A Guide to EJ25 Engine Performance Reliability

Share

You bought your Subaru for its potential. The AWD grip, the turbo spool—it all begs for more power. But before you chase bigger numbers, from a simple tune to a full track setup, you have to ask: can the stock engine handle it? Just adding boost is a gamble, and a risky one at that. The secret to unlocking your car's true potential isn't just adding power; it's building a foundation that can handle it. This guide is about creating bulletproof engine performance reliability. We'll show you how to fortify your motor so you can enjoy every last horsepower with confidence.

Key Takeaways

- Prioritize Maintenance as Your First Upgrade: A reliable EJ25 starts with a solid maintenance routine. Shorten your oil change intervals and keep a close eye on your cooling system to create a healthy foundation for any future performance modifications.

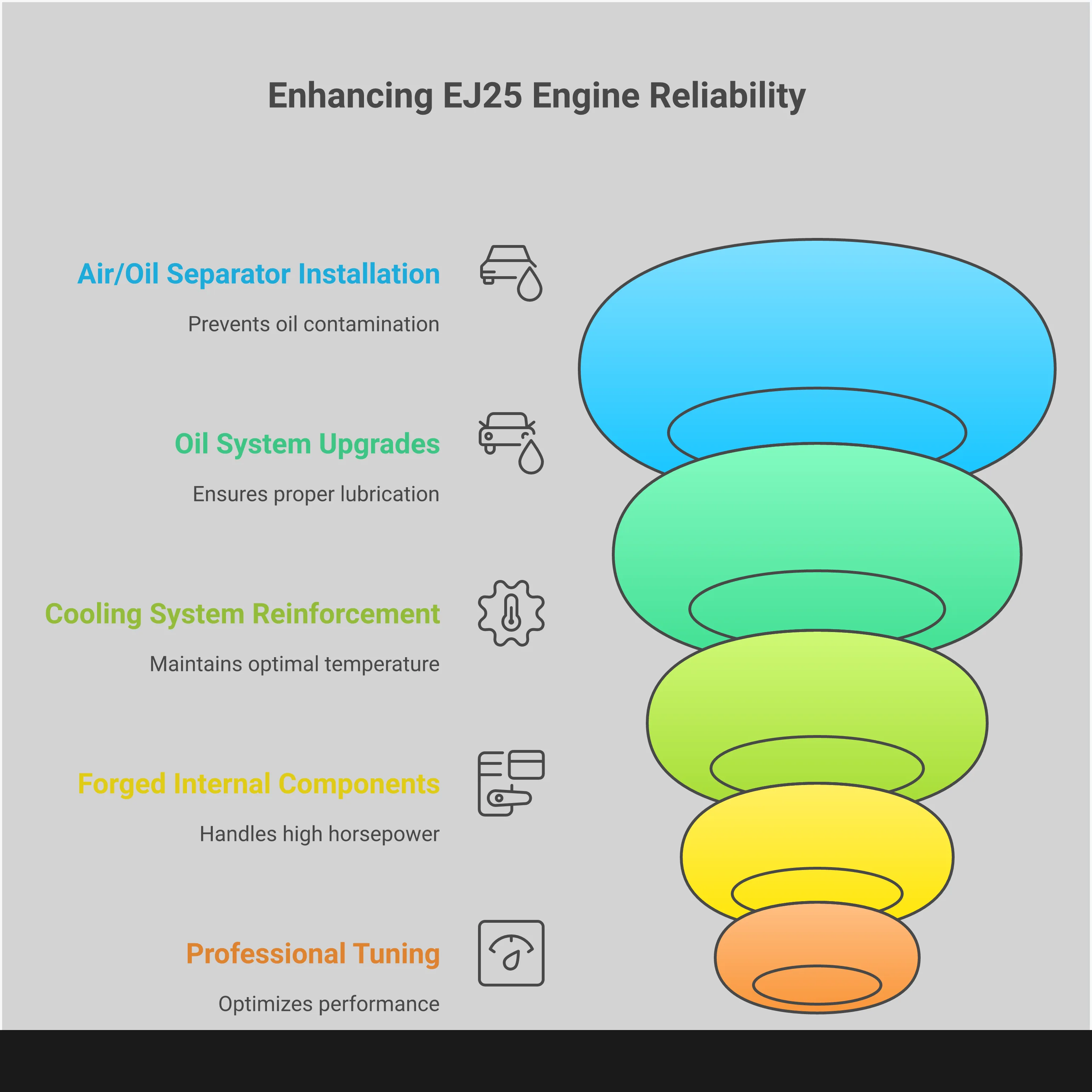

- Fortify the Engine's Known Weak Points: Protect your investment by addressing common failure points before they happen. Upgrades like an Air/Oil Separator, a stronger oil pickup tube, and forged internals are crucial for building a resilient engine that can reliably handle increased power.

- Combine Quality Parts with a Professional Tune: High-performance hardware is only half the equation. A successful build depends on precise assembly, a proper break-in period, and a professional tune to ensure all your new components work together for safe, reliable power.

Understanding Engine Reliability: The Basics

Before we get into the specifics of the EJ25, it's helpful to understand what makes any engine reliable. At its core, engine reliability is a balance of design, materials, and stress management. A well-built engine isn't just about making big power numbers on a dyno; it's about delivering that power consistently and safely, whether you're on a road trip or a track day. Factors like the quality of the metals used, the complexity of the design, and how aggressively the engine is tuned all play a massive role in its lifespan. Thinking about these fundamentals will give you a much clearer picture of why certain upgrades are essential for your Subaru and how they contribute to a build that you can trust for years to come.

What Makes an Engine Reliable?

Reliability isn't an accident; it's the result of intentional engineering choices. Two of the biggest factors that determine an engine's durability are its physical construction and the electronic instructions telling it how to run. An engine built with robust materials and a simple design has an inherent advantage in longevity. Similarly, an engine that is tuned to operate well within its mechanical limits will experience far less wear and tear than one pushed to its absolute maximum. Understanding this interplay between hardware and software is the first step toward building a powerful and dependable motor for your Subaru.

The Role of Materials and Design Simplicity

When it comes to engine longevity, simpler is often better. As one source notes, "Engines that are designed simply, with fewer parts, tend to last longer." Fewer components mean fewer potential points of failure. Material choice is just as critical. Using high-quality metals like forged steel or cast iron for key components like pistons and connecting rods helps them withstand heat and pressure, preventing premature wear. This is why upgrading to forged performance parts is a cornerstone of building a strong EJ25; you're replacing weaker, factory-cast parts with materials designed to handle the stress of increased performance without compromise.

Conservative Tuning vs. High-Output Performance

Pushing an engine to its absolute limit is a surefire way to shorten its life. A conservative tune that keeps the engine operating within a safe margin creates less stress on internal components, leading to a longer lifespan. This doesn't mean you can't make significant power. A professional tune is about finding the perfect balance between performance and reliability. Expert technicians who provide tuning services focus on creating a smooth powerband and ensuring fuel and ignition timing are optimized for your specific combination of parts, which protects your investment while delivering a thrilling driving experience.

How Engine Design Impacts Durability

The physical layout of an engine has a direct impact on its performance characteristics and long-term durability. Different configurations, like inline, V-type, or the boxer design found in your Subaru, each have unique strengths and weaknesses. The number of cylinders, the arrangement of the pistons, and even the type of fuel it uses contribute to its overall reliability profile. These design fundamentals influence everything from maintenance complexity to how the engine handles the stress of performance modifications, making it an important factor to consider when planning your build.

Inline vs. V-Type Engines

Engine configuration plays a big part in reliability. Inline engines, like an I4 or I6, are often praised for their durability because their simple design results in fewer moving parts and excellent primary balance. V-type engines, such as a V6 or V8, can produce more power in a compact package but are inherently more complex, which can lead to more intricate maintenance needs. The Subaru EJ25 uses a "boxer" or flat-four design, where pistons move horizontally. This layout provides a low center of gravity for superior handling but also has unique considerations for lubrication and cooling that must be addressed when adding power.

Gasoline vs. Diesel Longevity

While most performance Subarus run on gasoline, it's interesting to note the inherent durability of diesel engines. Generally, diesel engines are built with much stronger components to handle their higher compression ratios. This overbuilt nature means they can often last longer than their gasoline counterparts with proper care. The principles remain the same, however: a well-maintained engine built with quality parts will always have a better chance at a long life, regardless of the fuel it uses. This reinforces the importance of investing in a strong foundation for your gasoline-powered EJ25 build.

Turbocharged vs. Naturally Aspirated: A Reliability Comparison

The debate between turbocharged and naturally aspirated engines often comes down to a trade-off between power potential and complexity. A naturally aspirated engine relies on atmospheric pressure to fill its cylinders with air, resulting in a simpler, often more reliable design with fewer parts that can fail. In contrast, a turbocharged engine uses exhaust gases to spin a turbine, forcing more air into the engine and creating significantly more power from the same displacement. This added complexity introduces more heat and pressure, which places greater stress on engine components and demands more diligent maintenance and supporting modifications to ensure long-term reliability.

What is the EJ25 Short Block?

If you’re a Subaru enthusiast, you’ve definitely heard of the EJ25. This engine is the heart of many iconic models, from the rally-inspired WRX STI to the versatile Forester XT. But what exactly is the "short block"? Simply put, the short block is the bottom half of your engine. It’s the foundation that includes the engine block itself, the crankshaft, connecting rods, and pistons. Think of it as the core powerhouse where combustion and power generation begin.

Understanding the EJ25 short block is crucial because it’s both the source of your Subaru’s performance and, often, the focus of reliability concerns. The stock components are designed for daily driving and can handle moderate power increases, but when you start pushing for more significant gains, their limits can be exposed. This is where common issues like head gasket failure or piston ringland problems can surface. That’s why many owners eventually look into a "built" short block—a reinforced version with upgraded components designed to handle the stress of higher horsepower. Before we get into the common problems and fixes, let’s break down its core design, which models have it, and what makes its boxer layout so special.

Inside the EJ25: Core Components and Design

At its core, the EJ25 short block is a collection of essential moving parts. The engine block houses the cylinders where the pistons travel up and down. The crankshaft converts this linear motion into the rotational force that ultimately turns your wheels. Connecting rods link the pistons to the crankshaft. When you hear about a built short block, it means these stock, cast parts have been replaced with high-strength, forged internals.

Upgrading to a built short block is like buying an insurance policy against catastrophic engine failure. It creates a durable foundation that can safely handle the stress of significantly higher horsepower and aggressive tuning. These stronger performance parts are engineered to withstand greater heat and pressure, giving you the confidence to push your vehicle without worrying about a critical component giving way.

Which Subaru Models Use the EJ25 Engine?

The EJ25 engine has been a staple in Subaru’s lineup for decades, powering some of its most popular models in the US. It was designed to give American drivers the low-end torque and immediate power they wanted. If you’re driving a performance-oriented Subaru from 2002 to the present, there’s a good chance you have some version of the EJ25 under the hood.

You’ll find this engine in iconic models like the Subaru WRX from 2006 to 2014 and the Subaru WRX STI from 2004 to 2021. It also powered the Forester XT from 2004 to 2013, the Legacy GT from 2005 to 2012, and the Outback XT from 2005 to 2009. Each model has a slightly different variant of the EJ25, but they all share the same fundamental architecture.

Why the Boxer Engine Design Matters

One of the most distinctive features of the EJ25 is its "boxer" design. Unlike inline or V-shaped engines where pistons move up and down, a boxer engine has a flat-four layout. The pistons are horizontally opposed, moving toward and away from each other like a boxer throwing punches. This design is a hallmark of Subaru engineering and offers a significant performance advantage.

The flat layout gives the engine a lower profile, which results in a lower center of gravity for the entire vehicle. This improves stability, reduces body roll during cornering, and gives Subaru vehicles their famously nimble handling. The engine’s inherent balance also contributes to a smoother power delivery. While it produces good power in its stock form, this unique design makes it an excellent platform for performance modifications and expert engine tuning services.

Common EJ25 Problems to Watch For

The Subaru EJ25 engine is a true icon, powering some of the most beloved all-wheel-drive performance cars on the road. Its signature boxer rumble and incredible tuning potential have earned it a dedicated following. However, like any engine pushed to its limits, the EJ25 has a few well-documented weak points. Getting familiar with these issues isn’t about dwelling on negatives; it’s about being a smart owner and builder. When you understand the engine’s potential challenges, you can address them proactively, transforming those weaknesses into strengths.

Think of it as building a solid foundation. Before you start adding power, you need to ensure the core of your engine is prepared to handle it. Addressing these common problems from the outset is the key to creating a reliable powerhouse that you can enjoy with confidence, whether you're navigating a winding mountain road, hitting the track for a weekend session, or exploring a remote trail. Each potential issue presents an opportunity to upgrade with superior components that not only solve the problem but also enhance the engine's overall durability and performance. By taking a strategic approach, you can build an EJ25 that is far more robust than it was when it left the factory, ready for whatever you throw at it.

That Notorious Head Gasket Issue

If you've spent any time in Subaru circles, the topic of head gaskets has likely come up. On the EJ25, head gasket failure can be triggered by factors like overheating, high mileage, or increased cylinder pressures from performance modifications. The tell-tale signs often include unexplained coolant loss, rising engine temperatures, and white, sweet-smelling smoke from the exhaust. This indicates a breach between the coolant passages and the combustion chamber. The right fix involves more than a simple replacement; it’s a chance to install durable multi-layer steel (MLS) head gaskets and upgraded head studs. This combination provides a much stronger and more reliable seal, making it an essential step for any performance-oriented Subaru WRX upgrades.

Tackling Excessive Oil Consumption

Many EJ25 owners notice their engines consume oil between changes, a problem that can be amplified in modified vehicles. This is often due to oil blow-by, where oil vapor from the crankcase is forced into the intake system under boost. This not only lowers your oil level but can also coat your intercooler and valves, reducing your fuel's effective octane rating and hurting performance. The most effective solution is installing a high-quality Air/Oil Separator (AOS). An AOS system intercepts these oily vapors, separating the oil and returning it to the crankcase while allowing clean air to pass through. This keeps your oil where it belongs and protects your engine from the risks of running on a low oil level.

How to Prevent Piston and Ringland Failure

The stock pistons in turbocharged EJ25 engines are a known weak point, especially when you start increasing boost and power. Ringland failure occurs when the small piece of the piston that separates the piston rings cracks or breaks off. This leads to a sudden loss of compression, a noticeable knocking sound, and a severe drop in performance, often requiring a full engine rebuild. This type of failure is typically caused by detonation (knock), which puts extreme stress on the pistons. To build a truly resilient engine, upgrading to forged pistons is non-negotiable. Forged internals are significantly stronger than the factory cast components and are a foundational part of any build looking to make serious, reliable power with quality performance parts.

Solving Bearing and Oil Flow Problems

Rod bearing failure is one of the most serious potential issues for an EJ25, often resulting in catastrophic engine damage. This problem is typically rooted in oil starvation. During aggressive driving, high G-forces can cause oil to slosh away from the oil pickup tube, momentarily starving the rod bearings of the lubrication they desperately need. Over time, wear on the engine block's main bearing journals can also lead to a drop in oil pressure. Upgrading your oiling system with components like a high-capacity oil pan, an improved oil pickup tube, and a baffle plate is critical for preventing oil starvation and ensuring your engine’s bottom end remains healthy under pressure.

Why Casting Quality Is So Important

Not all engine blocks are created equal. Factory manufacturing processes can result in minor inconsistencies in the block casting, which can become significant issues in a high-horsepower build. Some blocks may have slight variations in material density or wall thickness that can create weak points when subjected to the stresses of increased power and torque. This is why a meticulous engine build starts with a carefully selected and inspected block. For a truly bulletproof setup, relying on expert knowledge is key. Professional engine tuning services and builders take the time to ensure every component, starting with the block itself, meets the highest standards required for a durable, high-performance engine.

Buying Used: What to Check on an EJ25

Whether you're buying a complete car or just a used engine for a project, a thorough inspection is your best defense against inheriting someone else's problems. A healthy, well-maintained EJ25 is the perfect starting point for a reliable performance build, but a neglected one can quickly turn your dream project into a financial nightmare. Before you commit, it’s essential to play detective and look for signs of the engine's past life. Paying close attention to maintenance records and performing a few key diagnostic tests can reveal the true condition of the engine and help you make a smart investment. This initial diligence will save you time, money, and a lot of frustration down the road.

The Importance of Service History

A detailed service history is one of the most valuable assets you can find when evaluating a used EJ25. A stack of receipts showing consistent oil changes, coolant flushes, and other routine maintenance is a strong indicator that the previous owner cared for the vehicle. As we always say, you should prioritize maintenance as your first upgrade. An engine with a solid maintenance routine has a much healthier foundation for future modifications. Look for evidence of shortened oil change intervals, especially if the car was modified, and check that the cooling system has been properly cared for. This documented history gives you confidence that you’re starting with a solid base, not an engine that’s already on the brink of failure.

Why a Compression Test is a Good Idea

If the service history is the engine's resume, a compression test is the interview. This simple diagnostic test measures the pressure inside each cylinder, giving you a direct look at the health of the pistons, rings, and valves. What you’re looking for are consistent numbers across all four cylinders. A healthy engine will show even readings, but significant variations can signal serious internal problems like worn piston rings, a failing head gasket, or valve issues. A compression test is a relatively quick and inexpensive procedure that can save you from purchasing an engine that needs an immediate and costly rebuild, making it an essential step in any pre-purchase inspection.

EJ25 Maintenance for Long-Term Reliability

Keeping your EJ25 running strong isn't about luck; it's about proactive maintenance. This engine can be incredibly reliable when you give it the attention it deserves. By staying on top of a few key areas, you can address common failure points before they become catastrophic problems. Think of this as the foundation for all future performance modifications. A healthy stock engine is the best starting point for a powerful and dependable build. Let's walk through the essential habits that will protect your investment and keep you on the road or track for years to come.

Stick to a Smart Oil Change Schedule

While Subaru recommends an oil change every 6,000 miles, you should treat that as a maximum, not a target. For an engine like the EJ25, especially if it’s turbocharged or driven spiritedly, more frequent changes are cheap insurance. I recommend changing your oil and filter every 4,000 miles or every four months, whichever comes first. This simple habit helps prevent oil breakdown and ensures internal components are properly lubricated, reducing wear and tear. Using high-quality synthetic oil is non-negotiable. Clean oil is the lifeblood of your engine, and sticking to a disciplined schedule is the single most effective thing you can do for its long-term health.

Keep Your Cooling System in Check

Overheating is the arch-nemesis of the EJ25, often leading to the dreaded head gasket failure. Your cooling system is the first line of defense. Make it a habit to regularly check your coolant levels and inspect hoses for any signs of cracking or leaks. Pay close attention to your temperature gauge while driving. If you notice it creeping higher than usual, address it immediately. Key warning signs of a cooling system issue or a potential head gasket problem include unexplained coolant loss, the engine running hot, or white smoke coming from the exhaust. Maintaining this system is critical for preventing the kind of heat-related damage that can sideline your Subaru.

Know Your Timing Belt Service Intervals

The timing belt is a critical component you absolutely cannot ignore. If it fails, the pistons can strike the valves, causing catastrophic and expensive engine damage. Your owner's manual specifies the replacement interval—typically around 100,000 miles—and you should treat this as a hard deadline. When you replace the timing belt, it's also standard practice to replace the water pump and tensioners at the same time. The water pump is another potential failure point that can lead to overheating, and since the mechanic is already in there, replacing it is a cost-effective, preventative measure that ensures the entire system is refreshed.

Spotting Trouble: Early Warning Signs

Learning to listen to your car can save you thousands in repairs. Be aware of the common issues that EJ25 owners report so you can spot them early. This includes symptoms of head gasket failure, signs of excessive oil consumption (like blue smoke from the exhaust), or the distinct sound of piston ringland failure, which can sound like a persistent ticking or knocking. If you notice a sudden drop in performance, strange noises, or new dashboard lights, don't ignore them. Investigating these signs promptly allows you to find the root cause and fix it before it cascades into a much larger problem.

Universal Signs of Engine Trouble

Your Subaru will almost always give you a heads-up before a major problem occurs; the trick is knowing what to look for. Pay close attention to any new or unusual sounds, like a persistent knocking or ticking, which could point to piston ringland or rod bearing issues. A sweet, syrupy smell from your exhaust, often accompanied by white smoke, is a classic sign of a failing head gasket. Also, keep a close eye on your oil levels. If you're constantly topping it off, you might be dealing with excessive oil consumption from blow-by. Any sudden drop in power or a new check engine light should be investigated immediately. Catching these signs early can be the difference between a manageable repair with the right performance parts and a full engine rebuild.

Why You Should Keep Detailed Maintenance Records

Whether you do the work yourself or use a trusted shop, keep a detailed log of every service performed on your Subaru. This includes oil changes, fluid flushes, timing belt services, and any repairs or performance parts installations. A thorough maintenance history is not only invaluable for troubleshooting any future issues, but it also significantly increases your car's resale value. When you decide to pursue professional engine tuning services, your tuner will have a clear picture of your engine's health and history, allowing them to create a safer and more effective tune. It’s a simple discipline that pays off in the long run.

How the EJ25 Stacks Up: A Look at Other Reliable Engines

It’s easy to get caught up in online forums where the EJ25’s reliability is debated endlessly. While it has a reputation for being sensitive, it's important to view it in the context of other legendary engines. No engine is indestructible, and every design has its own unique philosophy and set of characteristics. The EJ25 is a high-strung, turbocharged performance engine designed for a thrilling driving experience, which puts it in a different category than a naturally aspirated commuter engine built solely for efficiency and longevity. Understanding these differences is key to appreciating what makes any engine reliable.

The most common thread connecting all durable engines, from Japanese four-cylinders to American V8s, isn't a magic formula—it's a commitment to proper maintenance and a respect for the engine's design limits. Many of the best car engines can last for hundreds of thousands of miles when cared for correctly. The EJ25 is no exception. When you address its known weaknesses with quality performance parts and stick to a rigorous maintenance schedule, you build a powerplant that can deliver both incredible performance and surprising durability. Let's see how its design philosophy compares to other engines known for going the distance.

Legends of Longevity: Toyota and Honda

When you talk about engine reliability, Toyota and Honda are often the first names that come to mind. Engines like the Toyota/Lexus 3.5L V6 and various Honda V6 models have earned a stellar reputation for lasting well over 250,000 miles with basic care. These powerplants are the marathon runners of the automotive world. They are typically naturally aspirated and conservatively tuned from the factory, prioritizing smooth, consistent operation over peak horsepower. Their design philosophy is centered on minimizing stress on internal components to ensure a long, trouble-free service life. The EJ25, by contrast, is a sprinter—built to deliver an explosive burst of power, which inherently puts more strain on its parts. This doesn't make it less reliable, just different. It simply requires a more attentive approach to maintenance and a willingness to fortify its foundation for sustained performance.

The Workhorses: American and German Engines

On the other end of the spectrum are the workhorses, like the Mercedes-Benz OM617 diesel and classic American V8s like the Ford Windsor. These engines are legendary for their sheer toughness. The Mercedes diesel, built mostly from cast iron, is known to surpass 500,000 miles, while the simple, easy-to-fix American V8s often power trucks and vans well beyond the 200,000-mile mark. Their secret lies in robust, overbuilt designs and a focus on low-end torque rather than high-revving power. The most important lesson these reliable engines teach us is that diligent maintenance is the great equalizer. The same principle applies directly to your Subaru. While the EJ25 is a more complex, high-performance machine, providing it with clean oil, a healthy cooling system, and a professional tune is the universal recipe for a long and powerful life.

How Can You Protect Your EJ25 Engine?

Once you've mastered the fundamentals of maintenance, it's time to shift your focus to proactive protection. The EJ25 is a capable and beloved engine, but it has well-documented vulnerabilities that can lead to costly failures if left unaddressed. Taking strategic steps to fortify your engine isn't just about preventing disaster; it's about building a reliable foundation that allows you to confidently pursue more power. By addressing the root causes of common issues, you can transform potential weak points into sources of strength. This approach moves you from simply maintaining your Subaru to truly enhancing it for the long haul.

Focusing on critical areas like temperature control, oil system integrity, and component quality will safeguard your investment. The following strategies are essential for any EJ25 owner who wants to enjoy their car's full potential, whether that means daily driving, spirited track days, or rugged overlanding solutions. Think of these upgrades as the armor your engine needs to perform at its best for years to come. By implementing these fixes, you're not just patching holes; you're re-engineering your engine's weak points to create a more robust and resilient machine, ready to handle whatever you throw at it.

Keep Your Engine Temperatures Under Control

Heat is the enemy of any performance engine, and the EJ25 is no exception. Consistent overheating is a primary cause of premature failure, especially for head gaskets. As one expert notes, "Head gasket failures can happen because of overheating, the engine getting old, or not being maintained well." Keeping your engine temperatures stable is one of the most effective things you can do for its longevity. An upgraded aluminum radiator offers significantly better cooling capacity than the stock unit, while a lower-temperature thermostat can help regulate temperatures more effectively during spirited driving. Pairing these with high-quality coolant and regularly inspecting your hoses will create a robust cooling system that protects your engine from the stress of excess heat.

Why High-Quality Parts Are Non-Negotiable

When you start adding power, you expose the limits of the stock engine components. The factory pistons, rods, and bearings were designed for a specific output, and pushing far beyond that invites failure. Investing in superior parts is crucial for reliability. For those planning significant power gains, a built EJ25 short block "replaces those stock parts with high-strength, forged internals designed to handle significantly more power and stress, reliably." Even if you aren't doing a full build, choosing high-quality aftermarket performance parts for any replacement or upgrade ensures your engine is equipped to handle the demands you place on it. This approach turns potential weak points into sources of strength.

Should You Install an Air/Oil Separator (AOS)?

If you own a turbocharged Subaru, an Air/Oil Separator (AOS) is a non-negotiable upgrade for engine protection. The factory crankcase ventilation system can allow oil vapor to enter your intake, which has serious consequences. This oil mixes with the incoming air and fuel, effectively lowering your fuel's octane rating and increasing the chances of engine knock, or detonation. For any turbocharged EJ engine, you should "consider adding an air/oil separator (AOS). This helps keep oil out of the intake system, which improves cooling and prevents engine knock." By capturing this oil vapor and returning it to the crankcase, an AOS keeps your intake charge clean, ensuring consistent and safe performance.

Why You Should Upgrade Your Oil Pickup Tube

The factory oil pickup tube is a known Achilles' heel of the EJ25. The tube can develop cracks near its mounting flange, causing the oil pump to suck in air instead of oil. This leads to a sudden and catastrophic drop in oil pressure. As one forum user correctly identified, many of these engines "die from a lack of oil flow to the rod bearings." An oil-starved engine will fail in seconds, often destroying the crankshaft, rods, and bearings. Upgrading to a heavy-duty, fully welded oil pickup tube is an inexpensive and essential piece of insurance against this type of failure. It’s a small part that provides critical protection for your entire engine assembly.

Smart Upgrades for a Stronger EJ25

Once you’ve addressed the common maintenance points, you can start thinking about performance. Smart upgrades do more than just add horsepower; they build a more resilient and reliable engine. Focusing on the engine’s known weaknesses allows you to create a foundation that supports future power goals without sacrificing durability. These modifications are about building a balanced, robust EJ25 that you can depend on, whether you’re on the track, a trail, or your daily commute.

Why Forged Internals Are a Game-Changer

The stock pistons in an EJ25 are a known weak point, especially when you start increasing boost and power. Upgrading to a built short block with forged internals is the single best way to create a durable foundation for your engine. Forged pistons and connecting rods are significantly stronger than the factory cast components, allowing them to handle the increased stress of higher horsepower and more aggressive tuning. Think of it as an insurance policy against catastrophic failure. This step is essential if you have serious performance goals for your Subaru WRX or STI.

Essential Upgrades for Your Oil System

Oil starvation is a primary cause of rod bearing failure in the EJ25. The factory oiling system can struggle to provide consistent oil flow and pressure, especially under high-G cornering or when pushing the engine hard. Upgrading key components is critical for engine longevity. A high-quality oil pickup tube prevents cracking and failure, while our signature Crawford Performance Air/Oil Separator (AOS) prevents oil from contaminating your intake system. These upgrades work together to ensure your engine’s bearings receive a steady supply of clean oil, protecting them from premature wear.

Cooling System Upgrades You Shouldn't Skip

Heat is the enemy of any performance engine, and the EJ25 is particularly sensitive to overheating, which can lead to head gasket failure. The stock cooling system is adequate for a stock car, but it can quickly become overwhelmed once you add more power. An upgraded aluminum radiator offers superior heat dissipation compared to the stock unit with plastic end tanks. Combining a better radiator with high-quality coolant helps maintain stable operating temperatures, protecting your head gaskets and preventing detonation. This is a simple yet effective way to safeguard your investment in performance parts.

Tuning for a Balance of Power and Reliability

Hardware upgrades are only half the battle. Without a proper tune, even the best parts won’t perform correctly and can even damage your engine. A professional tune adjusts your engine’s fuel, timing, and boost parameters to match your specific modifications. This process ensures all your new components work together harmoniously, delivering safe and reliable power. It’s crucial to work with a tuner who has extensive experience with the EJ25 platform. Proper engine tuning services will not only maximize your performance gains but also refine drivability and protect your engine for the long haul.

The Role of Performance Chips and ECU Tuning

You've likely seen ads for plug-and-play "performance chips" that promise instant horsepower gains. While these devices can sometimes offer a minor change, their results are often inconsistent because they rely on generic, one-size-fits-all maps. A far more effective and safer approach is a professional ECU tune. High-performance hardware is only half the equation; a successful build depends on a professional tune to ensure all your new components work together for safe, reliable power. A custom tune adjusts your engine’s fuel, timing, and pressure levels to match your specific modifications. Without this critical step, even the best performance parts won’t function correctly and could even damage your engine. To truly get the most out of your upgrades, you need expert engine tuning services from a specialist who understands the unique demands of the EJ25 platform.

How to Build a Bulletproof EJ25

Building a "bulletproof" EJ25 isn't about making it indestructible, but about creating a robust and reliable engine that can handle serious power without compromising its integrity. It’s a systematic approach that transforms the stock engine into a powerhouse built for longevity. This process goes beyond simply bolting on new parts; it requires a deep understanding of the engine's weaknesses and a commitment to addressing them with the right components and assembly techniques.

A truly resilient EJ25 build starts with a solid foundation, followed by meticulous assembly, a disciplined break-in period, and a proactive maintenance plan. Each step is crucial for ensuring your engine can withstand the demands of aggressive driving, whether you're on the track or a remote trail. By focusing on quality and precision from the start, you can build an engine that delivers both thrilling performance and peace of mind. This approach turns your investment into a reliable heart for your Subaru, ready for whatever you throw at it.

Choosing the Right Components for Your Build

The foundation of a durable engine is a high-quality short block. A built EJ25 short block is more than just a collection of high-performance parts; it’s an insurance policy against catastrophic engine failure. The goal is to replace weaker stock components with forged internals that can handle significantly more stress. This includes forged pistons to resist ringland failure, forged connecting rods to manage higher cylinder pressures, and a balanced crankshaft to ensure smooth operation at high RPMs. Choosing these components from a reputable manufacturer ensures they are engineered to work together, creating a durable foundation for your power goals.

Engine Assembly: Best Practices to Follow

The world's best parts are useless if they aren't assembled correctly. Precision is everything. During assembly, every clearance—from piston-to-wall to bearing tolerances—must be measured and set to exact specifications. A clean environment is non-negotiable to prevent contaminants from causing premature wear. Following proper torque sequences for every bolt ensures the block and heads are sealed correctly, preventing leaks and maintaining structural integrity. This meticulous process is what separates a reliable build from one that fails early. For this reason, many enthusiasts trust professional builders who have the specialized tools and experience to get it right.

The Critical Engine Break-in Process

Once your engine is built and installed, the break-in period is the most critical phase of its life. The primary goal is to allow the new piston rings to seat properly against the cylinder walls, creating a tight seal for optimal compression. To do this, you need to vary the engine's RPM and load without pushing it too hard. Avoid constant highway speeds, full-throttle acceleration, and high-RPM pulls. After the initial break-in miles, perform an early oil and filter change to remove any metal particles from the assembly process. During this time, keep a close eye out for any potential issues, like the common oil leaks that can appear around timing chain covers.

Planning for Long-Term Engine Protection

A built engine is not a "set it and forget it" upgrade. It requires consistent attention to maintain its health. The EJ25's biggest enemy is oil starvation, as these engines can fail from a lack of oil flow to the rod bearings. To combat this, installing an upgraded oil pickup tube is a smart move to prevent oil starvation during hard cornering. An Air/Oil Separator is another essential addition, as it prevents oil from contaminating your intake system, which helps maintain octane levels and reduces the risk of detonation. These performance parts are not just accessories; they are vital components for protecting your investment and ensuring your engine performs reliably for years to come.

How to Create a Proactive Maintenance Schedule

A reliable EJ25 isn’t built on hope; it’s built on a solid, proactive maintenance plan. Staying ahead of potential issues is far better than reacting to them after something has gone wrong. Creating a schedule and sticking to it is the single best thing you can do to ensure your engine stays healthy for the long haul, whether you’re daily driving or pushing it on the track. This isn’t about just following the manufacturer's baseline—it’s about creating a personalized plan that accounts for your driving style and the performance you demand from your Subaru.

Defining Your Key Service Intervals

Let’s start with the lifeblood of your engine: oil. While Subaru suggests an oil change every 6,000 miles, we strongly recommend a more frequent schedule for modified or hard-driven cars. Aim for an oil change every 4,000 miles or every four months. This simple step is cheap insurance against premature wear. Fresh oil maintains its viscosity, lubricates critical components, and helps keep engine temperatures in check. Shortening the interval ensures contaminants are flushed out before they can cause damage, giving your engine the best environment to perform.

What Are the Critical Inspection Points?

Knowing what to look for is half the battle. The EJ25 has a few well-known areas that need regular attention. Make a habit of inspecting your head gaskets for leaks, listening for unusual engine noises that could indicate ringland issues, and monitoring for excessive oil consumption. Your timing belt and water pump are also critical components that should be checked regularly and replaced on a strict schedule, not just when they fail. A simple checklist helps you catch problems early, long before they become catastrophic failures.

How to Monitor Your Engine's Performance

Your car is always communicating with you; you just have to learn its language. Pay close attention to how your engine sounds, feels, and performs daily. A new noise, like a faint ticking on a cold start, could be an early warning sign of piston slap. Make checking your oil level a weekly ritual. If you’re losing oil between changes, it’s a red flag that needs immediate investigation. A professional engine tuning service can also help you establish a performance baseline, making it easier to spot when something is off.

The Importance of Documenting Everything

Keep a detailed log of every service, inspection, and modification. Record the date, mileage, parts used, and any notes about your engine’s performance. This log is invaluable because it helps you and your mechanic track the engine’s history and diagnose issues more effectively. It also allows you to spot patterns over time. Finally, if you ever sell your Subaru, a comprehensive maintenance record is proof of a well-cared-for vehicle, showing you’ve invested in quality performance parts and consistent service.

Modern Solutions for Classic EJ25 Issues

How Modern Designs Improve the EJ25

A built EJ25 short block is more than just a collection of high-performance parts; it’s an insurance policy against catastrophic engine failure. When you move beyond stock power levels, you expose the engine's original design limitations. Modern engineering addresses these weak points head-on. Upgrading to a built short block with forged internals creates a durable foundation that can safely handle the stress of significantly higher horsepower and aggressive tuning. This isn't just about swapping parts—it's about re-engineering the core of your engine for the demands of modern performance, ensuring it can withstand the pressures that would cause a stock block to fail. It’s the smartest way to protect your investment while pushing your Subaru to its full potential.

Key Modern Components to Consider

At its core, a built short block replaces stock cast parts with high-strength, forged internals designed to handle significantly more power and stress, reliably. Think of components like forged pistons, H-beam or I-beam connecting rods, and performance bearings. Unlike the stock cast aluminum pistons, forged pistons are denser and far more resistant to detonation and high cylinder pressures. Similarly, forged connecting rods won't bend or break under the increased load from higher boost. By upgrading these critical performance parts, you're building a robust rotating assembly that forms the backbone of a powerful and dependable engine, ready for the track or the street.

Is the Type-RA Block Right for You?

You might have heard about the Subaru Type-RA short block as a factory-upgraded option. It features stronger pistons and is often seen as a good way to make more power on a budget. While it's a step up from a standard EJ25, it's important to understand its limitations. Some builders have noted that the casting quality can be inconsistent, and it still doesn't offer the same level of strength as a custom-built block with fully forged internals. If you're planning moderate power goals, the Type-RA can be a viable choice. However, for those seeking serious power and maximum reliability, investing in a professionally built block provides superior materials and precision assembly you can count on.

Tuning a Built Engine: What You Need to Know

Building a strong engine is only half the battle; a proper engine tune is absolutely crucial for both reliability and performance. Your new, stronger components change how the engine breathes and responds, and the factory ECU map is no longer adequate. A professional tune adjusts fuel delivery, ignition timing, and boost pressure to create a safe and powerful calibration tailored to your specific hardware. This process ensures the engine runs efficiently without risking detonation or leaning out, which can destroy even the strongest internals. With expert engine tuning services, a high-horsepower built motor can be perfectly reliable for daily driving, giving you confidence every time you turn the key.

Related Articles

- The Ultimate EJ25 Short Block Installation Guide

- Built EJ25 Short Block: Everything You Need to Know

Frequently Asked Questions

What's the first upgrade I should make to my EJ25 for better reliability? If you're starting with a stock turbocharged EJ25, the best first step for engine protection is an Air/Oil Separator (AOS). It prevents oil vapor from entering your intake, which keeps your fuel's octane rating consistent and reduces the risk of engine knock. Another critical and inexpensive upgrade is a heavy-duty oil pickup tube, which prevents the stock unit from cracking and causing catastrophic oil starvation.

At what point do I actually need a built short block? There isn't a single horsepower number, but a built short block becomes necessary when you plan to significantly increase boost and power beyond what basic bolt-on parts provide. The stock pistons are the primary weak point and can fail under the stress of aggressive tuning. If your goals include a larger turbo and a substantial power increase, investing in a built block with forged internals is the only way to do it reliably.

My EJ25 has a head gasket leak. Can I just install stronger gaskets to fix it? Simply swapping in stronger head gaskets isn't a complete solution. When a head gasket fails, it's often due to an underlying issue like overheating, which can warp the cylinder heads or the engine block surface. For a lasting repair, a machine shop must check both surfaces for flatness and resurface them if needed. Using multi-layer steel gaskets and upgraded head studs on a properly prepared surface is the correct way to address the problem.

Why is a professional tune so important after building an engine? A built engine with forged internals and other upgrades flows air and fuel completely differently than a stock one. A professional tune is essential because it recalibrates the engine's computer to match the new hardware. The tuner will adjust fuel maps, ignition timing, and boost levels to ensure the engine runs safely and efficiently. Without a proper tune, you risk running too lean or experiencing detonation, which can destroy even the strongest components.

Is it better to buy a pre-assembled short block or have a local shop build my engine? Choosing a professionally pre-assembled short block from a reputable builder offers major advantages in quality control and consistency. These blocks are built in clean environments using proven component combinations and precise measurements that have been tested over countless builds. While a local shop can do great work, a specialized builder provides a level of expertise and a tested recipe for reliability that is difficult to replicate.