How to Choose the Best Built EJ25 Short Block

Share

There are two types of Subaru owners who upgrade their engines: those who do it proactively, and those who do it after a catastrophic failure. Waiting for your stock engine to fail under pressure leads to a sudden, expensive, and frustrating repair. Building your engine proactively, however, turns a potential disaster into a planned, exciting upgrade. It’s about making a strategic choice to create a reliable foundation before you push your car to its limits. The difference is choosing a built EJ25 short block on your own terms, giving you the confidence to pursue your power goals without worrying about what might break next.

Key Takeaways

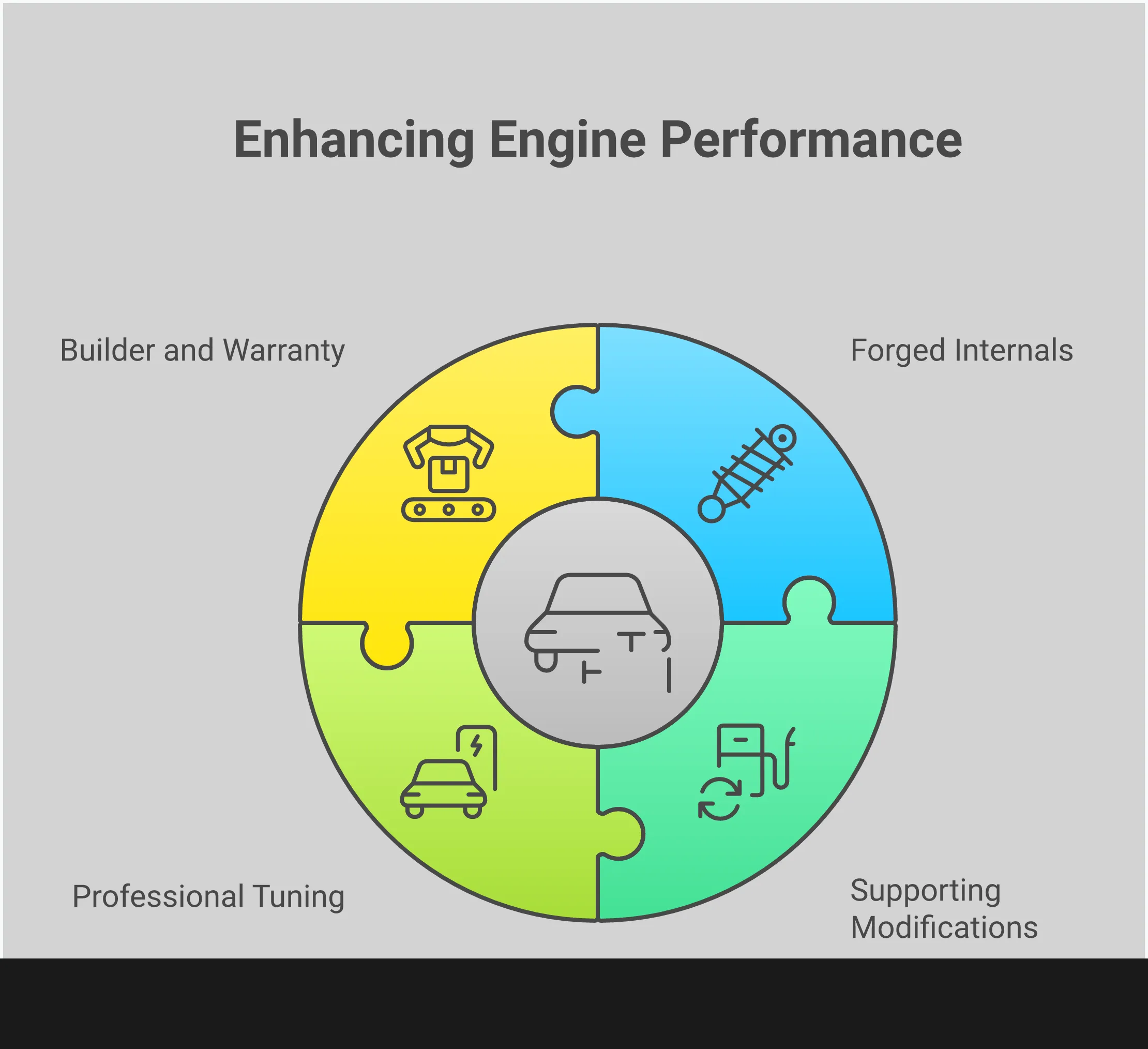

- Prioritize a Forged Foundation: The stock EJ25 is the weakest link in a performance build. A built short block with forged internals is the essential foundation that provides the strength and reliability needed to handle increased power safely, making it a non-negotiable step for serious upgrades.

- Budget for Supporting Mods and a Tune: A built block cannot reach its potential alone. Your final power output is determined by supporting components, so you must budget for a larger turbo, an upgraded fuel system, and cooling improvements, all unified by a professional engine tune.

- Evaluate the Builder, Not Just the Block: The quality of a built engine is defined by the builder's assembly process and component choices. Look for builders with a proven track record and prioritize one that offers a comprehensive warranty—it’s the clearest sign of their confidence in the product.

Understanding the Subaru EJ25 Engine

The Subaru EJ25 engine is an icon in the performance world, powering legendary models like the WRX and STI from 2002 to the present. Its distinct boxer layout and signature rumble make it a favorite among enthusiasts who want a platform with a high performance ceiling. While the engine’s design offers some inherent advantages for handling and balance, the stock components have well-known limitations, especially when you start adding significant power. Understanding these strengths and weaknesses is the first step in planning a reliable build that can handle the demands of the track, trail, or spirited street driving. It’s about knowing what makes the EJ25 great and what needs to be addressed to make it truly bulletproof.

The Boxer Advantage: Why Subaru's Design is Different

At the heart of what makes a Subaru feel like a Subaru is its boxer engine. Unlike V-type or inline engines, the EJ25’s pistons are horizontally opposed, moving toward and away from each other like a boxer throwing punches. This flat layout gives the engine a lower profile, allowing it to sit deep in the engine bay and creating a significantly lower center of gravity for the vehicle. This is a key reason why models like the Subaru STI are celebrated for their exceptional handling and cornering stability. The design is also naturally balanced, as the opposing piston motions cancel out vibrations, resulting in smoother operation and a more responsive feel without heavy counterweights.

Common Failure Points in Stock EJ25 Engines

While the boxer design is brilliant, the stock EJ25 engine has several known vulnerabilities that tend to surface when owners begin modifying their cars for more power. These aren't necessarily flaws in a daily driver, but they become critical failure points under the increased stress of higher cylinder pressures, heat, and RPMs. The most common issues are related to the head gaskets, piston ringlands, and the oiling system. Addressing these weak points proactively is the difference between a reliable, high-output build and one that ends with a catastrophic failure. For any owner of a Subaru WRX or STI planning for serious upgrades, reinforcing these areas is not just recommended—it's essential.

Head Gasket and Ringland Issues

Head gasket failure is one of the most notorious issues for the EJ25. The stock gaskets can struggle to maintain a seal under the high cylinder pressures created by increased turbo pressure, leading to leaks between the cylinder and coolant passages. This often results in overheating, coolant consumption, and white smoke from the exhaust. Equally common and far more destructive is piston ringland failure. The ringlands are the small metal sections on the piston that hold the piston rings in place. In stock cast pistons, these areas are brittle and can crack under detonation or pre-ignition, causing a sudden loss of compression and severe engine damage that requires a complete rebuild.

Oil Starvation from the Stock Oil Pickup

One of the most insidious failure points in the EJ25 is the stock oil pickup tube. This component is responsible for drawing oil from the pan and feeding it to the oil pump. Unfortunately, the factory part is known to develop cracks at its brazed joint due to engine vibrations over time. When a crack forms, the oil pump begins to suck in air along with oil, causing a drop in oil pressure and starving the engine's bearings of lubrication. This failure often happens without warning and can destroy an engine in seconds. Upgrading to a sturdier, properly welded oil pickup is one of the most important reliability modifications you can make to protect your investment in performance parts.

Standard Maintenance and Lifespan

Despite its known weaknesses under stress, a stock EJ25 engine that is properly cared for can be quite durable, often lasting well over 150,000 miles. The key is diligent and consistent maintenance. This means using high-quality synthetic oil, adhering to regular change intervals, monitoring coolant levels, and listening for any unusual noises that could signal a developing problem. The engine's longevity is a testament to its solid core design, but its reliability is directly tied to how it's treated. For enthusiasts, this means recognizing that as soon as you begin modifying for more power, you are operating outside the factory's reliability window, and both your maintenance schedule and component choices must be adjusted accordingly.

Built vs. Stock: Why Upgrade to a Built EJ25 Short Block Superior?

If you’re planning to push your Subaru past its factory limits, the stock EJ25 short block will eventually become your weakest link. While it’s a capable engine for daily driving, the original components, particularly the pistons and connecting rods, weren’t designed to handle the stress of high boost and aggressive tuning. This is where a built short block comes in. Think of it less as a replacement and more as a fundamental upgrade to your vehicle’s core.

Upgrading to a built short block with forged internals creates a durable foundation that can safely handle the stress of significantly higher horsepower. It’s about building a reliable powerhouse that won’t leave you stranded after a spirited track day or a demanding off-road climb. By swapping out the factory-grade parts for components engineered for strength, you’re not just preparing your engine for more power—you’re investing in its long-term health and performance. This proactive step is what separates a high-performance build from a ticking time bomb.

What's Inside? Stock vs. Built Components

The main distinction between a stock and a built EJ25 short block lies in the quality and strength of the internal components. Subaru’s factory engines use cast aluminum pistons and connecting rods, which are cost-effective for mass production but prone to failure under increased cylinder pressure. A built EJ25 short block is more than just a collection of high-performance parts; it’s an insurance policy against catastrophic engine failure. It replaces those weaker cast parts with robust, forged alternatives that are specifically designed to withstand the intense forces generated by a modified, high-output engine. This foundational change is what allows you to safely pursue your power goals.

How Built Blocks Handle More Power

At its core, a built short block replaces stock parts with high-strength, forged internals designed to handle significantly more power and stress, reliably. The most critical upgrades are the pistons and connecting rods. Forged pistons are denser and far more resistant to detonation than their cast counterparts. They are paired with forged connecting rods—often in an H-beam or I-beam design—that prevent bending or breaking under high torque. Many builds also include a stronger, nitrided crankshaft and upgraded bearings to reduce friction and improve durability. These carefully selected performance parts work together to create an engine that can take a beating and keep performing.

Why Forged Internals Are Essential for Durability

The term "forged" refers to the manufacturing process. Unlike casting, where molten metal is poured into a mold, forging involves shaping metal under extreme pressure. This process creates a much denser and more uniform grain structure, eliminating the microscopic voids that can lead to cracks in cast components. Forged internals are engineered for strength and reliability, making them essential for high-performance applications where the engine is subjected to increased stress. When you increase boost or refine your tune, these stronger components ensure your engine can handle the pressure without failing, giving you the confidence to push your vehicle to its true potential with proper engine tuning services.

What Is a Closed Deck and Why Do You Need It?

For those chasing serious horsepower, a closed deck modification is a crucial upgrade. The stock EJ25 block has a "semi-closed" deck, which leaves the tops of the cylinder walls partially unsupported. Under extreme pressure from high boost, these walls can flex or even crack. A closed deck design reinforces this area by adding metal supports, effectively bracing the cylinder walls. This modification dramatically increases the block’s rigidity and strength, making it capable of handling power levels well beyond what a stock or even a standard built block can manage. It’s a must-have for dedicated track cars and high-power drag builds, providing the ultimate foundation for extreme Subaru STI upgrades.

Finding the Best Built EJ25 Short Block for You

Once you’ve decided to go with a built short block, the next step is choosing the right builder. The market has several reputable options, each with different strengths, power ratings, and price points. Understanding this landscape will help you find the perfect match for your Subaru and your performance goals. Let's look at what sets different builders apart, what you can expect to invest, and why a warranty is non-negotiable.

Why Choose a Crawford Performance Block?

Think of a built EJ25 short block as more than just a performance upgrade; it’s an insurance policy against catastrophic engine failure. When you’re pushing for more power, the stock internals are the first weak point. Upgrading to a built short block with forged internals creates a durable foundation that can safely handle the stress of significantly higher horsepower and aggressive tuning. At Crawford Performance, we engineer our blocks to provide a reliable core for your build, whether you're aiming for a responsive daily driver or a dedicated track machine. Our precision assembly and high-quality performance parts ensure your engine is ready for whatever you throw at it.

How Do Other Top Brands Compare?

While we stand by our builds, it’s helpful to know the other players in the field. For those looking for a factory-fresh option, Subaru OEM short blocks are a solid choice. They are built to the same high standards as the engine that came with your car, offering reliability for stock or lightly modified setups. On the high-performance end of the spectrum, companies like IAG Performance are also well-known for building blocks capable of handling extreme power levels. Each builder has its own philosophy and component preferences, so it’s worth researching to see whose approach aligns best with your project.

Exploring Your Options: Pre-Built, OEM, and Custom Services

When upgrading your engine, you have a few paths to consider, each with its own set of trade-offs. Pre-built short blocks, like the ones we assemble at Crawford Performance, offer a reliable, proven package of high-quality performance parts designed to handle specific power levels. This option saves you the time and complexity of sourcing individual components. Alternatively, you can opt for an OEM high-performance block, which provides a factory-engineered solution for a moderate power increase. For those with very specific goals, custom engine building services allow you to hand-pick every component, though this requires deep technical knowledge and a larger budget. Your choice depends on your power targets, budget, and how hands-on you want to be with the process.

The Subaru Type RA Short Block

For enthusiasts seeking a reliable upgrade without committing to a fully forged aftermarket build, the Subaru Type RA short block is a fantastic choice. This is an OEM component straight from Subaru, featuring stronger, factory-balanced internals compared to the standard EJ25 block. It’s essentially a factory-built stage one upgrade, designed to offer improved durability for spirited driving and mild power increases. While it’s a significant step up from the stock block in your WRX or STI, it's important to remember its limitations. The Type RA is not designed for the extreme cylinder pressures of high-horsepower builds. If your goals include a large turbo and aggressive tuning, a forged block remains the necessary foundation for long-term reliability.

Understanding Closed Deck Services and Core Fees

As you explore high-performance builds, you'll encounter terms like "closed deck" and "core fees." A closed deck modification is a service that reinforces the top of the engine block, adding structural support around the cylinders. This is critical for high-boost applications, as it prevents the cylinder walls from flexing or cracking under extreme pressure—a common failure point in powerful builds. Additionally, most engine builders charge a core fee. This is a refundable deposit paid on top of the price of your new block. It ensures that you send your old, usable engine block (the "core") back to the builder. This practice allows builders to maintain a supply of blocks to build upon, keeping the process efficient and more affordable for everyone.

What Should You Expect to Pay?

A built short block is a significant investment, and prices can vary widely based on the components used and the power level the block is designed to handle. For perspective, you can find entry-level built blocks on the market starting around $4,000, rated for about 500 horsepower. For serious builds aiming for 1,000 horsepower or more, prices can climb to $18,000 or higher. The cost directly reflects the quality of the internals and the precision of the machine work. When planning your budget, remember that the block is the foundation, and its cost should align with your ultimate power goals for your Subaru WRX or STI.

Does Your Built Block Come with a Warranty?

A warranty is your single best indicator of a builder's confidence in their work. It’s a promise of quality and a safety net for your investment. While OEM short blocks come with a standard factory warranty, the terms for aftermarket built blocks can differ greatly between builders. This is an area where Crawford Performance stands out. We back our engines with a 12-month/12,000-mile warranty, one of the most comprehensive in the industry. This peace of mind allows you to push your vehicle's limits, knowing that the heart of your build is protected by the people who engineered it.

Getting the Most From Your New Built Block

Installing a built short block is a major step toward building a powerful and reliable Subaru, but it’s not the final one. Think of the built block as the strong foundation for your house. It’s essential, but you still need the right framework, plumbing, and electrical systems to make it a functional home. Similarly, your new engine needs a team of supporting components and a precise tune to deliver the performance you’re after. Simply dropping a built block into a stock car won't get you very far. To truly get the most out of your investment, you need to create a balanced system where every part works together. This means looking at your fuel delivery, air intake, cooling, and, most importantly, the engine's calibration. Planning for these additional needs from the start ensures you build a cohesive setup that is both powerful and dependable for the long haul, whether you're on the track or a backcountry trail.

How Much Power Can You Really Make?

This is the question on every enthusiast's mind. While a built EJ25 short block can handle immense power, the final number on the dyno sheet depends on your entire setup—turbo, fuel system, and tune. Instead of focusing on a specific horsepower goal, it’s better to think of a built block as an insurance policy against catastrophic engine failure. The forged internals create a durable foundation that can safely handle the stress of aggressive tuning and significantly higher output than a stock block. It gives you the headroom to push your Subaru WRX or STI further without worrying about ringland failure or other common issues. Your power potential is ultimately limited by your supporting mods, not the block itself.

Stock vs. Built Engine Power Limits

To understand the need for a built block, it helps to know the limits of the stock EJ25. The factory engine is generally considered reliable up to about 300 wheel horsepower (whp). Beyond that, you’re entering risky territory where the stock cast pistons and connecting rods become a liability. A basic built block, featuring upgraded forged pistons, raises the safety net to around 400 whp, which is a sweet spot for many street-driven Subaru STI builds. For those aiming higher, a more comprehensive build with stronger connecting rods, and potentially a closed deck modification, can reliably support 500-600 whp and beyond. Each tier represents a significant increase in durability, allowing the engine to handle more boost and a more aggressive tune without failing.

Upgrade Paths for Different Horsepower Goals

Your upgrade path should be guided by your goals and budget. For a reliable 400 whp daily driver, a built short block with forged pistons is your starting point. This provides the necessary strength without over-investing in components you may not need. If your sights are set on 500 whp or more for track days or serious competition, your build needs to be more robust. This means investing in a block with stronger I-beam or H-beam connecting rods and considering a closed deck for maximum cylinder support. Remember, the block is just one piece of the puzzle. Achieving these power levels requires a holistic approach, including a larger turbo, an upgraded fuel system, and professional engine tuning services to tie it all together safely.

What Other Parts Do You Need to Upgrade?

A built block is only as strong as its weakest link. To support the increased power potential, you need to upgrade several other key systems. Your fuel system is the first stop; larger injectors and a high-flow fuel pump are necessary to deliver enough fuel to prevent a lean condition, which can destroy an engine. Next, consider your turbocharger, as the stock unit will quickly become a bottleneck. A larger turbo needs a more efficient intercooler and a free-flowing exhaust to perform its best. Don’t forget about cooling—an upgraded radiator and an external oil cooler will help manage the extra heat generated by a high-horsepower engine, ensuring consistent performance and protecting your investment in high-quality performance parts.

Critical Oiling System Upgrades

The Subaru EJ engine's oiling system is its Achilles' heel, and this weakness is only amplified in a high-performance build. To protect your investment, several oiling upgrades are non-negotiable. Start with an upgraded oil pickup tube; the stock one is notoriously prone to cracking, which leads to instant oil starvation and catastrophic engine failure. Pair this with a high-capacity, baffled oil pan, which uses internal gates to keep oil surrounding the pickup during hard cornering and acceleration. Finally, an Air/Oil Separator (AOS) is essential. It prevents oil vapor from the crankcase from entering your intake, which keeps your air-fuel mixture clean and prevents detonation. These components work together to ensure your engine receives consistent oil pressure, making them a critical part of any reliable build.

Essential Cooling System Modifications

More power generates more heat, and the factory cooling system wasn't designed to handle the thermal load of a modified engine. Overheating can lead to detonation, warped heads, and other serious damage, so upgrading your cooling system is a must. The first step is a high-quality aluminum radiator, which offers superior heat dissipation and a larger coolant capacity compared to the stock unit. Complement this with silicone radiator hoses that can withstand higher temperatures and pressures without failing. For dedicated track builds or vehicles in hot climates, an external oil cooler is also a wise addition. These performance parts ensure your engine stays within its optimal temperature range, providing consistent power and long-term reliability.

Why a Professional Tune is Non-Negotiable

All the best hardware in the world won't perform correctly without a precise tune. Proper tuning is the final, critical step that brings all your modifications together and ensures your engine runs safely and efficiently. A professional tuner will calibrate your engine’s computer to optimize air-fuel ratios, ignition timing, and boost levels for your specific combination of parts. This process not only maximizes power but also protects your new built block from damage. Skipping a professional tune is like buying a race car and never taking it out of first gear. To ensure your engine performs at its peak, you need expert engine tuning services that can create a custom map tailored to your vehicle and your goals.

Your Pre-Installation Checklist

Before you hit the road, remember that a new built engine requires a careful break-in period. This process allows the new piston rings to seat properly against the cylinder walls, ensuring a good seal for optimal compression and oil control. Your engine builder will provide specific instructions, but it typically involves varying the engine RPMs and avoiding heavy loads or high boost for the first several hundred miles. Regular maintenance is also key to a long engine life. Even with a built block, you should stick to a strict schedule for oil changes using high-quality synthetic oil. Addressing any potential issues like leaks or unusual noises immediately will help protect your investment and keep your Subaru running strong for years to come.

Following Torque Specs and the FSM

When assembling your engine, the Factory Service Manual (FSM) for your specific year and model isn't just a suggestion—it's the rulebook. Every bolt has a specific torque specification for a reason. It’s the precise amount of clamping force needed to create a perfect seal without damaging parts. Over-tightening can warp surfaces or strip threads, while under-tightening can lead to leaks or catastrophic failure when a component comes loose. This is why a quality torque wrench is an essential tool for the job. Following the FSM meticulously ensures that every component, from the head studs to the oil pan, is secured correctly, protecting your investment and ensuring all your new performance parts function as a cohesive unit.

The All-Important Break-In Period

Once your engine is installed and tuned, the temptation to go for a full-throttle pull is strong, but patience during the break-in period is critical. This initial phase, typically the first 500 to 1,000 miles, is dedicated to seating the new piston rings against the cylinder walls. A proper break-in creates a tight seal, which is essential for achieving optimal compression, maximizing power, and ensuring proper oil control for the life of the engine. Your builder will provide a specific procedure, but the process generally involves varying the engine speed and avoiding constant RPMs, heavy loads, and high boost. This careful process ensures all the new components wear in together smoothly, protecting your high-performance Subaru STI engine for years to come.

How to Choose the Right Built Short Block for Your Subaru

Selecting a built short block is one of the most significant investments you'll make in your Subaru. It’s the heart of your high-performance build, so making the right choice is critical. This isn't about picking the most expensive option; it's about matching the engine's capabilities to your specific goals, budget, and driving style. A well-chosen block provides a reliable foundation for power, while the wrong one can lead to frustration and costly repairs. To get it right, you need to work through a few key considerations, starting with a clear vision for your car.

What Are Your Horsepower Goals?

Before you even look at a single part, you need to answer one question: How much horsepower are you aiming for? Your power target is the single most important factor that will guide your decision. A built EJ25 short block is more than just a collection of high-performance parts; it’s an insurance policy against catastrophic engine failure when you push beyond factory limits. A daily driver aiming for a reliable 400 WHP has very different needs than a dedicated track car shooting for 700+ WHP. Be realistic about how you use your vehicle and what you want to achieve. This will determine the strength of the internal components you need and help you and your tuner create a cohesive plan.

EJ25 vs. EJ20: Which Platform is Right for Your Build?

When planning your build, you’ll inevitably face the classic Subaru debate: EJ25 or EJ20? The USDM STI’s 2.5-liter EJ25 is loved for its low-end torque, which makes for a responsive and engaging daily driver. However, its larger bore and thinner cylinder walls make the stock version more prone to ringland failure under high boost. This is why a built EJ25 short block is so essential for reliability when adding power. On the other hand, the 2.0-liter EJ20, found in older WRX models and JDM STIs, features a "square" design with thicker cylinder walls. This architecture allows it to rev higher and handle more boost with greater reliability, though it sacrifices some of that instant, off-the-line torque. Your choice depends entirely on your goals. If you want a powerful street car with great response, a properly built EJ25 is an excellent foundation for your Subaru STI upgrades.

The Case for the JDM EJ207

For enthusiasts who prioritize high-RPM performance and OEM reliability, the JDM EJ207 engine is often seen as the holy grail. This 2.0-liter engine, sourced from Japanese-market STIs, comes from the factory with features that many builders add to their high-performance builds. Depending on the version, it includes a semi-closed deck, forged pistons, a more aggressive camshaft profile, and a higher redline, often around 8,000 RPM. This makes it an incredibly robust platform right out of the box. Swapping in an EJ207 can be a compelling alternative to building a block, as it provides a durable foundation engineered by Subaru for performance. While sourcing and installing one can be more complex, it’s a proven path for those seeking a high-revving, reliable heart for their track or street car, supported by a host of available performance parts.

How to Spot a High-Quality Build

The quality of a built short block comes down to the components and the craftsmanship. At its core, a built short block replaces stock cast parts with high-strength, forged internals designed to handle significantly more power and stress. Look for builds that feature forged pistons and connecting rods from reputable brands, as these are essential for durability under high boost. Pay attention to the details of the assembly process. A top-tier builder will use precise machining, verify all clearances are within spec, and assemble the engine in a clean, controlled environment. These details are what separate a reliable engine from one that fails prematurely.

Budgeting for More Than Just the Block

The price of the short block itself is only part of the total cost. Creating a comprehensive budget is essential to avoid surprises down the road. You’ll need to account for a host of supporting items, including a master gasket kit, new head studs, oil, coolant, and potentially a new oil pump and pan. Depending on your power goals, you may also need to factor in costs for cylinder head servicing, a stronger clutch, and other drivetrain upgrades. Finally, don’t forget professional installation and tuning, which are critical for protecting your investment and ensuring the engine performs as expected.

Will It Fit? Ensuring Compatibility

Not all EJ25 short blocks are interchangeable. Subaru has made subtle changes over the years, and ensuring compatibility with your specific model and year is a crucial final check. For example, a block designed for a 2004–2021 STI may have different requirements than one for a 2006–2014 WRX. Always double-check the product description and consult with the manufacturer to confirm fitment for your vehicle. Verifying details like compression ratio and compatibility with your specific cylinder heads will prevent major headaches during installation. This simple step ensures all your performance parts work together seamlessly.

Related Articles

Frequently Asked Questions

Do I really need a built short block for my Subaru? If you plan to stick with basic modifications like a cat-back exhaust or a simple air intake, your stock engine is perfectly capable. A built short block becomes necessary when you decide to pursue significant horsepower gains that require a larger turbo, more boost, and an aggressive tune. The stock pistons are the first point of failure in those scenarios, and a built block is the best way to create a reliable foundation for that extra power.

What's the difference between buying a pre-built block and having a shop build my original engine? A pre-built short block from an experienced manufacturer is assembled in a controlled, clean-room environment using a proven combination of parts that have been tested to work together. This process ensures consistent quality, precise clearances, and often comes with a warranty. While a local shop can certainly build your original engine, you are relying entirely on their specific expertise, and the outcome can vary. A pre-built block offers a tested and guaranteed foundation for your project.

Will a built engine change how my car feels during my daily commute? The built block itself won't dramatically alter your car's daily driving characteristics. The feel of your car is more dependent on the supporting modifications you choose. Your clutch, turbo size, and especially the quality of your tune will have the biggest impact on drivability. A well-planned build with a professional tune can feel just as smooth and responsive as a stock car during normal driving, with the power ready when you need it.

Why can't I just install the built block and worry about the tune and other parts later? Installing a built block without the right supporting parts and a professional tune is one of the fastest ways to destroy your investment. The engine is built to handle more fuel and air, and it needs a tune to tell it how to operate safely under those new conditions. Running it on a stock tune or without adequate fueling can cause lean conditions or detonation, which can damage even the strongest forged internals. The block is the foundation, not the entire house.

How does a built engine's lifespan compare to a stock one? A professionally built engine that is properly tuned and meticulously maintained can be incredibly durable, often outlasting a stock engine when subjected to high-performance use. The forged components are fundamentally stronger than the stock cast parts. However, its longevity depends entirely on the quality of the tune, the supporting modifications, and your commitment to regular maintenance with high-quality fluids. It's a high-performance component that rewards proper care.