The Essential Forged Piston Subaru Upgrade Guide

Share

Hearing the words "ringland failure" is a gut-punch for any Subaru STI owner. It’s the infamous weak point of the stock EJ25 engine, a catastrophic failure that can happen when you start chasing more power. But the answer isn't to stop modifying your car—it's to build a stronger engine from the inside out. This is exactly where a forged piston Subaru build becomes essential. They are engineered to eliminate this specific failure point, giving you the strength to handle higher boost and aggressive tuning with confidence. We’ll explore why this happens and how to choose the right pistons for a truly bulletproof engine.

Key Takeaways

- Choose Forged Pistons for Strength and Durability: Stock cast pistons are a common failure point when adding significant power. Upgrading to forged pistons provides the structural strength needed to handle higher boost and aggressive tuning, preventing issues like cracked ringlands.

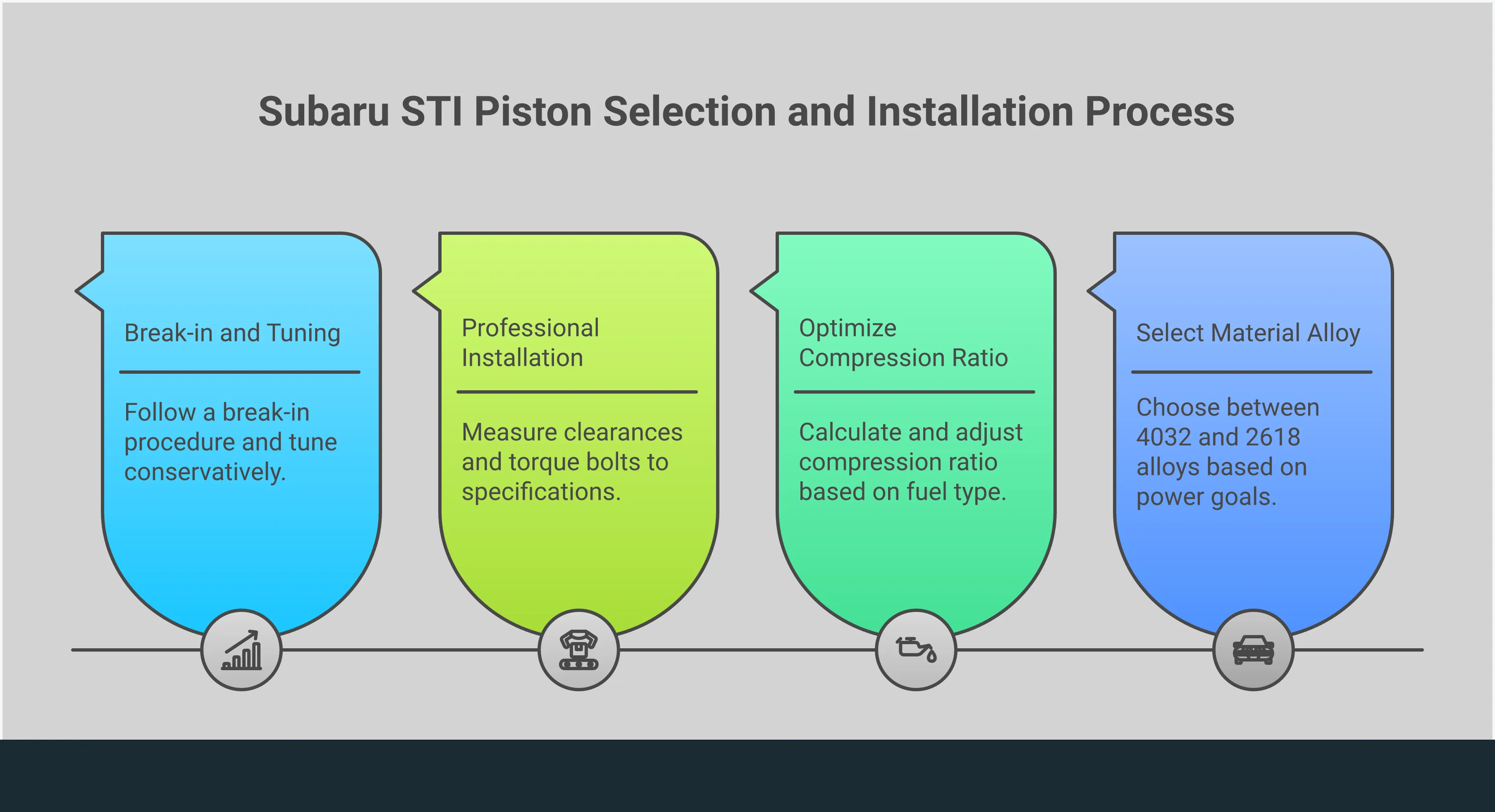

- Match Piston Specifications to Your Performance Goals: Select pistons based on your intended use. Key factors like the material alloy (e.g., 2618 for track, 4032 for street) and the compression ratio directly impact how your engine performs and its reliability under specific conditions.

- Rely on Professional Installation and Tuning: The right parts are only effective if installed and calibrated correctly. A professional engine build ensures precise clearances are set, while a custom tune is essential to optimize performance and protect your investment from damage.

Forged vs. Cast Pistons: What's the Difference?

When you pop the hood of a stock Subaru STI, you’ll find cast pistons doing their job inside the engine. They’re perfectly capable for daily driving and factory power levels. But once you start chasing higher horsepower, the conversation shifts to forged pistons. While both types of pistons serve the same fundamental purpose, the way they’re made and the materials they use create a world of difference in strength, durability, and performance potential.

Understanding these differences is the first step in planning a reliable engine build. A cast piston is made by pouring molten aluminum into a mold, which is an efficient and cost-effective process. A forged piston, on the other hand, is created by stamping a solid billet of aluminum into shape under extreme pressure. This process creates a much denser and stronger final product, free of the potential voids or weaknesses that can occur in casting. For anyone serious about adding significant power to their STI, knowing why this matters is essential for building an engine that lasts.

How Forged and Cast Pistons Are Made

The core distinction between forged and cast pistons begins with their creation. Factory cast pistons are typically made from a hypereutectic aluminum alloy, which has a high silicone content. This material is great for mass production because it expands less with heat, allowing for tighter tolerances and quieter operation in a stock engine.

Forged pistons are crafted from a higher-strength aluminum alloy with less silicone. The forging process aligns the grain structure of the metal, making it incredibly dense and robust. Think of it like the difference between particle board and a solid piece of hardwood. This superior strength is exactly what you need to handle the increased cylinder pressures that come with higher boost and more aggressive engine tuning services.

Where Performance Really Differs

The real-world advantage of a forged piston is its ability to withstand extreme stress. Because of their dense grain structure, forged pistons can handle significantly more power and heat without failing. This makes them a foundational component for any serious Subaru STI upgrade. Many high-quality forged pistons also feature special skirt coatings that reduce friction and wear inside the cylinder bore, further extending engine life under demanding conditions.

When you build an engine with forged internals, you’re creating a durable foundation that can safely support aggressive tuning and much higher horsepower levels. It’s the difference between an engine that’s simply running and one that’s built to perform reliably, lap after lap or mile after mile.

Common Piston Myths, Busted

Despite their strengths, forged pistons are surrounded by a few misconceptions. First, they aren't indestructible. While they are incredibly tough, they can still be damaged by detonation (or engine knock), which puts immense, uncontrolled pressure on the piston crown and ringlands. A proper tune is critical to protect your investment.

Another common point of discussion is "piston slap." This is a light ticking sound you might hear when the engine is cold. It happens because forged pistons expand more with heat than cast ones, so they require slightly more clearance within the cylinder. This sound is often normal and typically fades as the engine reaches operating temperature. It’s simply a characteristic of a high-performance engine, not necessarily a sign of a problem.

Why Your Subaru Needs Forged Pistons for Your Performance Goals?

If you’re serious about getting more power out of your Subaru STI, stock cast pistons will eventually become your engine’s weakest link. Moving to forged pistons isn't just an upgrade; it's a foundational step toward building a reliable, high-output engine. Forged pistons provide the strength and resilience needed to handle aggressive tuning, higher boost levels, and the intense conditions of track days or spirited driving. They are the key to transforming your engine from a capable street performer into a true powerhouse.

Built for Higher Horsepower and Torque

The primary reason to upgrade is simple: forged pistons can take a beating. The stock pistons in your STI are fine for factory power levels, but once you start adding a bigger turbo, more boost, and an aggressive tune, the internal engine stress increases exponentially. Upgrading to a built short block with forged internals creates a durable foundation that can safely handle that stress. The dense grain structure created during the forging process makes these pistons incredibly strong, allowing your engine to reliably support significantly higher horsepower and torque without failure. This is the confidence you need when pushing your Subaru STI upgrades to their full potential.

Pushing Past Stock Limits

The stock cast pistons in your STI are the first major hurdle when you start chasing serious power. They are a known failure point, especially when you introduce higher boost and more aggressive tuning. The casting process, while efficient for manufacturing, can leave behind microscopic weaknesses. Under the increased stress of a modified engine, these weaknesses can lead to catastrophic failure, like the dreaded cracked ringlands. This is why pushing past factory limits requires a fundamental change to your engine's core components. It’s not about finding a workaround; it’s about building a stronger foundation from the inside out.

This is where forged pistons become essential. Unlike their cast counterparts, forged pistons are created from a solid billet of high-strength aluminum alloy that is stamped into shape under immense pressure. This process creates an incredibly dense and uniform grain structure, eliminating the potential voids found in cast pistons. The result is a component that is dramatically stronger and more resilient. This superior strength is what allows your engine to safely handle the extreme cylinder pressures that come with serious performance parts and a professional tune, turning potential failure points into sources of reliability.

The strength of forged pistons isn't just about handling more power; it's about building a reliable engine that lasts. Many high-quality forged pistons also include advanced skirt coatings designed to reduce friction within the cylinder bore. This not only helps protect your engine under the demanding conditions of a track day but also contributes to its overall longevity. When you're investing in Subaru STI upgrades, choosing forged pistons isn't just an option—it's a necessity for creating a powerhouse that you can push with confidence, mile after mile.

Superior Strength Under Extreme Heat

More power means more heat, and managing that thermal load is critical for engine longevity. Forged aluminum alloys have superior thermal conductivity compared to cast materials, meaning they are much more effective at transferring heat away from the piston crown and into the engine's cooling system. This helps prevent hot spots that can lead to detonation—a destructive force in any high-performance engine. Many forged pistons also feature thermal barrier coatings on the crown and friction-reducing coatings on the skirts. These features work together to manage extreme temperatures, reduce wear on the cylinder walls, and maintain stable performance under the most demanding conditions.

Advanced Heat Dissipation

When you're pushing your engine hard, managing heat becomes one of the most critical factors for reliability. Forged pistons excel here because their material has superior thermal conductivity compared to cast pistons. This allows them to transfer heat much more effectively away from the piston crown and into the engine's cooling system, preventing the formation of hot spots that can lead to detonation—a destructive event that can quickly damage your engine's internals. This capability is essential when you're taking your Subaru STI to its limits, as increased power output always generates more heat. This efficient heat transfer is what protects your engine during aggressive engine tuning services and situations with high cylinder pressure, ensuring you can use your power reliably.

Beyond the inherent strength of the material, many high-quality forged pistons incorporate advanced coatings to further improve thermal management. You'll often find thermal barrier coatings on the piston crown, which help reflect intense heat away from the piston itself. At the same time, friction-reducing coatings are applied to the skirts to minimize wear against the cylinder walls. These features work in tandem to handle extreme temperatures and maintain stable performance under the most demanding conditions. Investing in these types of performance parts isn't just about adding strength; it's about building an engine with the thermal resilience to handle serious power for the long haul.

Greater Durability for Hard Driving

One of the most common failure points on stock STI pistons under high boost is the ringlands—the small metal ridges that hold the piston rings in place. The intense pressure can cause them to crack or break, leading to catastrophic engine failure. This is where the superior material strength of forged pistons truly shines. Their robust design, particularly in the ringland area, provides a much higher resistance to detonation and the mechanical stresses of high-RPM operation. By installing a set of quality forged pistons, you effectively eliminate this notorious weak point, creating a much more durable engine that can withstand the rigors of the track and aggressive street driving.

Proven Race-Ready Endurance

When it comes to high-performance engines, the durability of your components is everything. Forged pistons are specifically designed to withstand the extreme conditions of racing and aggressive driving, and their real-world advantage lies in an ability to endure significant stress. Due to their dense grain structure, forged pistons can handle much more power and heat without failing, making them an essential component for any serious Subaru STI upgrade. This durability is crucial for maintaining performance lap after lap, especially under the demanding conditions of a track day. The superior strength is particularly evident in the ringland area—a notorious failure point in stock pistons—providing much higher resistance to detonation and the mechanical stresses of high-RPM operation. Upgrading to quality forged engine internals is a foundational step toward building a reliable, high-output engine that can handle the challenge.

How to Fine-Tune Your Compression Ratio

Forged pistons give you the power to customize your engine's core characteristics. Unlike one-size-fits-all stock pistons, forged options are available in various compression ratios. This allows you or your builder to tailor the engine's setup for your specific goals, whether you're running high-octane pump gas, E85, or a massive turbo. Lowering the compression ratio can make your engine safer for high-boost applications, while raising it can improve throttle response and efficiency. Many forged pistons are also lighter than their cast counterparts, which reduces the rotating mass. This lighter assembly allows your engine to rev more freely, delivering sharper response every time you touch the throttle and making expert engine tuning services even more effective.

Improving Engine Efficiency

While forged pistons are known for handling immense power, they also play a huge role in your engine's overall efficiency. They open the door to custom compression ratios, which can extract more energy from the fuel-air mixture—leading to more power and sometimes even better fuel economy. The forged aluminum itself is excellent at dissipating heat, keeping temperatures stable and preventing performance loss under load. Many top-tier performance parts also incorporate features like special skirt coatings to reduce friction, a detail we include in our own designs. This blend of optimized compression, superior heat management, and reduced friction results in an engine that doesn't just produce more power, but runs more smoothly and efficiently.

Which Forged Piston Brand is Best for Your STI?

Once you’ve decided to go with forged pistons, the next big question is which brand to trust with your engine build. The market has several excellent options, but each manufacturer has its own engineering philosophy and specialty. Some focus on all-out race applications, while others prioritize street-friendly durability. Understanding these differences is key to finding the perfect match for your specific performance goals and driving style. Let's look at some of the top contenders for the Subaru STI to help you make an informed decision.

Crawford Performance

When it comes to Subaru-specific engineering, Crawford Performance is a name that consistently leads the conversation. They live and breathe these engines, and it shows in their products. Their CrawfordSPEC forged pistons for the EJ257 are engineered to handle serious abuse, with a focus on material science and track-tested results to ensure reliability. They are designed from the ground up by Subaru specialists who understand the unique demands of the boxer engine. If you’re looking for a piston that prioritizes strength and durability for a build where dependability is just as important as power, this is a fantastic place to start.

Manufacturing Process and Materials

Crawford Performance's approach to piston design is all about strength from the start. They begin with a high-strength aluminum alloy, a material specifically chosen for its ability to endure high-stress environments. Unlike factory cast pistons, which are made by pouring liquid metal into a mold, CrawfordSPEC pistons are forged. This process takes a solid billet of aluminum and stamps it into shape under extreme pressure. This method aligns the metal's grain structure, resulting in an incredibly dense and robust component that eliminates the potential voids and weak points common in casting. It’s this meticulous process that creates a piston ready to handle the intense heat and cylinder pressures of a modified engine, providing a solid foundation for all your other performance parts.

JE Pistons

JE Pistons is a highly respected name in the performance world, known for precision engineering and a massive catalog of options. For Subaru owners, they offer a wide range of pistons designed to provide optimal performance under high-boost conditions, making them a versatile choice for both street and track builds. One of their biggest strengths is the ability to create custom pistons, allowing you to tailor the specs perfectly to your engine setup and specific power goals. If you have a unique build in mind or need a very specific compression ratio, JE Pistons has the flexibility and experience to deliver exactly what you need.

Decades of Experience and Innovation

Crawford Performance isn't just another parts manufacturer; they are Subaru specialists with a deep history of engineering solutions for the boxer engine. This experience is evident in their approach to creating parts that address specific weaknesses in the factory design. Their forged engine internals are a prime example, crafted to be 40% stronger than the stock cast components. This strength comes from a meticulous forging process that uses a high-grade aluminum alloy, resulting in a dense grain structure that can reliably handle the extreme stress of high-horsepower builds. By focusing on proven reliability, they've developed pistons that effectively eliminate the notorious ringland failure point, giving drivers the confidence to push their cars hard on the track or the street without worrying about engine integrity.

Manley Performance

Manley Performance has built a strong reputation for producing high-quality forged components that cater to serious performance enthusiasts. Their pistons are designed using advanced engineering techniques to guarantee strength and reliability under the most extreme conditions. For the Subaru STI, Manley Performance offers a variety of piston designs that focus on maximizing power and efficiency while maintaining the durability needed for a high-output engine. They are a go-to choice for builders who want a proven, robust piston that can confidently handle aggressive tunes and heavy track use without compromise.

Component-Specific Strengths

Manley's strength lies in their meticulous attention to material science and design. Their forging process creates an incredibly dense grain structure, resulting in a piston that is far stronger than the stock cast units. This is crucial for STI owners because it directly addresses the engine's most notorious weak point: the ringlands. Under the intense cylinder pressures of a high-boost setup, stock pistons are prone to failure in this area. Manley pistons are engineered with extra reinforcement in these critical stress points, providing the durability needed to handle aggressive engine tuning services and high RPMs with confidence. This focus on robust construction makes them a trusted choice for builders aiming for a reliable, high-horsepower engine.

CP-Carrillo

Known for innovative designs and top-tier components, CP-Carrillo is a favorite among racers and professional builders. Their forged pistons are crafted from premium materials and engineered to handle the intense demands of high-performance Subaru engines. What often sets CP-Carrillo apart is their focus on lightweight construction without sacrificing strength, which can help improve engine response and overall performance. If you're building an engine for competitive racing or want a piston that leverages cutting-edge design for maximum output, CP-Carrillo is a brand that should be high on your list.

Ross Racing Pistons

Ross Racing Pistons specializes in custom piston manufacturing, offering a range of high-quality forged options for Subaru applications. Their products are designed for high-performance engines and are well-regarded for their durability and precision craftsmanship. A key advantage of choosing Ross Racing Pistons is the ability to select from various compression ratios and configurations, giving you the freedom to optimize your engine setup for your specific performance needs. Whether you're building a high-compression, naturally aspirated setup or a low-compression, high-boost monster, Ross has the expertise to create a piston that fits your build perfectly.

Wiseco

Wiseco is a well-respected name in the performance piston market, known for a deep commitment to quality and innovation. Their forged pistons are designed specifically for high-performance applications, making them a fantastic choice for Subaru STI owners looking to build a more resilient engine. Wiseco pistons are crafted from high-strength aluminum alloys, and their forging process results in a dense, strong piston capable of withstanding the increased pressure and heat that comes with more power. This is especially important for the EJ25 engine, where ringland failure is a major concern when you start adding serious performance parts.

Beyond their strength, Wiseco offers a variety of piston designs and compression ratios, allowing you to tailor your engine setup to meet specific goals. This flexibility is crucial whether you're optimizing your Subaru for the street or dedicating it to the track. Many of their pistons also feature advanced skirt coatings that reduce friction and wear, which helps with both engine longevity and overall performance. You can explore all the options for your build on the official Wiseco Performance Products website.

Choosing the Right Forged Pistons for Your Subaru Build

Picking the right forged pistons isn't just about finding a part that fits; it's about matching a component to your specific performance goals. With so many options on the market, it’s easy to get overwhelmed. To make the best choice for your build, you need to look past the brand name and focus on the technical details that truly matter. These components are at the heart of your engine, enduring incredible forces with every combustion cycle. Making the right choice here is fundamental to building a powerful and reliable engine that lasts. Considering factors like material composition, compression ratio, and key design features will ensure you get a set of pistons that can handle the power you want to make while providing the durability you need for the street or the track.

Compatibility Beyond the STI

While the EJ257 in the STI is famous for its performance potential and notorious for its stock piston limitations, the need for a stronger engine core isn't exclusive to that model. The principles of building a reliable, high-output engine apply across the entire Subaru family. Whether you're modifying a modern FA20-powered WRX, a rugged Forester, or even an adventure-ready Crosstrek, the factory pistons will eventually become a limiting factor as you increase power. Upgrading to forged internals is a smart move for any owner looking to push their vehicle beyond its stock capabilities, ensuring the engine can safely handle the added stress from tuning and hardware upgrades.

Covering EJ, FA, and Other Subaru Engines

The great news is that the aftermarket provides strong support for a wide range of Subaru engines. High-quality forged pistons are readily available for various EJ series engines (like the EJ20, EJ22, and EJ25) found in older WRX, Impreza, and Legacy models. The same goes for the newer FA and FB engine families. This means you can apply the same engine-strengthening strategies to a variety of platforms. Whether you're building a track-focused Subaru WRX or a capable overlanding rig, the foundational components for a reliable build are accessible, allowing you to create a powerhouse tailored to your specific needs.

Understanding Piston Sizes and Types

Once you've chosen a brand, the next step is selecting the correct size and type of piston for your engine. This isn't a one-size-fits-all decision; it depends on the condition of your engine block and your ultimate performance goals. The three main categories you'll encounter are standard, oversized, and stroker pistons. Each serves a distinct purpose in an engine build, from a straightforward strength upgrade to a complete overhaul of your engine's displacement. Understanding the difference is crucial for communicating with your engine builder and ensuring you get the right parts for the job.

Standard, Oversized, and Stroker Pistons

Standard-size pistons match the original factory cylinder bore diameter. They are the perfect choice for a new or low-mileage engine block that doesn't require any machine work. Oversized pistons are used when an engine block is bored out—a process where a small amount of material is removed from the cylinder walls to create a perfectly round and fresh surface. This is common in high-mileage engines or builds aiming for a slight displacement increase. Stroker pistons are part of a more comprehensive upgrade that includes a new crankshaft to increase the piston's travel distance, significantly increasing engine displacement and torque. This choice requires expert engine tuning services to ensure all components work together harmoniously.

Look at the Material and Alloy

The foundation of any great piston is the material it's made from. Forged pistons are typically crafted from high-strength aluminum alloys, but not all alloys are created equal. The two most common are 2618 and 4032. The 2618 alloy is known for its superior strength under extreme heat and pressure, making it ideal for high-horsepower track or race builds. However, it expands more when heated, requiring greater piston-to-wall clearance. The 4032 alloy contains more silicon, which means it expands less, allowing for tighter clearances and quieter operation—a great choice for a powerful daily driver. When browsing performance parts, always check the alloy to ensure it aligns with your engine’s intended use.

Select the Perfect Compression Ratio

Your piston choice directly influences your engine's compression ratio, which is a critical factor in its overall performance and character. A higher compression ratio can yield more power and better throttle response, but it also demands higher-octane fuel and a precise tune to prevent engine knock. A lower compression ratio provides a greater margin of safety for high-boost applications, like those with a large turbo. Forged pistons are specifically designed to handle the stresses of altered compression. Upgrading to a quality set, like those found in our Subaru STI upgrades, solves common issues like cracked ringlands that plague stock pistons under increased pressure.

Should You Get Piston Coatings?

Modern forged pistons often come with specialized coatings that serve a real purpose. The most common is a skirt coating, usually a dark gray or black layer applied to the sides of the piston. This isn't just for looks; it’s a dry-film lubricant designed to reduce friction between the piston and the cylinder wall. This reduction in friction minimizes wear on both components, leading to a longer-lasting and more efficient engine. Some pistons also feature thermal barrier coatings on the crown, which help reflect heat away from the piston. This keeps the piston cooler and directs more heat energy out of the exhaust, which can help spool a turbo and protect the piston from damage.

Why the Ringland Design Is Critical

The ringlands—the small metal ridges that hold the piston rings in place—are a well-known weak point on many stock Subaru engines, especially when you start adding power. Under high cylinder pressures, these areas can crack or break, leading to a catastrophic loss of compression. When choosing forged pistons, pay close attention to the ringland design. Reputable manufacturers engineer their pistons with thicker, more robust ringlands specifically to withstand the demands of a high-performance build. This design reinforcement is one of the most important reasons to upgrade, as it provides the structural integrity needed to reliably handle increased boost and power.

Get Your Piston-to-Wall Clearance Right

Proper piston-to-wall clearance is essential for a healthy engine build, and it’s a specification you can’t ignore. Because forged aluminum expands more than cast aluminum when it heats up, forged pistons require more clearance. This extra space can sometimes cause a light ticking sound known as "piston slap" when the engine is cold. This is generally normal and should quiet down as the engine reaches operating temperature. The exact clearance depends on the piston's alloy and your engine builder's expertise. This is why professional engine tuning services are so important—an expert can ensure your clearances are set perfectly for your specific combination of parts and performance goals.

Anatomy of a High-Performance Forged Piston

When you’re comparing forged pistons, the details make all the difference. Beyond the brand name and material, specific design elements determine how a piston will perform and how long it will last in your STI’s engine. Paying close attention to these features ensures you’re getting a component engineered for the power and stress you plan to throw at it. From the wrist pins to the oil channels, every part of the design serves a purpose. Here are the four critical features to inspect before making your choice.

Wrist Pins: What You Need to Know

The wrist pin connects the piston to the connecting rod. While it may seem like a simple component, its weight and strength are crucial. Look for pistons that come with lightweight yet durable wrist pins. Reducing the weight of the wrist pin lowers the overall rotating mass of your engine assembly. This seemingly small change can lead to a noticeable improvement in engine response and how quickly your engine revs. Many high-end piston kits offer upgraded wrist pins specifically for this reason, giving you a performance edge that starts deep inside the block.

Piston Skirts and Coatings Explained

The piston skirt is the side of the piston that makes contact with the cylinder wall. In a high-performance engine, this area is under immense stress. A well-designed piston will feature a specialized skirt shape and an anti-friction coating. These coatings are a game-changer for engine longevity, as they are specifically designed to reduce cylinder wear. This not only protects your cylinder walls but also minimizes friction, which helps the engine run more efficiently and reliably, especially under heavy loads. It’s a feature that pays dividends in both performance and durability for your Subaru STI upgrades.

The Importance of Ring Land Design

The ring lands are the small grooves on the side of the piston that hold the piston rings in place. This is a known weak point on the stock EJ25 pistons, which are prone to cracking under increased boost and cylinder pressure. Forged pistons solve this with a much more robust ring land design. When you’re shopping, look for pistons known for their strong, well-engineered ring lands. This feature is absolutely critical for preventing catastrophic failures like cracked or broken ring lands, ensuring your engine can reliably handle the extra power from your performance parts.

How the Piston Controls Oil

Proper oil management is essential for a healthy engine, and the pistons play a key role. High-quality forged pistons incorporate sophisticated oil control systems, including strategically placed oil drain-back holes and accumulator grooves. These features help manage oil flow, prevent oil from getting past the rings and into the combustion chamber, and ensure consistent lubrication. A built EJ25 short block with forged internals is designed to handle significantly more power and stress, and effective oil control is a major reason why. This is vital for keeping your engine protected during high-RPM track days or demanding daily driving.

Your Guide to Installation and Tuning

Choosing the right forged pistons is a major step, but the job isn’t finished once they arrive at your door. Proper installation and a precise tune are what truly bring your engine build to life. Skipping or rushing these final stages can undermine your investment and, in the worst-case scenario, lead to catastrophic engine failure. Think of it this way: the pistons are the star athletes, but the installation is the expert coaching and the tune is the game-day strategy. All three elements must work in harmony to achieve a winning performance. From ensuring perfect clearances to calibrating your ECU, every detail matters. Let’s walk through the critical steps that will protect your new engine and help you safely achieve your power goals.

Why Professional Installation Matters

Installing forged pistons is not a simple weekend project. It’s a precision-oriented task that requires specialized tools and a deep understanding of engine mechanics. A professional engine builder will meticulously measure piston-to-wall clearances, check ring gaps, and ensure the entire rotating assembly is perfectly balanced. Upgrading to a built short block with forged internals creates a durable foundation that can safely handle the stress of significantly higher horsepower and aggressive tuning. An expert ensures every component works together flawlessly, preventing premature wear and catastrophic failure. This isn't just about assembling parts; it's about building a reliable powerhouse. Entrusting your build to a seasoned professional is the best insurance policy for your high-performance investment.

What Other Mods Will You Need?

Forged pistons are designed to handle immense pressure, but they don't work in isolation. To support their strength, you need to evaluate the rest of your engine’s components. Stock connecting rods, for example, may not be able to withstand the increased cylinder pressures you’re aiming for. Upgrading to stronger I-beam or H-beam rods is a common and wise decision. You should also consider upgrading your rod and main bearings, head studs, and oiling system to create a robust foundation. A high-performance engine is a balanced system, and reinforcing these supporting components is essential for reliability. A complete plan ensures all your performance parts work together to create a durable and powerful engine.

Tuning Your Engine for Forged Pistons

Once your engine is assembled, a professional tune is absolutely mandatory. A stock ECU map is calibrated for cast pistons and lower power levels; running it with a forged setup is a recipe for disaster. A skilled tuner will adjust fuel delivery, ignition timing, and boost levels to create a custom map for your specific build. This process optimizes performance while maintaining safe operating parameters, preventing issues like detonation that can destroy even the strongest pistons. Proper engine tuning services are what protect your investment and allow you to safely access the full potential of your upgraded engine. Don’t even think about starting your newly built motor without a solid base map and a scheduled dyno session.

Don't Skip the Break-in Procedure

The first 500 to 1,000 miles on your new engine are the most important. The break-in period is crucial for seating the new piston rings against the freshly honed cylinder walls, creating a tight seal for optimal compression. During this time, you’ll need to vary your engine RPM, avoid constant speeds, and stay out of high boost or heavy load situations. You may also notice some new sounds. For example, "piston slap" when the engine is cold is normal with forged pistons due to their higher thermal expansion rate and looser cold clearances. It's normal when you run high clearances, but it will go away pretty quickly as the engine warms up. Following your engine builder’s specific break-in instructions and performing an early oil change are key to ensuring a long and healthy life for your Subaru STI upgrades.

The 500-Mile Seating Process

The first 500 miles are all about patience. This initial period is dedicated to seating the new piston rings against the cylinder walls, which is essential for creating the strong seal needed for optimal compression and power. To do this correctly, you need to drive with intention. Avoid cruising at a constant speed on the highway; instead, vary your engine speed by driving on roads that require you to accelerate and decelerate gently. Keep the RPMs moderate and, most importantly, stay out of boost and avoid putting the engine under any heavy load. After completing this initial break-in, an oil change is non-negotiable to clear out any microscopic metal particles. This careful process sets the stage for a healthy engine life and prepares it for the final calibration from professional engine tuning services.

What to Expect After Installing Forged Pistons: Performance and Maintenance

Upgrading to forged pistons changes how you interact with your engine. While they provide a massive performance and durability advantage, they have unique characteristics you’ll want to understand for daily driving and long-term care. Knowing what to expect will help you keep your high-performance engine running strong for years to come.

What to Expect During Cold Starts

One of the first things you might notice after installing forged pistons is a light knocking sound during a cold start. This is often called "piston slap," and it’s completely normal. Forged aluminum alloys expand more with heat than the stock cast pistons do. To account for this, they are installed with slightly more clearance inside the cylinder. When the engine is cold, this extra space allows the piston to make a slight ticking or knocking sound. As your engine warms up and the pistons expand to their optimal size, the noise will fade away. Just be sure to let your car warm up properly before putting it under heavy load.

Oil Considerations for Your New Setup

Your engine's oil system is the lifeblood of your high-performance build. Forged pistons are a significant investment, and proper lubrication is essential to protect them. Many high-quality forged pistons come with special skirt coatings designed to minimize friction and reduce wear on the cylinder walls. To support this, you need a clean and efficient oiling system. Keeping your oil clean and at the right level is critical. For many tuned Subarus, an Air/Oil Separator is one of the most important supporting performance parts you can install to prevent oil contamination and maintain stable lubrication, ensuring a long life for your new pistons.

How to Monitor Your Engine's Health

Staying in tune with your car is key to engine longevity. A primary reason many STI owners upgrade to forged pistons is to prevent the notorious ringland failure common with stock pistons under increased power. While quality forged pistons are far more resilient, it’s still wise to monitor your engine’s health. Pay attention to any new or unusual sounds, check your oil levels regularly, and watch for any changes in performance or oil consumption. Think of high-quality forged pistons as a core component of your engine’s reliability, providing a strong foundation for all your other Subaru STI upgrades.

How to Care for Your Built Engine

Think of a built short block with forged internals as an insurance policy for your engine. It’s not just about making more power—it’s about building a durable foundation that can handle that power reliably. This upgrade gives you the confidence to push your vehicle harder without worrying about catastrophic failure. To get the most out of your investment, pair your hardware with professional tuning. Proper engine tuning services will ensure your air/fuel ratios, timing, and boost levels are all optimized for your specific setup, creating a powerful and dependable engine that you can count on for the long haul.

Ready for an Upgrade? Here's How to Plan

Upgrading to forged pistons is a serious step toward building a powerful and reliable engine, but it requires careful planning. Before you start ordering parts, take the time to map out your project. Thinking through your budget, goals, timeline, and professional support will ensure your build goes smoothly and delivers the results you’re looking for. A well-planned upgrade is the foundation for a high-performing STI that you can enjoy for years to come.

How to Budget for Your Piston Upgrade

A piston upgrade involves more than just the cost of the pistons themselves. You need to account for supporting components like connecting rods, bearings, gaskets, and fluids. Labor is also a significant factor, whether you’re paying a professional or valuing your own time. It’s helpful to view this as an investment in your engine's longevity. A built short block with quality forged internals is an insurance policy against catastrophic failure, creating a durable foundation that can safely handle aggressive tuning and higher horsepower. When you budget, plan for the entire scope of the engine build, including potential machine shop services and a professional tune.

Typical Costs and Market Factors

When you start pricing things out, you'll find that a quality set of forged pistons for your STI typically costs between $750 and $900. The final price depends on factors like the brand and the specific aluminum alloy used. However, the pistons are just one piece of the puzzle. The largest part of your budget will likely be labor, which can range from $2,000 to $2,500. This cost reflects the precision required for the job, including machine work like honing the cylinders to ensure perfect clearances. It's essential to view this as a complete engine project. You're not just buying parts; you're investing in the expertise needed to build a durable foundation for all your future Subaru STI upgrades.

What Are Your Real Performance Goals?

What do you want your STI to do? Your answer will guide your piston selection. Are you building a responsive daily driver, a weekend track car, or an all-out race machine? Your horsepower target is a key factor, but so are other characteristics. For example, lighter-weight pistons can improve engine response, which is fantastic for autocross or tight, technical tracks. Meanwhile, features like specialized skirt coatings are designed to reduce cylinder wear, adding durability for a high-performance street car. Defining your goals helps you and your engine builder choose the right Subaru STI upgrades for the job.

How to Create a Realistic Timeline

An engine build is not a weekend project, so it’s important to be realistic about the timeline. Start by accounting for parts availability and potential shipping delays. Once you have everything, the engine needs to be pulled, disassembled, and sent to a machine shop for inspection and prep work. Reassembly requires meticulous attention to detail, followed by reinstallation and, finally, tuning. Be prepared for your car to be out of commission for several weeks, or even longer. Rushing any of these steps is a recipe for disaster, so plan for the downtime and focus on getting it done right.

Finding a Pro to Handle Your Build

Unless you’re a seasoned engine builder, you’ll need professional help. Finding a reputable shop with extensive Subaru experience is critical to your project's success. An expert builder will ensure proper piston-to-wall clearances are set and can address common issues, like the stock piston ringland failures that forged pistons are designed to prevent. They can also guide you on supporting modifications. Equally important is your tuner. A skilled tuner will create a safe and reliable map that maximizes your new setup's potential. Investing in professional engine tuning services protects your new engine and ensures you get the performance you paid for.

Related Articles

Frequently Asked Questions

At what horsepower level should I seriously consider upgrading to forged pistons? There isn't a single magic number, as the need depends more on engine stress than just peak horsepower. Generally, once you move beyond basic bolt-ons and start increasing boost with a larger turbo and an aggressive tune, you're entering the territory where stock cast pistons become a significant risk. Think of it as a foundational upgrade for any build aiming to reliably push past the factory's intended limits.

Is the 'piston slap' I hear on cold starts harmful to my engine? That light ticking sound you hear when the engine is cold is a normal characteristic of a motor with forged pistons, not a sign of damage. Because forged aluminum expands more with heat, your engine builder must set a wider piston-to-wall clearance. The sound is simply the piston moving within that extra space. It will fade as the engine warms up and the metal expands to its ideal operating size. Just be sure to let the engine warm up properly before driving aggressively.

Can I just install forged pistons and skip other engine upgrades? Installing forged pistons in an otherwise stock engine is not a good strategy. A high-performance engine is a balanced system, and the pistons are just one part of the equation. When you add pistons capable of handling more power, you shift the stress to the next weakest components, like the stock connecting rods. To build a reliable engine, you should pair your pistons with stronger rods, upgraded bearings, and other supporting parts to ensure the entire rotating assembly can handle the increased load.

Which piston alloy is better for my build: 2618 or 4032? The right choice depends entirely on how you plan to use your car. The 4032 alloy is an excellent option for a high-performance daily driver because it expands less, allowing for tighter clearances and quieter cold starts. The 2618 alloy is softer but much stronger under extreme heat, making it the preferred choice for dedicated track cars and all-out race builds where maximum durability under intense stress is the top priority.

Does installing forged pistons mean my engine is indestructible? While forged pistons dramatically increase your engine's strength and resilience, they are not indestructible. They provide a much higher tolerance for heat and pressure, but they can still be damaged by factors like engine knock, or detonation, which can result from a poor tune. The key to a long-lasting built engine is combining quality components like forged pistons with professional assembly and a precise, expert tune.