EJ25 Short Block Installation: Your Step-by-Step Guide

Share

A tiny metal shaving, an incorrect torque value, or a misaligned timing mark can turn a brand-new engine into a very expensive paperweight. When it comes to engine building, the small details are everything. Many enthusiasts dive into the project with excitement, only to be sidelined by a preventable mistake. This guide is designed to help you sidestep those common but costly errors. We’ll cover more than just the assembly sequence; we’ll highlight the critical checkpoints and quality-control measures that protect your investment. Think of this EJ25 short block installation guide as your roadmap to a successful, stress-free build that results in a powerful and reliable engine.

Key Takeaways

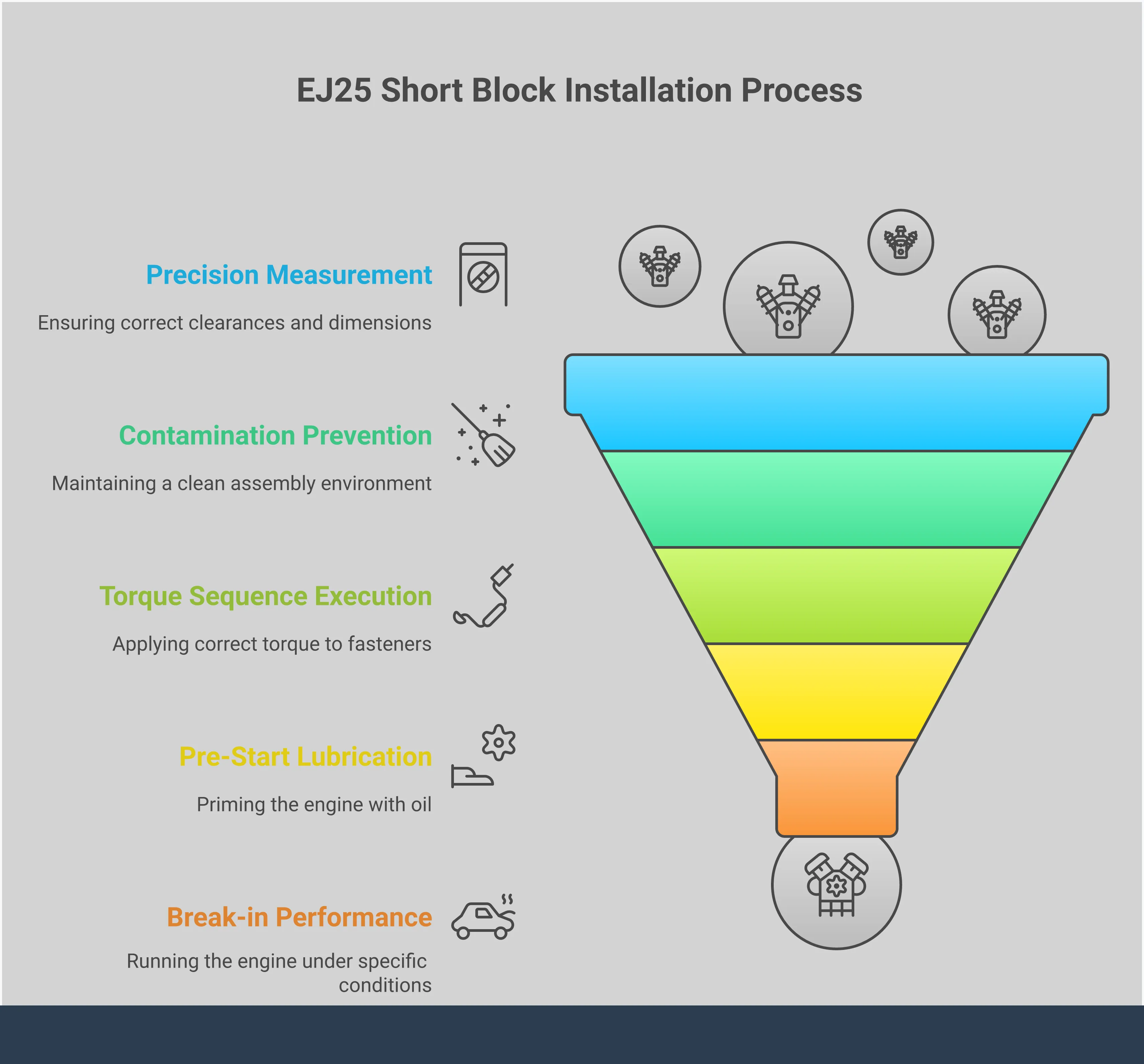

- Master the Prep Work Before You Begin: A successful engine build is determined before you ever touch the block. A meticulously clean workspace, organized parts, and a thorough inspection of every component are the foundational steps that prevent contamination and assembly errors.

- Precision is Non-Negotiable: Your engine's reliability hinges on exact measurements, not guesswork. Use the right tools to verify all clearances, file piston rings to spec, and follow factory torque sequences precisely to ensure every part functions correctly under pressure.

- Prioritize Post-Installation Care: The job isn't finished once the engine is installed. A careful break-in procedure, a diligent maintenance schedule, and learning to recognize early warning signs are essential for protecting your investment and ensuring long-term performance.

What is an EJ25 Short Block?

The EJ25 is the heart of many modern Subarus, and the short block is its core foundation. Think of it as the bottom half of your engine—the engine block, crankshaft, pistons, and connecting rods—all professionally assembled. This is where the power generation begins. The EJ25 is famous for its horizontally opposed "boxer" design, where pistons move side-to-side instead of up and down. This unique layout gives your Subaru a lower center of gravity, which is a huge part of why it feels so planted and handles so well on winding roads or uneven trails.

So, why would you get a short block instead of a complete engine? It’s all about control and performance. For enthusiasts looking to push the limits with performance parts or those needing to replace a tired motor, a new short block is the ideal starting point. It allows you to pair a brand-new, solid foundation with your choice of cylinder heads, cams, and other components to create an engine tailored to your exact goals. Whether you're building a high-horsepower WRX for the track or a torque-focused Forester for overlanding, starting with a fresh short block ensures reliability and gives you the perfect canvas for your build.

What Comes in the Box

When you're ready to start your engine build, knowing what to expect is key. While the short block itself is the main event, a quality installation kit is what brings it all together. You don't want to be scrambling for parts mid-project. A comprehensive EJ25 installation kit typically includes all the essential gaskets you'll need for a secure, leak-free assembly. This usually means a set of Genuine OEM head gaskets, intake manifold gaskets, and exhaust manifold gaskets. Having these critical components on hand from the start makes the process smoother and ensures every connection is sealed properly, setting your new engine up for a long and healthy life.

Signs It's Time for a Replacement

How do you know your trusty EJ25 is ready for a refresh? Your car will usually give you a few tell-tale signs. One of the most common indicators is head gasket failure. You might notice coolant loss, overheating, or white smoke from the exhaust. This can happen over time from age or if the engine has been pushed hard. Another major red flag is excessive oil consumption. If you find yourself constantly topping off the oil between changes, it could point to worn piston rings or cylinder walls. While these issues can sometimes be repaired, installing a fresh short block is often the most reliable long-term solution for your Subaru WRX upgrades, especially if you plan on adding more power.

Common Installation Hurdles

An engine build is a rewarding project, but it’s important to go in with your eyes open. A few common hurdles can trip up even experienced mechanics. One issue people sometimes face is the motor being difficult to turn over by hand after assembly. This often points to an alignment or assembly problem that needs to be addressed immediately. Another critical area is getting the measurements and clearances just right. This isn't a "close enough" kind of job. You'll need to be precise, which might involve carefully filing piston rings to get the perfect gap. Taking your time and double-checking your work here will save you major headaches down the road and ensure your new engine performs exactly as it should.

Gather Your Tools and Materials

Before you get your hands dirty, let's talk about prep. Getting all your tools and materials in order is the foundation of a successful build and will save you from major headaches down the road. Having everything you need ready to go ensures you can work efficiently and avoid any last-minute scrambles. We’ll cover the essential tools for the job, what comes in a standard installation kit, the precision measurement tools you can’t skip, and the cleaning supplies that will protect your investment.

Your Essential Tool List

To tackle this project, you’ll need more than just a standard socket set. A quality torque wrench is non-negotiable for hitting precise specifications and preventing damage. You'll also need a piston ring filer to get the end gaps just right, along with a ring expander to install them safely without bending or breaking them. Of course, a solid collection of hand tools—wrenches, sockets, and screwdrivers—is a must for disassembly and reassembly. Having the right equipment makes the job less of a struggle and more of a satisfying project. For a more detailed breakdown, many builders share their go-to tool lists for short block assembly online, which can be a great resource.

What's in the Installation Kit

To simplify your build, we highly recommend getting a dedicated installation kit. It’s a huge time-saver and ensures you have compatible, high-quality components ready to go. Our EJ25 Subaru Short Block Installation Kit, for example, comes with all the crucial gaskets you'll need for a perfect seal. This includes Genuine OEM head gaskets, intake manifold gaskets, and exhaust manifold gaskets. Using fresh, correct gaskets is critical for preventing leaks and ensuring your engine performs at its peak. Piecing these items together yourself can be a hassle, so a comprehensive kit lets you focus on the build itself, knowing you have the right parts on hand.

Must-Have Measurement Tools

Engine building is a game of precision, and you can't guess your way through it. Accurate measurements are absolutely vital, so this is not the place to cut corners. You will need a good set of digital or dial calipers, a micrometer for measuring bearing clearances and journals, and a set of feeler gauges. These tools allow you to verify that every component fits within the manufacturer's specifications. Remember the golden rule: measure twice, assemble once. Taking the time to confirm every clearance and dimension before final assembly is what separates a reliable, high-performance engine from one that fails prematurely. This detailed engine assembly guide shows just how critical these measurements are.

Necessary Cleaning Supplies

Your new short block deserves a spotless home. Any dirt, grime, or leftover debris can cause catastrophic damage to your engine, so a thorough cleaning is mandatory. Before you start, stock up on some key supplies. You’ll want a good degreaser, several cans of brake cleaner, and plenty of lint-free cloths or shop towels to wipe everything down. Some builders use kerosene or even boiling water to ensure parts are perfectly clean. A clean workspace is just as important as clean parts. Lay down some cardboard or a clean tarp to keep components off the floor. Taking this extra time for cleaning is one of the most important steps to protect your engine and ensure its longevity from day one.

Prepare Your Workspace

Before you even think about unboxing that beautiful new short block, let's talk about where the magic is going to happen. A successful engine build is as much about preparation as it is about execution. Taking the time to set up a clean, organized, and safe workspace isn't just a nice-to-have; it's the foundation for a smooth installation and a reliable engine. A cluttered or dirty environment is a recipe for frustration and costly mistakes. Think of it this way: professional shops maintain pristine conditions for a reason. Let’s get your space ready so you can work efficiently and confidently, ensuring every component goes together perfectly.

Create a Clean Work Environment

This is the golden rule of engine building: everything must be spotless. A single grain of sand or a metal shaving can destroy bearings, score cylinder walls, or clog oil passages, leading to catastrophic failure down the road. Start by thoroughly cleaning your garage or workshop. Sweep, vacuum, and wipe down all surfaces to remove dust and debris. When you start working, keep your hands and tools clean. I like to have a roll of shop towels and some brake cleaner handy at all times. As you disassemble the old engine, clean each part you plan to reuse before setting it aside. This meticulous approach is standard for professional engine tuning services and is absolutely essential for your build.

Key Safety Precautions

Your safety and the integrity of your engine are top priorities. Always wear safety glasses and gloves. An engine block is heavy and has plenty of sharp edges, so protect yourself. Beyond personal safety, you need to protect your investment. This means being precise. Adopt the "measure twice, install once" mindset. Before you begin, make sure you have a complete set of quality tools, including a calibrated torque wrench, feeler gauges, and a piston ring filer. Having the right tools prevents guesswork and ensures every bolt is tightened to spec and every clearance is perfect. This isn't the time to "make it work" with the wrong tool; precision is key to getting the most out of your new performance parts.

Organize Your Parts

An engine is a complex puzzle with hundreds of pieces. Keeping them organized is crucial for a stress-free reassembly. As you remove bolts, brackets, and components, place them in labeled plastic bags or sectioned organizers. This is especially important for internal parts; pistons, rods, and bearing caps must go back to their original locations and orientations. A simple mistake here can be disastrous. When you’re integrating new Subaru WRX upgrades, lay them out alongside the old parts to visually confirm you have everything you need. A little organization upfront saves hours of searching for that one specific bolt later on.

Document Your Process

Your smartphone is one of the most valuable tools in your arsenal. Take photos and videos of everything before and during disassembly. Document how brackets are mounted, how the wiring harness is routed, and where every vacuum line connects. These images will be your personal instruction manual during reassembly. I also recommend keeping a small notebook to write down key measurements, torque specs you've completed, and any notes or observations you make along the way. This logbook is not just for the current build; it’s an invaluable record for future maintenance and troubleshooting. Trust me, you’ll be glad you have it.

Your Pre-Installation Checklist

Before you even think about grabbing a wrench, let’s talk about prep work. A successful engine build is 90% preparation and 10% assembly. Taking the time to go through this checklist will save you from costly mistakes and ensure your new EJ25 short block performs exactly as it should. Rushing this stage is the fastest way to turn a dream upgrade into a frustrating and expensive project. Think of this as setting the foundation for a powerful and reliable engine. Every step you complete here is an investment in your Subaru’s future performance and your own peace of mind. From inspecting your parts to ensuring your workspace is spotless, these procedures are non-negotiable for a professional-quality installation.

Inspect Every Component

The moment your parts arrive, lay everything out and give it a thorough inspection. Even brand-new components can be damaged during shipping or have rare manufacturing defects. Compare every item to your packing list to confirm you have everything you need. This is your first and best chance to catch a problem. Check for any dings, scratches, or imperfections on machined surfaces. It’s far easier to address an issue with a supplier now than when you’re halfway through the build. Make sure all the performance parts you've gathered are the correct ones for your specific build goals and vehicle model.

Prep the Engine Bay

Your engine bay needs to be impeccably clean before the new short block goes in. Any dirt, grime, or leftover debris can easily find its way into your new engine and cause major damage. Start by thoroughly degreasing the entire area. Scrape off any old gasket material from mating surfaces and use a vacuum to remove any loose particles. Remember the golden rule: your workspace and all your parts must be spotless. Dirty hands or a contaminated environment can compromise your entire build. A clean engine bay not only prevents contamination but also makes it much easier to spot any potential leaks after the installation is complete.

Take Critical Measurements

Engine building is a game of precision, and there’s no room for guesswork. You must measure everything carefully and then measure it again before anything is permanently installed. This is where you verify that all clearances are within the manufacturer's specifications. Use tools like Plastigage to check the oil clearance for the rod and main bearings. You’ll also need to check piston ring end gaps, crankshaft end play, and other critical tolerances. If you’re not confident in this step, it’s worth seeking professional help. Proper engine tuning and services rely on these initial measurements being perfect.

Final Cleaning Procedures

The final and most critical rule of engine assembly is to keep everything obsessively clean. Every single component that goes into your engine must be cleaned until a white, lint-free cloth comes away spotless. Use a combination of degreaser, hot water, and compressed air to ensure all oil passages, bolt holes, and surfaces are free of any contaminants. Even a microscopic piece of grit can score a bearing or clog an oil passage, leading to catastrophic engine failure. This isn't the time to cut corners. Your diligence here will directly impact the performance and longevity of your new engine.

The Installation Guide

With your workspace prepped and your components inspected, it's time to get to the heart of the project: installing your new EJ25 short block. This is where precision and patience really pay off. Rushing through these steps can lead to major headaches down the road, so take your time and double-check your work as you go. Following a methodical process ensures every part fits perfectly, creating a solid foundation for a powerful and reliable engine. We'll walk through the core assembly steps, from removing the old hardware to torquing the final bolts. This guide will give you the sequence and the key considerations for each step, but always have your Subaru Factory Service Manual (FSM) open for the exact specifications for your model. Think of the FSM as your co-pilot for this build—it has the final say on every measurement and torque value. Getting this part right is what separates a good build from a great one, ensuring your engine is ready to handle everything from daily drives to track days.

Step 1: Remove Old Components

Before the new short block can go in, the old one has to come out. Start by safely detaching the engine from the vehicle and securing it on a reliable engine stand. From there, you’ll begin the teardown process, carefully removing the heads, intake manifold, and other external components you plan to reuse. This is a great time to label everything and take photos to remember where everything goes. Keep your workspace organized as you strip the old block down, setting aside parts for cleaning and inspection. A clean slate is essential for a successful build.

Step 2: Position the New Short Block

Now for the exciting part. Carefully mount your new, clean EJ25 short block onto the engine stand. Make sure it’s securely fastened and stable before you begin adding components. This gives you 360-degree access for the assembly process, which is crucial for getting everything right. Proper positioning prevents you from having to awkwardly reach over or under the block, reducing the risk of dropping a tool or component into your pristine engine. This stable base is your canvas for building a high-performance Subaru engine that's ready for whatever you throw at it.

Step 3: Install the Bearings

Installing the main and rod bearings is a task that demands absolute precision. Start by ensuring the block and crankshaft surfaces are spotless—even a tiny piece of debris can cause catastrophic failure. Gently place the bearing halves into their respective saddles in the block and on the connecting rods. Use a high-quality assembly lube on all bearing surfaces. Before the final assembly, you must check your oil clearances with Plastigauge to confirm they are within the specifications outlined in the Subaru Factory Service Manual (FSM). Don't skip this; it's your best insurance against premature engine wear.

Step 4: Assemble Pistons and Rings

With the bearings in place, you can move on to the pistons and rings. Carefully install the piston rings onto the pistons, making sure the gaps are oriented correctly according to the FSM. A ring expander tool will prevent you from accidentally bending or breaking a ring. After lubricating the cylinder walls and piston skirts with engine oil, use a piston ring compressor to gently guide each piston assembly into its cylinder. This step connects all the essential performance parts that will bring your engine to life and deliver the power you're looking for.

Step 5: Follow Torque Specifications

Properly torquing your fasteners is not just a recommendation—it's a requirement for a reliable engine. Every bolt, from the connecting rod caps to the main case bolts, has a specific torque value and sequence. Always use a calibrated torque wrench and follow the multi-step torque-to-yield procedures detailed in the FSM. Skipping this step or guessing the values can lead to warped components, fluid leaks, or complete engine failure. Getting the torque right ensures your engine will handle the power you plan to throw at it for years to come.

Assemble Key Components

With your workspace prepped and your short block ready, it’s time to start assembling the core components. This is where your attention to detail really pays off. Each part you install builds upon the last, creating the foundation for a powerful and reliable engine. Rushing through these steps can lead to major headaches down the road, so take your time and double-check your work. Having high-quality performance parts is crucial, but their potential is only realized through meticulous assembly. This is the phase where your engine truly comes to life, transforming from a collection of precision-machined parts into the heart of your Subaru. From the crankshaft to the timing components, every piece has a specific role, and getting the assembly right ensures they all work together in perfect harmony.

Install the Crankshaft

The crankshaft is the backbone of your engine, converting the linear motion of the pistons into rotational force. Proper installation is non-negotiable. Before you even think about dropping it in, you need to measure the block and check all your clearances with precision tools like a bore gauge and micrometer. This ensures there’s just enough space for a lubricating film of oil to form between the bearings and the crank journals. When installing the piston rings, you may need to file them down slightly to achieve the perfect end gap. This step prevents the rings from butting together as they expand with heat, which could cause catastrophic damage to your cylinder walls and pistons.

Assemble the Connecting Rods

Connecting rods link the pistons to the crankshaft, and assembling them correctly is critical for a balanced and smooth-running engine. To do this right, you’ll need the proper tools. A ring filer is essential for setting the correct piston ring end gap, while a ring expander helps you install the rings onto the pistons without bending or breaking them. Using the right tools prevents damage and ensures every component is aligned and fitted correctly. This precision is what allows your engine to handle the increased power from your Subaru WRX upgrades and rev freely without risking component failure. Take your time to ensure every rod is assembled to spec.

Set Up the Oil System

Your engine’s oil system is its circulatory system, and a flawless setup is vital for longevity and performance. A key step during assembly is installing the block O-ring set. These small but mighty seals fit between the oil and water galleries of the block halves, preventing cross-contamination and leaks. If these O-rings fail, you could end up with coolant in your oil or vice-versa, leading to rapid engine failure. Ensuring a perfect seal here maintains stable oil pressure, which is essential for lubricating all the critical moving parts you’ve so carefully assembled. Don’t overlook this detail; it’s a simple step that protects your entire investment.

Install Timing Components

Installing the timing components is one of the final—and most critical—steps in assembling your short block. This is where you synchronize the rotation of the crankshaft and camshafts, ensuring the valves open and close at the correct time. Pay close attention to the alignment of the heads and the position of the timing belt. Many builders run into trouble here, so it’s wise to double- and even triple-check that all timing marks are perfectly aligned before you release the tensioner. A mistake of even one tooth can result in bent valves and catastrophic piston damage. Once everything is assembled, a professional tune from our engine tuning services will ensure your engine’s timing is optimized for peak performance.

Perform Quality Checks and Tests

You’ve done the heavy lifting, and your new EJ25 short block is almost ready to roar. But before you turn the key, it’s time for the most critical phase: quality control. These final checks and tests are what separate a reliable, high-performance build from one that ends in heartbreak. Rushing through this stage can undo all your hard work, so take your time and be meticulous. This is where you confirm that every component is perfectly seated, properly lubricated, and ready for action. Think of it as the final inspection before your engine is cleared for takeoff.

Take Final Measurements

You’ve heard the old saying, "measure twice, cut once." In engine building, it’s more like "measure three times, then measure again." Before you seal everything up, grab your calipers and micrometers for one last round of checks. Re-measure everything from piston-to-wall clearance to deck height. This is your last chance to ensure all your performance parts fit together with the precision they were designed for. It might feel tedious, but confirming these numbers now prevents catastrophic failures later. Remember, even a tiny discrepancy can cause major issues down the road, so always re-measure before doing anything permanent. This step ensures your engine will perform reliably under pressure.

Verify Clearances

Proper clearances are the lifeblood of your engine, creating the space needed for oil to lubricate moving parts. This is where a tool like Plastigage becomes your best friend. Use it to verify the oil clearance for your rod and main bearings, and don't forget to check the side gap and thrust clearance. You also need to confirm your piston ring end gaps are within spec for your specific build, which sometimes requires carefully filing them down. Checking all the clearances is a non-negotiable step. It ensures that every component moves freely without binding or creating excessive friction, which is essential for preventing premature wear and engine seizure.

Run the Pre-Start Checklist

Before you even think about starting the engine, you need to get oil flowing. This is called pre-lubing or priming the engine, and it’s a vital step to protect your new bearings and surfaces from a dry start. The easiest way to do this is to remove the fuel pump fuse and the spark plugs. With those out, you can turn the crankshaft a few times by hand or with the starter. This will allow the oil pump to circulate oil throughout the entire engine, coating every critical component before it faces the stress of combustion. This simple procedure is one of the best things you can do to ensure a long and healthy life for your new build.

Follow Break-in Procedures

Your engine’s long-term health depends heavily on how you treat it in its first few hundred miles. A proper break-in procedure is essential for seating the piston rings against the cylinder walls, creating a tight seal for optimal compression and oil control. This process involves varying the engine speed and load, avoiding constant RPMs and full-throttle acceleration. Just as important is getting a professional tune. A skilled tuner will ensure your air-fuel ratios and timing are perfect for your new setup. As the experts say, if an engine is assembled, installed, and driven correctly, it will last. A proper break-in and professional engine tuning services are key parts of that equation.

Avoid These Common Mistakes

Installing a new short block is a major milestone for your Subaru, but a few simple missteps can turn your dream upgrade into a frustrating setback. Even seasoned mechanics can overlook small details during a complex build. Paying close attention to the common pitfalls is just as crucial as following the installation steps. Getting it right the first time saves you from costly repairs and gets you back on the road—or the track—sooner. This section covers the most frequent errors we see and gives you actionable advice to sidestep them, ensuring your engine build is smooth, successful, and ready to perform. From keeping your components spotless to double-checking your measurements, these tips will help you build with confidence.

Top Installation Errors to Sidestep

One of the most critical moments is installing the heads and aligning the timing components. A common red flag appears when the motor can't be turned over by hand past a certain point. This almost always signals a misalignment or an installation error that could lead to catastrophic valve and piston damage. Before you even think about starting the engine, always rotate the crankshaft by hand for several full rotations. It should move smoothly without any binding or hard stops. If you feel any resistance, stop immediately and re-check your timing marks and component installation. Getting this right is fundamental to the health of your new engine and the performance of your Subaru WRX upgrades.

How to Prevent Contamination

The golden rule of engine building is to keep everything impeccably clean. As one expert builder puts it, "You should clean parts until your rag or paper towel stays white." Any speck of dirt, metal shaving, or debris left on bearing surfaces or in oil passages can cause serious damage once the engine is running. Before assembly, thoroughly clean the engine block, crankshaft, and all related parts. Use lint-free towels and appropriate solvents. Work in a clean, organized space to minimize the risk of airborne contaminants. This meticulous approach ensures that your high-quality performance parts can function exactly as designed, free from the threat of premature wear.

Address Alignment Issues

A short block installation is a precision job, not a simple swap. You have to measure everything to ensure perfect fitment and function. This includes checking block clearances, measuring bearing tolerances, and filing piston rings to the correct gap for your specific application. Skipping these steps can lead to low compression, excessive oil consumption, or even complete engine failure. Taking the time to measure twice and assemble once is non-negotiable. If you're not equipped or comfortable with these precise tasks, it's wise to consult professional engine tuning services to guarantee every component is perfectly matched and aligned for optimal performance and longevity.

Avoid Torque Wrench Mistakes

Every bolt on your engine has a specific torque value for a reason. It ensures the right amount of clamping force without stretching the bolt or damaging the components. Using a calibrated torque wrench and following the factory torque sequence is absolutely essential. As one guide notes, every step "needs to be done with great care, lubrication, and correct bolt tightening (torque)." Under-tightening can lead to leaks or parts coming loose, while over-tightening can warp surfaces or cause bolts to fail under stress. Always use assembly lube where specified and follow the multi-stage torque procedures for critical components like head studs and main bolts. This precision is key for any build, especially for high-performance Subaru STI upgrades.

Keep Your New Engine Healthy

You’ve put in the hard work to install your new EJ25 short block, and now the real fun begins. But getting your engine installed is only half the battle; keeping it in peak condition is what ensures you’ll enjoy that power and reliability for years to come. A high-performance engine requires a proactive approach to maintenance. Think of it as a new relationship—it needs consistent attention and care to thrive. By establishing a solid maintenance routine and learning to listen to your vehicle, you can protect your investment and keep your Subaru running exactly how it was meant to. Let’s walk through the essential steps to keep your new engine healthy, powerful, and ready for the road or track.

Your New Maintenance Schedule

Sticking to a maintenance schedule is non-negotiable for a performance engine. While Subaru provides a factory-recommended schedule, your modified setup will benefit from more frequent attention. For oil changes, it's wise to shorten the interval. Instead of every 6,000 miles, consider changing your oil and filter every 4,000 miles or every four months, especially if you drive aggressively. This helps keep contaminants out of your new system. Also, keep a close eye on your timing belt and water pump. These critical components should be replaced together around the 105,000-mile mark to prevent catastrophic failure. Using high-quality performance parts for these routine jobs will give you extra peace of mind.

Monitor Engine Performance

Your new engine will communicate with you—you just have to learn its language. Pay close attention to how your car feels, sounds, and responds after the installation. Is the power delivery smooth? Are there any new or unusual noises? Keeping a mental baseline of normal operation will help you spot potential issues before they become serious problems. Regular check-ups are crucial for longevity. If you notice any dips in performance or changes in engine behavior, don't wait to investigate. Professional engine tuning services can also help you dial in performance and ensure all systems are working together correctly, giving you a clear picture of your engine's health.

Know the Warning Signs

Being able to identify trouble early is one of your best defenses against major engine damage. For the EJ25, there are a few common culprits to watch for. Head gasket failures can result from overheating, so keep an eye on your temperature gauge and look for signs like coolant loss or white smoke from the exhaust. Ringland failure, which is a break in the piston, often announces itself with a distinct knocking sound or a noticeable loss of power. Finally, monitor your oil levels closely. Some engines consume oil faster than others, and letting it run low can cause serious damage. If you hear knocking or feel a drop in power, check your oil immediately.

Perform Regular Inspections

Make it a habit to pop the hood and look around your engine bay regularly. You don’t have to be a master mechanic to spot a loose hose, a small leak, or a frayed belt. These quick visual checks can help you catch a problem in its earliest stages. When you combine these inspections with your knowledge of the warning signs, you create a powerful preventative maintenance strategy. If you spot an issue, address it right away. Finding the right components is straightforward, whether you're looking for simple replacements or considering further Subaru WRX upgrades. Acting quickly will save you time, money, and headaches down the road.

Related Articles

Frequently Asked Questions

Can I reuse my old cylinder heads on a new short block? Yes, you can often reuse your existing cylinder heads, but they need a professional evaluation first. Before bolting them onto your new short block, you must take them to a reputable machine shop. They will need to be inspected for cracks, cleaned, and resurfaced to ensure a perfectly flat mating surface. This is critical for the new head gaskets to seal properly and prevent leaks that could ruin your new engine.

What's the difference between a short block, a long block, and a crate engine? Think of it in terms of completeness. A short block, like the EJ25 we've discussed, is the assembled bottom half of the engine—the block, crank, pistons, and rods. A long block includes the short block plus the cylinder heads, camshafts, and valvetrain. A crate engine is the most complete option, typically arriving as a fully assembled engine from the oil pan to the valve covers, ready to be installed.

Do I absolutely need a professional tune after the installation? Yes, a professional tune is not optional; it's a requirement for engine health and performance. Your Subaru's factory computer is programmed for the original engine's specifications. A new short block, especially one built for performance, changes the engine's characteristics. A professional tune adjusts the fuel, ignition timing, and other parameters to match your new setup, ensuring it runs safely and makes the power you built it for.

How critical is the engine break-in period? The break-in period is arguably the most important time in your new engine's life. This is when the piston rings properly seat against the cylinder walls, which is essential for creating strong compression and preventing excessive oil consumption down the road. Following a careful break-in procedure—varying engine speed and avoiding heavy loads—ensures your engine will be healthy and powerful for years to come.

Is this a realistic DIY project for a beginner? An engine build is an advanced project that requires a high level of precision and specialized tools. If you're not comfortable using tools like micrometers and torque wrenches or checking critical clearances, this might not be the best first project. It's a rewarding job, but a small mistake can be very costly. If you're new to this level of work, consider partnering with an experienced friend or a professional shop to ensure it's done right.