Your Guide to a Perfect Subaru AOS Install

Share

Planning to add more power to your Subaru? Before you even think about a bigger turbo or a new tune, you need to build a strong foundation. An Air/Oil Separator is that foundation—it's non-negotiable for a healthy engine. It works by preventing oil blow-by from lowering your fuel's octane and gunking up your intercooler. A clean engine is an efficient engine, and an AOS ensures all your future performance parts can work at their best. This guide will show you exactly how to tackle your Subaru AOS install, setting your build up for reliable power for years to come.

Key Takeaways

- Protect Your Engine's Foundation: An AOS is a critical mod that prevents oil buildup in your intake, which preserves your engine's power, improves reliability, and helps prevent damaging engine knock.

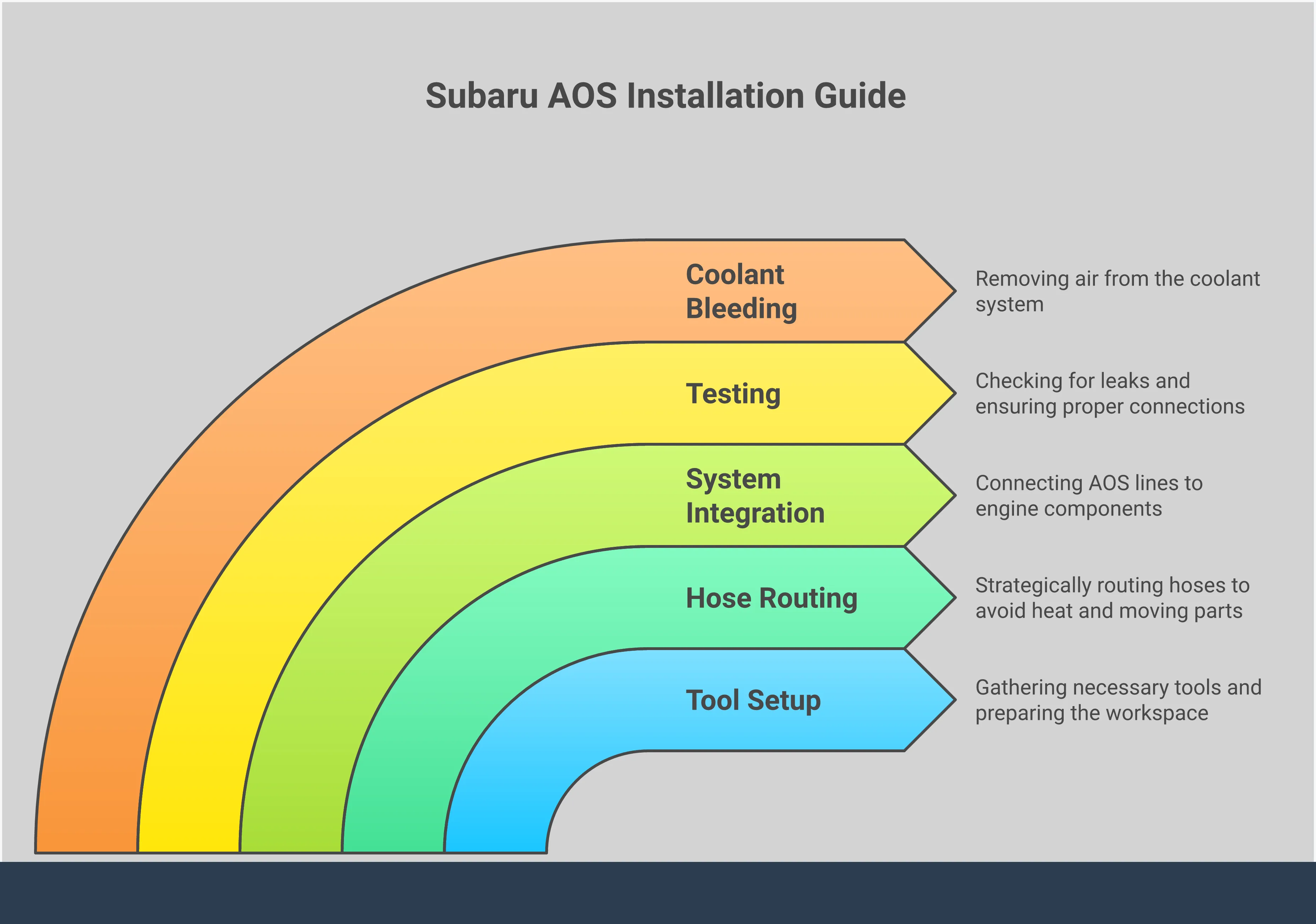

- A Successful Install is in the Details: Master the installation by taking "before" photos for reference, carefully routing all new hoses away from heat and moving parts, and properly bleeding the coolant system as a final step.

- Perform Regular Health Checks: Your AOS is a low-maintenance part, but not a no-maintenance one. A quick monthly inspection of hoses and connections ensures it continues to protect your engine for the long haul.

What Does an Air/Oil Separator (AOS) Do?

Before we get our hands dirty with the install, let’s talk about what an Air/Oil Separator actually is and why it’s one of the most recommended upgrades for any Subaru. Think of it as a guardian for your engine. While it might not be the flashiest part you'll ever install, its role is absolutely critical. It doesn't add a ton of horsepower on its own, but it protects the power you already have and lays a solid foundation for any future modifications you have planned. Every engine produces something called "blow-by," which is a mix of gases and oil vapor that slips past the piston rings and into the crankcase. Your car's stock PCV (Positive Crankcase Ventilation) system is designed to handle this, but it often falls short, especially on modified or hard-driven engines. It allows oily vapor to get sucked right back into your intake. An AOS is the definitive solution to this problem. Whether you're pushing your car on the track or just want to ensure its long-term health, understanding how an AOS works will make you appreciate its role in your build. It’s a simple concept that delivers significant results, protecting your investment and keeping your boxer engine running strong.

Breaking Down its Form and Function

An Air/Oil Separator (AOS) does exactly what its name suggests: it separates oil from the air inside your engine’s crankcase ventilation system. During normal operation, your engine produces pressure that contains oil vapor. The AOS is designed to capture this oily mist before it gets recirculated back into your intake. Just like an air filter keeps dirt out of your engine, an AOS filters out oil, ensuring only clean, dry air enters the combustion chamber. This simple function is critical for maintaining your engine's efficiency and power, making it one of the most effective performance parts you can install for engine longevity.

Why an AOS is Heated

You might notice that most quality Air/Oil Separators have coolant lines running to them, and there’s a very important reason for that. The gases coming from your crankcase aren't just oily; they also contain a significant amount of water vapor. When these hot gases hit a cold metal AOS canister, especially in cooler weather, that water vapor can condense and mix with the separated oil. This creates a thick, milky sludge that can clog the system and prevent it from working correctly. By circulating hot engine coolant through the AOS body, the unit stays warm enough to keep the water in a vapor state. This allows the water vapor to pass through the system and get burned off in the combustion chamber as intended, while only the liquid oil is separated and returned to your engine. A heated AOS ensures consistent performance year-round, protecting your engine from both oil contamination and sludge buildup.

AOS Variations for Street, Track, and Non-Turbo Models

Not all Air/Oil Separators are created equal, and the right one for you depends entirely on how you use your Subaru. For the vast majority of owners who daily drive their car with some spirited weekend fun, a street-focused AOS is the perfect fit. For example, the Crawford Performance V3 AOS features a patented dual-chamber design that is incredibly efficient at separating oil without requiring the removal of any factory smog equipment, making for a much simpler installation. However, if you have a dedicated track car that experiences high G-forces and extreme conditions, you might consider a competition-oriented model. These systems, like the Crawford V2, are designed for maximum performance in a racing environment. Just be aware that some track-focused AOS kits may require removing certain emissions components, so always check your local regulations before you install one.

The Science Behind How It Works

So, how does it pull this off? As your engine runs, pressurized air and oil vapor are pushed out of the crankcase. This mixture enters the AOS unit, where it passes through a series of baffles or a centrifugal chamber. This process causes the heavier oil droplets to separate from the air and condense. Once separated, the collected oil is safely drained back into the engine's oil pan, ready to be used again. Meanwhile, the now-clean air is routed back into your intake manifold. It’s a closed-loop system that constantly cleans the air your engine breathes, preventing oil from contaminating vital components and keeping your oil where it belongs.

Why Your Subaru Needs One

For Subaru’s boxer engines, especially turbocharged models, an AOS is practically essential. Without one, that oil vapor goes straight into your intake, coating everything from the manifold to the valves in a layer of gunk. This buildup can lower your fuel's effective octane rating, which increases the risk of engine knock or detonation—something you definitely want to avoid. By keeping the intake system clean, an AOS helps maintain consistent performance, prevents power loss from carbon buildup, and protects the overall health of your engine. It’s a foundational upgrade for any Subaru STI looking for reliability and sustained power.

The Link Between Oil Blow-By and Ringland Failure

Subaru's flat engine design is unique, but it has a specific quirk: it tends to push more oil toward the top of the pistons. When this oil vapor gets recirculated into your intake via the stock PCV system, it mixes with your fuel and air. This contamination effectively lowers your fuel's octane rating, making it more prone to "detonation"—uncontrolled explosions inside the combustion chamber. Detonation puts immense stress on your engine's internals and is a leading cause of ringland failure, a notoriously common and costly issue for Subaru owners. An AOS intercepts this process entirely. By capturing the oil before it ever reaches the intake, it ensures your fuel's octane remains pure, preventing detonation and protecting your pistons from damage. It’s a critical defense for the long-term health of your engine.

Benefits for Ethanol-Fueled Engines

If you’re running ethanol-based fuels like E85 to make more power, an AOS becomes even more important. While ethanol is great for performance, it can also lead to fuel dilution, where unburnt fuel vapors seep past the piston rings and mix with your engine oil. This compromises the oil's viscosity and its ability to properly lubricate critical components. An AOS improves crankcase ventilation, helping to pull these harmful fuel vapors out of the oil and send them back through the combustion process. This protects your engine's lubrication system from premature wear and is an essential supporting mod for any high-performance engine tuning service that utilizes ethanol fuels.

Prepping for Your Subaru AOS Install

A great installation starts with great preparation. Before you get under the hood, taking a few minutes to organize your tools and parts will save you a ton of headaches later. It’s the difference between a frustrating afternoon and a smooth, successful upgrade. We'll walk through the essential tools, what's in your kit, and the most important safety steps to take before you begin.

Setting Realistic Expectations: Difficulty and Time

Alright, let's be real about the installation process. Installing an Air/Oil Separator is a significant step up from a simple bolt-on mod, and it's important to go in with the right mindset. This is not a quick afternoon project; you should set aside several hours, or even a full day, especially if it's your first time. Even experienced mechanics find it to be a time-consuming job. The main challenge often comes down to tight spaces and one particularly stubborn hose connected to the PCV valve. Rushing through it is the fastest way to make a mistake, so patience is your most valuable tool here. Many find that the included paper instructions can be a bit vague, so I highly recommend watching a few different installation videos online beforehand. Seeing it done will give you a much clearer picture and help you prepare for the tricky spots, ensuring your new AOS can properly protect your engine's performance for years to come.

Your Essential Tool Checklist

Nothing slows down a project like having to stop and search for the right tool. Let's get your toolbox in order first. While every car and kit can have its quirks, this list covers the basics you'll likely need for the job. Having these on hand will make the process much more efficient.

- Phillips and flathead screwdrivers

- 3/8" ratchet with 10mm, 12mm, and 19mm sockets

- A few 3/8" extensions (6" and 12" are great to have)

- Allen sockets (1/4", M3, M5)

- Combination wrenches (10mm, 12mm, 7/8", 11/16")

- Trim removal tool

- Needlenose pliers

- Hose cutter

- Electrical tape

Specialty Tools That Make the Job Easier

While the essential tools will get the job done, a few specialty items can make the process significantly smoother and more professional. Think of these as your secret weapons against frustration. A pair of dedicated hose clamp pliers, for instance, will save your knuckles when dealing with stubborn factory clamps in tight engine bays. A quality hose cutter ensures every cut is clean and straight, which is critical for preventing future leaks. When you're routing new lines, a 90-degree pick is perfect for maneuvering hoses into the ideal position, safely away from hot or moving components. Finally, a torque wrench is a must-have for peace of mind, guaranteeing every bolt is tightened to the exact spec. Investing in these tools not only simplifies this installation but makes working on all future performance parts a much more enjoyable experience.

What's Inside the AOS Kit?

Now, let's open up your AOS kit. Lay everything out and check it against the parts list that came with it. It’s much better to find out if something is missing now than when your car is half apart. Your kit should include core performance parts like these:

- The Air/Oil Separator unit itself

- A variety of coolant and breather hoses

- Oil drain and lower breather hose assembly

- Mounting bracket and any necessary hardware (bolts, washers, clamps)

- ECU relocation bracket (if required for your model)

- Zip ties, high-temp caps, and PCV fittings

- Upper recirculation housing with a preinstalled o-ring

How to Create a Safe Workspace

This is the most important step of your prep work. Before you do anything else, grab a 10mm wrench and disconnect the negative terminal on your battery. This is non-negotiable. It protects you from any electrical mishaps and safeguards your car’s sensitive electronics, like the Power Steering Control Module. A safe workspace is a smart workspace. Make sure you have good lighting and that your car is parked on a level surface, especially if you need to jack it up. Taking these simple precautions ensures your install goes smoothly and safely from start to finish.

How to Prep Your Subaru for the Install

Before you start turning wrenches, taking a few minutes to prep your car will make the entire installation process much smoother. Think of it as setting yourself up for success. Proper preparation not only saves you from future headaches but also ensures the job is done safely and correctly the first time. You’ve already invested in quality performance parts, so let’s make sure the installation matches that standard.

Positioning and Cooling Your Car

First things first: safety. Before you do anything else, make sure your engine is completely cool to avoid any burns. The most important step is to disconnect the negative battery terminal using a 10mm wrench. This simple action prevents any accidental electrical shorts while you work, protecting both you and your Subaru’s sensitive electronics, like the Power Steering Control Module. It’s a non-negotiable step that takes less than a minute but can save you from a world of trouble. Once the battery is disconnected, you’re clear to start working in the engine bay without worrying about causing any electrical issues.

Don't Skip This: Take "Before" Photos

Trust me on this one—your future self will thank you. Before you disconnect a single hose or remove a single bolt, pull out your phone and take plenty of pictures of your engine bay from multiple angles. Pay special attention to how factory hoses are routed, particularly around the turbo and intake manifold. For extra clarity, grab some masking tape and label the hoses before you remove them. This creates a perfect visual roadmap for when it’s time to put everything back together. It eliminates any guesswork and ensures every connection goes exactly where it belongs, making reassembly a breeze.

Common Prep Mistakes to Avoid

Let’s be real: sometimes the instructions that come with a new part can be a bit confusing. One of the most common hurdles with an AOS install is routing the new hoses correctly. Always run them under or behind components like wiring harnesses and AC lines, and double-check that they are far away from any moving parts, especially the cooling fan blades. Another tricky spot can be the PCV valve hose. On some models, like the Subaru WRX, you might find access is tight. Reading through the instructions beforehand and supplementing with a video tutorial can help you anticipate these challenges.

Pro Tips Before You Begin

Before you dive in, let's cover a couple of pro tips that can make a huge difference. These aren't always in the official instructions, but they come straight from the community and experienced installers. Think of this as the advice you'd get from a friend who has done this job a dozen times. Taking a few extra minutes to follow these steps can save you from common frustrations and help ensure your installation is clean, correct, and secure. It’s all about working smarter, not harder, and setting your project up for a smooth finish from the very beginning.

Why You Should Watch Installation Videos First

While the instructions included with your kit are a great starting point, they don’t always capture the full picture. Many Subaru owners find that watching a few installation videos on YouTube provides invaluable context that a printed manual just can't offer. Seeing someone else perform the install helps you visualize tricky steps, like routing a specific hose or accessing a hard-to-reach bolt. It also prepares you for potential snags before they happen. Instead of relying solely on diagrams, you get a real-world look at the process, often with helpful commentary and tips that the installer discovered along the way. This is especially useful for complex installs on models like the Subaru STI.

Pre-Cleaning Mounting Threads

Here’s a simple trick that can prevent a major headache. Before you try to mount the AOS bracket, take one of the mounting bolts and carefully screw it into the threaded holes on your car’s frame or engine block by hand. These factory threads can often have a bit of paint overspray, dirt, or corrosion in them, which can make it difficult to start the bolts correctly. Running a bolt through first acts like a tap, cleaning out the threads and ensuring a smooth installation. This small step significantly reduces the risk of cross-threading or stripping the threads, which would be a much bigger problem to fix. It’s a perfect example of how five minutes of prep can save you an hour of frustration.

Your Step-by-Step Subaru AOS Install Guide

Alright, this is where the fun begins. With your tools laid out and your Subaru ready, it’s time to get hands-on. Remember to work slowly and methodically. Following these steps carefully will ensure your new Air/Oil Separator is installed correctly, giving you peace of mind and a healthier engine. If you get stuck, don't be afraid to pause and review your kit's specific instructions or re-read a step. You've got this.

Critical Warnings and Torque Specs

Now we're getting into the details that truly matter. These aren't just friendly suggestions; they are critical steps that directly impact how well your AOS functions. Getting these small things right ensures your engine is protected and your new part works exactly as designed. Pay close attention here, as a mistake in one of these areas can undermine the entire installation and lead to problems down the road. We'll cover the most common pitfalls so you can avoid them entirely.

Proper Drain Hose Routing

This is one of the most important rules of the entire install: the drain hose from the AOS must never go higher than the drain port on the bottom of the can. The system relies entirely on gravity to return the separated oil to your engine's oil pan. If you create an uphill path, the oil simply can't drain. It will pool in the hose or back up into the AOS unit itself, completely defeating the purpose of the installation. Make sure the hose has a consistent downward slope with no kinks or high spots. Double-check its path before you secure it, ensuring it’s clear of any hot or moving components.

Correct PCV Hose Orientation

Inside the 3/8-inch PCV hose, there's a small but vital one-way valve. It's crucial to know that this valve is not centered in the hose. The orientation is specific: the longer side of the hose connects to the engine's intake, while the shorter side connects to the AOS can. Installing this hose backward will block the flow of crankcase gases, causing pressure to build up inside your engine. This can lead to oil leaks from seals and gaskets, which is the exact opposite of what we want. Proper ventilation is key to the health of all your performance parts, so take a moment to identify the long and short sides to ensure you get it right the first time.

Remember to Reuse Factory Gaskets

As you remove parts like the blow-off valve and throttle body, be careful not to lose the factory gaskets. You will need to reuse them during reassembly. These gaskets are essential for creating an airtight seal, and forgetting them is a surefire way to introduce a boost or vacuum leak. A leak can cause all sorts of issues, from a rough idle to a check engine light, completely negating the benefits of your hard work. Before reinstalling, give the gaskets a quick inspection. If they look cracked, brittle, or damaged in any way, it's best to replace them. This ensures all your Subaru STI upgrades work together seamlessly.

Step 1: Disconnect and Remove Stock Parts

First things first, you need to clear some space in the engine bay. Start by removing the plastic engine cover—it usually just pops off. Next, take out the factory air intake snorkel and, on most models like the WRX and STI, the top-mount intercooler. This will give you much better access to the back of the engine where the PCV hoses live. Be gentle with all the plastic clips and electrical connectors you disconnect. I like to label them with masking tape so I remember exactly where everything goes during reassembly. Taking your time here prevents headaches later.

Step 2: Securely Mount the AOS Canister

Now, let's get the AOS unit itself situated. Your kit will come with a specific mounting bracket. Attach this bracket to the AOS can first, making sure the bolts are snug. The most common mounting location is on the passenger-side shock tower, where there are usually pre-existing threaded holes you can use. Go ahead and bolt the entire assembly into place. You want it to be solid and secure, as it will be subjected to engine vibration. A well-mounted unit is the foundation for a clean and reliable installation of your performance parts.

Step 3: Route and Connect the New Hoses

This is the most involved step: routing all the new hoses. You'll be connecting the AOS to the crankcase vents, the PCV valve, and the turbo inlet. The key is to route the hoses away from anything that gets hot (like the turbo and downpipe) or moves (like the alternator belt). A melted or chafed hose will cause a massive vacuum leak. Use the supplied zip ties to secure the hoses neatly. A clean routing not only looks professional but also ensures the long-term reliability of your setup, which is essential for any Subaru WRX upgrade.

Step 4: Tie into the PCV System

With the hoses routed, it's time to make the final connections to the PCV system. This involves connecting one of the AOS lines to the PCV valve port on the engine block and another to the crankcase breather ports on top of the engine. This setup allows the AOS to intercept the oily vapor coming from the crankcase before it can get into your intake. Double-check that all your hose clamps are tight. A loose clamp is a common source of post-installation vacuum leaks, which can cause rough idling and other engine issues.

Step 5: Reassemble and Double-Check Your Work

Before you put everything back together, take a moment to review your work. Are all the hoses secure? Are all clamps tight? Once you're confident, you can reinstall the intercooler, intake snorkel, and engine cover. Now, start the car and immediately check for any fluid leaks, especially from the coolant lines if your AOS uses them. Let the engine run for a few minutes and listen for the hiss of a vacuum leak. If everything looks and sounds good, you'll need to properly bleed the coolant system to remove any air pockets. A proper install is key to engine health, but pairing it with professional engine tuning services ensures your Subaru runs at its absolute best.

How to Handle Common Install Hurdles

Installing an Air/Oil Separator is one of the most rewarding upgrades for your Subaru, but it’s also one of the more involved projects you can take on in your garage. It’s totally normal to hit a few snags along the way. Even professional mechanics find it challenging. The key is to know what to expect and how to handle it.

From wiggling parts into a crowded engine bay to making sure every hose is perfectly placed, a few common hurdles can pop up. But don't worry, we've got you covered. Think of these challenges as part of the process. With a little patience and the right approach, you can get the job done right and be proud of the work you put in. Let’s walk through some of the most common installation issues and how to solve them like a pro.

Working in Tight Engine Bay Spaces

Let’s be honest: the Subaru engine bay doesn’t offer a ton of extra room. You’ll be working in some tight corners, especially around the intake manifold and turbo. The best advice here is to take your time and have the right tools on hand. A good set of flexible hose clamp pliers, extensions for your ratchet, and a magnetic parts tray will be your best friends. If you feel yourself getting frustrated, step away for a few minutes. Rushing the job is how bolts get dropped and knuckles get busted. A little patience goes a long way toward a successful and stress-free installation.

Tackling the PCV Hose Connection

Ask anyone who has installed an AOS, and they’ll likely tell you the PCV hose connection was the most frustrating part. It’s tucked away in an awkward spot, and the factory hose can feel practically welded on after years of heat cycles. This is a common hurdle, especially on turbocharged models like the Subaru STI, where space is at a premium. The secret to conquering this step is a combination of patience and the right approach. Use a long set of needle-nose pliers or a hose pick to gently work the old hose loose—twisting it is often more effective than just pulling. When you're ready to install the new hose, make sure the connection is clean and fully seated before tightening the clamp. A secure connection here is non-negotiable, as it prevents the vacuum leaks that can cause rough idling and tuning headaches down the road.

How to Route Hoses Without Kinks

How you route your AOS hoses is critical for the system to work correctly and safely. Poorly routed hoses can get kinked, rub against moving parts, or melt on hot components. As you connect everything, pay close attention to the path each hose takes. Make sure they run cleanly under wiring harnesses and away from things like cooling fan blades or belts. Use zip ties to secure them in place and prevent any movement. This simple step protects your investment in high-quality performance parts and ensures your engine runs smoothly for years to come.

Managing Coolant Lines and Spills

Your AOS integrates with your car’s coolant system to heat the unit and prevent condensation from turning into sludge. This means you’ll have to disconnect a couple of coolant lines during the install. To minimize spills, use a set of hose pinch-off pliers before you disconnect the factory hoses. Once the AOS is installed, you absolutely must bleed the coolant system to remove any air bubbles that got in. Trapped air can create hot spots in the engine and lead to overheating, so don't skip this crucial final step. It’s essential for protecting your engine’s health.

Quick Fixes for When Things Go Wrong

So you’ve finished the installation, but something seems off? Maybe you’re seeing an unexpected check engine light or odd sensor readings. First, don’t panic. Go back and double-check all your connections, especially the electrical ones. Make sure every hose clamp is tight and that no hoses are pinched. It’s also a good idea to inspect the O-rings on any fittings for wear and apply a bit of assembly lube to ensure a perfect seal. If you’ve re-checked everything and are still running into issues, it might be time to consult an expert. Sometimes a professional eye can spot something you missed, and our engine tuning services can help get everything dialed in perfectly.

Post-Install: Your First Start-Up Checklist

You’ve done the hard part—the wrenches are down, and your new AOS is in place. But before you hit the road, a few final checks are essential to make sure everything is running perfectly. Taking a few extra minutes now will save you from potential headaches later. This final phase is all about confirming a clean, leak-free installation so you can enjoy the benefits of your hard work. Let’s walk through these last crucial steps together.

Starting Your Engine for the First Time

This is the moment of truth. Once you’re confident everything is connected, it’s time for the first start-up. Turn the key and let your Subaru’s engine come to life. The goal here isn’t to go for a drive just yet, but to give the system its first run in a controlled way. Let the car idle for a few minutes while you stay close. This initial run cycles fluids through the new components and hoses, making it the perfect time to spot any issues right away. It’s a simple but critical step to confirm your installation was a success.

Performing a Thorough Leak Check

With the engine running, it’s time to play detective. Grab a flashlight and carefully inspect all the connection points, especially where you attached new hoses to the AOS unit and the engine. Look for any drips, moisture, or seeping fluids—coolant is the most common culprit here. Check the ground underneath your car as well. A secure, leak-free installation is a sign of a job well done. If you spot a leak, shut off the engine immediately, let it cool down, and then tighten the problematic connection before starting the car again.

How to Properly Bleed the Coolant System

Don’t skip this step! Air bubbles can get trapped in the coolant lines during the install, leading to overheating and inaccurate temperature readings. You need to bleed the system to get them out. With the engine cool but running, locate the small bleeder screw on your AOS unit. Using a 1/8" allen wrench, carefully loosen the screw until you see a steady stream of coolant with no sputtering air bubbles. Once it’s just fluid, hand-tighten the screw back into place. This ensures your cooling system and your new performance parts operate exactly as they should.

Using the Bleeder Screw

Anytime you open the cooling system, air gets in. This final step ensures you get it all out. With the engine cool but running, find the small bleeder screw on your AOS unit. Using a 1/8" allen wrench, carefully loosen the screw just enough to let air escape. You’ll hear some hissing and see some sputtering coolant at first—that’s the air working its way out. Keep it open until you see a steady, bubble-free stream of coolant. Once the stream is solid, hand-tighten the screw back into place. This simple procedure is non-negotiable; it guarantees your cooling system is free of air pockets, allowing it to protect your engine and new performance parts effectively.

Monitoring Coolant Temperature

With the system bled, let the car continue to idle for several minutes. Keep a close eye on the temperature gauge on your dashboard. You want to see the temperature rise steadily to its normal operating point and then hold steady as the thermostat opens and the cooling fans kick on. If the needle starts to climb into the red or fluctuates erratically, shut the engine off immediately. This is a sign that there might still be air trapped in the system or a potential leak. A stable temperature is the best indicator that your cooling system is happy and your installation was a success.

Topping Off the Coolant

After running the engine and bleeding the system, the coolant level in your overflow tank will likely have dropped. Turn off the engine and let it cool down completely before opening any part of the cooling system again. Once it’s cool, check the level in the overflow reservoir and top it off to the "Full" line with the appropriate Subaru coolant. This is also a great time to do one final visual inspection for any leaks around the new hoses and connections. A clean, dry engine bay confirms you’ve done the job right, setting the stage for reliable performance from your Subaru STI.

Final Checks to Confirm a Successful Install

One last look-over will give you total peace of mind. Double-check that all the new hoses are routed safely, away from any moving parts like belts or pulleys. You don’t want anything rubbing or getting pinched once you’re driving. It’s also a good idea to quickly review the parts list from your kit’s instructions to confirm every nut, bolt, and clamp is accounted for and in its proper place. This final verification ensures your Subaru WRX upgrades are ready for the road and the track.

Long-Term AOS Maintenance and Care

Installing your AOS is a huge step, but a little regular maintenance will ensure it protects your engine for years to come. Think of it like any other high-performance part on your Subaru—it works best when you keep an eye on it. A few simple checks can make all the difference in keeping your engine running strong and clean.

Your Simple Inspection Checklist

About once a month, or every time you change your oil, take a few minutes to give your AOS a quick once-over. You don’t need to be a master mechanic to spot potential issues. Just pop the hood and look for anything out of the ordinary. Here’s what to check:

- Hoses and Lines: Look for any cracks, brittleness, or soft spots. Make sure all clamps are tight and secure.

- Fittings and Connections: Check where the hoses connect to the AOS and the engine. Are there any signs of oil seepage or coolant drips?

- Mounting Bracket: Give the AOS unit a gentle wiggle to ensure it’s still firmly mounted. A quick visual inspection helps you catch small problems before they become big headaches, keeping all your performance parts working in harmony.

Cleaning and Maintaining Your AOS Unit

Over time, your AOS will collect a mixture of oil, water, and fuel vapors—that’s its job! To keep it working efficiently, it’s a good idea to clean it out periodically. For most daily drivers, cleaning it once a year is plenty. If you frequently track your car or live in a very cold climate, you might want to do it more often. The process is straightforward: carefully disconnect the lines, remove the unit, and use a quality degreaser or solvent to flush out all the accumulated gunk. Let it dry completely before reinstalling. A clean AOS is essential for a healthy engine, especially if you're considering professional engine tuning services.

Watching for Changes in Engine Performance

Your car will tell you if something isn't right—you just have to listen. After installing your AOS, pay attention to how your engine runs. You should notice a smooth, stable idle and consistent performance. If you suddenly experience rough idling, hesitation during acceleration, or hear new whistling or sucking sounds from the engine bay, it’s a sign that something may be amiss. It could be a vacuum leak from a loose hose or a sign that the system needs attention. Keeping tabs on your engine's behavior is one of the best ways to ensure your Subaru WRX upgrades are delivering the results you expect.

When to Call in a Pro

There’s no shame in asking for help. While most AOS maintenance is simple, some issues are best left to the experts. If you’ve checked all your connections and are still facing problems like a persistent check engine light, noticeable oil consumption, or engine misfires, it’s time to call a professional. Trying to diagnose complex engine issues without the right tools can lead to more significant damage. A qualified technician can properly diagnose the root cause and get your Subaru running perfectly again. When in doubt, reaching out to a trusted shop like Crawford Performance can save you time, money, and frustration in the long run.

Getting the Most from Your AOS Upgrade

Getting your Air/Oil Separator installed is a huge step, but the journey to a healthier, more powerful engine doesn’t stop there. Now it’s time to fine-tune your setup and habits to get the absolute most out of your new hardware. Think of your AOS as the foundation for a stronger engine. These tips will help you build on that foundation, ensuring your Subaru runs at its best whether you’re on the track, the trail, or just heading to the grocery store. Let’s get into some expert advice straight from the pros.

The Role of Temperature in AOS Efficiency

One of the biggest enemies of a high-performance engine is excessive heat. Your AOS plays a crucial role in temperature management by keeping hot oil vapor out of your intake system. When oil vapor is re-circulated, it can lower your fuel's octane rating and lead to pre-ignition, or knock, which is incredibly damaging. By separating that oil, the AOS ensures cleaner, cooler air enters the engine, which helps maintain consistent power and protects internal components. This is a core principle behind Crawford’s original Air Oil Separator design and a key benefit for any modified Subaru.

Fine-Tuning Your Crankcase Pressure

Your Subaru’s engine relies on a delicate balance of internal pressures to operate efficiently. An AOS helps maintain this balance by properly venting excess crankcase pressure. Without it, that pressure can build up and force oil past seals and gaskets, leading to messy and potentially serious leaks. This is especially important for turbocharged Subarus, which generate significantly more pressure than naturally aspirated engines. By giving that pressure a safe escape route while capturing oil, your AOS keeps the engine sealed, clean, and running smoothly. Proper pressure management is a cornerstone of reliable engine tuning services.

Upgrades That Complement Your New AOS

An AOS is a fantastic supporting mod that enables other upgrades to perform at their peak. Because it keeps the intake tract and intercooler clean from oil residue, it allows components like a high-flow intake or a larger turbo to work much more efficiently. A clean system means your engine is getting the dense, cool air it needs for maximum power. Pairing an AOS with a professional tune and other performance parts creates a synergistic effect, where each component helps the others achieve their full potential. It’s a smart move for anyone serious about getting reliable power from their build.

Secrets from the Crawford Performance Garage

The team at Crawford has seen it all, and their top tip is simple: stay on top of your maintenance. While an AOS is largely a set-it-and-forget-it part, it’s wise to periodically check the drain lines to ensure everything is flowing correctly. This is especially true after a track day or a spirited drive. Another pro tip is to always use high-quality synthetic oil. Better oil is more resistant to breaking down under heat and pressure, which means the AOS will have an easier job to do. Consistent maintenance and quality fluids are the secret ingredients to a long and happy engine life.

Related Articles

- All About Subaru's Original Air Oil Separator & Why You Need One

- 2008-2014 Subaru WRX Air Oil Separator V2 Crawford Performance

Frequently Asked Questions

Do I really need an AOS if my Subaru is completely stock? Absolutely. While an AOS is essential for modified cars, it’s also one of the best preventative upgrades you can make to a stock engine. Every boxer engine produces oil vapor "blow-by," and the factory system isn't perfect. Installing an AOS ensures your engine is only breathing clean air from day one, which prevents long-term carbon buildup on your valves and pistons and helps maintain its health for years to come.

Will installing an AOS add horsepower to my car? An AOS doesn't directly add horsepower like a turbo upgrade or an exhaust system would. Instead, think of it as a performance protector. It prevents the power loss that occurs when oil vapor contaminates your intake system, which can lower your fuel's octane and increase the risk of engine knock. It ensures your engine can consistently and safely deliver the power it was designed to make.

What’s the difference between an Air/Oil Separator and a catch can? The main difference is how they handle the collected oil. A catch can is a simple container that "catches" the oil, which you then have to manually drain at regular intervals. An AOS is a more advanced, closed-loop system that separates the oil and automatically drains it right back into the engine's oil pan, making it a true set-it-and-forget-it solution.

How often do I actually need to clean or maintain my AOS? For a daily driven Subaru, the system is very low-maintenance. A quick inspection of the hoses and fittings during your regular oil changes is always a good idea. We recommend giving the unit a thorough cleaning about once a year to clear out any accumulated gunk. If you frequently track your car, you may want to inspect and clean it more often.

Do I need to get my car tuned after installing an AOS? No, a new engine tune is not required after installing an AOS. The system is designed to work seamlessly with your stock or modified setup without altering the engine's air-to-fuel ratio. It simply improves the quality of the air entering your engine, which is a benefit that doesn't require any changes to your ECU mapping.