STI Engine Build Cost: A Realistic Budget Guide

Share

You know the story from the Subaru forums: the stock EJ257 has its limits. Pushing past 350-400 wheel horsepower on factory internals is a gamble that rarely pays off. The clear solution is a built motor, but that brings up the biggest question of all: what is the real STI engine build cost? It's so much more than just the price of a short block. This guide gives you a transparent breakdown of the entire investment, from forged internals and supporting mods to precision labor and the final tune. We'll cover everything you need for a reliable build so you can plan your budget with total confidence.

Key Takeaways

- Start with a clear objective to guide your build: Whether you want a 450-hp daily driver or a track-focused machine, defining your goal upfront ensures you invest in the right components and avoid overspending on parts you don't need.

- Your engine's reliability hinges on quality parts and expert assembly: Forged internals provide the necessary strength for higher power, but it's the precision of a professional builder and a meticulous tune that ensures all components work together safely.

- A successful build budget includes more than just the engine itself: Factor in essential supporting costs like machine work, a comprehensive gasket kit, installation labor, and a final dyno tune to prevent unexpected expenses and protect your investment.

Signs Your STI Engine Needs a Rebuild

Before you can budget for a build, it’s important to recognize when your engine is asking for help. The Subaru EJ257 engine is a fantastic platform, but it has well-known vulnerabilities, especially when you start adding power. Catching the warning signs early can be the difference between a controlled, planned rebuild and a catastrophic failure on the side of the road. If your STI starts showing any of these symptoms, it’s time to stop pushing it and start planning for its next chapter. Ignoring them will only lead to more extensive and expensive damage.

Loud Knocking or Tapping Noises

This is the one sound no Subaru owner ever wants to hear. A deep, rhythmic knocking noise from the engine, often called "rod knock," is a critical warning sign. This sound is typically caused by worn or failed connecting rod bearings, which create excessive space between the bearing and the crankshaft. As the engine rotates, the connecting rod hammers against the crank, creating the distinct knock that gets faster and louder with RPM. If you hear this, pull over and shut the engine off immediately. Continuing to drive risks a thrown rod, which can punch a hole through the engine block and destroy any chance of a simple rebuild.

Excessive Smoke from the Exhaust

Your exhaust tells a story about your engine's health. If you see consistent puffs of blue smoke, especially during acceleration, your engine is burning oil. In an STI, this often points to failing piston ringlands, a common weak point on the stock pistons. On the other hand, thick white smoke that smells sweet is a classic sign of a blown head gasket, meaning coolant is leaking into the combustion chambers. Both scenarios are serious, as they indicate a major internal failure that compromises compression and contaminates your oil. A proper rebuild with quality performance parts is the only reliable fix.

Noticeable Loss of Power

If your once-responsive STI now feels sluggish and struggles to accelerate, your engine may be losing compression. This happens when piston rings, cylinder walls, or valves wear down and can no longer create a tight seal in the combustion chamber. The engine can't generate the pressure needed to make power efficiently, leading to poor performance and often worse fuel economy. While other issues can cause power loss, it’s a significant red flag when combined with increased oil consumption or strange noises. A professional diagnosis, including a compression and leak-down test, can confirm if the engine's internals are the source of the problem.

Metal Shavings in Engine Oil

Finding a glittery sheen in your used oil during an oil change is definitive proof of a serious internal problem. Those shiny particles are tiny bits of metal from bearings and other components grinding themselves apart inside your engine. It’s a clear sign that critical tolerances have been lost and metal-on-metal contact is occurring. This is not a symptom you can ignore or hope will go away; it's physical evidence that your engine is self-destructing. Catching this early allows you to schedule a rebuild before a bearing seizes completely, which can save your crankshaft and other core components from being damaged beyond repair, making your investment in new Subaru STI upgrades more effective.

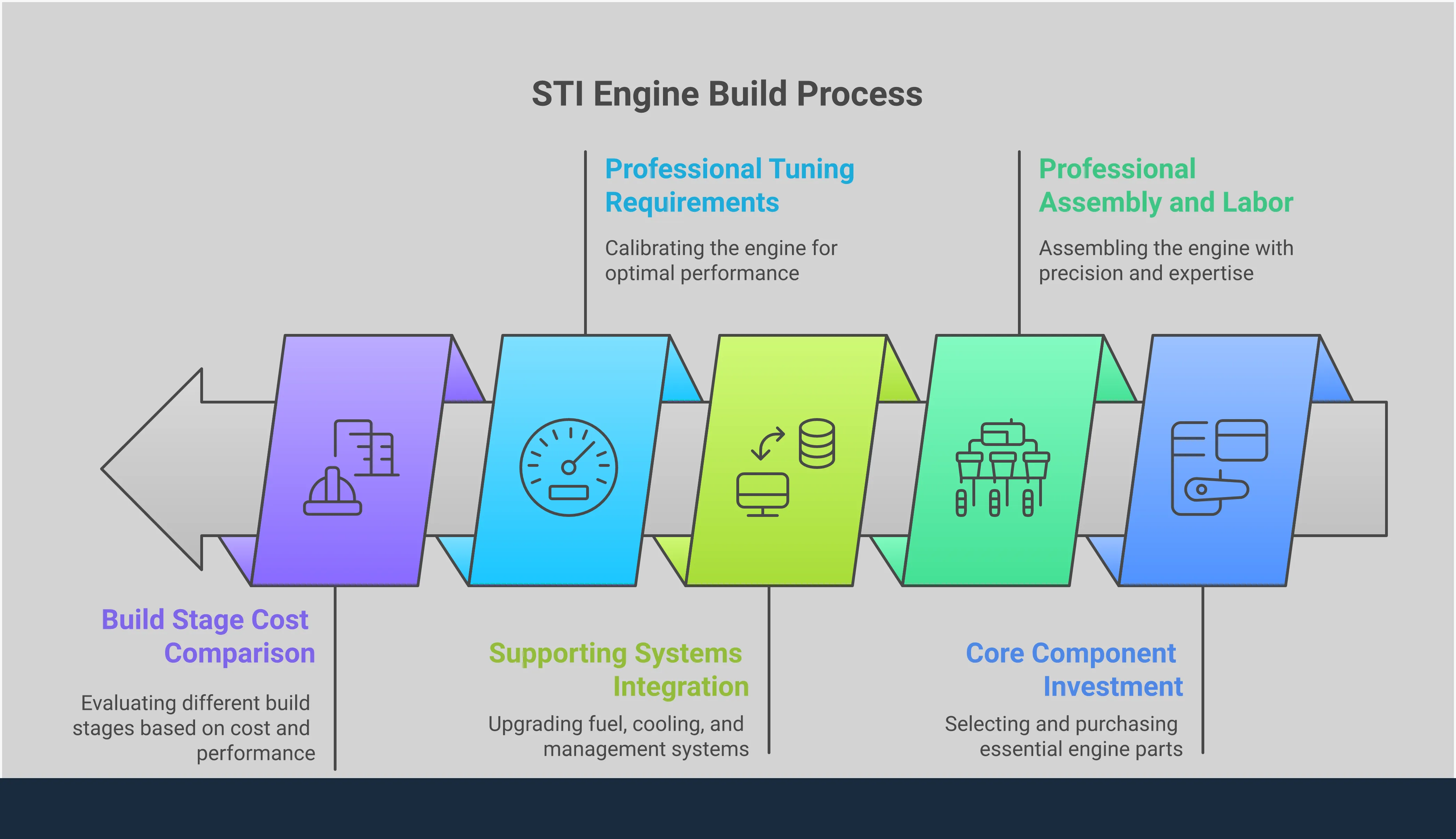

Breaking Down Your STI Engine Build

An STI engine build is a complete overhaul of your motor’s core components. It’s not about simply bolting on new parts; it’s a meticulous process of replacing factory internals with stronger, more durable hardware designed to handle serious power. This process transforms your engine from a capable street motor into a high-performance powerhouse, built to your exact specifications. The goal is to create a balanced and robust system that delivers the performance you want without sacrificing dependability.

Whether you’re aiming for a responsive daily driver or a competitive track car, understanding the fundamentals is the first step. It involves careful planning, selecting the right components, and partnering with experts who can bring your vision to life reliably. This means looking beyond just peak horsepower numbers and considering the entire powerband, drivability, and long-term health of the engine. A successful build accounts for how the turbo, fuel system, and engine internals will all work together. In the following sections, we’ll break down the key differences between stock and performance parts, how to define your goals, and why component quality is something you can't afford to compromise on.

Stock vs. Performance: Which is Right for You?

The factory EJ257 engine in your STI is impressive, but it has its limits. For a daily-driven car, the general consensus is that the stock internals are reliable up to around 350 to 400 wheel horsepower. Pushing beyond that on stock pistons, rods, and bearings is a gamble that often ends with catastrophic failure. The factory parts are cast, which is fine for production cars, but they can’t withstand the higher cylinder pressures and heat generated by aggressive tunes and larger turbochargers.

A performance build addresses these weaknesses head-on. It involves replacing the stock internals with forged components, which are significantly stronger and more resistant to heat and stress. This allows the engine to safely handle much higher power levels. A proper build isn't just about swapping in stronger parts; it's about creating a cohesive system where every component is chosen to support your specific power goals. This foundation of quality performance parts is what separates a reliable build from a ticking time bomb.

Start by Defining Your Power Goals

Before you buy a single part, you need a clear goal. What do you want your STI to do? A 450-horsepower street car has very different needs than a 700-horsepower track machine. Your power target and intended use will dictate every decision, from piston choice to the size of your turbo. Be realistic about how you drive. A build optimized for the drag strip might be frustrating in daily traffic, while a responsive street setup might feel underpowered at the track.

Defining your goals helps you and your builder create a detailed plan and budget. The cost of a built motor can vary widely, often falling between $8,000 and $12,000, but it can go much higher depending on the extent of the work. This plan ensures you invest in the right Subaru STI upgrades for your application, preventing you from overspending on parts you don’t need or underspending on critical components that could fail.

Understanding Reliability at High Horsepower

It’s a common myth that high-horsepower engines are inherently unreliable. The truth is, reliability is all about matching components to your goals. A stock engine pushed far beyond its factory limits is unreliable because its parts were never designed for that level of stress. In contrast, a properly built engine can be incredibly dependable, even at double the factory horsepower. This is because every component, from the forged pistons to the robust bearings, is specifically chosen to handle the increased heat and pressure. A well-assembled engine isn't a fragile race motor; it's a durable powerhouse built to last.

This dependability hinges on two critical factors: the quality of the assembly and the precision of the tune. Strong performance parts are the foundation, but it’s an expert builder who ensures perfect clearances and tolerances. After assembly, the final tune protects your investment. A skilled tuner creates a safe and efficient map that delivers consistent power without putting the engine at risk. This synergy between quality components, expert assembly, and professional engine tuning services is what creates a powerful STI you can drive with confidence.

Why Quality Parts Are a Must

In engine building, you truly get what you pay for. Settling for cheaper, lower-quality components is one of the most common and costly mistakes you can make. A single failed part can destroy your entire investment, turning your dream build into a nightmare. Engines fail due to poor component selection, so it’s critical to choose parts from reputable manufacturers known for their durability and precision engineering. Each component must work in harmony with the others to create a reliable system.

Even the best parts in the world won't perform correctly without a proper tune. Investing in professional engine tuning services is non-negotiable. An expert tuner ensures all your new components work together safely and efficiently. They will calibrate your engine management system to optimize fuel delivery, ignition timing, and boost pressure, giving you the reliable power you paid for and protecting your investment for the long haul.

Breaking Down the Cost of Engine Components

Building a high-performance engine is about selecting the right parts that work together to meet your power goals. The total cost is a sum of these individual components, and prices can vary significantly based on the brands you choose and the power levels you're aiming for. Think of this as the foundation of your build—investing in quality core components now will pay dividends in both performance and reliability down the road. Let's break down the essential parts and what you can expect to invest in each.

Your Foundation: The Engine Block & Internals

The engine block is the literal foundation of your build. If you're starting from scratch, a new OEM Subaru short block, which typically includes the block, crankshaft, connecting rods, and pistons, will run you between $1,600 and $1,800. This is a great starting point for a stock rebuild or a mild street build. However, the stock internal components have their limits. If you plan on pushing for significant power gains, you’ll need to look beyond the factory setup and invest in stronger, more durable parts that can handle the increased stress.

Why You Need Forged Pistons, Rods, & Cranks

When you increase horsepower, you increase the pressure inside your engine. The stock cast pistons and rods are often the first components to fail under high boost. This is where forged internals come in. Forged pistons and connecting rods are manufactured to be much stronger and more resistant to heat and detonation. A built short block with these upgraded performance parts typically starts around $3,000. While it's a bigger initial investment, it's essential for the longevity and reliability of any engine built for the track or aggressive street driving.

Choosing Your Turbocharger & Support Systems

The turbocharger is the heart of your STI's power production, and a larger turbo is the key to making bigger numbers. But simply installing a bigger turbo isn't enough. It needs a strong supporting cast of components, including an upgraded intercooler, intake, and exhaust system to handle the increased airflow. Most importantly, all these new parts must be synchronized. This is achieved through professional engine tuning services, which ensure your engine runs not just powerfully, but also safely and reliably with its new hardware.

Don't Forget Fueling & Cooling Upgrades

More air from a bigger turbo requires more fuel to maintain a safe air-fuel ratio. This means you'll likely need to upgrade your fuel pump, fuel injectors, and potentially your fuel rails to keep up. If you plan on running high-performance fuels like E85, a robust fuel system is non-negotiable. At the same time, more power generates more heat. Protecting your investment requires an efficient cooling system. Upgrades like a high-performance radiator, an external oil cooler, and an Air/Oil Separator are critical for managing temperatures and maintaining engine health during demanding conditions.

Taking Control with an Engine Management System

The engine management system, or ECU, is the brain of your entire operation. It controls everything from fuel delivery and ignition timing to boost levels. While the stock ECU can be tuned, a standalone engine management system offers far greater control and flexibility, allowing a tuner to fine-tune every parameter for maximum performance and safety. A proper tune via a capable engine management system is what ties all your expensive hardware together. It ensures every component works in harmony, protecting your engine while unlocking the full potential of your build.

How Much Does Labor and Tuning Cost?

Once you’ve selected your core components, the next phase of your STI engine build involves the skilled labor that brings it all together. This is where precision and expertise become just as important as the quality of the parts themselves. The costs for machine work, assembly, installation, and tuning can vary significantly based on your location and the shop you choose, but they are absolutely critical for achieving a reliable, high-performance result.

Think of this stage as the difference between a pile of expensive parts and a fully integrated, powerful engine. Cutting corners here can lead to catastrophic failure, wiping out your entire investment. From the initial machine work that ensures perfect tolerances to the final dyno tune that optimizes performance, every step requires a professional touch. Budgeting properly for these services is essential for protecting your engine and unlocking its true potential. This is where you lean on the experience of seasoned builders who understand the specific demands of a Subaru boxer engine.

Labor Costs: Specialist vs. Dealership

When it comes to labor, you have two main options: a dealership or an independent specialist. While a dealership might seem like the default choice, they are geared toward factory-spec repairs, not custom performance builds. For a project like this, a specialist shop is almost always the better route. Their technicians live and breathe high-performance Subarus and understand the intricacies of assembling an engine with aftermarket performance parts designed to handle significant stress. The cost for professional installation typically ranges from $1,500 to $3,000, but this investment buys you peace of mind. An experienced builder ensures every component is installed with precision, which is critical for the engine's longevity and reliability. This expertise is something you won't find at most dealerships, where the focus is on returning a vehicle to its stock condition.

The Cost of Machine Shop & Precision Work

Before any assembly can begin, your engine block and key components need to visit a machine shop. This isn't an optional step; it's the foundation of a durable build. Services like cleaning, decking the block for a perfect head gasket seal, boring and honing the cylinders to match your new pistons, and balancing the rotating assembly are all part of this process. Expect machine shop services to range from $8,000 to $12,000, depending on the complexity of your build. This precision work ensures every component fits and functions exactly as it should, preventing premature wear and failure.

The Value of Professional Engine Assembly

With the machined parts ready, the next step is assembly. While it might be tempting to tackle this yourself, common engine building mistakes like improperly installing bearings or using the wrong seals can destroy your engine before it even starts. A professional engine builder meticulously measures clearances, torques every bolt to spec, and follows proven procedures to ensure everything is perfect. This expertise is what separates a reliable powerhouse from a ticking time bomb. Investing in professional assembly is your best insurance policy for the entire project.

What to Do After a Spun Bearing

A spun bearing is a catastrophic engine failure that requires a complete teardown and rebuild; there are no simple fixes. The first step is a thorough inspection. The engine must be removed and disassembled to assess the extent of the damage. The crankshaft, connecting rods, and block all need to be carefully examined for scoring and heat damage. In some cases, the crankshaft can be machined and paired with oversized bearings, but often, replacement is the safer route. This is a meticulous process where every component must be cleaned and checked for metal debris from the failed bearing.

During the rebuild, replacing certain components is non-negotiable to prevent a repeat failure. The oil cooler, oil pump, and any oil lines must be replaced, as it's nearly impossible to flush out all the fine metal particles that can destroy your new engine. While some parts like the cylinder heads might be salvageable after a deep clean and light resurfacing, the risk of contamination is high. This is why relying on professional services, from the meticulous assembly to the final engine tune, is so critical. An expert builder will ensure every oil passage is clear and that all clearances are perfect, giving your new motor a fighting chance at a long and powerful life.

Verifying Power with Dyno Testing

After assembly, a reputable builder will perform dyno testing. This isn't just about chasing a peak horsepower number; it's a critical quality control step. Running the engine on a dynamometer allows the builder to break it in under controlled conditions, check for any leaks or issues, and ensure all the new components are working together harmoniously. This process verifies that the engine is healthy and performing as expected before it’s installed in your car. It’s the final check that guarantees you’re getting the safe, reliable power you paid for.

The Final Steps: Installation & First Start

Once the engine is assembled and tested, it’s time to install it back into your STI. This process involves more than just bolting it in; it requires carefully connecting the fuel, cooling, electrical, and exhaust systems. Labor for installation can add another $1,500 to $3,000 to your budget. The first startup is a critical moment where the builder will monitor pressures and temperatures to confirm everything is operating correctly. This meticulous attention to detail ensures a smooth transition from the engine stand to the road.

Why Expert Tuning is Non-Negotiable

The final and most crucial step is expert tuning. A new engine build requires a custom tune to calibrate the ECU for the new components. This involves adjusting fuel maps, ignition timing, and boost pressure to optimize performance and ensure engine safety. A proper tune from an experienced professional is what truly brings your build to life. You should budget around $500 for a comprehensive tune, plus another $200 to $300 for a full set of gaskets needed for reassembly. Professional engine tuning services are the key to maximizing power and ensuring long-term reliability.

Explore Performance Build Packages

While every engine build is tailored to a specific car and driver, most projects fall into a few common categories. Thinking about your build in terms of a "stage" or "package" is a great way to align your performance goals with a realistic budget. These packages provide a clear roadmap, helping you select the right components without getting overwhelmed. The costs mentioned here are general estimates based on community data and can vary depending on your chosen parts, shop labor rates, and the condition of your existing engine. Think of these as starting points to help you plan your own path to more power.

Understanding these common build types helps you communicate more effectively with your chosen shop and ensures you're investing in parts that work together harmoniously. From strengthening the engine's core for daily driving to assembling a purpose-built motor for competition, each stage represents a significant step in performance and investment. Let's look at some of the most common approaches to building an STI engine, from mild street setups to all-out custom powerhouses.

Stage 1: The Perfect Daily Driver Build

If you’re looking to add a significant and reliable power bump to your daily driven STI, the Stage 1 Street Build is your ideal starting point. This build focuses on strengthening the engine's core to handle more power than stock, without sacrificing drivability. Typically, this involves upgrading to forged pistons and rods, along with ARP head studs and quality bearings. The goal is to create a robust foundation that can support a larger turbo and a more aggressive tune down the line. Expect costs to range from $6,000 to $8,000, making it a popular choice for enthusiasts who want more performance for spirited street driving. It’s the perfect way to get a taste of what your STI is truly capable of.

Stage 2: Built for the Track Day Enthusiast

For the enthusiast who spends weekends at the track or autocross events, the Stage 2 build is designed for durability under pressure. This setup takes the forged internals from Stage 1 and adds components built for sustained high-RPM use. You’ll often see upgrades like a larger turbocharger, an improved cooling system, and a high-flow fuel system to support higher power levels safely. The focus here is on creating an engine that can handle repeated abuse without failure. With costs generally falling between $8,000 and $12,000, this build requires precise engine tuning services to ensure all the new components work together flawlessly for maximum performance and reliability on the track.

Full Custom: When You Want It All

When your goal is to push the absolute limits of performance, a full custom build is the only way to go. This is where you move beyond pre-defined stages and into the realm of bespoke engineering, tailored specifically to your competitive goals. These builds often feature high-end components like a fully-built short block, ported cylinder heads, aggressive camshafts, and a massive turbocharger. Costs can easily exceed $16,000 for the engine alone, especially when using top-tier crate engines or commissioning a complete custom assembly. This path is for the serious racer or enthusiast who demands uncompromising power and is ready to invest in the best performance parts available.

OEM+ & Stock Rebuilds for Reliability

Not every engine project is about chasing horsepower. Sometimes, you just need a reliable replacement for a failed motor. A stock rebuild using OEM parts is a solid choice for getting your STI back on the road with factory performance and dependability. The OEM short block itself typically costs between $1,600 and $1,800. For a little extra peace of mind, many owners opt for an "OEM+" build. This approach uses stock components but with meticulous, professional assembly and potentially a few key upgrades—like better bearings or head studs—to address known weak points. It’s a smart, cost-effective solution for those who value longevity over raw power.

Don't Forget These Additional Costs

When you’re planning an engine build, it’s easy to focus on the big-ticket items like the short block, turbo, and pistons. But the final invoice often includes a list of smaller, yet critical, expenses that can catch you by surprise. A successful build isn’t just about power; it’s about reliability, and that means accounting for every component, from gaskets to the final tune. Thinking through these additional costs ahead of time will help you create a realistic budget, prevent frustrating delays, and ensure your project goes smoothly from start to finish. Let’s break down the common expenses that are easy to overlook but essential for a solid build.

The "Little Things": Supporting Parts & Hardware

An engine build is a complex puzzle, and the main components are only part of the picture. You'll also need a host of supporting parts and hardware to put it all together correctly. Think of items like a complete engine gasket kit, new head studs, a timing belt kit, a water pump, and various seals and fluids. While individually inexpensive, these parts add up fast. Skimping here is a bad idea, as a failed $10 seal can destroy thousands of dollars worth of work. Always budget for fresh, high-quality performance parts to ensure every connection is secure and leak-free for long-term reliability.

What Are Core Charges and How Do They Work?

If you're buying a pre-built short block or long block, you'll almost certainly encounter a core charge. Think of it as a deposit on your old engine. The builder charges you an extra fee—often several thousand dollars—which is refunded once you send them your old, rebuildable engine (the "core"). This process ensures they have a steady supply of blocks to build for future customers. While you get this money back, it's a significant upfront cost that you need to have available. Be sure to clarify the core return policy, including the timeframe and condition requirements, before you make a purchase.

Drivetrain Upgrades for High-Power Builds

A powerful engine is only effective if the rest of your car can handle the torque. Once you start pushing well beyond factory power levels, the stock drivetrain becomes the next weak link. A high-performance clutch is the first and most essential upgrade to prevent slippage and ensure power is transferred to the transmission. Depending on your power goals, you may also need to invest in a built transmission with stronger gears to avoid catastrophic failure under load. Finally, upgrading the differentials helps manage the power distribution to the wheels, improving traction and durability. These are not optional expenses for a serious build; they are critical Subaru STI upgrades necessary to protect your investment and make your power usable.

Budgeting for Downtime: Car Rentals and Towing

An engine build is a significant undertaking that can take several weeks, or even months, to complete. If your STI is your daily driver, you need to plan for how you'll get around while it's in the shop. Factoring in the cost of a rental car for a month or two is a realistic step that prevents logistical headaches. Additionally, consider the possibility of towing fees. Your car may need to be transported to the machine shop, the builder, and the tuner. Having a small contingency fund set aside for these types of logistical expenses ensures that your project stays on track without adding unexpected financial stress to the process.

Protecting Your Investment: The Break-in Period

Once your new engine is installed, the work isn't over. The break-in period is a critical phase that allows the new piston rings to seat properly against the cylinder walls, ensuring optimal compression and oil control for the life of the engine. This process requires specific driving procedures and at least one early oil change. After the break-in is complete, your car will need a final professional tune to dial in the air-fuel ratios and ignition timing for your specific setup. Factoring in the cost of break-in oil, filters, and professional engine tuning services is a non-negotiable part of the process.

How to Budget for the Unexpected

No matter how meticulously you plan, unexpected issues can always pop up during an engine build. When the old engine comes apart, your mechanic might discover a cracked component, a stripped bolt hole, or a worn-out sensor that wasn't part of the original quote. These surprises can add both cost and time to your project. A smart strategy is to build a contingency fund into your budget—typically 10% to 15% of the total estimated cost. This buffer gives you peace of mind, ensuring that a minor setback doesn't derail your entire build.

What to Expect for Long-Term Maintenance

A built performance engine is not the same as a stock motor from the factory. It requires more attentive long-term care to maintain its health and performance. For example, if your previous engine failed due to a bearing issue, it's wise to replace the oil cooler to prevent metal debris from contaminating your new investment. You should also plan for more frequent oil changes using high-quality synthetic oil and regular inspections of your entire setup. Investing in robust Subaru STI upgrades is just the first step; consistent maintenance is what protects that investment and keeps you enjoying the power you paid for.

Is an Engine Build a Good Investment?

Deciding to build your STI's engine is a major step. It’s not just about fixing a problem; it’s about fundamentally transforming your car’s performance and durability. A well-executed engine build is an investment in power, reliability, and the driving experience you’ve always wanted. When you move beyond the limits of the stock block, you open up a new world of capability, whether you’re aiming for a responsive street car or a dedicated track machine.

However, it's a significant commitment of both time and money. The key is to approach it with a clear plan, realistic expectations, and a focus on quality. A properly built engine can handle substantially more power than a stock one and can even be more reliable when pushed hard. The real question isn't just if it's a good investment, but what it takes to make it a good investment. It starts with understanding the true costs, choosing the right parts, and trusting the right hands to put it all together.

Exploring Alternatives to a Full Engine Build

A full engine build is a massive undertaking, and it's not the right path for every owner. Before you commit to a project that can easily run into five figures, it’s worth exploring other options that might better suit your budget and goals. Sometimes, a more moderate approach can deliver the reliability and performance you’re looking for without the complexity and cost of a ground-up build. These alternatives are about making smart, strategic choices that align with how you actually use your car, ensuring you get the most enjoyment out of your investment.

Partial Rebuilds and Reconditioned Engines

If your primary goal is to restore reliability or add a modest amount of power, a partial rebuild is an excellent alternative. This approach, often called an "OEM+" build, involves using a new factory short block but assembling it with greater care than the original. A professional builder might add specific Subaru STI upgrades like better bearings, ARP head studs, and a more robust head gasket to address common failure points of the EJ257 engine. This method provides a fresh, dependable foundation that’s stronger than stock without the expense of forged internals, making it a smart choice for a daily driver or a car with light track use.

Considering a Different Vehicle Platform

This might be tough to hear, but sometimes the most cost-effective way to achieve your high-horsepower goals is to start with a different car. Pushing a Subaru STI to 500, 600, or even 700 horsepower requires a significant investment in not just the engine, but also the transmission, axles, and supporting systems. At a certain point, the cost and complexity can outweigh the benefits. If your ultimate goal is extreme power, it may be more practical to sell your STI and invest in a platform that is engineered to handle that kind of output from the factory, potentially saving you thousands of dollars and countless headaches in the long run.

How to Set a Realistic Budget for Your Build

Before you do anything else, you need to get real about the costs. A comprehensive, professional STI engine build isn't cheap. Based on builds across the country, you can expect the average cost to range from $8,000 to $12,000. This figure typically covers high-quality internal components, machine shop services, professional assembly, and the final tune. Trying to cut corners on a project of this scale is a recipe for disaster. A single failed part can destroy your entire investment. Plan for this price range, and it’s always wise to have a small cushion for any unexpected needs that might pop up during the teardown and assembly process.

How to Select the Right Components for Your Goals

An engine is a complex system where every part has to work in perfect harmony. The strength of your build is determined by its weakest link. That’s why choosing high-quality performance parts is absolutely critical. Forged pistons, stronger connecting rods, and a balanced crankshaft form the foundation of a durable engine capable of handling serious power. Just as important is the final step: the tune. Investing in professional engine tuning services ensures all your new components work together safely and efficiently. A great tune protects your investment and delivers the smooth, reliable power you paid for.

What About a Warranty?

When you’re investing thousands of dollars into an engine, peace of mind is priceless. Ask any potential builder about their warranty policy upfront. Many shops offer little to no coverage, leaving you on the hook if something goes wrong. A reputable builder will stand behind their work. At Crawford Performance, we include a 12-month/12,000-mile warranty on our engine builds because we are confident in our components, our assembly process, and our tuning. This kind of guarantee is a clear indicator that you’re working with professionals who prioritize quality and long-term reliability, protecting you from unforeseen issues down the road.

Reaping the Rewards: Performance & Power

So, why go through all this effort? The answer is simple: power you can actually use. The stock STI engine is impressive, but its internals are generally considered reliable only up to about 350 to 400 wheel horsepower. If you want to push past that ceiling safely, a built motor is the only way to do it. This is where your investment truly pays off. You’re not just getting a higher peak horsepower number; you’re getting an engine that can handle the stress of aggressive driving, track days, and repeated full-throttle pulls without failing. With the right Subaru STI upgrades, you can create a car that delivers exhilarating, reliable performance every time you turn the key.

How to Ensure Long-Term Reliability

A powerful engine is useless if it isn’t reliable. The internet is full of horror stories about built motors failing prematurely, and this is almost always due to mistakes made during the assembly process. Common errors like settling for cheaper parts, improper bearing installation, or using the wrong seals can lead to catastrophic failure. This is why choosing an experienced builder is non-negotiable. A professional shop with a proven track record understands the precise tolerances and meticulous procedures required to build a Subaru engine that lasts. A correctly assembled and tuned engine isn’t just more powerful—it’s built to withstand the demands you place on it for years to come.

How to Choose the Right Build for You

Deciding to build your STI engine is a major step, and the right approach depends entirely on your personal goals, timeline, and budget. There’s no single "best" build—only the one that’s best for you. Before you start ordering parts or booking shop time, it’s critical to map out your project. Thinking through your performance targets will clarify which components you need, while finding a trustworthy builder ensures the work is done right.

Planning your timeline and budget from the start prevents surprises and keeps the project on track. A well-planned build is more than just an upgrade; it’s a long-term investment in your car’s performance and reliability. By carefully considering each of these factors, you can create a clear roadmap for transforming your STI into the machine you’ve always wanted.

Start by Evaluating Your Driving Goals

First, ask yourself: what do you want your STI to do? Are you building a responsive daily driver, a weekend canyon carver, or a dedicated track machine? Your answer will define the entire scope of your project. The stock STI engine is quite capable, with its internals generally considered reliable for up to 350-400 wheel horsepower in a daily-driven car. If your power goals exceed that, a built engine becomes essential for long-term reliability. A street-focused build might prioritize quick spooling and low-end torque, while a track build will require components that can handle sustained high RPMs and extreme heat. Defining your goals helps you select the right Subaru STI upgrades from the start.

How to Find a Reputable Engine Builder

Your engine build is only as good as the person assembling it. While it’s tempting to shop around for the lowest price, expertise is what truly protects your investment. A comprehensive engine build can range from $8,000 to $12,000 or more, and the quality of the labor is paramount. Look for a shop with a proven history of building reliable Subaru engines. Ask for references, look at their past projects, and ensure they offer transparent communication throughout the process. A professional builder will not only assemble the engine correctly but will also provide critical guidance on parts selection and offer expert engine tuning services to ensure everything works together perfectly.

Getting Multiple Quotes

Once you've identified a few potential builders, it's time to request detailed quotes. This isn't just about comparing final numbers; it's about understanding what each shop includes for the price. A professional quote should be itemized, breaking down the costs for specific parts, machine work, assembly labor, and the final engine tune. Be wary of the lowest bid. While an attractive price is tempting, it can often signal the use of lower-quality components or less experienced technicians, which can lead to catastrophic failure down the road. Use the quote as a conversation starter. Ask why they chose certain parts and what their process looks like. A builder who can confidently explain their choices and stands behind their work with a solid warranty is worth the investment.

Setting a Realistic Project Timeline

An engine build takes time, and your car will be off the road for the duration. Be realistic about how long you can be without your vehicle. The project timeline depends on several factors, including parts availability, the machine shop’s schedule, and your builder’s current workload. A quality build shouldn’t be rushed. Discuss the timeline with your chosen shop upfront and get a clear estimate in writing. This includes time for engine removal, machining, assembly, installation, and the final tune. Building in a buffer for potential delays will help manage expectations and ensure every step is completed to the highest standard without cutting corners.

Tips for Managing Your Build Budget

A performance engine build is a significant financial commitment that goes far beyond the cost of a standard engine replacement. While a basic used engine swap might cost around $5,000 to $6,000, a performance build involves higher-quality parts, precision machine work, and specialized labor. Create a detailed budget that accounts for all major components, including the engine block, internals, turbo, and supporting systems. Don’t forget to factor in costs for machining, assembly, and tuning. It’s also wise to set aside a contingency fund of 10-15% for unexpected expenses. Browsing high-quality performance parts can give you a realistic idea of where your budget will go.

Selling Old Parts to Offset Costs

Embarking on a full engine build is a serious financial commitment, but one smart way to manage the expense is by selling the usable components from your old motor. You'd be surprised what other enthusiasts are looking for. Parts like the stock turbo, intake manifold, or even the bare engine block can find a new home with someone doing a stock rebuild or a budget project. This not only helps you recoup a portion of your investment but also supports the wider Subaru community by making affordable parts available. Listing these items on platforms like eBay, Craigslist, or dedicated Subaru forums is a great way to connect with potential buyers. Every dollar you make back can be put toward higher-quality performance parts for your new build, making your performance goals that much more attainable.

Related Articles

Frequently Asked Questions

Why can't I just add a bigger turbo to my stock engine for more power? While a larger turbo will force more air into your engine, the stock internal components, specifically the pistons and connecting rods, aren't designed to handle the increased cylinder pressure. The factory parts are strong enough for their intended power level, but pushing far beyond that is a major risk. Doing so often leads to catastrophic engine failure, which is a far more expensive problem to fix than building the engine correctly from the start.

What is the single biggest mistake to avoid during an engine build? The most common and costly mistake is trying to cut corners on cost. This usually happens in one of three areas: choosing cheap, unproven parts; hiring an inexperienced builder to save on labor; or skipping a professional tune. A high-performance engine is a balanced system, and a failure in any one of these areas can compromise the entire investment, leading to premature failure and disappointment.

Do I need a full engine build if I just want a fun, reliable daily driver? Not necessarily. If your power goals are modest and stay within the 350-400 wheel horsepower range, the stock engine is generally quite reliable. A full build is for those who want to safely push past that limit. For daily drivers who need a new motor, an "OEM+" rebuild, which uses factory parts but with professional assembly and attention to detail, can be a fantastic and cost-effective option for long-term dependability.

How do I find a trustworthy shop to build my engine? Look for a builder who specializes in Subaru engines, as they have unique demands. A reputable shop will have a proven track record, be transparent about their process, and be willing to discuss your specific goals. Most importantly, ask them if they stand behind their work with a warranty. A shop that offers a warranty on their builds is showing confidence in their parts, assembly, and tuning.

My engine is assembled with the best parts. Is a professional tune still necessary? Absolutely. The tune is what synchronizes all of your high-performance components, telling them how to work together safely and efficiently. It calibrates everything from fuel delivery to boost pressure. An improper tune can easily destroy a perfectly assembled engine, while a professional tune not only protects your investment but also ensures you get the smooth, reliable power you paid for.