STI Forged Pistons: A Complete Buyer's Guide

Share

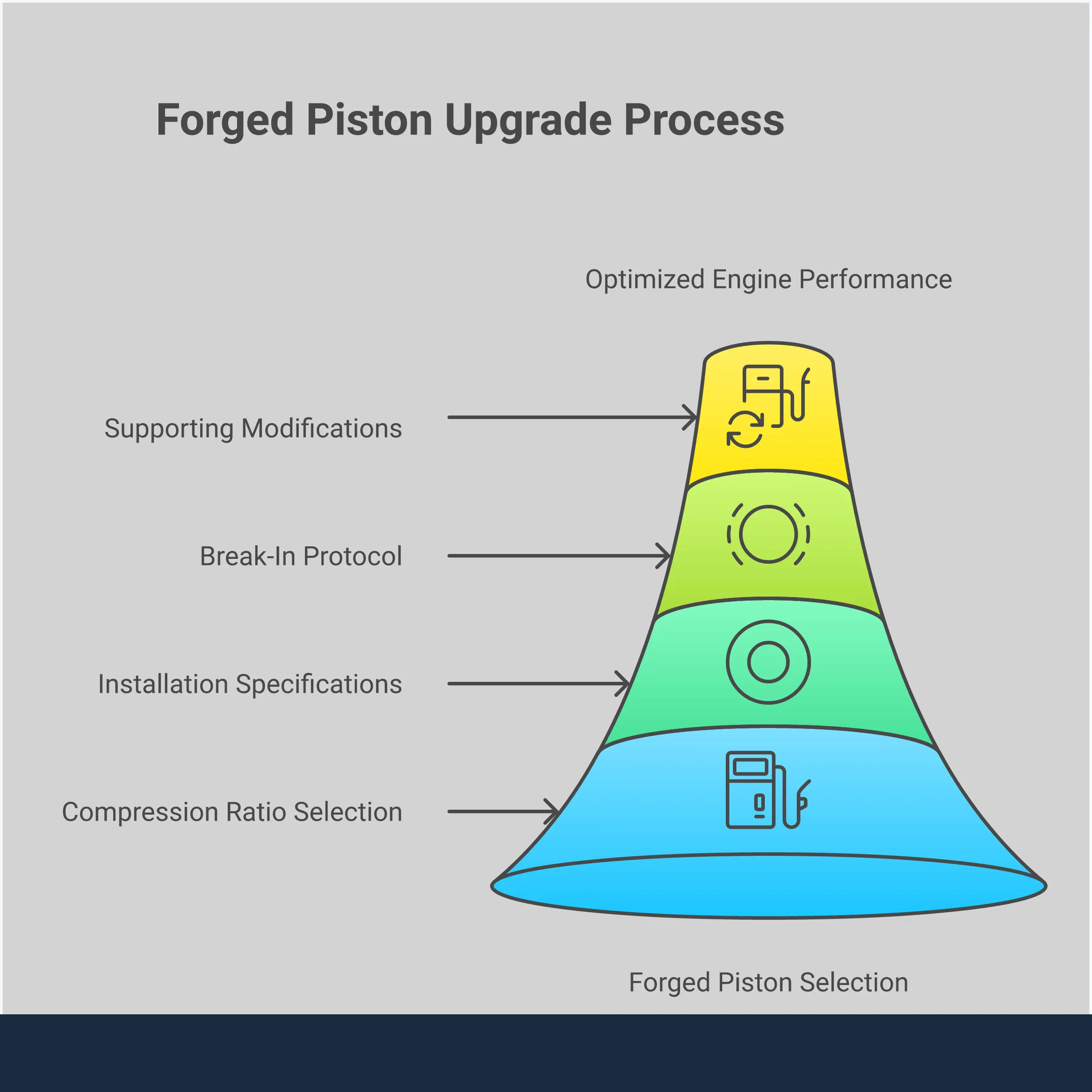

At the heart of your engine, a simple but critical process determines its strength: how the pistons were made. Your Subaru came with cast pistons, created by pouring molten aluminum into a mold. This method is cost-effective for stock power, but it leaves microscopic weaknesses. Forged pistons, however, are created from a solid block of high-grade aluminum under immense pressure, resulting in a component that is dramatically stronger and more resilient. Understanding this difference is the first step in building a powerful engine that lasts. This article will demystify engine internals, explaining why upgrading to STI forged pistons is a non-negotiable step for serious performance.

Key Takeaways

- Build a Stronger Engine Foundation: Your Subaru's stock cast pistons are the first major weak point when adding power. Forged pistons are essential for creating a durable engine that can safely manage the intense heat and pressure that come with higher horsepower and aggressive tuning.

- Choose Specs That Align With Your Goals: The right forged pistons depend entirely on your build. Key specifications like compression ratio and bore size must be carefully selected to match your turbo setup, fuel type, and whether you're building a street car or a track machine.

- Protect Your Investment with a Pro Install and Tune: High-quality parts are only half the battle. A successful forged piston upgrade requires precise installation by an experienced engine builder and a professional tune to synchronize all components, ensuring your engine runs safely and performs at its peak.

What Are Forged Pistons (And Why Do They Matter)?

If you’re planning to push your Subaru STI past its factory limits, you need to think about what’s happening inside your engine. At the heart of it all are the pistons, and the stock ones can only handle so much. Forged pistons are high-strength replacements designed to withstand the intense pressure and heat that come with serious performance upgrades. Think of them as the foundation of a powerful and reliable engine build.

When you start adding modifications like a larger turbo, an E85 tune, or increased boost, you’re asking your engine to do a lot more work. The original cast pistons weren't designed for that kind of stress. Upgrading to forged pistons is a critical step in fortifying your engine, allowing it to safely handle significantly more horsepower and torque. This upgrade isn't just about chasing bigger numbers; it's about building an engine that lasts, whether you're setting lap times on the track or building a dependable daily driver with a lot more punch.

Forged vs. Cast: What's the Difference?

Your STI’s engine came from the factory with cast pistons. They are made by pouring molten aluminum into a mold, which is a cost-effective process that works perfectly for stock power levels. However, once you push past the 400 horsepower mark, cast pistons become a liability. Under the increased stress, they can crack or shatter, leading to catastrophic engine failure.

Forged pistons, on the other hand, are the solution for high-performance builds. They are created from a solid billet of aluminum that is heated and pressed into shape under extreme pressure. This process creates a much denser and stronger internal grain structure, making them far more resilient. Choosing to install forged Subaru engine internals is the definitive way to ensure your engine can handle the power you want to make.

The Forging Process and Materials

The incredible strength of a forged piston comes from how it’s made. The process starts with a high-grade billet of 6061-T6 aluminum alloy, known for its excellent strength-to-weight ratio. This billet is heated to around 800°F and then forced into a die under an immense 2,000 tons of pressure. This forging process aligns the aluminum's grain structure, eliminating the microscopic pores and inconsistencies found in cast pistons. The result is a component that is up to 40% stronger than its cast equivalent, giving you the durability needed for a high-boost, high-horsepower engine.

Debunking Common Forged Piston Myths

You might have heard that forged pistons are only for race cars and aren't suitable for a street-driven STI. The common myth is that they require looser tolerances, leading to "piston slap" (a rattling noise when the engine is cold) and increased oil consumption. While this was a concern with older forging technologies, modern advancements have largely solved these issues.

Today’s high-quality forged pistons are made from advanced alloys that have a much lower thermal expansion rate. This means they can be installed with tighter clearances, just like stock pistons, minimizing noise and oil use. When paired with a professional installation and a precise engine tune, modern forged pistons deliver track-ready strength without compromising street-friendly reliability.

Why Upgrade to Forged Pistons?

Your Subaru’s stock engine is impressive, but its factory-installed cast pistons have their limits. They are designed for standard driving conditions, not the high-horsepower, high-stress environment of a modified engine. When you start adding significant power through tuning and bolt-on parts, the original pistons become a critical weak point. Upgrading to forged pistons isn't just about adding a shiny new part; it's about building a stronger, more resilient foundation for all your current and future performance goals. This is the step you take when you move from casual modifications to serious, reliable power.

This upgrade is fundamental for anyone serious about pushing their vehicle's limits. Whether you're building a track-day monster or a high-performance street car that you can rely on, forged pistons provide the strength and durability needed to handle the increased pressure and heat that come with more power. Think of it as essential insurance for your engine, allowing you to confidently chase higher horsepower without worrying about catastrophic failure. It’s the key to transforming your engine from a capable factory unit into a truly robust powerhouse, ready for whatever you throw at it.

Unmatched Strength and Durability

The primary reason to switch to forged pistons is their incredible strength. Unlike standard cast pistons, which are made by pouring molten aluminum into a mold, forged pistons start as a solid billet of high-grade 6061-T6 aluminum. This billet is then subjected to extreme heat and thousands of tons of pressure, compressing the metal's grain structure and eliminating internal weak spots. The result is a component that is 40% stronger than a cast equivalent. This process ensures your engine's core can withstand the intense forces generated by higher boost and aggressive engine tuning.

Better Heat Resistance

Heat is the enemy of any high-performance engine. As you increase power, you generate more heat, and your engine's ability to manage it becomes critical. Forged pistons excel in this area, dissipating heat 60% more effectively than their cast counterparts. This superior thermal conductivity helps keep piston crown temperatures down, reducing the risk of detonation (or engine knock) and protecting the piston rings and cylinder walls from premature wear. By running cooler, your engine maintains consistent performance and its internal components last longer, even under demanding track conditions.

Handle More Power

If your goal is to make serious power, forged pistons are non-negotiable. Stock pistons can often fail when horsepower levels start climbing, but forged internals are built to take the abuse. A set of quality forged pistons can reliably handle up to 550 horsepower on a turbocharged or supercharged engine, providing a massive safety margin. This gives you the confidence to install more aggressive performance parts and turn up the boost, knowing your engine's rotating assembly is up to the task and ready for the next stage of your build.

Reliability on the Street and Track

This upgrade isn't just for dedicated race cars. Forged pistons are essential for anyone looking to build a reliable, high-performance street machine. The added strength and heat resistance translate directly to a more durable engine that you can depend on every day. Whether you're enjoying a spirited drive on a back road or pushing your car at a track event, you gain peace of mind. Investing in a robust foundation with forged Subaru STI upgrades ensures your engine remains healthy and responsive for years to come, protecting your investment and letting you enjoy the power you've built.

Decoding Piston Specs: What to Look For

Once you’ve decided to go with forged pistons, the next step is to sort through the technical specifications. Choosing the right specs is just as important as choosing the right material. These numbers and terms might seem intimidating at first, but they are the blueprint for your engine's future performance. Getting these details right ensures your new pistons work perfectly with the rest of your engine build, helping you safely achieve your power goals. Let’s break down the key specs you’ll encounter so you can make an informed decision for your Subaru.

Choosing Your Piston Material

Not all forged pistons are created equal. The specific alloy used makes a big difference in strength and performance. High-quality pistons typically start as a billet of strong 6061-T6 aluminum. This material undergoes an intense forging process involving extreme heat and pressure, which aligns the grain structure of the metal. The result is a piston that is significantly stronger—often up to 40% stronger—than a standard cast piston. This added strength is exactly what you need to prevent catastrophic failures when you start pushing for more power, making our forged Subaru engine internals a reliable foundation for any high-performance build.

Selecting the Right Compression Ratio

The compression ratio is a critical spec that dictates how much the air-fuel mixture is compressed inside the cylinder. This choice directly impacts your engine’s performance, efficiency, and tuning flexibility. You’ll see options like 8.5:1, 9.5:1, or 10.0:1. A lower compression ratio is generally preferred for high-boost applications, as it reduces the risk of engine knock or detonation. A higher compression ratio can offer better throttle response and efficiency off-boost but limits how much boost you can safely run. Your decision here should align with your overall power goals and whether you’re building a track monster or a responsive street car.

Getting the Bore Size Right

Piston bore size must match the cylinder bore of your engine block. The standard STI bore size is 99.5mm, but you’ll see options like 99.75mm and 100mm. These larger sizes are for engines that have been machined or "bored out" to correct imperfections or to increase displacement. It is absolutely essential to have your cylinder bores measured precisely by a machine shop before ordering pistons. Choosing the wrong size will lead to improper sealing, excessive oil consumption, or catastrophic engine failure. Always work with your engine builder to confirm the exact bore size your block requires for optimal performance parts integration.

Understanding Ring Lands

The ring lands are the small grooves on the side of the piston that hold the piston rings in place. On stock STI pistons, this is a notorious weak point, especially under the stress of increased boost and aggressive tuning. Forged pistons are designed with thicker, more robust ring lands to withstand that pressure. This reinforcement is one of the most important advantages of upgrading, as it directly addresses a common failure point in the factory EJ25 engine. Stronger ring lands ensure your piston rings maintain a proper seal, which is vital for making consistent power and maintaining long-term engine health.

Accounting for Thermal Expansion

You might hear that forged pistons aren't suitable for street cars because they expand more with heat than cast pistons. This is only a partial truth. Because of their material composition, forged pistons do require slightly more clearance between the piston and the cylinder wall when the engine is cold. This can sometimes cause a light ticking sound known as "piston slap" on cold starts, which goes away as the engine warms up. However, a skilled engine builder will set the proper clearances during installation, ensuring reliability for both daily driving and track use. When installed correctly, forged pistons offer superior performance without compromising longevity.

How to Choose the Right Forged Pistons

Selecting the right forged pistons isn't just about picking a brand off the shelf. It's a calculated decision that balances your performance ambitions, your specific engine setup, and your budget. Getting this choice right is fundamental to building a reliable, high-power Subaru engine that lasts. Let's walk through the key factors you need to consider to make sure you invest in the perfect set for your build, whether you're upgrading a WRX, STI, or Crosstrek.

Define Your Power Goals and Use Case

First, be honest about what you want from your car. Are you building a reliable 400-horsepower daily driver, a weekend track car, or an all-out competition machine? Your answer directly influences your piston choice. Forged pistons are designed to make your engine stronger and perform better, but the specific design you need will vary. A street car might prioritize longevity and quieter operation, while a race build will require pistons that can withstand extreme heat and cylinder pressures. Thinking about your end goal first ensures every other decision supports that vision.

Match Pistons to Your Engine Build

Your new pistons need to work in harmony with the rest of your engine's rotating assembly. If you're rebuilding your engine, chances are the cylinders will be machined. This process, known as boring, creates a fresh, perfectly round surface but also slightly increases the cylinder's diameter. You'll need to select oversized pistons to match. The most critical measurement is the piston-to-wall clearance, which is the small gap left for oil and thermal expansion. This isn't a DIY measurement; letting your machinist handle the final check is the way to go. This ensures your forged engine internals operate with precision.

Determine Your Compression Needs

The compression ratio is a key spec that dictates how your engine will behave. In simple terms, it’s the ratio of the cylinder volume when the piston is at the bottom of its stroke versus the top. Pistons are available with different compression ratios, such as 8.5:1 or 9.5:1. A lower compression ratio is generally preferred for high-boost applications, as it helps prevent engine knock (detonation). A higher compression ratio can offer better throttle response and efficiency, making it a solid choice for naturally aspirated or lower-boost builds. Your choice here must align with your turbo setup and fuel type, all of which will be dialed in with professional engine tuning services.

Factor in Your Budget

A forged piston upgrade is a significant investment in your vehicle's performance and reliability, so it's important to plan your budget accordingly. Prices for a complete piston kit can range from several hundred to over $1,700, depending on the brand and specific features. Remember that the pistons themselves are just one part of the equation. Your budget should also account for new rings, connecting rods, bearings, gaskets, and the necessary machine shop labor. This is not the place to cut corners—investing in quality components and professional installation will save you from a catastrophic engine failure down the road.

Weighing Piston Slap vs. Performance

If you've been around built engines, you've probably heard the term "piston slap." This is the slight ticking sound an engine can make when it's cold, and it's a known characteristic of forged pistons. Because forged aluminum expands more than cast aluminum when it heats up, forged pistons are installed with a looser tolerance. This extra room prevents the piston from seizing in the cylinder bore when it reaches operating temperature. While some worry that this looser fit will wear down the cylinder wall faster, it's a necessary trade-off for the strength and heat resistance you need in a high-performance engine. With a proper warm-up, the noise subsides as the metal expands to its ideal clearance.

Proper Installation and Care

Upgrading to forged pistons is a serious investment in your Subaru's performance, but the job isn’t finished once you’ve made the purchase. Proper installation and diligent care are what truly protect that investment and ensure you get the power and reliability you’re paying for. Unlike factory components,

This process goes far beyond simply swapping parts. It involves precise machining of the engine block, meticulous measurement of clearances to account for thermal expansion, and careful assembly by a technician who understands the nuances of a high-output Subaru engine. After the build is complete, the responsibility shifts to you. The break-in period is your engine's first test, requiring patience and a specific driving style to ensure components seat correctly. Long-term, your maintenance habits will directly impact the engine's lifespan. A built motor is less forgiving of neglect than a stock one, making regular fluid checks and high-quality oil changes absolutely essential. We'll cover why a professional install is non-negotiable, common mistakes to watch out for, and how to properly care for your built engine so you can enjoy that extra power with peace of mind.

Why Professional Installation is Crucial

Forged pistons are not a direct, drop-in replacement for their cast counterparts. Because they are made from a different alloy that expands more with heat, they require specific clearances and careful handling that only an experienced engine builder can provide. An expert mechanic understands the nuances of measuring piston-to-wall clearance, filing piston rings to the perfect gap, and ensuring every component is torqued to spec. This isn't a weekend project for a novice. Entrusting your build to a professional who specializes in performance engines, especially Subarus, ensures the job is done right the first time, preventing catastrophic failure down the road.

Avoid These Common Installation Mistakes

Even seasoned mechanics can make mistakes if they aren't familiar with high-performance Subaru builds. One common issue is misinterpreting engine sounds after installation. Forged pistons often produce a different "noise" than stock cast pistons, which can sometimes be mistaken for false knock by the engine's sensors. A professional tuner will know how to adjust the ECU to account for this. Another critical area is cylinder boring. Your machinist must bore the cylinders to a precise oversize and meticulously check the piston-to-wall clearance to match the piston manufacturer's specifications. Getting this wrong can lead to piston slap, excessive oil consumption, or engine seizure.

Mastering the Break-in Period

Once your engine is assembled, you can't just hit the track. A crucial 500-mile break-in period is necessary to let the new components settle in correctly. This process allows the piston rings to properly seat against the freshly honed cylinder walls, creating a tight seal that is essential for compression and oil control. During this time, you should vary the engine RPM and avoid both high-revving and constant-speed cruising. Drive the car gently, allowing it to warm up completely on each trip and avoiding heavy throttle or boost. This patience pays off by ensuring the long-term health and performance of your engine.

Your Long-Term Maintenance Checklist

A built engine with forged pistons requires a more attentive maintenance schedule than a stock motor. Because these engines are built to tighter tolerances and often pushed harder, keeping up with fluid changes is non-negotiable. You should plan to check your oil levels frequently and change your oil and filter every 3,000 miles or every six months, whichever comes first. Use a high-quality synthetic oil that can withstand the higher temperatures of a performance engine. Regularly inspecting all your fluids, belts, and hoses will help you catch small issues before they become major problems. This proactive approach is key to enjoying your Subaru STI upgrades for the long haul.

The Importance of Monitoring Temps

One of the most common concerns with forged pistons is "piston slap," a light ticking sound that can occur when the engine is cold. This happens because forged alloys need more clearance to allow for thermal expansion. As the engine warms up, the piston expands and the noise disappears. While this is normal, it highlights the importance of letting your engine reach full operating temperature before applying heavy loads or high RPMs. Installing oil temperature and pressure gauges can give you a much clearer picture of your engine's health than the factory coolant gauge alone, allowing you to push your car with confidence once it's properly warmed up.

Essential Supporting Mods for Your Build

Installing forged pistons is a major step toward building a powerful and reliable Subaru engine, but they can't do the job alone. To truly capitalize on their strength and protect your investment, you need to create a balanced system where every component can handle the increased stress. Think of it as building a team—your forged pistons are the star player, but they need a strong supporting cast to win. Neglecting these supporting modifications can lead to bottlenecks or, even worse, catastrophic engine failure. Let's walk through the essential upgrades that should accompany your new pistons.

Strengthening Your Engine Block

When you install forged pistons, you're preparing the engine to handle much more power, which means more cylinder pressure and greater force on the entire rotating assembly. For high-horsepower goals, simply dropping in pistons isn't enough. You should also consider upgrading to forged connecting rods and a balanced crankshaft to match. This creates a fully "built" short block with a robust foundation. Building the engine with strengthened internals is what allows you to safely push for extreme power levels, ensuring all components work together to manage the increased load without failure.

Upgrading Your Fuel System

More power requires more air and, crucially, more fuel. The stock fuel pump and injectors are designed for factory power levels and will quickly become a weak link in a modified engine. To support the higher output enabled by forged pistons, you'll need to upgrade to higher-flow fuel injectors and a higher-capacity fuel pump. This ensures your engine can maintain the correct air-to-fuel ratio under heavy load. Running lean is one of the fastest ways to damage a high-performance engine, making a robust fuel system one of the most critical Subaru STI upgrades you can make.

Choosing an Engine Management System

The factory Engine Control Unit (ECU) is programmed for stock components and power levels. Once you start adding parts like forged pistons, bigger turbos, and an upgraded fuel system, the stock ECU tune is no longer safe or effective. An engine management system, whether it's a standalone ECU or a custom tune on the factory unit, acts as the brain of your operation. It allows a tuner to precisely adjust critical parameters like fuel delivery, ignition timing, and boost pressure to match your new hardware, ensuring the engine runs efficiently and safely.

The Role of a Professional Tune

All your new hardware is just a collection of parts until a professional tune brings them to life. This is the final, non-negotiable step that ties everything together. An experienced tuner optimizes your engine's performance and ensures its longevity. For example, forged pistons often create a different acoustic signature than cast pistons, which can cause the factory knock sensors to register "false knock." A professional providing engine tuning services can recalibrate the sensor sensitivity and dial in every parameter to work in harmony, giving you a powerful, reliable, and smooth-running engine.

Comparing Top Forged Piston Brands

Once you’ve decided to upgrade, the next step is choosing the right brand for your build. The market is full of options, each with its own engineering philosophy and performance claims. Making the right choice comes down to understanding your power goals, your budget, and the reputation of the manufacturer. A quality set of forged pistons is a significant investment in your engine's reliability and performance, so it pays to do your research and select a brand known for its strength and precision engineering. Let's look at what sets different brands apart and what you should consider before making a final decision.

Why Choose Crawford Performance Pistons

When it comes to building a robust Subaru engine, material science and track-tested results matter. Our forged pistons are engineered from 6061-T6 aluminum, a material that is 40% stronger than the standard cast pistons found in your engine from the factory. This superior strength allows them to reliably handle serious power—up to 650 horsepower in naturally aspirated builds and 550 horsepower in turbocharged or supercharged applications. We don't just rely on specs, though. These pistons have been proven in the most demanding environments, enduring over 500 quarter-mile passes in race cars making more than 1,200 horsepower. That’s the kind of durability that gives you confidence on both the street and the track.

Exploring Other Reputable Brands

While we stand behind our engineering, we know it’s helpful to understand the broader market. You'll likely come across other well-known brands like Manley, Wiseco, CP Pistons, and JE Pistons during your research. These manufacturers offer a wide range of options for Subaru engines, giving builders plenty of choices when it comes to specific compression ratios and bore sizes. You’ll find pistons designed for various setups, with compression ratios like 8.5:1 for high-boost applications or 10.0:1 for builds seeking a bit more response. The key is to compare their materials, design features, and track records to find the best match for your specific engine build and performance targets.

Understanding Piston Prices and Kits

Budget is always a factor in any engine build, and it’s important to know what to expect. A set of four forged pistons typically costs between $700 and $1,150. If you're looking for individual components, a single piston or a set of rings might run anywhere from $40 to over $200. For those who prefer an all-in-one solution, comprehensive piston kits are available, but prices can vary widely, from around $200 for a single piston kit to over $1,700 for a complete, high-end set. Remember that the initial price is just one part of the equation; always factor in the cost of professional installation and the necessary supporting modifications for your build.

Don't Forget the Warranty

Installing forged pistons is a precision job that should always be handled by an experienced engine builder. It’s not just about swapping parts; clearances must be perfect, and every component must be meticulously assembled. After the hardware is in, your vehicle’s ECU must be re-tuned to account for the new components and optimize performance. This step is non-negotiable for engine health and longevity. At Crawford, we back our work with a unique 12-month/12,000-mile engine warranty on our builds. This peace of mind is rare in the performance world and highlights the importance of pairing quality parts with expert engine tuning services.

Related Articles

Frequently Asked Questions

At what horsepower level should I seriously consider forged pistons? While there's no single magic number, the general consensus is that the stock cast pistons in a Subaru STI become a significant risk once you push past 400 horsepower. At that point, the increased cylinder pressure and heat can cause them to fail. Upgrading to forged pistons is a proactive step to build a strong foundation before you reach that limit, ensuring your engine can safely handle the power you plan to make.

Will forged pistons make my daily driver noisy or unreliable? This is a common concern, mostly related to "piston slap," a light ticking sound when the engine is cold. Modern forged pistons are made from advanced alloys that expand less than older designs, which minimizes this noise. When installed by a professional who sets the correct clearances, the sound is often minor and disappears completely once the engine warms up. For a daily driver, this trade-off is well worth the massive increase in strength and reliability.

What's the difference between a lower and higher compression ratio piston? Think of compression ratio as a choice between all-out power and everyday responsiveness. A lower compression ratio, like 8.5:1, is ideal for high-boost builds because it reduces the risk of engine knock, allowing a tuner to be more aggressive with boost pressure. A higher compression ratio, like 9.5:1, can provide better throttle response and fuel efficiency when you're not in boost, but it limits how much boost you can safely run. Your choice should align with your turbo setup and how you plan to use the car.

Is upgrading just the pistons enough to make my engine stronger? Upgrading the pistons is a critical first step, but they are part of a larger system. To build a truly robust engine, you should also consider upgrading the connecting rods to match. The pistons handle the pressure from combustion, but the rods transfer that force to the crankshaft. Installing both forged pistons and forged rods creates a much stronger rotating assembly that can reliably handle significantly more power.

Why is a professional tune so important after installing forged pistons? Installing forged pistons fundamentally changes how your engine operates, and the factory ECU tune is no longer safe or effective. A professional tune adjusts fuel delivery, ignition timing, and boost levels to match your new hardware. It also allows the tuner to recalibrate the knock sensors, as forged pistons can create different engine acoustics that might be misinterpreted as knock. This final step is essential for protecting your investment and ensuring your engine runs smoothly and reliably.