningless without reliability. A key benefit of a built engine is its enhanced durability under demanding conditions. Before adding power, it's critical to address the FA20's common vulnerabilities with essential upgrades like an Air-Oil Separator and improved cooling. A properly built motor uses stronger materials like forged pistons and connecting rods that can withstand the increased stress of higher cylinder pressures and temperatures. This reinforcement gives you peace of mind, knowing your engine is built to last, whether you're pushing it on the track or relying on it for daily commutes. It’s about building a smarter, stronger engine, not just a more powerful one.

Achieving Instant Throttle Response

Beyond raw power, a built FA20 delivers a much more connected and responsive driving feel. Upgrading components like the factory intercooler is one of the best modifications you can make, as it provides cooler, denser air to the engine for better combustion. This translates directly to a quicker and more immediate reaction when you hit the gas. The lag you might feel in a stock setup is significantly reduced. When combined with professional engine tuning services, every input from your right foot results in a crisp, predictable power delivery. This heightened responsiveness makes the car feel more agile and engaging to drive in any situation.

Beyond Peak Horsepower: Improving Driveability

While a high horsepower number is great for bragging rights, the real improvement from a built engine is in its overall driveability. It’s about how the car feels and responds in everyday situations, not just at wide-open throttle. The synergy between high-quality performance parts, like forged internals and an upgraded valvetrain, creates an engine that is both stronger and more efficient. This translates to a sharper throttle response and a more connected feeling to the road. Because the engine can breathe better and handle stress more effectively, you get a smoother, more predictable power curve. You gain the confidence that your engine is not only powerful but also durable enough to handle whatever you throw at it, from a spirited drive on a back road to a demanding day at the track.

Choosing Your FA20 Build Path

Choosing to build your FA20 engine opens up a world of performance possibilities, but it’s not a one-size-fits-all process. The right build for you depends entirely on your goals. Are you looking for a more responsive and reliable daily driver, a dedicated track machine, or an all-out powerhouse? Each objective requires a different approach to internal components, tuning, and supporting mods.

Understanding the common build paths is the first step in planning your project. By defining what you want to achieve, you can select the right combination of parts to create an engine that is both powerful and durable for its intended use. We’ll look at three popular configurations: a street performance build for enhanced daily driving, a track-focused setup for competitive racing, and a forced induction build for those chasing maximum horsepower. Each configuration balances power, reliability, and cost differently to match specific driving demands.

The Daily Driver: A Street Performance Build

If you want to add some excitement to your daily commute without sacrificing reliability, a street performance build is the perfect solution. This configuration focuses on making smart, effective upgrades that improve power and responsiveness while maintaining drivability. A common approach involves using ported cylinder heads and an upgraded valvetrain to improve the engine's airflow. This allows the engine to breathe more efficiently, resulting in a noticeable performance gain you can feel every time you press the accelerator. This path gives you a stronger, more capable engine that’s still perfectly suited for everyday use, making your Subaru WRX more engaging than ever.

The Weekend Warrior: A Track-Focused Build

For those who spend their weekends at the track, a build needs to be engineered for sustained high-RPM use and extreme conditions. A track-focused FA20 build prioritizes durability under intense stress. One key strategy is lowering the compression ratio, which allows the engine to handle higher boost levels more safely and generate more power at the top end. While this might slightly reduce responsiveness at lower RPMs, it’s a necessary trade-off for maximizing performance during competitive laps. These builds almost always include forged pistons, stronger connecting rods, and other reinforced internals to withstand the heat and pressure of racing, all dialed in with precision engine tuning services.

Going Big: Forced Induction Builds

When your goal is to make serious power, a forced induction build is the way to go. This setup is designed to handle the immense pressure from a larger turbocharger or supercharger. To achieve this, the engine requires a completely rebuilt bottom end with forged internals capable of withstanding outputs of 550 horsepower or more. Even a moderately upgraded setup with a new turbo-back exhaust, cold air intake, and upgraded intercooler can push you well past 300 wheel horsepower. This path is for the enthusiast who wants to transform their car into a true performance machine, and it demands a comprehensive approach to ensure all performance parts work together to support the massive power gains.

Alternatives to a Built FA20

While building an FA20 is a proven path to impressive performance, it’s not the only option on the table. For some enthusiasts with very specific or extreme horsepower goals, starting with a different engine platform altogether can be a more direct route. Pushing any engine far beyond its original design limits requires a significant investment, and sometimes, the cost and complexity of a max-effort FA20 build can approach that of an engine swap. If you're aiming for power levels that test the absolute limits of the FA20 architecture, it's worth exploring other platforms that might offer a different set of advantages in terms of powerband, aftermarket support, or proven reliability at those higher outputs.

Engine Swaps for High Horsepower Goals

When the goal is astronomical horsepower, some builders look outside the Subaru family. Engine swaps like the GM LS3 or Honda K-series are popular in the tuning community for good reason. These platforms have extensive aftermarket support and a long history of making reliable, high-end power. An LS swap, for example, brings V8 torque and a completely different character to the car, while a K-swap is known for its high-revving nature and incredible power-to-weight ratio. These swaps are complex and costly projects that require custom fabrication, wiring, and a host of supporting performance parts, but for some, the unique result is worth the effort.

Considering Other Subaru Engines: EJ22 vs. FA24

If you want to stay within the Subaru ecosystem, there are other boxer engines to consider. The older, closed-deck EJ22 is a legendary block known for its incredible strength, making it a favorite for high-boost builds. On the other end of the spectrum is the newer FA24, found in the latest WRX and BRZ models. Building an FA24 instead of an FA20 gives you the advantage of starting with more displacement, which can help produce more torque and power more efficiently. Both options present a different set of challenges and benefits compared to building an FA20, and the choice often comes down to your budget, power goals, and the kind of expert engine tuning services available to you.

Essential Supporting Mods for Your Built FA20

A built FA20 engine is the foundation for serious power, but it can’t reach its full potential alone. To get the performance and reliability you’re paying for, you need to upgrade the components around it. Think of it like an athlete—a strong heart is essential, but it needs a powerful respiratory system to win the race. These supporting mods ensure your entire setup works in harmony, delivering maximum power safely and efficiently.

Upgrading Your Turbo and Intercooler

One of the most effective changes you can make is upgrading the factory intercooler. A high-performance intercooler dramatically improves your turbo’s efficiency and can add up to 65 horsepower at 6100 RPM. It keeps the charge air cool, allowing for denser air to enter the engine, which is critical for making consistent power. For those pushing for higher output, ported cylinder heads and an upgraded valvetrain are also key. These performance parts improve airflow, allowing your engine to breathe better and handle the demands of increased power levels without strain.

Matching Your Fuel System and Exhaust

To make more power, your engine needs more air and more fuel. A proven combination for the FA20 is an aftermarket intake, a j-pipe, and a cat-back exhaust. Paired with a professional tune, this setup completely changes your car’s performance. If you plan on running E85 fuel for even greater gains, you’ll need to prepare your fuel system. This typically involves upgrading the intercooler, downpipe, and electronic boost control solenoid (EBCS). Depending on your E85 mixture, a new low-pressure fuel pump may also be necessary. You can find many of these essential Subaru WRX upgrades to build out your system.

The Final Touch: Professional ECU Tuning

Hardware is only half the equation; the other half is the tune. A simple Stage 1 tune can add an impressive 20–30 horsepower, making it one of the most cost-effective mods available. For an even bigger jump in performance, a Stage 1 E85 tune offers incredible value. After installing significant hardware like a new turbo or fuel system, a custom professional tune is not just recommended—it’s required. Proper engine tuning services ensure all your new components work together correctly, maximizing performance while keeping your engine safe and reliable.

Fuel System Upgrades for 450+ WHP

When you start pushing past the 450 wheel horsepower mark, you’ll find the limits of the stock direct injection fuel system. To make that much power, your engine needs a significant amount of fuel, and at a certain point, you need a secondary system to deliver it. This is where adding port injection comes in. This setup provides the extra fuel required to support massive power gains safely. If you're planning to use E85 for its performance benefits, upgrading your fuel system is non-negotiable. This often includes a higher-flow low-pressure fuel pump to keep up with the demand. These performance parts are essential for creating a reliable, high-output build.

Reliability Mods: TGV, EGR, and Air-Oil Separators

Building a powerful engine is one thing; making sure it lasts is another. An Air-Oil Separator (AOS) is widely considered the most important reliability modification for the FA20. It prevents oil vapor from the crankcase from entering your intake, which stops harmful carbon buildup on the intake valves and keeps your fuel's octane rating pure. Another common reliability upgrade is deleting the Tumble Generator Valves (TGV) and Exhaust Gas Recirculation (EGR) system. While these are emissions components, they can contribute to carbon buildup. Removing them helps keep your engine’s intake cleaner and cooler, but it’s critical to remember that this modification requires professional engine tuning services to ensure the car runs correctly.

Strengthening Your Drivetrain

Once you have a built engine capable of producing serious power, the stress moves to the next link in the chain: the drivetrain. The stock clutch, transmission, and axles were designed for factory power levels and often can't handle the massive increase in torque from a built motor. A slipping clutch is usually the first sign that you’ve exceeded the limits of your stock components. To reliably put all that new power to the ground, you’ll need to invest in drivetrain upgrades. This typically includes a high-performance clutch and flywheel, and for very high-horsepower builds, you may need to consider strengthening the transmission and axles as well. These upgrades are crucial for a balanced and durable performance build for your Subaru WRX.

Breaking Down the Cost of a Built FA20

Investing in a built FA20 engine is a serious commitment, and understanding the costs involved is the first step. The final price tag isn't just about the engine itself; it includes the build type, labor, and the essential supporting modifications needed to handle the new power. Think of it as building a complete system, not just swapping a single part. The total cost can vary widely based on your performance goals, the components you choose, and whether you handle any of the work yourself. Let's break down the primary expenses you can expect when planning your build.

How Much Does the Engine Itself Cost?

The core of your expense will be the engine itself. A professionally built FA20 long block, which typically includes the assembled block and cylinder heads, can range from $5,000 to $6,000. This is a great option if you want a solid foundation built with high-quality internals ready for installation. If you're looking for a more comprehensive solution, a full engine rebuild often costs between $6,000 and $9,000. This price reflects a complete overhaul of your existing engine or a new build from the ground up, tailored to your specific power goals with top-tier performance parts.

Factoring in Installation and Labor Costs

Once you have your engine, you need to get it into your car. Professional installation is highly recommended to ensure everything is fitted and connected correctly. Labor costs can vary by shop, but they are a significant part of the budget. If you're mechanically skilled and plan to do some work yourself, you can save money. For example, installing a bolt-on turbo kit might cost around $3,000 for the kit, but you'll still need to budget about $1,000 for professional engine tuning services to dial everything in safely and effectively.

The "Other" Costs: Supporting Mods and More

A built engine can't reach its potential without the right support system. These modifications are crucial for reliability and performance, and they can easily add $5,000 to $10,000 or more to your total cost. Essential upgrades often include a high-flow exhaust system, a larger intercooler, and an upgraded fuel system to deliver the necessary fuel and manage heat. Depending on the condition of your engine heads, you might also need a rebuild, which can start around $800. These Subaru WRX upgrades work together to create a balanced, powerful, and durable setup.

Potential Hurdles and How to Handle Them

A built FA20 engine is a serious investment in your Subaru's performance, but it's important to go in with your eyes open. Building a high-horsepower engine isn't just about dropping in a new block; it involves a holistic approach to the entire powertrain. Anticipating a few common challenges will ensure your build goes smoothly and you get the reliable power you're paying for. From managing oil to getting the tune just right, being prepared for these next steps is key to a successful project and a thrilling driving experience.

Keeping an Eye on Oil Consumption

One of the first things to address with any high-performance FA20 is oil control. When you increase cylinder pressure to make more power, you also increase blow-by—the small amount of combustion gas that slips past the piston rings. This gas carries oil vapor with it, which can get into your intake system, lower your fuel's octane rating, and lead to detonation. The solution is an Air-Oil Separator (AOS). An AOS is one of the most critical performance parts you can install. It captures that oily vapor, separates the oil, and returns it to the crankcase, ensuring only clean air enters the intake. This simple device is essential for maintaining engine health and consistent performance.

Dialing In Your Turbo and Tune

A built short block is the foundation, but it doesn't make power on its own. To truly unlock its potential, you need to upgrade the components that feed it air and fuel. This often means ported cylinder heads for better airflow, an upgraded valvetrain to handle higher RPMs, and a larger turbocharger to force more air into the engine. These supporting modifications are what allow the built block to do its job. Remember that this all needs to be tied together with a professional tune. Proper engine tuning services are non-negotiable; a precise tune ensures all your new components work in harmony, delivering reliable power without risking your investment.

Does a Built Engine Affect Your Warranty?

When you install a built engine, you can assume your factory powertrain warranty is void. That’s why the warranty offered by your engine builder is so important. It’s a statement of their confidence in their product and craftsmanship. Before you buy, read the terms carefully. At Crawford Performance, we stand behind our work with a 12-month/12,000-mile warranty, but it’s crucial to understand what’s covered and what isn’t. Often, a builder’s warranty will require specific supporting modifications—like an AOS or a professional tune—to be valid. Make sure you know the requirements upfront to protect your engine and your investment for the long haul.

Common Mistakes to Avoid

One of the biggest mistakes enthusiasts make is viewing a built engine as a simple drop-in replacement. A high-performance short block is only one part of a complex system, and it can't function properly without the right supporting cast. You must budget for and install upgraded fuel, air, and cooling systems to handle the increased output. Neglecting these performance parts is a recipe for failure. Another common pitfall is treating the final tune as an afterthought. Without precise calibration from professional engine tuning services, your expensive new hardware can't work in harmony. An improper tune not only leaves power on the table but also puts your entire investment at risk of catastrophic damage.

Planning for Potential Wait Times

Another mistake is underestimating the project timeline. Building a high-performance engine is a craft, not an assembly line process, so it's wise to plan for potential wait times. Sourcing specific forged internals can sometimes lead to delays, and reputable builders often have a queue of projects. Once your built engine is ready, the timeline doesn't end there. You still need to account for shipping, professional installation, and the crucial final tuning session, all of which take time. Be sure to communicate with your chosen builder about their current lead times and factor that into your project schedule. Patience during this phase is key to ensuring every component is assembled and calibrated for peak performance and long-term reliability.

Your Installation and Compatibility Checklist

Choosing the right built FA20 engine is a huge step, but the process doesn’t end there. Proper installation is what brings your performance goals to life. A built engine is a precision machine, and ensuring it integrates flawlessly with your Subaru is critical for both power and longevity. Compatibility checks and a professional installation process are your best insurance for the investment you’ve made in your vehicle. Think of it as the final, crucial piece of the puzzle that ensures every component works together in perfect harmony.

Confirming Fitment for Your Subaru Model

Before you even think about installation, you need to be certain you have the correct engine for your specific Subaru model. The FA20 engine family has a few key variations. For instance, the naturally aspirated FA20 in the BRZ is different from the turbocharged FA20DIT found in the WRX from 2015 onward. They have different intake systems and other architectural distinctions that make them incompatible with one another. Always confirm the engine you’re buying is designed for your exact year and model to avoid costly mistakes and headaches. Checking compatibility for all your Subaru WRX upgrades ensures a smooth and successful build from start to finish.

Why Professional Installation Matters

A built engine is the heart of your car, and its installation is not the place to cut corners. These high-performance parts are critical for engine health, and unless you have the specialized skills and tools, a professional installation is the best way to protect your investment. An experienced technician ensures everything is set up correctly, from torquing bolts to spec to connecting sensors and fluid lines. They can also manage the crucial first startup and break-in period. Pairing your new engine with professional engine tuning services is also essential to dial in performance and ensure your Subaru runs reliably for years to come.

Long-Term Care for Your Built Engine

Installing a built FA20 engine is a huge milestone, but the work doesn’t stop there. To protect your investment and get the most out of your high-performance setup, you need a solid long-term care plan. A built engine is a precision machine that requires more attention than a stock motor, but consistent care ensures it delivers the power and reliability you paid for. Think of it as a partnership with your car—give it what it needs, and it will reward you with incredible performance for years to come. This means staying on top of routine maintenance, monitoring its health, and ensuring your tune is always dialed in for your specific setup.

Your New Maintenance Schedule

The foundation of a long and healthy life for your built engine is diligent maintenance. These engines have known vulnerabilities, but you can easily address them with the right upgrades. One of the most critical additions is an Air-Oil Separator (AOS). The FA20 is prone to oil consumption, and an AOS prevents oil from entering your intake system, protecting your engine from detonation and power loss. Upgrading your cooling system is another smart move to prevent overheating during spirited driving or track days. By installing these essential performance parts, you’re building a reliable foundation for all the power you plan to make.

Staying on Top of Tuning and Performance

Your engine’s tune is its brain, and it needs to be perfectly matched to the hardware. A tune isn't a one-and-done deal, especially if you continue modifying your Subaru. Any time you change a major component—like upgrading your turbo, installing a new exhaust, or switching to E85 fuel—you need a retune. Running new parts on an old tune can lead to poor performance and even engine damage. Working with a professional who provides expert engine tuning services is non-negotiable. It’s also your job to be the first line of defense. Pay attention to how your car feels, listen for unusual noises, and keep an eye on your gauges to catch any potential issues before they become serious problems.

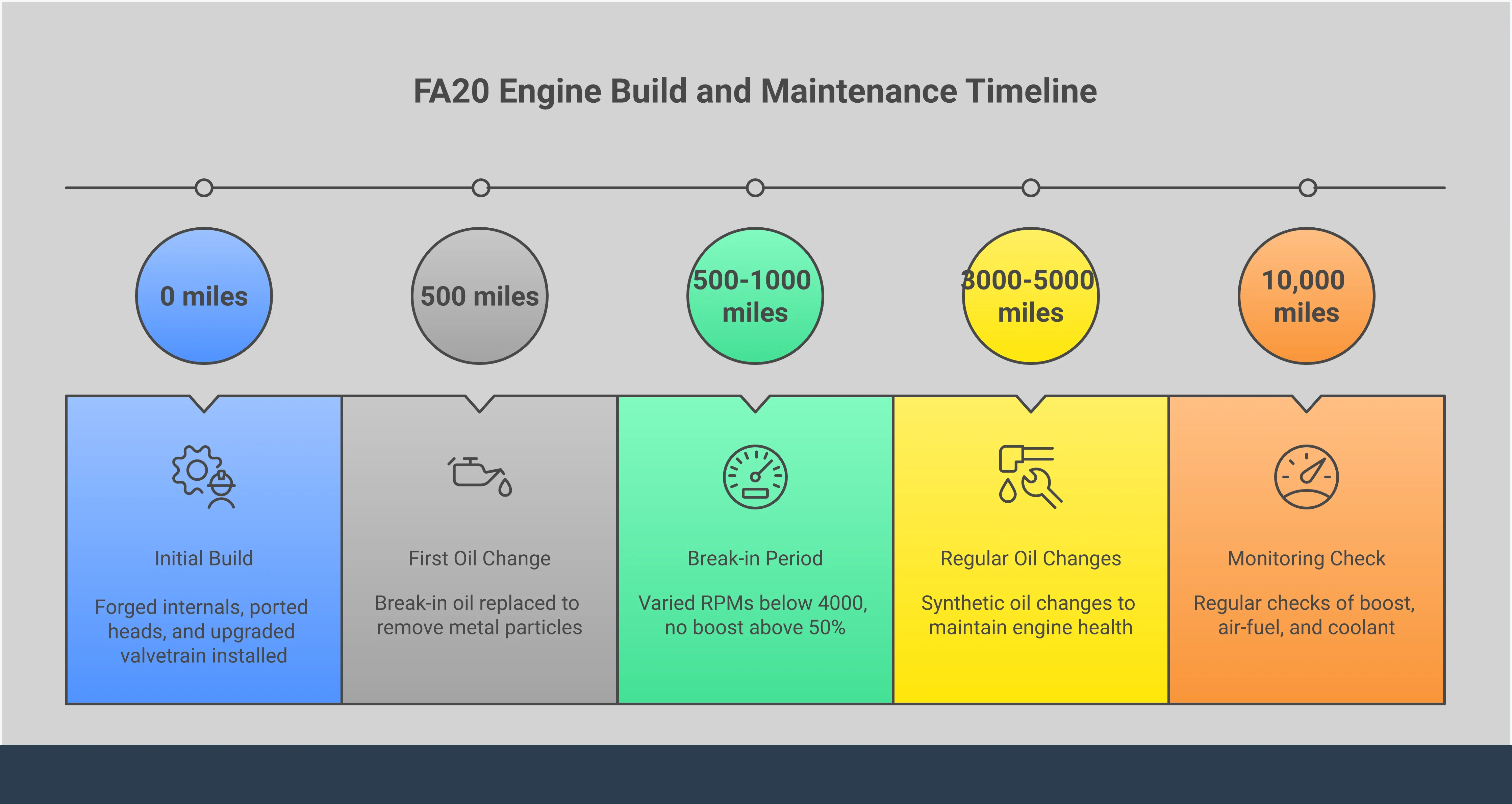

The Critical Break-In Period

The first 1,000 miles on your new built engine are the most important of its life. This isn't the time to see what your car can do; it's the time to ensure its longevity. During this critical break-in period, internal components like the piston rings need to seat properly against the cylinder walls. This process creates a tight seal that is essential for compression, oil control, and overall engine health. Following a strict break-in procedure—which typically involves varying your RPMs, avoiding heavy loads, and staying out of boost—establishes a solid foundation for all the performance parts you've invested in. Rushing this step can lead to excessive oil consumption and reduced performance down the road, so patience now pays off for years to come.

Daily Driving: Warm-Up Procedures and Monitoring

Once your engine is broken in, smart daily habits will keep it running strong. Always allow the engine to warm up completely before driving aggressively. Pay attention to your oil temperature, not just the coolant gauge, as oil takes longer to reach its optimal operating temperature. Consistently monitoring your engine’s health is also non-negotiable. Using a tool like a Cobb Accessport or dedicated gauges allows you to keep an eye on vital signs like oil pressure, air-fuel ratios, and knock feedback. This proactive approach helps you catch small issues before they become catastrophic failures, ensuring your investment is protected. It’s a key part of the ownership experience and works hand-in-hand with professional engine tuning services to maintain peak performance and reliability.

Related Articles

- Built FA20 Engine: Power, Cost & Top Builders

- Best Built FA20 Engine for BRZ: A Complete Guide

- 4 Mods to Boost FA20 Engine Reliability

- FA20 Engine Price: A Breakdown of the Total Cost

Frequently Asked Questions

Is a built engine really necessary for my goals? That all depends on how much power you're aiming for. If you're looking for modest gains and want to stay under the 350 wheel horsepower mark, you can often get there reliably with bolt-on parts and a quality tune on the stock block. However, if your goal is to push significantly beyond that, a built engine becomes a necessity. The stock internal components simply weren't designed to handle the intense stress of high boost, making a built motor the only safe and reliable foundation for a serious power build.

What's the difference between buying a short block versus a long block? Think of it in terms of how complete the package is. A "short block" is the bottom half of the engine—the engine block itself, with the crankshaft, pistons, and connecting rods already assembled inside. A "long block" is more comprehensive; it includes the entire short block plus the cylinder heads, camshafts, and valvetrain. Your choice depends on your project's needs and the condition of your existing cylinder heads. A long block is a more turn-key solution, while a short block is a great option if you plan to use custom or refurbished heads.

How long can I expect a built FA20 engine to last? A professionally built engine that is properly maintained and tuned can be just as reliable as a stock one, and sometimes even more so because it's assembled with superior parts. Longevity isn't about a specific mileage number; it's a direct result of the build quality, the precision of the tune, and how you care for it. Consistent oil changes, using an Air-Oil Separator to manage blow-by, and responsible driving habits are the keys to ensuring your investment provides years of high performance.

Why can't I just upgrade the turbo on my stock FA20? While it's tempting to go straight for a bigger turbo, the stock FA20's internal components are the weak link in the system. The factory pistons and connecting rods are not engineered to handle the massive increase in cylinder pressure that a larger turbo creates. Pushing them too far is the fastest way to cause catastrophic engine failure. A built engine replaces those weak points with strong, forged parts that can safely manage the extra power, making it the required first step for any big-turbo project.

What does the break-in process for a built engine involve? The break-in period is absolutely critical for seating the new piston rings and ensuring the long-term health of your engine. Every builder has a specific procedure you must follow, but it generally involves driving the car gently for the first 500 to 1,000 miles. This means keeping the RPMs varied but low, avoiding high boost or aggressive acceleration, and performing an early oil change. Following your builder's break-in instructions to the letter is the most important thing you can do to protect your new engine.