Short Block Install Kit: What You Need to Know

Share

The last thing you want during an engine build is uncertainty. Did I buy the right gaskets? Are these head studs strong enough? Will all these parts actually work together? A complete short block install kit is designed to eliminate that stress entirely. Think of it as a comprehensive solution where every component has been selected and tested for perfect compatibility and performance. This approach lets you build a powerful engine with confidence, knowing there are no weak links. The key to that confidence is understanding exactly what's in the box. This guide will show you how each part contributes to a strong, reliable engine.

Key Takeaways

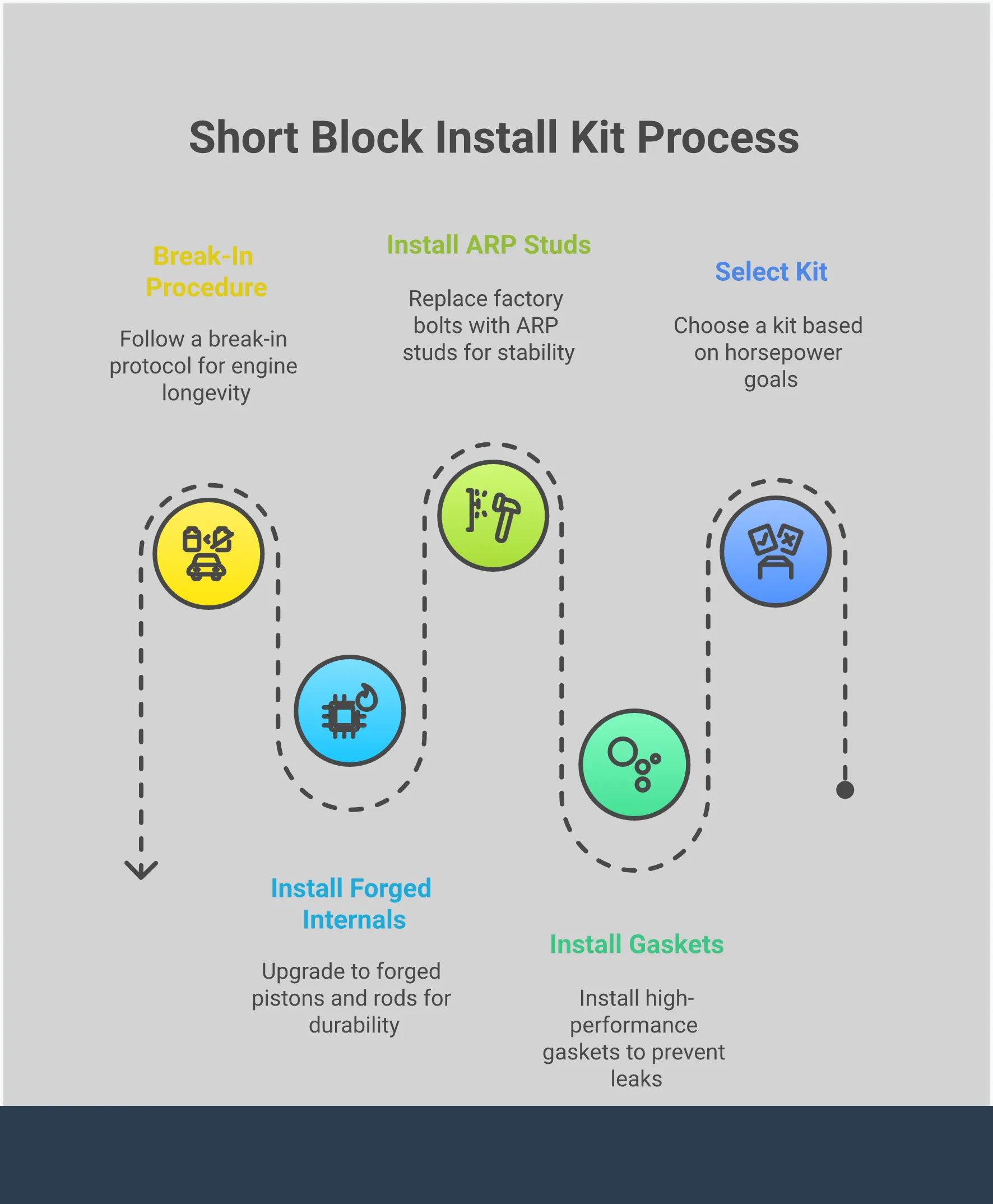

- Choose a Complete Kit for Guaranteed Compatibility: A full install kit is the smartest way to start your engine build. It eliminates guesswork by providing every gasket, seal, and fastener you need, ensuring all components are designed to work together flawlessly.

- Align Your Parts with Your Power Goals: Before buying, decide on your target horsepower. Select a kit with internal components, like forged pistons and ARP head studs, that are specifically rated to handle the stress of your intended build.

- Prioritize the Break-In and Professional Tune: The first 1,000 miles are critical for your engine's longevity. Following a strict break-in procedure and getting a professional tune are non-negotiable steps to protect your investment and ensure reliable performance.

Understanding Your Engine Options

When you decide to build or replace your Subaru's engine, you're faced with a few key choices that will define the entire project. The path you take depends on your budget, your mechanical skill, and your ultimate performance goals. Understanding the difference between a short block, a long block, and a deluxe long block is the first step in making an informed decision. Each option offers a different level of completion and customization, allowing you to choose the perfect starting point for your build, whether you're aiming for a reliable daily driver or a track-ready powerhouse.

What is a Crate Engine?

Before we get into the specifics, let's clarify a common term: the crate engine. Simply put, crate engines are new or rebuilt engines that you can purchase separately from a vehicle, and yes, they often arrive in a crate. This isn't a single type of engine but rather a category that includes various levels of assembly. Both short blocks and long blocks are considered types of crate engines. Opting for a crate engine is a popular choice for performance builds because it provides a professionally assembled foundation, saving you the time and complexity of building an engine from scratch while ensuring key components are fresh and ready for high-performance use.

Short Block vs. Long Block Engines

The main distinction in crate engines comes down to how complete they are. The two most common configurations are the short block and the long block. A short block is the foundational core of the engine, while a long block is a more comprehensive package that gets you closer to a fully operational motor. Choosing between them is a critical decision that hinges on how much of the assembly you want to handle yourself and which components you plan to customize for your specific Subaru build. This choice will set the tone for your entire project, from the parts you'll need to the time it will take to get your car back on the road.

The Short Block: A Foundation for Customization

A short block engine includes the engine block itself and the core rotating assembly: the crankshaft, pistons, and connecting rods. Think of it as the bottom end of your engine. This option is ideal for enthusiasts who enjoy customizing their build, as it provides the freedom to select your own cylinder heads, camshafts, and valvetrain components. If you have specific power goals that require a unique combination of performance parts, starting with a professionally assembled short block gives you a solid, reliable foundation to build upon without limiting your creativity or forcing you into a pre-set configuration.

The Long Block: A More Complete Solution

A long block engine includes everything in a short block, plus the cylinder heads and the complete valvetrain. This is a great choice for those who want a more direct path to completion and prefer not to get into the complexities of head assembly and valvetrain geometry. By providing a fully assembled top and bottom end, a long block significantly reduces assembly time and eliminates potential compatibility issues between core components. It's the perfect middle ground for builders who want a reliable, professionally assembled engine but still plan to add their own intake, exhaust, and accessories to finish the job.

Deluxe Long Block: The Turnkey Option

For the most straightforward installation, there's the deluxe long block, often called a turnkey engine. This is the most complete engine you can buy, arriving with nearly everything you need, sometimes including the intake manifold, fuel injectors, spark plugs, and wiring. This option is designed to minimize downtime and simplify the installation process as much as possible. While it's the most complete package, remember that any new engine build requires professional engine tuning services to ensure it runs safely and performs optimally in your specific vehicle and with your chosen modifications.

What Comes in a Short Block Install Kit?

When you're ready to build a stronger, more reliable Subaru engine, a short block install kit is your best friend. Think of it as a complete, curated package that takes all the guesswork out of sourcing the essential components for your project. Instead of spending hours hunting down every last gasket, seal, and bolt, you get everything you need in one box. This not only saves you a ton of time but also ensures every part is designed to work together perfectly, giving you peace of mind that your build is starting on the right foundation. These kits are the go-to solution for both professional builders and dedicated enthusiasts who want a seamless and successful engine assembly.

Understanding the Core Components

At its heart, a short block install kit is a comprehensive collection of high-quality parts needed to properly install a short block and assemble your engine. The goal is to provide all the necessary supporting hardware and seals that should be replaced during a rebuild. This includes items that are often overlooked but are absolutely critical for reliability and performance. By bundling everything together, these kits prevent the common mistake of reusing old, worn-out components that could compromise your brand-new build. It’s a smart, efficient way to ensure you have all the correct performance parts on hand before you even turn the first wrench.

The Gaskets and Seals You'll Need

One of the most critical aspects of any engine build is ensuring a perfect seal. A quality install kit comes packed with all the genuine, fresh gaskets you'll need. This typically includes a set of head gaskets, intake and exhaust manifold gaskets, a water pump gasket, and the main oil pump seal. These aren't just simple pieces of paper; they are precision-engineered components that prevent fluid leaks and maintain compression under extreme heat and pressure. Using new, high-quality gaskets from a kit is non-negotiable for a durable engine, especially when you're pushing for more power in your Subaru WRX or STI.

Essential Supporting Parts

A successful engine build is about more than just the big-ticket items like forged pistons and connecting rods. The smaller, supporting components are just as critical to achieving reliable power. These are the parts that ensure your engine's core systems function correctly under pressure. Think of them as the unsung heroes of your build. A comprehensive install kit addresses this by including high-quality supporting hardware that is often overlooked. From the oil pump that circulates life-giving lubrication to the spark plugs that ignite the combustion process, each piece plays a vital role. Skimping on these performance parts can undermine your entire project, leading to premature failure and costly repairs.

High-Performance Oil Pump and Seals

The oil pump is the heart of your engine, responsible for circulating oil to lubricate and cool critical moving parts. In a high-performance Subaru engine, maintaining consistent oil pressure is non-negotiable. That's why a quality install kit includes a genuine Subaru oil pump. These units are proven to provide the reliable flow needed to protect your investment, especially under the increased stress of higher horsepower. Equally important is the main oil pump seal. Reusing an old seal is a recipe for disaster, as a leak here can lead to rapid oil loss and catastrophic engine failure. A new, genuine seal ensures a perfect fit and a leak-free installation, giving you confidence that your engine's lubrication system is solid.

Spark Plugs and Filters

In a performance engine, spark plugs do more than just create a spark; they manage heat. That's why our kits include NGK One Step Colder Iridium Spark Plugs. "Colder" plugs transfer heat away from the combustion chamber more quickly, which is essential for preventing detonation in engines running higher boost or more aggressive timing. This simple upgrade is a critical safety measure for any modified Subaru STI. Similarly, a high-quality oil filter is your engine's first line of defense against contaminants. The included K&N oil filter provides superior filtration to capture harmful particles without restricting oil flow, ensuring only clean oil reaches your bearings and other sensitive components during the crucial break-in period and beyond.

Included Hardware and Fasteners

The small parts can make the biggest difference. That’s why a top-tier install kit includes upgraded hardware, most notably high-strength head studs. Many kits feature ARP head studs, which are the industry standard for a reason. Unlike factory bolts that can stretch under the high cylinder pressures of a tuned engine, ARP studs provide consistent and superior clamping force. This is your best defense against head gasket failure, one of the most common issues in high-performance Subaru engines. Investing in a kit with premium hardware ensures that your engine stays securely bolted together, no matter how hard you push it on the track or trail.

Do All Brands Offer the Same Kit?

Not all install kits are created equal. The specific components can vary depending on the manufacturer and the intended application. For example, a kit designed for a daily driven Subaru Crosstrek might differ slightly from one intended for a track-focused STI build. Reputable brands like Crawford Performance offer multiple installation kits tailored to different engine types and power goals. When choosing a kit, it’s important to select one from a trusted source that uses genuine OEM or better-quality components. This ensures you’re getting parts that fit perfectly and are built to last.

Anatomy of a Short Block Kit

When you open a short block install kit, you’re looking at the core of your engine’s future performance. Each part is chosen to work in harmony, creating a foundation that can handle more power and stress than your stock setup ever could. Understanding what these components do will help you appreciate why a quality kit is so important for your build. Let’s break down the key players inside the box and what makes them essential for upgrading your Subaru.

Engine Block: Materials and Construction

Think of the short block as the central hub of your engine. It’s not just a metal casing; it’s a pre-assembled unit that includes the crankshaft, pistons, and connecting rods. This is the rotating assembly—the parts that move to create power. A performance short block is built from the ground up to be stronger than the original. The materials are selected for durability, and the internal clearances are precisely measured to handle the increased stress from higher horsepower and torque. This solid foundation is what allows you to safely add more power through other performance parts and tuning.

The Role of Forged Pistons and Rods

Stock pistons and rods are typically cast, which is fine for daily driving. But when you start adding serious power, they become a weak link. That’s why high-quality kits include forged pistons and connecting rods. Forging compresses the metal, creating a much denser and stronger component that can withstand higher temperatures and pressures without failing. For example, Crawford SPEC JE Forged Pistons are designed specifically for the demands of racing and high-performance driving. Upgrading to forged internals is one of the most critical steps in building an engine that’s both powerful and reliable, especially for popular models like the Subaru WRX.

Crankshafts and Bearings: The Foundation

The crankshaft converts the up-and-down motion of the pistons into the rotation that turns your wheels. In a performance short block, the crankshaft is balanced to work perfectly with the specific pistons and rods in the kit. The bearings are just as important—they sit between the moving parts, reducing friction and allowing everything to spin smoothly at thousands of RPM. A quality kit comes with the crank and bearings already installed, ensuring that the clearances are perfect. This professional assembly removes the guesswork and is crucial for engine longevity, preventing premature wear and catastrophic failure down the road.

Why High-Performance Gaskets Are a Must

You can have the strongest internal parts in the world, but they won’t matter if your engine can’t hold itself together. That’s where high-performance gaskets come in. A complete install kit should include a full set of upgraded gaskets for the heads, intake, and exhaust. These are designed to create a much stronger seal than factory gaskets, preventing leaks under the extreme pressure and heat of a modified engine. This is especially important for preventing head gasket failure, a common issue in high-boost Subaru engines. A proper seal ensures you maintain compression, avoid fluid leaks, and get the most out of your engine tuning services.

The Importance of ARP Head Studs

Standard head bolts are designed to be tightened once and can stretch over time, especially in a high-horsepower engine. This stretching can lead to "head lift," where the cylinder head slightly separates from the block under pressure, causing a blown head gasket. To prevent this, premium kits include ARP head studs. These are made from a superior-strength alloy that won't stretch. They provide significantly more clamping force, locking the cylinder head firmly in place no matter how much boost you’re running. For any serious Subaru STI build, ARP head studs are considered an essential, non-negotiable upgrade for reliability.

How to Spot a High-Quality Kit

When you’re ready to invest in a short block kit, you want to be sure you’re getting your money’s worth. Not all kits are created equal, and the differences can have a major impact on your engine's performance and lifespan. A top-tier kit is more than just a collection of parts; it’s a carefully engineered system where every component is designed to work in harmony. Spotting a quality kit comes down to looking at the details—from the materials used and the precision of the manufacturing to the support provided after the sale. It’s about understanding what separates a good-enough kit from a great one. A cheap kit might save you money upfront, but it can lead to catastrophic failure down the road. On the other hand, a high-quality kit provides the reliability and strength needed to handle serious power. By paying attention to a few key indicators, you can confidently choose a kit that will serve as a solid foundation for your build, whether you're aiming for a reliable daily driver with a bit more punch or a track-ready monster built for competition. This section will walk you through exactly what to look for so you can make an informed decision.

What Manufacturing Standards to Look For

The first thing to look at is how the components are made. High-quality parts are manufactured to tight tolerances using superior materials, which is essential for handling the stress of aggressive modifications and tuning. Look for brands that are transparent about their manufacturing processes and the materials they use, like forged aluminum for pistons or chromoly steel for connecting rods. These details matter because precisely engineered performance parts create a stronger, more reliable engine that can safely handle increased power without compromising its integrity. A reputable manufacturer will always prioritize quality over cutting costs, ensuring every piece fits and functions exactly as it should.

Understand Power Handling Specifications

Before you buy, have a clear idea of your horsepower goals. A short block kit designed for 400 horsepower will have very different components than one built to handle 700 horsepower. Reputable brands will provide clear power handling specifications for their kits, letting you know what the components are rated for. This is crucial for matching the kit to your build. Choosing a kit that aligns with your performance needs ensures you aren't overspending on a setup you don't need or, worse, pushing a weaker kit past its breaking point. It’s all about building a balanced engine where every component can support your ultimate goal without becoming a weak link.

Identify Key Features for Durability

Durability is everything when it comes to engine building. When you’re examining a kit, look for features that point to long-term strength. Forged pistons and connecting rods are a great sign, as they are significantly stronger than their cast counterparts. Also, check for high-quality bearings and multi-layer steel head gaskets. These components are designed to withstand higher cylinder pressures and temperatures, which is exactly what you’ll get with performance Subaru WRX upgrades. A kit that includes these durable parts shows that the manufacturer has built it to last, giving you peace of mind when you’re pushing your car hard and expecting it to perform reliably every time.

Look for Reputable Component Brands

The brand that assembles the kit is important, but so are the brands of the individual components inside. A high-quality kit will be transparent about the parts it includes, often featuring well-respected names like ARP for fasteners or JE for pistons. Be wary of kits that use generic, unbranded parts, as their quality can be inconsistent. Reputable suppliers, like Crawford Performance, curate their installation kits with genuine OEM or superior aftermarket performance parts that are proven to work together. This ensures every component, from the main seals to the head gaskets, fits perfectly and is built to last, giving you confidence that you’re not introducing a weak link into your new engine.

Technical Details That Signal Quality

Beyond brand names, the technical specifications of the components are a clear indicator of quality. Look for manufacturers who are open about their processes and the materials they use, such as forged 4032 aluminum alloy for pistons or chromoly steel for connecting rods. High-quality parts are always manufactured to extremely tight tolerances, ensuring perfect fitment and balanced operation. These details are what separate a reliable engine from one that might fail under pressure. Precisely engineered components create a stronger, more resilient engine that can safely handle aggressive engine tuning and deliver the power you expect without compromising its integrity.

Why Break-in Requirements Are Crucial

A quality kit doesn’t just stop with the parts in the box; it also includes clear guidance for what comes next. The engine break-in period is one of the most critical phases of your build. A reputable manufacturer will provide a detailed break-in procedure designed to properly seat the piston rings and ensure all the new components mesh perfectly. They might even include specialized break-in oil. Following these instructions is essential for the longevity and performance of your new engine. This level of post-purchase support is a hallmark of a brand that stands behind its product and wants to see your build succeed for years to come.

Why Choose a Complete Install Kit?

When you’re ready to build your engine, you have two main paths: sourcing every single part yourself or opting for a complete install kit. While hunting for individual components can feel like a treasure hunt, it often leads to headaches, compatibility issues, and unexpected costs. A complete kit, on the other hand, is engineered to give you everything you need in one box, taking the guesswork out of the equation. It’s a strategic move that saves you time, money, and stress, whether you’re a seasoned mechanic or tackling your first major build. Think of it as the difference between following a detailed recipe with pre-measured ingredients versus trying to bake a cake from scratch without any instructions. One path is straightforward and reliable; the other is a gamble. By choosing a kit, you’re setting your project up for success from the very beginning, ensuring every component works together perfectly to deliver the performance you’re after. This approach is about more than just convenience; it's about building a reliable, powerful engine without the common pitfalls that can turn an exciting project into a frustrating ordeal. It ensures that from the main bearings to the smallest gasket, every piece is accounted for and designed to work in harmony.

How a Kit Can Save You Money

Building a high-performance engine is a significant investment, and managing your budget is key. One of the most compelling reasons to choose an install kit is the cost savings. Buying a kit is often a more affordable option than sourcing every gasket, seal, and fastener individually. When you purchase parts one by one, you’re not just paying for the components; you’re also racking up multiple shipping charges and potentially paying higher prices for single items. A complete kit bundles everything together at a better price point. This approach also helps you avoid the hidden costs of buying the wrong part and having to replace it, saving you from expensive mistakes that can quickly derail your budget.

Calculating the Total Project Cost

While a short block kit covers the core components, it's important to budget for the entire project. The total cost will also include labor (if you're not doing the work yourself), potential machine shop services for your cylinder heads, fluids like break-in oil and coolant, and a professional tune. This is where a complete kit really shines. It gives you a fixed, predictable cost for a massive portion of your build, making it much easier to budget for these other expenses. Instead of a long, uncertain list of individual parts with fluctuating prices and multiple shipping fees, you have one clear number. This helps you avoid the budget-breaking surprises that come from sourcing parts individually and ensures you have enough set aside for critical final steps, like professional engine tuning services, which are essential for protecting your new investment.

Ensure Every Part Works Together

Nothing stops a build in its tracks faster than discovering two critical components don’t fit together. A complete install kit eliminates this risk entirely. The kit includes everything you need in one box, saving you the time and hassle of finding each part separately. Every component, from the main gaskets to the smallest seals, has been selected and tested to ensure seamless compatibility. This means you can build with confidence, knowing that all the parts are designed to work in harmony. You won’t have to spend hours researching forums or cross-referencing part numbers. Instead, you get a proven combination of performance parts that provides reliability and peace of mind.

Spend Less Time on the Install

Your time is valuable, and a complete install kit helps you make the most of it. These kits are designed to be as straightforward as possible for both DIY mechanics and professional shops, with all necessary parts included. Instead of waiting on multiple shipments or making last-minute trips to the auto parts store for a forgotten gasket, you have everything you need right from the start. This streamlined process drastically cuts down on installation time and keeps your project moving forward without unnecessary delays. For those who prefer professional help, bringing a complete kit to your mechanic can also simplify their workflow, making the engine tuning services more efficient and getting you back on the road or track sooner.

Get Peace of Mind with a Warranty

When you’re investing in your Subaru’s performance, you want assurance that your hard work and money are protected. This is where a complete kit truly shines. When you piece together an engine with parts from different manufacturers, you’re left with a patchwork of warranties—or none at all. In contrast, Crawford Performance offers a 12-month or 12,000-mile warranty on our engines when installed with our kits. This comprehensive coverage provides a crucial safety net for your investment. It’s a testament to the quality and reliability of the components, giving you the confidence to push your vehicle to its limits, whether you’re upgrading your Subaru STI for the track or your Crosstrek for an overland adventure.

What to Expect During Installation

Swapping in a new short block is a major project, but with the right preparation, it’s a totally manageable one. Whether you’re a seasoned pro or tackling your first engine build, knowing what’s ahead can make all the difference. The key is to be methodical, from checking your existing components to following the final torque sequence. A careful approach ensures your new engine will perform reliably for years to come. Let’s walk through the key phases of the installation so you can feel confident heading into your build.

Gathering the Right Tools and Equipment

Before you even think about turning a wrench, take stock of your current setup. A new short block is the heart of your engine, but it relies on healthy supporting components. Inspect your cylinder heads, turbo, and fuel and cooling systems. If any of these parts are worn or failing, now is the time to address them. Bolting old, tired parts to a brand-new block is a recipe for problems down the road. This is also the perfect opportunity to plan for other performance parts you want to install. Make sure you have essential tools like a quality torque wrench, an engine stand, and a clean, organized workspace ready to go.

How to Prepare for Your Installation

A smooth installation starts with good prep work. One of the biggest advantages of using a complete kit is that it saves you the headache of sourcing every little gasket and seal. Everything you need arrives in one box. Before you begin, lay out all the new parts and read the installation instructions from start to finish. This helps you visualize the process and avoid surprises. As you disassemble your old engine, keep everything organized. Labeling bags of bolts and laying out parts in the order they were removed will make reassembly much easier. A clean engine is a happy engine, so make sure all mating surfaces are spotless before installing new gaskets.

Should You Hire a Professional Installer?

Deciding between a DIY installation and hiring a pro comes down to your experience, time, and access to tools. If you’re comfortable with engine mechanics and have a well-equipped garage, you can definitely save on labor costs by doing the work yourself. However, there’s no shame in handing the keys to a trusted Subaru specialist. A professional installation ensures the job is done to exact specifications and often comes with a warranty on the labor. If you're investing in a high-quality short block, having an expert handle the install and subsequent engine tuning services can provide valuable peace of mind and protect your investment.

Typical Professional Installation Time

If you're handing your keys over to a professional shop, one of the first questions you'll have is how long you'll be without your car. For a short block installation, a good rule of thumb is to plan for about 15 to 20 hours of labor. Of course, this is just an estimate. The actual time can shift based on the shop's familiarity with Subarus and the condition of your vehicle—older cars can sometimes have seized bolts that add to the clock. This timeframe also assumes a direct swap; if you're adding other upgrades, that will naturally extend the job. Using a complete kit really helps here, since your mechanic won't be stuck waiting on a missing part. Just remember, the installation itself is only part of the process—you'll also need to account for the critical break-in period and a final professional tune to get everything dialed in perfectly.

How to Avoid Common Installation Mistakes

The best way to deal with complications is to prevent them from happening in the first place. During disassembly, create a list of anything that looks worn, cracked, or brittle—think hoses, belts, and plastic connectors. Replacing these inexpensive items now will save you from major headaches later. Pay close attention to detail during reassembly. Clean all bolt threads, use the correct sealants where specified, and follow all torque sequences precisely. Rushing through these final steps can compromise the entire build. A careful, patient approach is what ensures your upgraded Subaru WRX engine will be as reliable as it is powerful.

How to Choose the Right Short Block Kit

Picking the right short block kit is a critical decision for your build. As the heart of your engine, it sets the stage for reliable power and performance. With so many options, it can feel overwhelming. Let’s break down the key factors to help you choose a kit that perfectly matches your car and your goals.

Rebuild or Replace: Making the Right Call

When your engine gives out, you face a big decision: do you rebuild the existing block or replace it with a new short block? While rebuilding can sometimes seem like the cheaper route, it comes with significant variables. The final quality is entirely dependent on the skill of the builder, and there's always a risk that underlying damage to the original block goes unnoticed. A replacement short block kit, on the other hand, offers a clean slate. You get a professionally assembled foundation with brand-new, performance-matched components built to precise specifications. For a price that's often comparable to a high-quality forged rebuild, you eliminate the guesswork and gain the confidence of a proven, reliable solution, often backed by a comprehensive warranty.

Find the Perfect Match for Your Vehicle

First, not all Subaru short blocks are created equal. Your Subaru is unique, and your install kit should be too. It's critical to select a kit designed for your specific model and year, whether you drive a WRX, STI, or Crosstrek. Using an incorrect kit can lead to compatibility issues and poor performance. We offer over 10 different Subaru short block installation kits tailored to various models to ensure a perfect fit. Always double-check the specifications before you buy.

Define Your Performance Goals First

What’s your vision for your car? A reliable daily driver, a track warrior, or an off-road beast? Your answer guides your choice. A short block built for 400 horsepower has different components than one designed for 700 horsepower. High-quality components allow your engine to handle more aggressive modifications and tuning services safely. Be honest about your power goals and how you plan to use the car. This ensures you invest in a short block that can handle the intended stress.

How to Judge Material Quality

The details inside the kit separate a good short block from a great one. Look closely at the materials used. A top-tier kit will include parts designed for strength, like genuine head gaskets, strong ARP head studs, and Crawford SPEC JE Forged Pistons. Forged pistons are significantly stronger than stock cast versions, withstanding higher pressures and temperatures. Quality materials are essential for building an engine that not only makes power but also lasts. Examine the quality of the performance parts included.

Why Brand Reputation Matters

When you're investing in your engine, the manufacturer's reputation matters. You'll see names like Crawford, IAG, and Rallispec in forums. Look for a company with a proven history in the Subaru community. Reading reviews from other builders provides valuable insight. A reputable brand will stand behind its work with a solid warranty and customer support. Choosing a company known for precision engineering gives you peace of mind that you’re getting a product built to perform and last.

How to Care for Your New Short Block

Your new short block is the heart of your Subaru’s performance, and taking care of it from day one is the key to unlocking its full potential and ensuring it lasts. Proper break-in and consistent maintenance will protect your investment and set the stage for all the power and reliability you’ve been dreaming of. Think of it less as a list of rules and more as the first step in a long and exciting relationship with your upgraded engine.

Keep a Close Eye on Engine Health

The first 1,000 miles are the most critical for your new short block. This is the break-in period where all the new components learn to work together. We recommend using Motul Break-In Oil for this initial phase to ensure everything seats correctly. During this time, keep a close eye on your gauges, check your oil level frequently, and listen for any unusual sounds. It’s also the perfect time to get a professional tune. Proper engine tuning services will optimize your air-fuel ratios and timing, ensuring your new engine runs smoothly and safely from the start.

Never Ignore the Check Engine Light

That little glowing light on your dashboard is your engine’s way of talking to you, and it’s especially important to listen after installing a new short block. While a check engine light doesn't always signal a catastrophic failure, it serves as a critical early warning that something isn't right. Ignoring it can turn a minor issue, like a faulty sensor, into a major problem that could damage your new engine. Promptly diagnosing the code is essential for maintaining your vehicle's performance and reliability. It ensures your emissions system is functioning correctly and protects your investment, preventing small issues from escalating into more severe and costly repairs down the line.

Your Go-To Inspection Checklist

Once you’re past the break-in period, regular check-ins are your best friend. Make it a habit to pop the hood and look for any signs of leaks, especially around the gaskets and seals. Check your coolant and oil levels regularly to catch any potential issues before they become serious problems. You’ll also want to inspect your belts and hoses for any wear and tear. Your new short block is a major upgrade, and you need to be sure the rest of your engine’s supporting systems are in good shape to handle the performance.

Tips for Long-Term Performance

A high-quality short block with forged internals is built for durability, but its lifespan still depends on how you treat it. Always use high-quality fuel and the recommended oil to keep everything running clean. Sticking to a regular maintenance schedule is non-negotiable. This isn’t just about oil changes; it’s about creating a routine that keeps your engine in peak condition. Also, give your engine a chance to warm up properly before you start pushing it hard. This simple step helps protect your performance parts and ensures you get years of reliable power.

Thinking Ahead: Planning Future Upgrades

One of the best things about installing a built short block is that it creates a solid foundation for much more power. While the block itself doesn’t add horsepower, it gives you the strength and reliability needed to support other modifications. Now you can safely consider bigger turbos, upgraded fuel systems, and other Subaru WRX upgrades. As you plan your build, remember that a professional tune is essential to tie all your new components together and safely maximize their output. Your new short block is just the beginning of your performance journey.

Best Practices for a Flawless Installation

You’ve got your short block kit, and you’re ready to get it into your Subaru. This is where the real fun begins, but it’s also where attention to detail matters most. A successful installation sets the stage for years of reliable performance, while a rushed job can lead to headaches down the road. Taking the time to do things right from the start protects your investment and ensures your engine runs exactly as it should. It's not just about bolting parts together; it's about creating a cohesive, powerful system that you can trust on the street, track, or trail. Let’s walk through the key practices for a smooth, flawless installation process, from pre-install checks to that all-important first drive.

The Ultimate Pre-Installation Checklist

Before you even think about turning a wrench, take a step back and assess the health of your engine’s other major components. Installing a brand-new, high-performance short block into an engine with worn-out parts is like putting a race car engine in a rusty chassis—it’s just not a good idea. Carefully inspect your cylinder heads, turbocharger, and fuel system. Are they in good shape and ready to handle the increased performance? If you find any issues, it’s much easier and smarter to address them now. This is the perfect time to consider upgrading other performance parts to match the capability of your new short block.

Critical Steps for a Successful Install

Once you’ve confirmed the rest of your engine is ready, it’s time to begin the installation. One of the biggest advantages of using a complete install kit is that it includes everything you need in one box, ensuring all the components are designed to work together perfectly. Resist the temptation to mix and match parts from different sources. Stick to the components provided in your kit and follow the included instructions to the letter. These guides are written by experts who know exactly what it takes to get the job done right. Taking shortcuts or skipping steps can compromise the integrity of your build, so be patient and methodical.

How to Test and Break-in Your New Engine

After the installation is complete, the break-in period is arguably the most critical phase for your new engine’s long-term health. This is when the piston rings seat against the cylinder walls, creating a tight seal that’s essential for compression and performance. We recommend using a specialized break-in oil, like Motul, for at least the first 1,000 miles. During this time, vary your engine speed and avoid high RPMs or heavy loads. Once the break-in period is over, you’ll need to perform an oil change and schedule professional engine tuning services to dial in your ECU for optimal performance and reliability.

Safety First: Key Precautions to Take

Finally, be honest about your mechanical skill level. If you’re an experienced engine builder with the right tools and a clean workspace, you can definitely tackle this installation yourself and save on labor costs. However, if you have any doubts, there is absolutely no shame in handing the job over to a professional. A short block installation is a complex task that requires precision and expertise. Finding a trusted Subaru specialist to handle the work ensures it’s done correctly and safely, giving you peace of mind. Your safety and the success of your build are the top priorities.

Related Articles

- Subaru Short Block Installation Kits - Crawford Performance

- Subaru Short Block Installation Kits - Crawford Performance (German)

- Subaru Short Block Installation Kits - Crawford Performance (Spanish)

Frequently Asked Questions

Does installing a short block kit add horsepower to my Subaru? This is a great question and a common point of confusion. On its own, a new short block doesn't add horsepower. Think of it as building a stronger foundation for your house. The foundation itself doesn't make the house bigger, but it allows you to safely add a second story. A performance short block is built with stronger components, like forged pistons, that can handle the stress of future modifications like a bigger turbo or more aggressive tuning, which is where you'll get your power gains.

Can I reuse my old head bolts instead of the ARP studs in the kit? I strongly advise against this. The factory head bolts are designed to be tightened only once and can stretch under the high pressure of a modified engine. This stretching can lead to a blown head gasket, which is a costly and frustrating repair. The ARP head studs included in a quality kit are made from a much stronger material that provides consistent clamping force, keeping your cylinder heads sealed tight no matter how hard you push your engine. It's a critical upgrade for reliability.

What are the signs that my current engine might need a new short block? There are a few classic symptoms to watch for. You might hear a repetitive knocking sound from the engine, often called "rod knock," which indicates a serious internal problem. Excessive oil consumption or seeing metallic flakes in your oil during a change are also major red flags. A loss of compression in one or more cylinders, which you'd notice as a significant drop in power, is another clear sign that your engine's rotating assembly is failing and it's time to consider a rebuild.

Is a professional tune absolutely required after the installation? Yes, a professional tune is non-negotiable. Your new short block has different characteristics and stronger components than your stock engine, and your car's computer (ECU) needs to be adjusted to account for these changes. A proper tune ensures your air-to-fuel ratios are correct, prevents engine knock, and optimizes performance safely. Skipping this step is the fastest way to damage your brand-new engine and void your warranty.

What's the single biggest mistake people make during the break-in period? The most common mistake is being impatient. People get excited about their new engine and want to immediately see what it can do. Pushing the engine too hard with high RPMs or heavy loads before the piston rings have properly seated against the cylinder walls can cause permanent damage and reduce the engine's lifespan. Following the recommended break-in procedure, which involves varying your engine speed and avoiding aggressive driving for the first 1,000 miles, is the most important thing you can do to protect your investment.