The Definitive Subaru Short Block Buyer's Guide

Share

If you own an EJ-series Subaru, you know the fear. Ringland failure. A spun bearing. When your motor lets go, the real question isn't just what happened, but how you can make sure it never happens again. The answer is building a stronger foundation from the ground up. A high-performance Subaru short block is more than an upgrade for horsepower; it's a critical investment in reliability that addresses the factory engine's known weak points. This guide will help you understand why stock motors fail and how to choose the right built block for a powerhouse that's both strong and dependable.

Key Takeaways

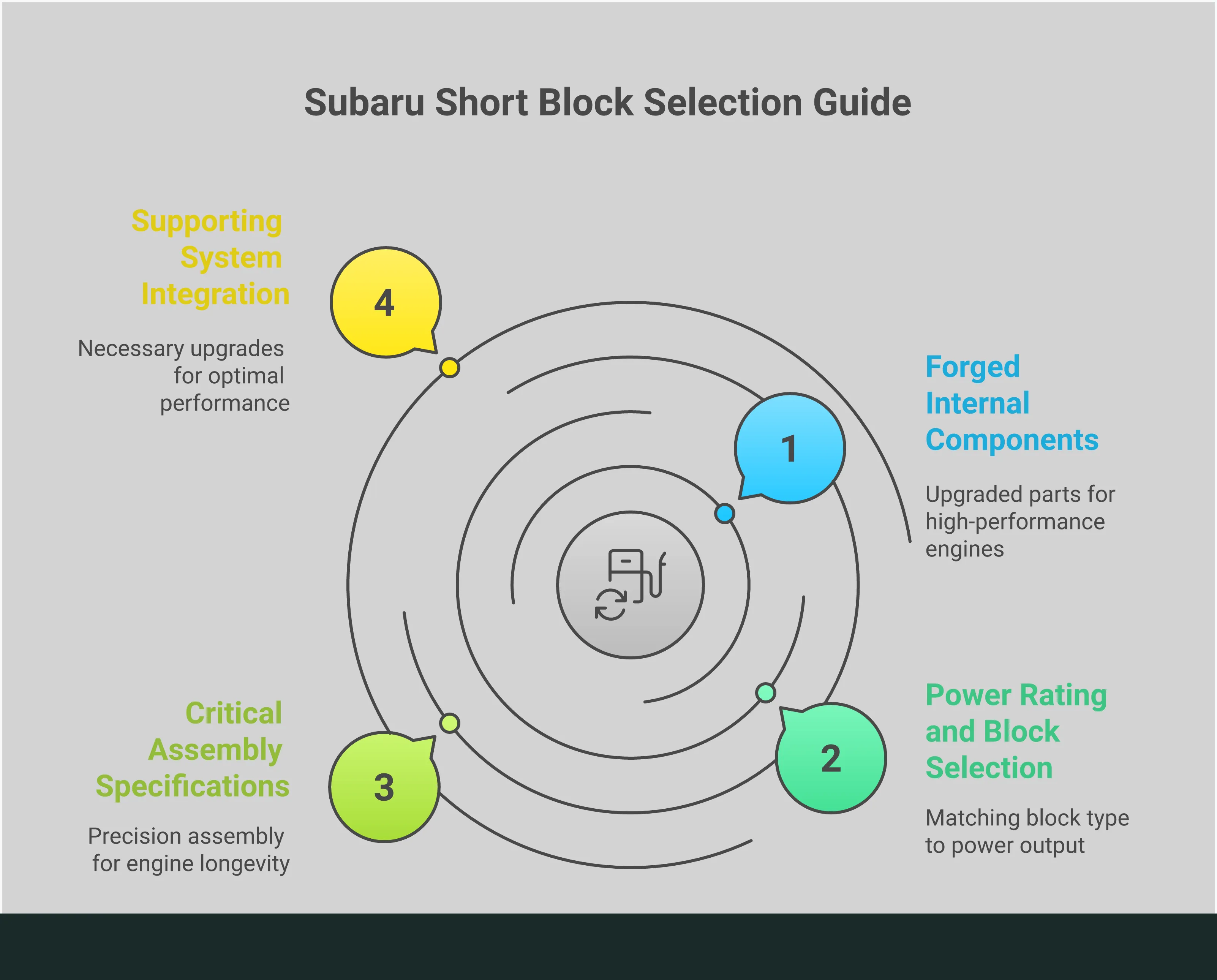

- Forged Internals are Non-Negotiable: To reliably handle more power, your engine's foundation must be stronger than stock. A performance short block with forged pistons and rods is the single most critical upgrade for preventing catastrophic failure when you increase horsepower.

- A Built Engine Requires a Complete System: Your new short block can't do its job alone. You must pair it with supporting upgrades like a better fuel system and turbo, and finalize the build with a professional tune to ensure every component works together safely and effectively.

- Select a Block That Fits Your True Needs: Choose between a pre-built or custom block by honestly evaluating your power goals, budget, and mechanical skill. For most builds, a professionally assembled block from a trusted brand provides peace of mind, a warranty, and a proven foundation for performance.

What is a Subaru Short Block?

Think of a short block as the heart of your Subaru’s engine. It’s the lower half of the engine assembly, containing the core rotating components that create power. This includes the engine block itself—the main structure—along with the crankshaft, connecting rods, and pistons. Essentially, it’s the foundation upon which the rest of your engine is built. When you press the accelerator, the short block is where the controlled explosions in the cylinders are converted into the rotational force that ultimately turns your wheels.

For enthusiasts looking to push their WRX, STI, or Forester beyond factory limits, the stock short block is often the first major bottleneck. While perfectly fine for daily driving, the original components weren't designed to handle the increased stress from higher horsepower and torque. This is why upgrading to a built short block is a fundamental step in any serious performance build. A well-built short block provides the strength and reliability needed to support additional power, ensuring your engine can handle the demands of the track, trail, or spirited street driving without failure. It’s the key to unlocking your Subaru’s true potential.

Short Block vs. Long Block vs. Bare Block

When you decide to build your engine, you'll encounter a few key terms: short block, long block, and bare block. These terms describe different stages of engine assembly, and knowing the difference is crucial for planning your build, budget, and timeline. Each option caters to a different level of mechanical expertise and performance goals. Choosing the right starting point will set the foundation for a successful and reliable build, whether you're aiming for a dependable daily driver with more punch or a dedicated track machine. Let's break down what each term means so you can make an informed decision for your Subaru.

Defining the Short Block

A short block is the engine's core foundation, pre-assembled for convenience and precision. It consists of the engine block itself, with the crankshaft, connecting rods, and pistons already installed and balanced. This is a popular choice for enthusiasts because it handles the most critical and sensitive part of the engine assembly, ensuring the rotating assembly is put together correctly. It offers a perfect middle ground, giving you a solid base while allowing you to select your own cylinder heads, camshafts, and other top-end components to match your specific performance goals. This approach saves you the complex work of internal assembly but still provides the flexibility to customize the engine's breathing characteristics.

What is a Long Block?

A long block takes the assembly a few steps further. It includes everything found in a short block, plus the cylinder heads, camshafts, and complete valvetrain, all bolted together. This makes it a much more complete engine package, significantly reducing the time and complexity of the final installation. For builders who are less experienced or simply want to get their car back on the road faster, a long block is an excellent option. It eliminates the guesswork of matching top-end components and ensures that the entire engine is assembled to proper specifications by professionals. Think of it as a nearly ready-to-run solution that just needs your external accessories bolted on.

Understanding the Bare Block

A bare block is exactly what it sounds like: just the engine block casting, completely empty. There are no pistons, no crankshaft, and no internal components whatsoever. This option is reserved for the most advanced and meticulous engine builders who want absolute control over every single part of their build. Starting with a bare block means you are responsible for sourcing, measuring, and assembling every component from scratch. It's the most labor-intensive and technically demanding route, requiring specialized tools and extensive knowledge. However, for those aiming to build a max-effort race engine with very specific, hand-picked parts, the bare block offers the ultimate level of customization.

How to Choose the Right Option for Your Build

Your choice between these options should come down to an honest assessment of your mechanical skill, budget, and power goals. If you're a seasoned mechanic with a clear vision for a custom build, a bare block or short block offers the most control. However, for most Subaru owners looking for a reliable way to add power, a professionally built short block is the ideal solution. It provides a warrantied, blueprinted foundation with forged internals ready to handle more power, while still allowing for some customization. A long block is even better if you want a straightforward, proven package. Ultimately, you need to select a block built to handle your target horsepower and pair it with the right supporting performance parts and a professional tune to ensure longevity and performance.

What Makes a Short Block "High-Performance"?

A high-performance short block is much more than just a collection of stronger parts; it’s an engineered system designed for durability and power. Unlike a standard factory unit, a built block is meticulously assembled to handle significantly more stress. The primary goal is to create a foundation that can support more power reliably. This means it’s built to withstand higher cylinder pressures, which allows you to get more performance from your turbo.

At Crawford Performance, our built Subaru short blocks are designed to be stronger, more precise, and more efficient. A properly engineered block can help you make more power at the same pressure level while also reducing internal engine strain, leading to a healthier and more responsive engine. It’s this combination of strength and efficiency that sets a true performance block apart from a simple replacement.

Breaking Down the Core Components and Materials

The secret to a durable short block lies in the quality of its internal components. The biggest upgrade is moving from the stock cast parts to forged ones. We build our celebrated Subaru short blocks using only premium components that we’ve tested and proven on the track and trail. This includes high-strength forged pistons and connecting rods, which are significantly stronger and more resistant to detonation and high-RPM stress than their factory counterparts.

Beyond the parts themselves, precision assembly is critical. Each component is carefully measured, balanced, and hand-assembled to exact tolerances. This meticulous process ensures optimal clearance and smooth operation, which is essential for engine longevity under high-performance conditions. It’s this attention to detail that guarantees every block is ready to perform reliably from the moment it’s installed.

Common Short Block Failures and How to Prevent Them

For many Subaru engines, especially the EJ series, the weakest link is the factory cast piston. When you start adding more power through tuning and bolt-on parts, these pistons are often the first thing to fail, leading to catastrophic engine damage. This is why nearly every high-performance build replaces the stock pistons and connecting rods with much stronger forged alternatives. A forged component can handle higher temperatures and pressures without breaking.

To avoid future issues, it’s crucial to understand why your original engine failed. Was it a tuning issue, an oiling problem, or simply pushing the stock components too far? A proper diagnosis can help you choose the right built block and supporting modifications. Pairing your new short block with professional engine tuning services is the best way to ensure all components work together safely, protecting your investment for years to come.

Who Builds the Best Subaru Short Blocks?

When you decide to build your Subaru engine, choosing the right short block is the most critical decision you'll make. The short block is the foundation of your entire build, and its quality determines both the power you can make and how long your engine will last. The "best" builder often depends on your specific goals, whether you're aiming for a reliable daily driver with a bit more punch, a dedicated track car, or a rugged overlanding rig.

Several highly respected companies specialize in building high-performance Subaru short blocks, each with its own philosophy and area of expertise. These builders address the known weak points of the factory EJ and FA engines by using stronger materials, more precise machining, and assembly techniques honed over years of racing and street tuning. We'll look at some of the top names in the industry to help you understand their offerings and find the perfect match for your project. From legendary race-proven builders to specialists in extreme horsepower, the right foundation for your build is out there.

Builder Spotlight: Crawford Performance

With a history deeply rooted in professional motorsports, Crawford Performance has a reputation built on precision and durability. As an official racing partner with Subaru of America, they have an impressive track record that includes building the engines for Ken Block's iconic Gymkhana 1 and Gymkhana 2 cars. This racing pedigree directly influences their commercial offerings.

Each of their Subaru short blocks is assembled by hand, using high-strength components like forged pistons and connecting rods to ensure they can handle significant power increases. They offer various stages tailored for different applications, from spirited street driving to all-out competition, giving you a race-proven foundation for your build.

Builder Spotlight: IAG Performance

IAG Performance is another major player in the Subaru engine world, known for its wide range of short blocks designed to meet specific power targets. They offer solutions for nearly every model, including the WRX, STI, Legacy GT, and Forester XT, covering vehicles from 2002 to the present.

Their product line is clearly tiered by horsepower rating, with options engineered to handle anywhere from 550 BHP to over 1,150 BHP. IAG focuses on systematically addressing common OEM failure points by upgrading to stronger pistons, rods, and fasteners. They also utilize advanced techniques like close-decking the block surfaces for added cylinder wall strength, making their blocks a popular choice for high-power street and track builds.

Builder Spotlight: Rallispec Engineering

Rallispec Engineering carves out a niche by focusing on high-end, performance-oriented builds, particularly for those who spend a lot of time on the track. Their blocks, like the Street Spec Pro Closed Deck Shortblock, are engineered for maximum durability under the extreme stress of racing.

By specializing in closed-deck conversions, Rallispec significantly reinforces the cylinder walls, which is a critical modification for preventing failure when running high boost levels. This makes their short blocks an excellent option for serious enthusiasts and weekend racers who demand the utmost reliability and performance from their engine when pushing it to its limits lap after lap.

Other Notable Builders to Consider

Beyond the big names, the Subaru performance world includes many other skilled builders and machine shops. Some specialize in reinforcing OEM blocks for reliable power at stock or slightly modified levels, while others offer their own custom solutions. The key takeaway is that any quality builder will address the factory engine's weaknesses.

This means using stronger internal components like forged pistons and connecting rods, employing more precise machining and balancing, and ensuring meticulous assembly. Whether you choose a well-known brand or a trusted local specialist, the focus should always be on quality components and expert craftsmanship to support your performance parts and power goals.

Outfront Motorsports

Outfront Motorsports has earned its reputation by offering a solution for just about every type of Subaru build imaginable. They provide a comprehensive lineup of short blocks that covers the full spectrum of performance needs. For those wanting a reliable engine with a bit more strength than stock, their "Grocery Getter" series is a popular choice for daily drivers. On the other end, their high-strength "Closed Deck" blocks are engineered to withstand the immense pressures of high-horsepower track and race applications. This variety makes it straightforward to find a foundation that aligns perfectly with your goals. Their staged options, like the Stage 2 and Stage 3 blocks, also help simplify the decision by matching specific component upgrades to clear power targets, so you can confidently choose the right balance of strength and performance for your project.

Comparing the Top Builders: Specs vs. Price

Choosing the right short block is a balancing act between your power goals and your budget. As you move up in price, you generally gain stronger components, more precise engineering, and a higher power handling capacity. However, the most expensive option isn't always the right one for your build. Understanding the different tiers of performance blocks will help you find the sweet spot for your Subaru. We'll look at what you can expect at various price points, from solid entry-level upgrades to competition-ready racing blocks, so you can make an informed decision that aligns with your specific needs. Remember to look beyond the price tag and consider the quality of the internals, the reputation of the builder, and the block's ability to support your future plans.

For Daily Drivers: Entry-Level Performance Blocks

When we say "entry-level" in the world of built short blocks, we're not talking about cutting corners. These are foundational upgrades designed for reliability and moderate power goals, typically up to around 550 brake horsepower (BHP). This tier is perfect for a spirited daily driver or a weekend warrior who wants a strong, dependable engine without needing to support extreme power levels. You'll find quality forged internals that replace the weaker stock components, giving you the confidence to turn up the power. Companies like IAG Performance offer blocks in this category that serve as a massive step up from the factory setup, providing a solid base for many street-focused builds.

Typical Price Range: $3,000 - $6,000

For most Subaru enthusiasts, the sweet spot for a high-quality built short block falls between $3,000 and $6,000. This price range represents a significant step up from factory components, offering a solid foundation for reliable power. In this tier, you can expect a block assembled with high-strength forged pistons and connecting rods, which are essential for handling the increased cylinder pressures that come with more horsepower. This investment is about more than just raw power; it's about building a durable engine that addresses the known failure points of the stock motors, giving you peace of mind for spirited street driving or occasional track days.

Many reputable builders offer meticulously assembled options in this price range. These blocks are designed to provide a race-proven foundation for street cars, ensuring every component is balanced and blueprinted for optimal performance and longevity. Investing in one of these quality Crawford Performance short blocks is a critical step toward building a dependable engine that can withstand the rigors of enthusiastic driving without the constant worry of catastrophic failure. It’s the smart move for creating a powerhouse that you can truly rely on.

For More Power: Mid-Range Options

If your goals are a bit more ambitious, the mid-range tier is where you'll likely find your match. These short blocks are engineered to handle more demanding applications, supporting power figures in the 550 to 750 BHP range. This is where you start seeing more advanced features, such as closed deck inserts that reinforce the cylinder walls for greater strength under high pressure. A mid-range block is ideal for serious enthusiasts who frequent the track or want a high-powered street car that can handle aggressive driving. They offer a fantastic blend of strength and performance, providing the durability needed for more extensive performance parts and tuning.

For the Track: High-Performance Racing Blocks

For those who accept no compromises, high-performance racing blocks are the ultimate solution. These are built for maximum power, durability, and precision, designed to withstand the harshest conditions of competitive racing. At this level, every component is optimized for strength and performance. Crawford Performance short blocks are engineered to this standard, with some capable of handling over 770 horsepower. These blocks are meticulously assembled with top-tier materials to ensure they can take the abuse of the track while delivering consistent, reliable power. This is the choice for dedicated race cars, time attack builds, and street machines where peak performance is the primary goal.

Pricing for Extreme Power: $6,000 to $18,000+

When you're aiming for extreme power, the investment in a short block reflects that ambition. Prices in this top tier typically range from $6,000 to over $18,000, representing a significant commitment to building a truly capable engine. This isn't just about chasing a horsepower number; it's about investing in reliability under extreme stress. A block in this category is meticulously engineered with the best materials available to handle the abuse of competitive racing while delivering consistent, dependable power. The foundation of these builds always includes moving from stock cast parts to superior forged internals, which is essential for withstanding the immense pressures of a high-output setup. Builders engineer these blocks to meet specific power goals, with some options designed to handle well over 1,150 BHP, ensuring you get a foundation perfectly matched to your ultimate performance vision.

Is It Worth It? Analyzing the Price-to-Power Ratio

It’s easy to get caught up in horsepower numbers, but the smartest way to assess value is by looking at the price-to-power ratio. This isn’t just about finding the cheapest block that can hit your power target. It’s about investing in reliability and future-proofing your build. A slightly more expensive block from a reputable builder might save you thousands in the long run by preventing a catastrophic failure. Consider the quality of the components, the builder's reputation, and the warranty. A well-built engine provides peace of mind, which is an invaluable part of the equation. The best value is the block that meets your goals reliably, without forcing you to buy another one when you decide you want more power later.

Pre-Built vs. Custom: Which Path Should You Take?

Deciding between a pre-built short block and a custom build is one of the most significant choices you'll make for your Subaru. One path offers proven reliability and convenience, while the other provides ultimate control and potential cost savings. Neither is universally "better"—the right choice depends entirely on your goals, budget, timeline, and mechanical expertise. Let's break down the factors to help you decide which route is the best fit for your project.

Why Choose a Pre-Built Short Block?

For many drivers, a pre-built short block is the most logical and effective solution. Opting for a professionally assembled engine from a reputable builder like Crawford Performance removes the guesswork and potential for error. These blocks are constructed in controlled environments by technicians who specialize in Subaru engines, ensuring every clearance is perfect and every component is correctly installed. You get a reliable foundation that's ready to handle serious power right out of the crate.

Many enthusiasts report getting tens of thousands of hard miles out of their pre-built blocks without a single issue. This peace of mind is invaluable, especially when you're investing heavily in your vehicle's performance. With a Crawford Performance built short block, you’re not just buying parts; you’re buying decades of Subaru-specific engineering, track-tested data, and a warranty to back it all up.

What to Know Before Building a Custom Block

If you're mechanically inclined and want full control over every component, a custom build can be a rewarding project. However, it requires careful planning and a deep understanding of engine mechanics. Before you even start ordering parts, the first step is to perform a thorough analysis of your old engine. What was the exact point of failure? Was it oil starvation, detonation, or a component failure?

Understanding why your previous engine failed is critical to preventing a repeat performance. You also need to consider your car's modification history and your own maintenance habits. A custom build gives you the chance to address specific weaknesses and tailor the engine precisely to your needs, but success hinges on meticulous research and assembly.

Performance vs. OEM Replacement Blocks

When your engine fails, you're faced with a critical choice: do you go with a standard OEM replacement or invest in a performance-built short block? While an OEM block will get your car back to factory spec, it’s important to understand its limitations. The stock short block was engineered to handle stock power levels and daily driving conditions—and that’s it. For enthusiasts looking to push their WRX or STI beyond factory limits, the original components quickly become a bottleneck. They simply weren't designed to handle the increased stress from higher horsepower and torque, making them vulnerable to the same failures you just experienced.

A high-performance short block, on the other hand, is an engineered system designed specifically for durability and power. It’s not just a collection of stronger parts; it’s a foundation meticulously assembled to handle significantly more stress. By replacing weak factory cast components with robust forged pistons and rods, a built block provides the strength needed to support a wide range of performance parts and aggressive tuning. This upgrade is about more than just making power—it's about creating a reliable engine that gives you the confidence to use that power without worrying about catastrophic failure.

When an OEM Short Block Makes Sense

While a built block is the superior choice for any performance application, an OEM replacement can be a practical option in one specific scenario: returning a completely stock vehicle to its original factory condition with zero plans for future modifications. If your only goal is to get your car back on the road exactly as it was when it left the showroom, an OEM short block is a cost-effective solution designed to work perfectly with the stock turbo, fuel system, and ECU tune. However, this path comes with a major caveat. The moment you add more power—even with a simple software tune—you reintroduce the same risks of failure. If there's any chance you'll want to modify your Subaru down the road, investing in a built block from the start is the smarter, safer, and more economical choice. It provides a reliable foundation that won't hold you back, and pairing it with professional engine tuning services ensures your entire setup works together to protect your investment.

A Look at the Costs: Pre-Built vs. Custom

The primary motivation for most custom builds is the potential for cost savings. Sourcing all the components yourself can certainly be cheaper than buying a completed short block. For example, gathering the parts for a Stage 2 equivalent block might cost you around $2,500, whereas a pre-built version from a major manufacturer could be priced over $4,000. That's a significant saving that could be allocated to other performance parts for your build.

However, this calculation only accounts for the raw cost of the components. It doesn't include the price of specialized tools, machining services, or any mistakes made during assembly that could require you to repurchase parts. While the upfront savings are attractive, it's important to budget for the entire process, not just the parts list.

Do You Have the Time and Skill for a Custom Build?

The biggest trade-off for the cost savings of a custom build is the investment of time and expertise. Building an engine is not a simple weekend project; it demands precision, patience, and a clean, dedicated workspace. Measuring clearances, checking tolerances, and ensuring every bolt is torqued to spec requires skill and the right tools. If you’re not an experienced engine builder, the learning curve can be steep and the risk of a catastrophic error is high.

This is where the value of a pre-built block truly shines. You're paying for the builder's expertise and efficiency. A professional can assemble a block in a fraction of the time it would take a hobbyist. Furthermore, a professionally built engine often comes with the support and warranty of an established company, protecting your investment. When you factor in the peace of mind that comes with expert engine tuning services and post-installation support, the higher initial cost of a pre-built block often proves to be a smarter long-term investment.

Non-Negotiable Features for Your Performance Short Block

When you’re ready to move beyond the limits of your stock Subaru engine, a performance short block is the foundation of your build. But not all aftermarket blocks are built the same. The difference between a reliable, high-horsepower engine and one that fails prematurely often comes down to a few critical features. Understanding what to look for ensures you’re investing in a component that can handle the power you plan to throw at it, whether you’re building a daily driver with a bit more punch or a dedicated track machine.

From the materials used inside to the hands that assemble it, every detail matters. A truly robust short block is more than just a collection of strong parts; it’s a precisely engineered system designed to withstand intense heat, pressure, and stress. Let’s break down the non-negotiable features that separate the best from the rest.

Forged Internals: The Foundation of a Strong Build

If you take away only one thing, let it be this: a performance short block must have forged internals. The stock pistons and connecting rods in most Subaru engines are cast, which is fine for factory power levels. However, when you start adding horsepower, those cast parts become the weakest link. Forged components are created under immense pressure, resulting in a denser, stronger grain structure that can handle significantly more abuse.

At Crawford, we build our Subaru short blocks exclusively with high-strength forged pistons and rods that we’ve tested and proven on the track and trail. This is the single most important feature for engine reliability in a performance application.

Why Precision Assembly Matters

Having the best parts in the world doesn’t mean much if they aren’t assembled correctly. The process of building a short block is a craft that demands incredible attention to detail. Key measurements like bearing clearances, piston ring gaps, and bolt torque specs must be absolutely perfect. An engine assembled by an experienced technician who understands the nuances of Subaru platforms will always outperform and outlast one that was quickly pieced together.

This is why every Crawford short block is carefully assembled by hand. This meticulous process ensures every component fits and functions exactly as it should, giving you a solid foundation that runs smoothly and reliably under pressure.

Keeping It Cool: The Importance of Cooling

More power means more heat—it’s a simple fact of thermodynamics. Effectively managing that heat is crucial for protecting your investment and maintaining consistent performance. A well-designed performance short block incorporates features that improve cooling and oiling to keep temperatures in check. This can include optimized oil passages that ensure consistent lubrication to critical components and designs that help reduce internal crankcase pressure.

Proper heat management prevents issues like oil breakdown, detonation, and premature wear on bearings and pistons. It’s an essential feature for any build, from spirited street driving to demanding overlanding solutions where engine stress is high.

Built to Handle Power: Key Design Innovations

To build an engine that can handle 500, 600, or even more horsepower, you need more than just standard upgrades. Top-tier short blocks often feature innovations designed specifically to reinforce the engine against the extreme forces of high-power builds. This includes features like closed-deck inserts, which strengthen the cylinder walls to prevent flexing under high boost.

Other key innovations include upgraded case bolts or studs that keep the engine case halves from separating and specialized piston designs that improve durability. These are the features that allow a block to be rated for extreme power levels, sometimes exceeding 800 brake horsepower. These are the details that make our WRX upgrades and STI builds so reliable.

How to Support Your New Short Block with the Right Mods

Installing a built short block is like laying the foundation for a skyscraper—it’s the strongest, most important part, but it can’t stand on its own. To get the performance, power, and reliability you’re paying for, you need to surround your new engine core with components that can keep up. Simply dropping a built block into an otherwise stock car will create new weak points and prevent you from reaching your goals.

The rest of your build, from the fuel system to the exhaust, must be able to support the power your new short block can handle. This is where you get to match all the performance parts to create a cohesive, powerful machine. A well-planned engine setup ensures every component works in harmony, giving you a car that’s not just fast, but dependable whether you’re on the track or a remote trail. Thinking about the entire system, rather than just one part, is the key to a successful build.

The Must-Have Supporting Modifications

Your stock Subaru components were designed for stock power levels. When you add a built short block capable of handling significantly more stress, those factory parts become the next failure point. For example, a stock block can typically only handle about 50 extra horsepower before you start pushing your luck. Your new short block blows that ceiling away, so you need to upgrade the parts that feed and support it.

Essential supporting mods often include a high-flow fuel pump, larger fuel injectors, an upgraded turbo, and a more efficient intercooler. You’ll also want to consider a stronger clutch to transfer the new power to the wheels. Think of these Subaru WRX upgrades as the necessary support system for your engine’s new potential.

Why a Professional Tune is Non-Negotiable

All the high-performance hardware in the world won’t do you any good without a brain to control it. That’s where tuning comes in. An ECU tune is a custom map that tells your engine how to use its new parts. It adjusts critical parameters like fuel delivery, ignition timing, and boost pressure to extract power safely and efficiently. Without a professional tune, your engine is just a collection of expensive parts that aren't working together.

Proper engine tuning services are not optional; they are a fundamental requirement for protecting your investment. A good tune will not only maximize your horsepower and torque but will also ensure your engine runs smoothly and reliably for years to come, preventing catastrophic failures caused by improper air-fuel ratios or detonation.

Creating a Balanced and Reliable Build

A successful engine build is all about synergy. Every part needs to be matched to the others to create a balanced system. You wouldn’t pair a massive turbo with stock injectors, and you shouldn’t pair an 800-horsepower short block with a tiny factory turbo. Each component has a performance ceiling, and your goal is to create a setup where everything is working in its ideal operational range.

Before you buy a single part, map out your entire build. For example, our overlanding solutions are designed as a complete system where each part complements the others. This approach prevents bottlenecks, where one under-specced component holds back the entire system. A well-matched setup ensures smooth power delivery and predictable performance because all your components are working as a team.

Setting Realistic Power Goals for Your Setup

Before you get lost in dyno sheets and horsepower figures, take a moment to define what you really want from your car. Are you building a daily driver with some extra punch, a dedicated track weapon, or a capable off-roader? Your answer will determine your realistic power goals. Chasing a massive number on paper can sometimes result in a vehicle that’s difficult and unpleasant to drive on the street.

Crawford Performance builds short blocks for a wide range of applications and budgets. By setting a clear goal from the start, you can choose a block and supporting Subaru STI upgrades that align with your vision. A realistic target helps guide every decision, ensuring the final result is a car that not only meets your performance expectations but also fits your driving style perfectly.

How to Protect Your Investment: Warranty and Support

A high-performance short block is a serious investment in your Subaru's future, and protecting it goes beyond just the initial purchase. The support you receive from the builder is just as critical as the components inside the engine. A solid warranty, clear installation guidelines, and accessible expert advice are hallmarks of a manufacturer that stands behind their work. When you choose a builder, you're not just buying a part; you're gaining a partner for your build. This partnership is key to ensuring your engine performs reliably for years to come, whether you're on the track, the trail, or the street. Look for a company that provides comprehensive support, as it reflects their confidence in the quality and durability of their products.

What Does the Warranty Actually Cover?

A warranty is the manufacturer's promise to you, backing the quality of their craftsmanship and materials. For example, Crawford Performance offers a 12-month/12,000-mile warranty on their performance engines, which is a strong indicator of their confidence. When reviewing any warranty, pay close attention to the details. Most will cover defects in materials or assembly but won't cover failures caused by improper installation, incorrect tuning, or abuse. It’s essential to understand these limitations. A transparent warranty policy clearly outlines what is and isn't covered, helping you set realistic expectations and ensuring there are no surprises down the road.

Installation Do's and Don'ts to Protect Your Warranty

Proper installation is the single most important step in ensuring the longevity of your new short block. Even the best-built engine can fail if it isn't installed correctly. Reputable builders provide detailed instructions, and following them precisely is non-negotiable. A common recommendation is to replace key surrounding components, such as the oil pump, oil cooler, and timing belt tensioner, with new OEM parts. Reusing old, worn parts can introduce contaminants or create weak points that compromise the entire system. Always use the specified fluids and follow the torque specs to the letter. If you’re not 100% confident in your abilities, having the engine installed by a professional technician who specializes in Subarus is a wise investment.

Keeping Your Engine Healthy: Long-Term Maintenance

Once your new short block is installed, the work isn't over. The break-in period is your first and most critical task. This process allows the piston rings to seat properly against the cylinder walls, creating a tight seal for optimal compression. Your builder will provide a specific break-in procedure—follow it without deviation. After that, consistent maintenance is key. This includes using high-quality synthetic oil, performing regular oil changes, and keeping an eye on fluid levels and engine temperatures. A professional engine tuning service is also crucial to ensure the engine operates safely and efficiently within its new performance parameters, protecting it from harmful conditions like detonation.

Evaluating Builder Support Before You Buy

When you buy a short block, you're also buying into the manufacturer's ecosystem of support. Look for a builder with a proven track record and a reputation for being accessible and helpful. A company's history can speak volumes; for instance, Crawford Performance's long-standing relationship with Subaru of America and its history building engines for icons like Ken Block demonstrate a level of trust and expertise that is hard to replicate. Good support means having experts you can call with questions during installation or tuning. It means clear documentation, responsive customer service, and a community of users who can share their experiences. This level of support provides peace of mind and is an invaluable part of your purchase.

Additional Services to Look For

When you choose a builder, look beyond the short block itself and consider the full range of services they offer. A partner who provides expert engine tuning services and understands the nuances of proper installation is invaluable. A professional tune is non-negotiable; it’s the final step that protects your investment by ensuring all your performance parts work together safely to maximize power and reliability. A builder who guides you through the entire process—from installation to tuning and long-term maintenance—demonstrates a true commitment to your success. This level of comprehensive support, often backed by a solid warranty, is the clearest sign you're partnering with a company that stands behind its products and is invested in your build's success.

How to Choose the Right Subaru Short Block for Your Build

Selecting the right short block is one of the most critical decisions you'll make for your Subaru build. It’s the foundation of your engine, and your choice will influence everything from daily drivability to track-day performance. This isn't just about picking the one with the biggest power rating; it's about finding the perfect match for your goals, budget, and long-term plans for the car. By carefully considering a few key factors, you can invest in a short block that delivers the reliable power you’re looking for.

Step 1: Define Your Power Goals

Before you look at a single part, you need a clear answer to one question: How much horsepower are you aiming for? Your power target is the single most important factor in choosing a short block. If your goal is a modest and reliable 350hp, your needs will be very different than if you're chasing 500hp or more. A built short block becomes essential for reliability as you push past the factory limits. Higher power levels place immense stress on internal components, so you'll need forged pistons and rods that can handle the pressure. Being honest about your goals ensures you invest in a block that can safely support your ambitions without failure.

Step 2: Set a Realistic Budget

Building a high-performance engine involves more than just the cost of the short block itself. You need to create a comprehensive budget that accounts for supporting modifications, installation labor, and a professional tune. While it can be tempting to save money by sourcing parts yourself, weigh the cost against the value of a professionally assembled block. For example, a pre-built short block from a reputable builder includes precision machining and assembly that ensures durability. Factoring in the cost of gaskets, fluids, and potential "while you're in there" upgrades will give you a realistic financial picture and prevent surprises down the road.

Understanding Core Charges

When you're shopping for a built short block, you'll likely come across the term 'core charge.' Think of it simply as a refundable deposit. You pay this extra fee upfront when you purchase your new performance block. This charge acts as an incentive for you to send your old, original engine block back to the builder. Once they receive your old block—the 'core'—and confirm it's in a rebuildable condition, they refund the deposit to you. This process is crucial for companies that build performance engines because it ensures they have a steady supply of original blocks to use for future builds, which helps manage costs and promotes sustainability in the industry.

Step 3: Plan Your Installation

How you plan to install the short block is just as important as which one you buy. If you’re replacing a failed engine, it’s crucial to understand what caused the original failure to avoid repeating it. Was it a maintenance issue or a modification that pushed things too far? A professional installer can help diagnose this. When installing a new short block, it's also the perfect time to replace wear-and-tear items like the oil pump, water pump, and timing components. Proper installation and a subsequent professional engine tuning service are non-negotiable steps to protect your investment and ensure everything works together perfectly.

Step 4: Analyze the Long-Term Value

A built short block is a significant investment, so think about its long-term value. A block built with high-quality materials and assembled with precision will provide years of reliable performance. Companies like Crawford Performance build Subaru short blocks designed for strength and durability, using stronger pistons and connecting rods to handle increased power reliably. While a cheaper option might seem appealing now, a well-built engine from a trusted manufacturer offers peace of mind and saves you from the potential cost and headache of another engine failure in the future. It’s about buying the right part once.

Related Articles

- OEM Subaru Short Blocks - Crawford Performance

- High-Performance Subaru Short Blocks & Long Blocks Engine – Crawford Performance

- The Ultimate Subaru Engine Upgrade Guide – Crawford Performance

Frequently Asked Questions

At what power level should I seriously consider a built short block? There isn't a single magic number, but a widely accepted rule of thumb is to start planning for a built short block when you're aiming for anything beyond 350-400 wheel horsepower. The factory pistons and connecting rods, especially in the EJ series engines, were not designed for that level of stress. While some stock blocks can hold more for a while, you're running on borrowed time. Investing in a built block at this stage is about building a reliable foundation for that power, not just waiting for the inevitable failure.

Is a built short block less reliable for daily driving than a stock one? Quite the opposite, as long as it's built and tuned correctly. A high-quality built short block is engineered to handle stress far better than the original factory engine. The reliability issues people associate with modified cars often come from pushing stock components too far, improper installation, or a poor tune. A professionally assembled short block paired with a proper tune creates a system that is significantly stronger and more durable than stock, giving you peace of mind whether you're in traffic or at the track.

Why can't I just install forged pistons and rods in my original block myself? While sourcing the parts yourself can seem like a way to save money, a performance engine is much more than the sum of its parts. The real value in a professionally built short block comes from the precision machining, balancing, and assembly. Experts measure clearances down to the ten-thousandth of an inch to ensure everything operates perfectly under load. This meticulous process is what creates a durable engine that can handle high horsepower reliably. Simply dropping in new parts without these critical steps can lead to premature failure.

What is the "break-in" period and why is it so important? The break-in period is the critical first 1,000 miles or so for your new engine. During this time, you need to drive moderately, varying the engine RPMs and avoiding high boost or constant speeds. This process allows the new piston rings to wear in perfectly against the cylinder walls, creating a tight seal that is essential for good compression and preventing oil consumption. Skipping or rushing the break-in is one of the easiest ways to compromise the long-term health and performance of your investment.

Besides the short block, what is the single most important supporting upgrade I need? Without a doubt, the most critical piece of the puzzle is a professional ECU tune. Your new short block and any other performance parts are just a collection of hardware until the engine's computer is programmed to use them correctly. A professional tuner will create a custom map for your specific setup, optimizing air-fuel ratios, timing, and boost levels to make power safely. A good tune is what protects your entire investment and ensures all your new components work together in harmony.