Why Your Subaru Needs a 5-Angle Valve Job

Share

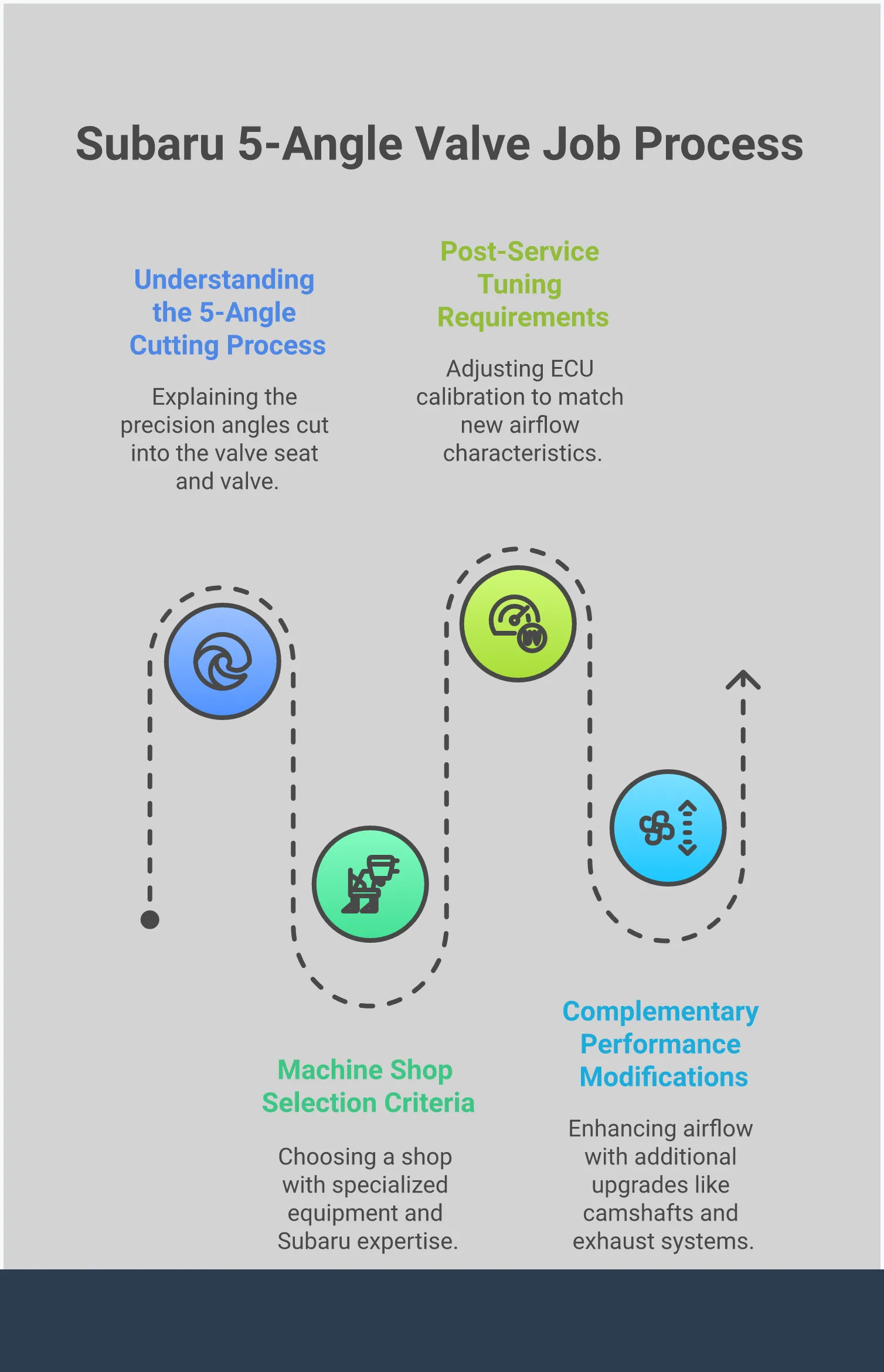

If you've already upgraded your intake and exhaust, you know the thrill of helping your Subaru breathe better. But to make serious power, you have to go deeper—right into the engine's core. This is where a 5-angle valve job comes in. It’s a precision machining process that fundamentally improves how air and fuel enter the combustion chamber, removing a critical bottleneck. Think of it as the next essential step beyond simple bolt-on parts. We'll explain exactly what this modification is, how it generates more horsepower, and why professionally prepared Subaru 5-angle valve job heads are a foundational upgrade for any serious performance build.

Key Takeaways

- Optimize Airflow for Real Power: A 5-angle valve job is a performance modification that reshapes your cylinder heads to help the engine breathe more efficiently. This improved airflow is the foundation for making more horsepower and torque, especially in turbocharged applications.

- Vet Your Machine Shop Carefully: The success of this service depends entirely on precision. Always choose a specialist with proven experience in Subaru engines and the right equipment, as poorly cut angles can hurt performance instead of helping it.

- A Professional Tune is Not Optional: To capitalize on the increased airflow, you must get a professional engine tune. Recalibrating the ECU is essential for unlocking the power gains from your new head work and ensuring your engine runs safely and reliably.

The 5-Angle Valve Job, Explained

If you’re looking to get more power out of your Subaru engine, you’ve probably heard the term “5-angle valve job” thrown around. It’s a highly effective cylinder head modification that goes beyond a standard factory setup to significantly improve airflow. Think of it as creating a smoother, more efficient pathway for the air-fuel mixture to enter the combustion chamber and for exhaust gases to exit. This optimization is key to gaining more horsepower and torque, making it a popular upgrade for enthusiasts who demand higher performance from their vehicles, whether on the track or the trail.

Signs Your Engine Needs a Valve Job

Your Subaru's engine usually tells you when something is wrong, and worn valves are no exception. One of the most obvious signs is a noticeable loss of power. If your WRX or STI feels sluggish and isn't pulling as hard as it used to, it could be because the valves aren't sealing correctly, causing a drop in compression. You might also see blue smoke puffing from your exhaust, which often points to worn valve seals allowing oil to leak into the combustion chamber. Another classic symptom is a rough idle or engine misfires. When valves don't seat properly, combustion becomes inconsistent, leading to that shaky feeling at a stoplight. These issues signal that your engine's airflow is compromised and it's time to look into more serious performance parts and services.

Common Causes of Valve and Seat Wear

So, what causes this kind of wear in the first place? For performance-oriented Subaru owners, frequent high-RPM operation is a major factor. Pushing your engine hard on the track or during spirited drives generates immense heat and pressure, which accelerates wear on the valve seats. Overheating is another enemy, as excessive temperatures can warp engine components and prevent the valves from sealing tightly. Over time, simple high mileage, corrosion, and material fatigue can also take their toll, especially without meticulous maintenance. A proper engine tune is crucial for managing these stresses, ensuring your engine operates safely even when you're demanding maximum performance.

First, How Does a Standard Valve Job Work?

From the factory, your Subaru’s cylinder heads come with a standard 3-angle valve job. This means there are three distinct angles cut into the valve seat—the surface where the valve seals against the cylinder head. These angles are designed to ensure the valve closes tightly, preventing leaks and maintaining compression, which is essential for any engine to run properly. While a 3-angle job is perfectly adequate for a stock vehicle, it’s not optimized for maximum airflow. It gets the job done, but it leaves a lot of performance potential on the table for those looking to push their engine further.

Decoding the Five Critical Angles

Here’s where things get a little misunderstood. A "5-angle valve job" isn't actually five separate angles cut into the valve seat itself. The term is a bit of a shorthand in the performance world. It still includes the three critical angles on the seat, but adds two more cuts on the valve itself: one on the face of the valve and a "back cut" on the rear side. These additional angles on the valve work in harmony with the seat angles to create a more streamlined path for air to flow around the valve head, reducing turbulence as it enters the port. This meticulous shaping of all related performance parts is what truly defines a high-quality valve job.

Understanding the Angle Combinations

The magic of a 5-angle valve job lies in how the different cuts work together to create a super-efficient pathway for air. The central, most important cut is the 45-degree angle, which serves as the primary sealing surface for the valve. To smooth the transition, machinists add "top cuts" (often at 35 and 25 degrees) that guide the air-fuel mixture as it enters the combustion chamber. Below the 45-degree seat, "bottom cuts" (like 55 and 65 degrees) help the air flow smoothly out of the port and around the valve head. This multi-angle approach eliminates the sharp edges found in a standard 3-angle job, creating a curved, funnel-like shape that reduces turbulence and allows the engine to inhale and exhale with much greater efficiency.

How Machinists Choose the Right Angles

Choosing the perfect combination of angles isn't a one-size-fits-all formula; it's a craft that requires deep expertise. A skilled machinist considers the specific architecture of your Subaru's cylinder heads, including the port size and valve dimensions. They also factor in your performance goals—whether you're building a high-revving track car or a torque-focused overlander. The objective is always to maximize airflow without sacrificing the integrity of the valve seal. This process demands incredible precision and specialized equipment, which is why it should only be trusted to professionals. A poorly executed valve job can actually hurt performance or, even worse, damage your cylinder heads, making professional engine services a critical investment.

3-Angle vs. 5-Angle: Does It Really Matter?

The primary difference between a 3-angle and a 5-angle valve job is the level of performance optimization. While a 3-angle job creates a functional seal, the transitions between the angles can be abrupt, creating turbulence that restricts airflow at high RPMs. A 5-angle valve job is considered a true performance cut because it adds those extra angles to blend the valve seat into the port more smoothly. This creates a funnel-like effect that encourages air to flow faster and more efficiently into the cylinder. For owners seeking serious Subaru WRX upgrades, this improved airflow directly translates to a stronger, more responsive engine.

Common Myths About Multi-Angle Valve Jobs

It’s crucial to understand that more angles aren't always better, and the quality of the work is paramount. You can't just cut random angles into a cylinder head and expect positive results. In fact, poorly executed machining with incorrect angles can create a "radius" effect that actually hurts airflow and reduces power. The specific angles used must be carefully selected based on the engine, camshaft profile, and intended use. This is why choosing a machine shop with deep expertise in Subaru engines is so important. Proper execution requires precision equipment and a technician who understands the complex dynamics of engine airflow, which is often perfected through professional engine tuning services.

Why Your Subaru Needs a 5-Angle Valve Job

A 5-angle valve job is more than just a repair; it's a fundamental upgrade that refines your engine's breathing ability. By optimizing the path air and fuel take into and out of the combustion chamber, this precision service delivers tangible gains in power, efficiency, and longevity. Whether you're pushing your WRX on the track or equipping your Crosstrek for a long-haul overlanding trip, understanding these benefits shows why it's a cornerstone of any serious engine build.

Achieve Better Airflow for More Power

The primary goal of any performance engine modification is to improve airflow, and a 5-angle valve job excels at this. By cutting additional angles on the valve seat, we create a smoother, less restrictive path for the air-fuel mixture to enter the cylinder. This significant increase in airflow allows your engine to breathe more freely, especially in high-performance or turbocharged applications. More air means a more potent combustion event, which translates directly into more horsepower and torque. It’s a foundational step for anyone looking to maximize their engine’s potential with other performance parts.

The Science of Smoother Airflow

At its core, a 5-angle valve job is all about fluid dynamics. The standard 3-angle cut found in factory heads gets the job done, but the sharp transitions between the angles create turbulence. This choppy airflow acts like a bottleneck, slowing down the air-fuel mixture as it enters the cylinder. By adding two extra, carefully calculated angles, a machinist creates a smoother, more gradual "funnel" for the air to follow. This streamlined path significantly reduces turbulence and allows the air to move faster and more efficiently. For a turbocharged engine that relies on forcing as much air as possible into the cylinders, this modification is critical for building a truly powerful and responsive performance engine.

Potential Gains: A Look at the Numbers

While it’s impossible to quote exact horsepower figures from a valve job alone, its impact is foundational. Think of it as removing a major restriction in your engine's respiratory system. The gains are most noticeable at higher RPMs, where a standard 3-angle job starts to choke off airflow. By allowing the engine to breathe freely, a 5-angle valve job enables your turbo, intake, and exhaust to perform at their full potential. For owners of high-performance models like the Subaru STI, this means the engine can sustain power deeper into the rev range. The true potential is unlocked during the final tune, where your tuner can adjust fuel and timing to take full advantage of the massive increase in airflow.

Create a Tighter, More Reliable Valve Seal

Precision is key to performance, and a 5-angle valve job creates a much better seal between the valve and the valve seat. This improved seating ensures that no compression is lost during the combustion cycle, making your engine run more efficiently. A perfect seal prevents leaks, which can rob your engine of power and lead to bigger problems down the road. This enhancement also improves low-lift flow, meaning the engine breathes better even at lower RPMs. The result is a smoother, more responsive engine that makes the most of every single ignition.

What Makes an Ideal Performance Seal?

An ideal performance seal does two things perfectly: it prevents any compression leaks when the valve is closed and facilitates maximum airflow when it's open. The precision of a 5-angle valve job is what makes this possible. The carefully machined angles ensure the valve face and seat meet with perfect contact, containing the explosive force of combustion to push the piston down. This prevents power loss and improves engine efficiency. Just as importantly, the smooth transition created by the multiple angles reduces turbulence, allowing the engine to breathe better even at lower RPMs. This results in a more responsive throttle and a smoother powerband, which requires expert engine tuning services to fully utilize.

Protect Your Engine for the Long Haul

While the power gains are exciting, a 5-angle valve job is also a smart investment in your engine's health. Over time, the constant heat and pressure of combustion can cause wear and corrosion on the valve seating surfaces, leading to leaks and a loss of compression. Our Subaru machine shop services address this by creating a fresh, perfectly machined surface that stands up to abuse. By ensuring a perfect seal and reducing wear on critical components, this service extends the life of your engine, giving you peace of mind on the street, track, or trail.

A Note on Durability in High-RPM Engines

Engines that operate consistently at high RPMs subject valvetrain components to immense stress. The combination of intense heat and pressure can rapidly wear down factory valve seats, which can lead to compression loss and, eventually, engine failure. A precision 5-angle valve job is a direct countermeasure, creating a much stronger and more reliable seal that is built to withstand the demands of high-performance driving. This superior seal ensures that compression remains consistent during the combustion cycle, even under the most extreme conditions. For owners of powerful, turbocharged vehicles like the Subaru STI, this modification isn't just about gaining power—it's about building a resilient engine that can handle repeated track days and aggressive driving without sacrificing its long-term health.

How Different Subaru Models Benefit

While a standard 3-angle valve job is fine for a basic rebuild, a 5-angle cut is widely considered a true performance upgrade. The extra angles create a more gradual transition, or "blend," from the port to the valve seat, which is critical for high-revving engines in models like the Subaru WRX and STI. This refinement leads to noticeable improvements in throttle response and overall engine efficiency. For overlanding builds like the Forester or Crosstrek, the added efficiency and reliability from a perfect valve seal are just as valuable, ensuring your engine performs flawlessly when you're far from home.

Limitations and Alternatives to Consider

While a 5-angle valve job is a fantastic upgrade for many Subaru builds, it’s not a universal solution for every goal or budget. Understanding its limitations is just as important as knowing its benefits. The effectiveness of any cylinder head work depends heavily on the engine's overall setup, your specific performance goals, and most importantly, the skill of the machinist performing the work. Before you commit, it’s wise to consider if it’s the right fit for your project, what kind of results you can realistically expect, and whether other options might better suit your needs. This balanced perspective ensures you invest your money where it will make the most impact.

When a 3-Angle Job Might Be Better

A standard 3-angle valve job is often the most practical choice for a basic engine rebuild or a daily driver that isn't destined for the track. If your goal is simply to restore your engine to factory specifications and ensure a reliable seal, the complexity and cost of a 5-angle cut may not be necessary. A 3-angle job effectively seals the combustion chamber, maintains compression, and provides perfectly adequate performance for stock or lightly modified vehicles. It’s a solid, dependable service that gets the job done without the premium price tag associated with high-performance machining, making it a smart choice for budget-conscious rebuilds.

Managing Performance Expectations

It's important to see a 5-angle valve job as one component of a complete performance system, not a standalone magic bullet. The primary difference between it and a 3-angle job is how it optimizes airflow at high RPMs by reducing turbulence. However, to truly capitalize on that improved airflow, your engine needs supporting modifications. Without a performance camshaft, upgraded intake and exhaust systems, and a professional engine tune to recalibrate the ECU, the gains will be minimal. The valve job creates potential; the tune is what unlocks it, ensuring all your components work together to produce safe, reliable power.

Why Results Vary Between Engines

Not all engines respond to a 5-angle valve job in the same way. The specific architecture of your Subaru’s cylinder heads plays a huge role in the outcome. For example, some head designs have more restrictive ports from the factory and therefore have more to gain from precision machining. Others might already be fairly efficient. Factors like whether the valve seats are raised or sunken can also influence the final results. This is why there’s no universal horsepower number to quote—the gains are entirely dependent on the unique characteristics of your engine and the synergy between all of its performance parts.

Alternative: The Fully Radiused Valve Job

For those seeking the absolute maximum in airflow, a fully radiused valve job is another option to consider. Instead of cutting a series of flat angles, this technique creates one continuous, smooth curve from the port throat to the combustion chamber. This design theoretically offers the least possible resistance to airflow. However, it is a highly specialized and expensive process that requires incredible precision. It also highlights a critical point: more angles are not always better. A poorly executed 5-angle job can accidentally create a "radius" effect that hurts flow, proving that the quality of the work and the machinist's expertise are far more important than the number of angles cut.

A Step-by-Step Look at the Process

A professional 5-angle valve job isn’t a quick fix; it’s a detailed procedure that requires specialized equipment and a deep understanding of engine dynamics. When you invest in this service, you’re paying for precision, expertise, and peace of mind. Understanding what goes on behind the scenes will help you appreciate the craftsmanship involved and ensure you’re working with a shop that doesn’t cut corners.

The entire process can be broken down into four key stages: a thorough inspection, precision machining, rigorous quality control, and post-service integration. Each step is essential for unlocking the full potential of your Subaru’s engine, whether you’re building a track-ready STI or a capable overlanding Crosstrek. At Crawford Performance, our Subaru machine shop services follow this exact methodology to guarantee reliable and repeatable results, ensuring your cylinder heads are returned to you in better-than-new condition. Let’s walk through what a high-quality service looks like from start to finish.

Step 1: A Thorough Cylinder Head Inspection

Before any machining begins, the cylinder heads are completely disassembled and meticulously cleaned. This isn't just a quick wipe-down; it's a deep clean to remove all carbon buildup, oil, and grime, revealing the bare metal. From there, a comprehensive inspection begins. Technicians check for any warping on the head surface, measure for correct thickness, and assess the condition of the valve guides. They also perform careful checks for any hidden cracks or bent components that could lead to major engine failure down the road. This foundational step is non-negotiable, as it identifies any underlying issues that must be addressed to ensure a successful and reliable build.

Step 2: Machining the Five Angles with Precision

This is where the performance gains are created. Using highly accurate machinery, a technician cuts the five distinct angles into each valve seat. This process requires extreme precision to ensure every angle is perfect and every seat is identical. During this stage, additional services like flow bench testing may be performed to measure the increase in airflow and validate the effectiveness of the work. The goal is to create a smooth, aerodynamic path for the air-fuel mixture to enter the combustion chamber. This is especially critical for turbocharged engines like those in the Subaru WRX, where efficient airflow is the key to making more power.

Replacing vs. Resurfacing Valve Seats

During the machining process, a critical decision is made: whether to resurface the existing valve seats or replace them entirely. Resurfacing, or "cutting," is the standard procedure where a thin layer of material is machined off the seat to create a fresh, perfectly angled surface for the valve to seal against. This is usually all that’s needed for a high-performance valve job. However, if the seats are severely worn, damaged, or have been cut too many times in the past, they may be too thin to machine safely. In these cases, replacement is the only option. A skilled technician will make this call after a thorough inspection, as choosing the right path is crucial for ensuring a reliable seal and optimal engine performance. This is why trusting your heads to a shop with deep Subaru expertise is so important for any performance parts build.

Step 3: Final Checks and Quality Testing

Once the machining is complete, the work isn’t finished. The next critical step is quality control. The cylinder heads are rigorously tested to ensure they are perfectly sealed and free from leaks. This involves pressure testing the coolant and oil passages to expose any hidden cracks or porosity in the casting that might have been missed during the initial inspection. This test is vital for engine reliability, as it prevents catastrophic issues like oil and coolant mixing. A reputable shop will never skip this step, as it guarantees the structural integrity of the cylinder heads before they are reinstalled on your engine.

Step 4: Following the Proper Break-in Procedure

A well-executed 5-angle valve job delivers immediate and lasting benefits. Unlike some modifications, the improvements in airflow, particularly at low valve lift, don’t fade over time. While the valve job itself doesn’t require a specific break-in period, the newly rebuilt engine will. It’s crucial to pair this mechanical upgrade with the right supporting modifications and a professional tune. Proper engine tuning services will adjust the fuel and ignition timing to take full advantage of the increased airflow, ensuring you get the power, efficiency, and reliability you paid for. Following proper reassembly and tuning protocols will solidify your investment for years to come.

How to Find a Shop You Can Trust

A 5-angle valve job is a precision task. The quality of the work directly impacts your engine's performance and longevity, so choosing the right shop is non-negotiable. You're not just paying for a service; you're investing in your Subaru's heart. Look for a partner who understands these engines inside and out and has the right tools and experience to deliver results you can feel on the road or track.

Check for the Right Tools and Expertise

Finding a shop with the right tools is the first step. A performance 5-angle valve job requires specialized machinery, like a Serdi or Sunnen seat and guide machine, to achieve the necessary precision. A standard automotive shop might not have this equipment. Beyond the tools, look for technicians with deep experience in Subaru boxer engines. Ask about their background and if they have certifications or a portfolio of Subaru builds. True expertise means understanding the unique demands of these engines, which is essential for any engine tuning services you might need down the line. An expert knows how to maximize flow without compromising reliability.

What to Ask a Potential Performance Shop

A reputable performance shop will be transparent about its process. When you call or visit, ask them to walk you through how they handle a valve job. Do they start with a thorough inspection and pressure test to diagnose issues like wear or corrosion? A great shop can explain why the work is needed, not just what they're going to do. Look for reviews from other Subaru owners and ask to see examples of their work. A shop that is proud of its craftsmanship will be happy to show you. This initial evaluation helps build the trust needed for a major engine project.

What Should You Expect to Pay?

The cost of a valve job can vary significantly, often ranging from a few hundred to over a thousand dollars. This depends on the initial condition of your cylinder heads. A basic service on clean, undamaged heads will be on the lower end. However, if your heads are warped, require crack repair, or need new valve guides and seats, the price will increase. Always ask for a detailed, itemized quote before agreeing to any work. This should break down the costs for inspection, machining, parts, and labor. Understanding the full scope of the project upfront prevents surprises and ensures you know exactly what you're paying for.

How to Spot High-Quality Machining Work

Once the work is done, you should be able to see the quality. After machining, a perfect valve seal will leave a distinct, even grey line on the valve seat. This contact patch should be consistent all the way around and centered on the valve face. If it's uneven or too wide, the seal won't be optimal. A top-tier shop will often provide documentation, like flow bench results or photos of the finished work. They also use high-quality performance parts if replacements are needed, and they won't replace components unnecessarily. Quality is in the details, and precision is everything.

Always Ask About Their Warranty

Any shop performing major engine work should stand behind it with a warranty. Don't hesitate to ask about their coverage before you commit. What does the warranty include—parts, labor, or both? How long does it last, and are there any conditions you need to meet? For example, we offer a comprehensive 12-month/12,000-mile warranty on our engine builds because we are confident in our process and craftsmanship. A strong warranty is a clear sign that the shop believes in the quality of its work and is committed to your engine's long-term performance and reliability. It’s your peace of mind.

The Crawford Performance Engine Warranty

A warranty is more than a document; it’s a shop’s statement of confidence in its own craftsmanship. At Crawford Performance, we back every engine build with a comprehensive 12-month/12,000-mile warranty because we trust our process. This guarantee is built on decades of experience and a meticulous approach to every detail, from initial machining to final assembly. We know our engines are built to be both powerful and reliable. This warranty gives you the assurance that your investment is protected, whether you’re pushing your STI on the track or taking your Forester on a remote overlanding adventure. It’s our commitment to quality, ensuring our expert engine tuning services and custom builds deliver the performance you demand.

Making the Most of Your New Valve Job

A 5-angle valve job is a fantastic upgrade for your Subaru's engine, but it doesn't work in a vacuum. To truly capitalize on the improved airflow and efficiency, you need to think about the entire system. The work you do after the service is just as important as the machining itself. By pairing your newly serviced heads with the right modifications, a precise tune, and consistent maintenance, you’ll ensure you get every bit of power and reliability you paid for. Think of the valve job as the foundation—now it’s time to build upon it.

Choose Supporting Mods That Work Together

With your cylinder heads now flowing significantly more air, the next logical step is to address other components that might create a bottleneck. To maximize gains, you need to ensure the entire intake and exhaust path is optimized. Consider modifications like "Clover Leafing," a technique that involves removing material around the valves to further improve airflow. This small change can add a surprising amount of extra flow at full valve lift.

Beyond head-specific work, look at performance camshafts, a high-flow intake manifold, and a less restrictive exhaust system. Each of these performance parts complements the 5-angle valve job, creating a cohesive system that breathes more efficiently. The goal is to create a clear, unobstructed path for air to enter and exit the engine, allowing you to take full advantage of your head work.

Why a Professional Tune is Non-Negotiable

After making significant changes to your engine's airflow, a professional tune isn't just recommended—it's essential. Your Subaru's factory ECU is calibrated for stock components. The increased airflow from the 5-angle valve job means the engine's volumetric efficiency has changed, and the stock fuel and ignition maps are no longer adequate. Running on a stock tune can lead to poor performance, lean conditions, and potentially catastrophic engine damage.

A proper tune adjusts the air-fuel ratio and ignition timing to match the new airflow characteristics. This not only unlocks the full power potential of your modifications but also ensures your engine runs safely and reliably. Professional engine tuning services will optimize these parameters on a dynamometer, giving you a custom map tailored specifically to your vehicle and its unique set of upgrades.

Adjust Your Maintenance Routine

High-performance engines demand a higher level of care. Now that your Subaru is making more power, a diligent maintenance routine is your best insurance policy against premature wear and tear. Stick to a schedule of regular oil changes using high-quality synthetic oil that can withstand the increased stress and heat. Consistently check all your fluid levels and be mindful of any new or unusual sounds from the engine bay.

It’s also wise to have a professional periodically inspect your engine. Technicians can check for issues that aren't always visible, like bent components, worn valve guides, or hidden cracks that could lead to major problems down the road. Protecting your investment with proper maintenance ensures you can enjoy the added performance for years to come without worry.

What's the Next Step in Your Build?

A 5-angle valve job is a major step forward, but it can also be a gateway to even bigger builds. As you enjoy your car's new capabilities, start thinking about your long-term goals. Are you aiming for a reliable daily driver with some extra punch, or are you building a dedicated track or rally car? Your answer will guide your next steps.

If you're chasing maximum power, your path might lead to fully aftermarket cylinder heads, which often feature improved port designs and valve angles beyond what's possible with factory castings. For those building an overlanding solution, the focus might shift to strengthening the bottom end for long-term durability. Planning your build in stages helps you make smart, cohesive choices that bring you closer to your ultimate performance goals.

Related Articles

- Subaru Machine Shop Services at Crawford Performance

- The Ultimate Subaru Engine Upgrade Guide

- Your Complete Subaru AOS Installation Guide

Frequently Asked Questions

Is a 5-angle valve job really necessary for a daily-driven Subaru? While it’s a foundational upgrade for track builds, a 5-angle valve job offers significant benefits for a daily driver, too. Think of it less as a racing-only mod and more as a way to make your engine fundamentally better. The improved airflow and perfect valve seal lead to better throttle response, increased efficiency, and smoother operation at all RPMs. It also enhances long-term durability by ensuring critical components are perfectly mated, which is a smart investment for any engine you care about.

How much horsepower will I actually gain from this service? This is the big question, but there isn't a single number. A 5-angle valve job doesn't create horsepower on its own; it enables your engine to breathe more efficiently so other modifications can reach their full potential. The final power gain depends entirely on your complete setup, including your turbo, camshafts, exhaust, and most importantly, your engine tune. The valve job removes a major restriction, allowing a properly tuned engine to make significantly more power safely and reliably.

What’s the difference between a 5-angle valve job and "porting and polishing"? It's easy to confuse the two, but they address different parts of the airflow path. A 5-angle valve job focuses specifically on the valve and the seat where it seals, creating a precise, aerodynamic transition right at the combustion chamber entrance. Porting and polishing involves reshaping and smoothing the entire intake and exhaust runners inside the cylinder head to reduce turbulence. The two services are complementary; a valve job perfects the seal, while porting perfects the path leading to it.

Will this service make my car less reliable or harder to drive? Quite the opposite. When performed correctly by an experienced technician, a 5-angle valve job actually increases engine reliability. By creating a perfect, durable seal, it prevents compression leaks and reduces wear on the valves and seats. This leads to a healthier, more efficient engine. Any potential reliability issues would stem from poor workmanship or an improper tune that fails to account for the engine's new airflow capabilities, which is why choosing the right shop is so critical.

How long does a 5-angle valve job usually take? This isn't an in-and-out service. The process is meticulous and requires precision at every step. Once the cylinder heads are removed from the car and delivered to the machine shop, you should expect the inspection, cleaning, machining, and testing to take several days. The total time can vary based on the initial condition of your heads—if they need repairs like crack welding or new valve guides, the process will take longer. A quality shop will never rush the job.