Engine Forged Piston: The Ultimate Upgrade Guide

Share

Every performance build starts from the inside out. While turbos and tunes get all the glory, the real foundation of a powerful engine lies with its pistons. Get this choice wrong, and you're setting yourself up for catastrophic failure and a very expensive paperweight. That's why understanding the forged vs cast pistons STI debate is non-negotiable. This guide will walk you through the critical differences in strength, heat tolerance, and cost. We'll show you why a quality engine forged piston is the key to building a motor that can handle serious power, reliably.

Key Takeaways

- Forging Creates Strength, Casting Creates Value: Forged pistons are pressed from a solid aluminum billet, giving them the dense structure needed to handle high boost and power. Cast pistons are poured into a mold, making them a quiet, reliable, and cost-effective solution for stock or lightly modified engines.

- Match the Piston to Your Purpose: Your driving habits and power goals should dictate your choice. Forged pistons are a necessity for track use or significant power upgrades, while high-quality cast pistons are perfectly suited for a dependable daily driver.

- An Engine Is a Complete System: Upgrading pistons is not a standalone job. A successful build requires professional installation to ensure proper clearances, supporting modifications like stronger connecting rods, and a professional tune to safely tie everything together.

Forged vs. Cast Pistons: What's the Difference?

When you start planning a serious engine build for your Subaru, the conversation will inevitably turn to pistons. The choice between forged and cast pistons is one of the most critical decisions you'll make, directly impacting your engine's strength, power handling, and longevity. While your factory pistons are perfectly fine for daily driving, pushing for more power requires parts that can handle the extra stress. Understanding how these two types of pistons are made and what they're made of is the first step in choosing the right foundation for your performance goals.

How Are Forged and Cast Pistons Made?

The names "cast" and "forged" describe exactly how these pistons are created, and the process dictates their internal structure. A cast piston is made by pouring molten aluminum alloy into a mold. It’s a quick and cost-effective method, but as the metal cools, it can result in a more porous and less uniform grain structure. You can often identify a cast piston by the visible lines and marks left behind by the mold. In contrast, a forged piston starts as a solid billet of high-grade aluminum alloy, which is heated and then pressed into shape under immense pressure. This forging process creates a much denser, stronger component with a smooth finish and a grain structure that is aligned for superior strength.

The Origins of Forging

The concept of forging is ancient, rooted in the timeless practice of blacksmithing. At its core, the process involves taking a solid piece of metal, heating it to a malleable state, and then using immense force—through pounding, stamping, or pressing—to shape it. This intense process does more than just change the metal's form; it fundamentally refines its internal grain structure. By compressing the metal, any microscopic voids or inconsistencies are eliminated, and the grains are forced to align in a continuous, flowing pattern. This alignment is what gives forged components their legendary strength and resilience, making them the ideal choice for the high-stress, high-heat environment inside a performance engine.

Comparing Manufacturing: Forged, Cast, and Machined

While casting is an efficient manufacturing method, it creates a fundamentally different product. Pouring molten aluminum into a mold is fast and cost-effective, but the cooling process can leave the final piston with a more porous and less consistent grain structure. Forging, on the other hand, starts with a solid billet of high-grade aluminum alloy that is heated and pressed into its final shape. This method produces a much denser and stronger component with a smooth finish. The result is a piston with an internal structure perfectly aligned to handle the extreme pressures of a high-output Subaru engine, which is why they are essential for any serious build using performance parts.

How Speed and Precision Differ

The aligned grain structure of a forged piston directly translates to superior strength and durability. This inherent toughness allows manufacturers to design pistons with thinner walls and less material without sacrificing integrity, making them significantly lighter than their cast counterparts. A lighter piston reduces the engine's reciprocating mass, allowing it to rev more quickly and freely. Furthermore, the forging process allows for extremely tight tolerances and precise shaping. This precision is critical for building a balanced and efficient engine, ensuring that every component in your Subaru WRX upgrade works in perfect harmony under demanding performance conditions.

What Materials Give Pistons Their Strength?

The material composition is just as important as the manufacturing process. Piston alloys often include silicon, which helps control how much the piston expands when it gets hot. However, there's a trade-off. Factory cast pistons are often "hypereutectic," meaning they have a high silicon content. While this minimizes expansion, it also makes the piston more brittle and prone to shattering under the extreme cylinder pressures of a high-performance engine. Forged pistons use alloys with lower silicon content, which makes them more ductile. They can deform slightly under stress without breaking, giving them the resilience needed to handle the abuse from higher boost and aggressive engine tuning.

How Piston Design Affects Durability

Beyond the material, forged and cast pistons have distinct design differences tailored to their intended use. Factory cast pistons are designed for a quiet, efficient ride at stock power levels. They fit snugly in the cylinder bore, which reduces engine noise on cold starts and minimizes "blow-by"—exhaust gases leaking past the piston rings. However, their ringlands (the areas between the piston rings) are thinner and can crack under detonation. Forged performance parts are built for abuse. They feature thicker, more robust ringlands to withstand intense pressure and are engineered to be much stronger overall. Because they expand more as they heat up, they require slightly more clearance, which can sometimes cause a light ticking sound known as "piston slap" when the engine is cold.

When Cast Pistons Make Sense

While the allure of forged components is strong, especially when you're planning significant power gains, it's important to recognize that cast pistons are the right choice for many drivers. If your Subaru is your daily driver and you're running a stock or very lightly modified setup with a few performance parts, high-quality cast pistons are more than capable. They are engineered for reliability and efficiency under normal driving conditions. Because they are poured into a mold, they are a cost-effective option that provides a quiet and smooth ride, fitting snugly in the cylinder to minimize noise on cold starts. For the average enthusiast who isn't chasing massive horsepower numbers, sticking with a robust cast piston makes perfect sense for a dependable engine.

How Do Forged and Cast Pistons Perform in Your Engine?

The way a piston is made directly influences how it behaves inside your engine. It’s not just about raw power; it’s about how each type handles the intense heat, pressure, and stress of combustion. A cast piston is designed for reliability and quiet operation in a stock engine, offering predictable performance for daily driving. It’s the dependable workhorse that came with your STI from the factory.

A forged piston, on the other hand, is engineered for a much higher threshold of abuse. Its dense grain structure gives it the resilience needed to withstand the extreme cylinder pressures created by higher boost and aggressive timing. When you start pushing your engine with serious performance parts, the differences in durability, heat management, and even sound become very clear. Understanding these performance characteristics is key to choosing the right foundation for your build.

Which Piston Is More Durable Under Pressure?

This is where forged pistons truly shine. The forging process creates a dense, uniform grain structure that makes the metal incredibly strong and resistant to cracking. This is why they can handle significantly more power and higher boost levels than their cast counterparts. Forged pistons often feature thicker ringlands—the area between the piston rings—which is a common failure point on cast pistons when an engine experiences detonation. If you’re planning significant Subaru STI upgrades like a larger turbo or an aggressive tune, the superior strength of a forged piston isn’t just an advantage; it’s a necessity for keeping your engine together under load.

Handling Higher RPMs Safely

When you push your engine to higher RPMs, you're asking the pistons to change direction thousands of times every minute. This creates incredible stress, not just from combustion pressure, but from pure inertia. The piston is constantly being pulled and pushed, and at 7,000 RPM or more, those forces are immense. A stock cast piston is designed for the predictable stress of a daily commute, not the sustained abuse of a track day. Its heavier weight and more brittle nature make it vulnerable to fatigue and failure under these high-revving conditions. For any build that involves frequent trips to the redline, you need a component specifically engineered to handle that kind of mechanical violence without coming apart.

This is where the superior strength-to-weight ratio of a forged piston becomes critical. Because they are lighter and more ductile, forged pistons can endure the violent changes in direction at high RPMs without fatiguing. Their robust design, especially around the wrist pin boss, provides the integrity needed to stay reliable lap after lap. If your goal is to build an engine that can safely explore the upper limits of the tachometer, investing in forged pistons is non-negotiable. They are a core component of any serious set of performance parts, providing the confidence you need to push your Subaru STI to its full potential without worrying about catastrophic engine failure.

Which Piston Handles Heat Better?

High-performance engines generate a tremendous amount of heat, and your pistons are on the front line. Cast pistons are effective in stock applications, but they can become brittle after repeated exposure to extreme temperatures. This makes them more susceptible to catastrophic failure, especially during engine knock. Forged pistons are made from alloys that are far more resilient to thermal stress. They manage heat more effectively and are much less likely to fail when things get hot on the track or during a spirited drive. This thermal stability is crucial for anyone seeking reliable power, as a proper engine tuning service will push your engine’s thermal limits.

How Piston Weight Impacts Engine Response

While forged pistons are known for their strength, they also play a role in your engine's responsiveness. Many high-performance forged pistons are designed to be lighter than the stock cast units, reducing the overall mass of the rotating assembly. This lower mass allows the engine to rev more freely and respond more quickly to throttle inputs. A lighter, stronger piston can improve acceleration and help the engine build RPMs faster. However, it's important to remember that the entire rotating assembly—pistons, rods, and crankshaft—must be properly balanced to ensure smooth operation, especially at high speeds.

The Impact on Fuel Efficiency

When you're building a high-performance engine, fuel efficiency usually takes a backseat to power and reliability. Cast pistons are engineered for the stock setup, where their design and tight clearances contribute to the predictable fuel economy you get from the factory. On the other hand, forged pistons are all about handling immense power. While some forged designs are lighter than stock, which can slightly reduce the energy needed to move the rotating assembly, this benefit is often overshadowed by the other modifications you'll be making. A larger turbo, more aggressive fuel maps, and higher boost levels—all things that necessitate forged pistons—will naturally consume more fuel. The key takeaway is that the pistons themselves have a minimal direct impact on your MPG. The real factor is the professional engine tuning that ties your entire build together, optimizing combustion for your specific power goals.

Why Thermal Expansion Matters for Your Engine

Different metals expand at different rates when they heat up, and this is a critical factor in engine building. The aluminum alloys used to create forged pistons typically expand more than the alloys in cast pistons. Because of this, forged pistons require a greater piston-to-wall clearance when the engine is cold to allow for this expansion. An experienced engine builder will set this clearance precisely based on the specific piston and its intended use. If the clearance is too tight, the piston can seize in the cylinder bore once it reaches operating temperature, causing catastrophic engine failure.

Piston Slap: Is It Really a Problem?

If you’ve been around built engines, you’ve probably heard the term "piston slap." This is the light knocking or ticking sound that can sometimes be heard when an engine with forged pistons is cold. It’s caused by the piston rocking slightly in the cylinder due to the larger cold clearance needed for thermal expansion. While it can be alarming to hear, a minor amount of piston slap is a normal characteristic of many high-performance builds and typically fades away as the engine warms up and the pistons expand to their proper size. Modern alloys and piston skirt designs have significantly reduced this tendency, but it’s still a known trait, not necessarily a flaw.

Which Piston Matches Your Power Goals?

Choosing the right piston isn't just about chasing the highest horsepower number; it's about matching the component to your car's purpose. The demands of a daily commute are worlds apart from the stress of a track day or a rally stage. Your decision between cast and forged pistons should start with a clear, honest assessment of how you drive and what you expect from your Subaru. A piston that’s perfect for a 500-horsepower track build might be impractical and noisy for a car that spends most of its time in city traffic.

Think of it as choosing the right tool for the job. You wouldn't use a sledgehammer to hang a picture frame. Similarly, the piston you select needs to align with your power targets, driving habits, and budget. Pushing a stock engine too far can lead to catastrophic failure, while overbuilding a street car can introduce compromises you might not want to live with every day. Let's break down which piston type is the right fit for different scenarios, from the street to the racetrack.

Choosing Pistons for Your Daily Driver

If your Subaru is your daily driver and you’re running stock power levels or light modifications, the factory cast pistons are often the best choice. They are engineered for reliability and efficiency under normal driving conditions. Because they are cast, they can be manufactured with very tight tolerances. This close fit minimizes engine wear, reduces "blow-by" (exhaust gases leaking past the piston rings), and makes for a quieter engine, especially during cold starts. For a dependable car that gets you where you need to go without fuss, a quality cast piston does the job perfectly.

Why Racers Choose Forged Engine Pistons

When you start adding serious power through a larger turbo, increased boost, or an aggressive tune, forged pistons become a necessity. The forging process creates a much stronger and more durable piston that can withstand the intense heat and pressure of a high-output engine. Forged pistons feature thicker ringlands—the area between the piston rings—which is a common failure point on cast pistons under high stress. For any serious Subaru STI upgrades aimed at racing or competitive events, forged pistons provide the strength and peace of mind you need when pushing your engine to its limits.

Why the Pros Trust Forged Pistons

Professionals and experienced engine builders rely on forged pistons for one simple reason: unmatched strength. Unlike a cast piston poured from molten metal into a mold, a forged piston begins as a solid billet of high-grade aluminum. This billet is heated and then pressed into its final shape under immense pressure, a process that aligns the metal's grain structure. This creates an incredibly dense and uniform component, free from the microscopic pores or weak points that can make cast pistons brittle. This superior structural integrity is what gives forged pistons their incredible resistance to cracking, allowing them to handle the extreme cylinder pressures generated by high boost and aggressive engine tuning. It’s the essential foundation for any reliable, high-horsepower build.

Durability for Heavy-Duty Use

Beyond raw strength, forged pistons are engineered with specific design features for heavy-duty use. They have significantly thicker ringlands—the crucial area of metal between the piston rings—which is a notorious weak point on factory cast pistons, especially when an engine experiences detonation. If you're planning to install a larger turbo or get a custom tune, this added durability isn't just a recommendation; it's essential for engine survival under load. Furthermore, the high-grade alloys used in forged pistons are far more resilient to thermal stress. They manage and dissipate heat more effectively, making them much less likely to fail when you're pushing the car hard on the track. This thermal stability is critical for anyone seeking reliable power from their Subaru STI upgrades.

How Much Power Can They Actually Handle?

There isn't a single magic number, but there are clear guidelines. Stock cast pistons can typically handle factory power levels and modest increases from basic bolt-ons. However, once you plan to exceed that and move into serious performance territory, forged pistons are the only reliable option. They are the foundation of any high-horsepower build and are known for their incredible strength. In fact, many high-performance vehicles come with forged pistons directly from the factory. When paired with professional engine tuning services, a forged bottom end can reliably handle substantial power gains.

Are Forged Pistons Practical for Daily Driving?

If you use your STI for daily commuting and it remains mostly stock, sticking with cast pistons can help you avoid some of the trade-offs that come with forged components. Forged pistons expand more as they heat up, requiring looser clearances that can sometimes result in "piston slap"—a light tapping noise when the engine is cold. While modern forged pistons have minimized this, it’s still a consideration. For a street car with minor performance tweaks, a high-quality cast piston provides reliable performance without the potential noise or expense of a forged setup designed for the track.

Is an Engine Forged Piston Worth the Investment?

Choosing between forged and cast pistons isn't just a performance decision—it's a financial one. The right choice depends on how you balance upfront costs with long-term performance goals. While one option has a lower initial price tag, the other can be a smarter investment for a high-powered build. To make an informed decision, you need to look beyond the price of the pistons themselves and consider installation, long-term value, and any specific maintenance needs that come with your choice. This complete picture will help you align your budget with your build, ensuring you get the performance you want without any financial surprises down the road.

The Initial Cost: Forged vs. Cast

The most immediate difference you'll notice between forged and cast pistons is the price. Forged pistons carry a significantly higher upfront cost, and for good reason. The complex manufacturing process and superior materials required to create a forged piston that can handle immense pressure and heat contribute to its premium price. For example, a set of forged pistons for an STI can cost more than three times as much as cast equivalents. This initial investment reflects their role as a true performance part, designed from the ground up for durability and strength in demanding applications, which is a stark contrast to the mass-production focus of cast pistons.

Typical Cost Range for Forged Pistons

So, what kind of price tag are we talking about? While costs vary depending on the brand and specific application for your Subaru, you can generally expect a set of high-quality forged pistons to range from around $700 to over $1,100. This price directly reflects the advanced alloys and the intensive forging process required to achieve their superior strength. When you consider that this can be more than three times the cost of cast alternatives, it’s clear that forged pistons are a serious investment. However, for anyone planning a high-horsepower build, this cost is a critical part of ensuring the engine’s reliability and longevity. These aren't just replacement components; they are foundational performance parts designed to protect your entire engine investment.

Budgeting for Professional Installation

The total cost of your engine build goes far beyond the parts list. Installing forged pistons often requires more specialized labor and machine work than a standard rebuild with cast pistons. Because forged pistons are built to tighter tolerances for high-output engines, your engine builder may need to perform additional modifications to ensure perfect fitment and clearance. As some enthusiasts have noted, forged parts are engineered to handle power levels far beyond stock, and preparing an engine to support them properly is a critical step. This meticulous installation process adds to the overall cost but is essential for the reliability and performance of your final build.

Tailoring Pistons to Your Build

Ultimately, the right piston for your engine is the one that matches your specific goals. There's no one-size-fits-all answer. If you're building a high-horsepower track car or planning significant power upgrades with a larger turbo, forged pistons are non-negotiable. Their dense, uniform grain structure, created through an intense forging process, gives them the strength to handle extreme cylinder pressures and heat without failing. For a reliable daily driver with stock or lightly modified power, a high-quality cast piston is more than sufficient and offers quieter operation. The key is to be realistic about your driving habits and power targets. Investing in the right foundation ensures your engine can reliably support all the other Subaru STI upgrades you have planned.

Which Option Offers Better Long-Term Value?

For anyone planning to seriously upgrade their Subaru's performance, forged pistons offer superior long-term value. While the initial cost is higher, their ability to withstand the stress of increased horsepower and torque protects your investment in the long run. Think of it as insurance for your engine. Some worry that forged pistons aren't suitable for daily driving, but their widespread use in many factory performance vehicles proves they can be perfectly reliable for years. If you plan on adding a bigger turbo, running higher pressure, or hitting the track, the strength of forged pistons provides peace of mind that cast pistons simply can't match.

What Are the Maintenance Requirements?

Owning a vehicle with forged pistons involves being mindful of their unique characteristics. Forged alloys expand more with heat than cast materials, so they require greater piston-to-wall clearance. This can lead to a sound known as 'piston slap' when the engine is cold—a light tapping noise that typically disappears as the engine warms up and the pistons expand. While this is normal for many built engines, it's something owners should be aware of. It doesn’t signal a problem, but it does highlight the importance of proper engine warm-up procedures and regular maintenance checks to ensure your high-performance engine remains healthy.

What Other Parts Does Your Engine Need?

Upgrading your pistons is a major step, but it’s not a standalone modification. To build a reliable, high-performance engine, you need to think about the entire system. Dropping forged pistons into an otherwise stock engine without considering the supporting components is a recipe for disappointment and, potentially, another engine failure. A powerful engine is a balanced engine, where every part is chosen to work in harmony. This is especially true for Subaru’s EJ and FA engines, which have their own unique characteristics and demands.

Before you finalize your piston choice, it’s crucial to plan for the other critical elements your build will require. Think of it like building a house—you wouldn't install marble countertops on a crumbling foundation. The same principle applies here. Your new pistons need a strong, stable environment to perform at their best and deliver the power you’re looking for. Let’s cover the other essential parts of the equation to ensure your engine can handle the extra power and stress safely for years to come.

Ensuring a Perfect Fit for Your Engine

The first step is to align your piston choice with your driving style and overall power goals. Are you building a weekend track car that will see high RPMs and intense heat, or a spirited daily driver with moderate Subaru STI upgrades? For a high-horsepower race build, forged pistons are the clear winner, as they are designed to handle extreme cylinder pressures and temperatures. However, for a daily driver with mild bolt-ons, a quality set of cast or hypereutectic pistons can provide quiet, reliable performance without the cold-start quirks of a forged setup. Be honest about how you’ll use your car—it’s the best way to ensure you build an engine that you’ll love to drive.

Why Piston Clearance is Non-Negotiable

Forged pistons expand more than cast pistons as they heat up. Because of this, they require a larger gap between the piston and the cylinder wall, known as piston-to-wall clearance. This extra space is what can cause "piston slap"—a light knocking sound when the engine is cold. Once the engine reaches operating temperature, the piston expands and the noise disappears. Getting this clearance perfect is a job for a professional machine shop. If the clearance is too tight, the piston can seize in the bore. If it’s too loose, you’ll have excessive noise and oil consumption. This is why professional assembly and a precise engine tuning service are non-negotiable for a successful build.

How to Choose the Right Compression Ratio

Your piston choice directly impacts your engine’s compression ratio—the ratio of the cylinder volume at the bottom of the stroke to the volume at the top. Pistons come in different designs: domed, flat-top, or dished, each altering this ratio. A higher compression ratio can yield more power and efficiency but requires higher-octane fuel to prevent detonation (knock). A lower compression ratio is safer for high-boost applications, as it reduces stress on internal components. Your decision should be based on your fuel choice (pump gas vs. E85) and how much boost you plan to run. This is a critical detail to discuss with your engine builder to ensure your setup is both powerful and reliable.

What Other Upgrades Do You Need?

Forged internals are incredibly strong, but they won't fix underlying weaknesses in your engine. If your stock engine failed due to a bad tune, oil starvation, or overheating, those issues must be addressed first. When building for more power, you should also upgrade other key components. This includes stronger connecting rods, high-performance bearings, and ARP head studs to prevent head lift under high boost. A robust cooling system and a high-volume oil pump are also essential to keep temperatures and pressures stable. Viewing your engine as a complete package of performance parts is the key to building something that will withstand the abuse you plan to throw at it.

Why Connecting Rods and Crankshafts Matter

Your new forged pistons are only one part of the rotating assembly. They connect to the crankshaft via connecting rods, which have the critical job of converting the linear, up-and-down motion of the pistons into the rotational force that drives your car. The crank and rods handle all the stress of this conversion. While the factory components are fine for stock power, they become a major weak point when you introduce the higher cylinder pressures from a built motor. Upgrading to stronger, forged connecting rods is essential to ensure the entire assembly can handle the added power from your new pistons and tune. A powerful engine is a balanced engine, and matching your rods to your pistons is a non-negotiable part of building a reliable setup with quality performance parts.

Debunking Common Piston Myths

When you start exploring engine builds, you’ll run into a lot of strong opinions, especially about forged versus cast pistons. It’s easy to get lost in forum debates and conflicting advice. Let’s clear the air and tackle some of the most common myths so you can make a decision based on facts, not fiction. The right choice always comes down to your specific goals for your Subaru, whether it’s a daily driver or a dedicated track machine.

Myth: Forged Pistons Aren't for Street Cars

A common myth is that forged pistons are strictly for race cars and are impractical for a daily driver. The truth is more nuanced. If you plan on adding significant power with performance parts like a larger turbo or aggressive tune,

Which Piston Is Actually More Reliable?

Some people believe forged pistons are less reliable or have a shorter lifespan in a daily driver. This idea is challenged by the fact that many high-performance vehicles come with forged pistons straight from the factory. Their strength is precisely why manufacturers use them in engines designed for high output. When installed correctly with proper clearances and paired with professional engine tuning services, forged pistons are incredibly reliable. Reliability issues often stem from a poor build or an improper tune, not from the piston material itself.

How Long Do Forged Pistons Really Last?

Let's talk about "piston slap." It’s true that forged pistons can be noisier when the engine is cold. This is because they are made from an alloy that expands more with heat, requiring more clearance within the cylinder. That light knocking sound you might hear on a cold start is normal and typically goes away as the engine warms up and the pistons expand to their operating size. A well-built engine with forged pistons is designed to last, giving you a solid foundation for all your Subaru STI upgrades.

How Will Forged Pistons Change Your Daily Drive?

It’s crucial to understand that forged internals are not a cure-all for engine problems. They are designed to handle more power safely, but they won't fix underlying issues like bad bearings or leaking head gaskets. Factory cast pistons are great for stock power levels, but they can become brittle over time with repeated heat cycles, making them a liability if you increase power. Upgrading to forged pistons is a proactive step to support future power modifications and ensure your engine’s bottom end can handle the demands you place on it.

Installation and Long-Term Care

Choosing the right pistons is a huge step, but the work doesn’t stop there. Proper installation and long-term care are what truly determine the success and lifespan of your engine build. Getting these next steps right ensures you get all the performance you paid for without compromising reliability. Think of it as protecting your investment. A little extra attention to detail during installation and a consistent maintenance routine afterward will keep your STI running strong whether you’re on the street, track, or trail.

How to Prep Your Engine Block for New Pistons

Before any new pistons go in, your engine block needs some careful preparation. The most critical step is ensuring the cylinder bores are perfectly sized and finished for your chosen pistons. This isn't a one-size-fits-all process. Forged pistons expand more than cast pistons as they heat up, so they require greater clearances within the cylinder bore. This extra space is essential to prevent the piston from binding or causing serious damage when your engine is at operating temperature. An experienced machinist will measure everything precisely to guarantee the perfect fit for your specific set of performance parts and application.

How to Properly Break In Your New Engine

Once your engine is assembled, the break-in period is your first and most important task. This process is vital for seating the new piston rings against the cylinder walls, creating a tight seal that’s crucial for compression and oil control. While cast pistons might offer a slightly better fit when the engine is cold, the superior durability of forged pistons allows them to handle the stresses of the break-in process exceptionally well. It’s important to follow a specific procedure of varying engine loads and RPMs, avoiding both excessive idling and full-throttle pulls. This careful process ensures everything wears in together properly, setting the stage for a long and powerful engine life.

Why a Professional Tune Is Essential

After installing new pistons—especially forged ones—a professional tune isn't just recommended; it's absolutely necessary. Forged pistons are built to handle significantly more power, but your engine’s computer needs to be told how to use them. A professional tuner will recalibrate the air-fuel mixture and ignition timing to match the new components, optimizing performance and preventing dangerous conditions like engine knock. This step is what unlocks the full potential of your build safely and reliably. Skipping it is like buying a racehorse and never training it. To get the most out of your investment, professional engine tuning services are the final piece of the puzzle.

Long-Term Care for Your Built Engine

With your engine broken in and tuned, long-term care becomes your focus. The key is consistent monitoring and maintenance. Keep a close eye on your oil levels and engine temperatures, especially if you’re pushing the car hard. Regular oil changes with high-quality lubricants are non-negotiable, as this is the lifeblood of your engine and critical for protecting your new pistons and bearings. Even though forged pistons are incredibly tough and shatter-resistant, a proactive maintenance schedule is the best way to ensure the longevity of your entire build. Proper care ensures your Subaru STI upgrades continue to perform at their peak for years to come.

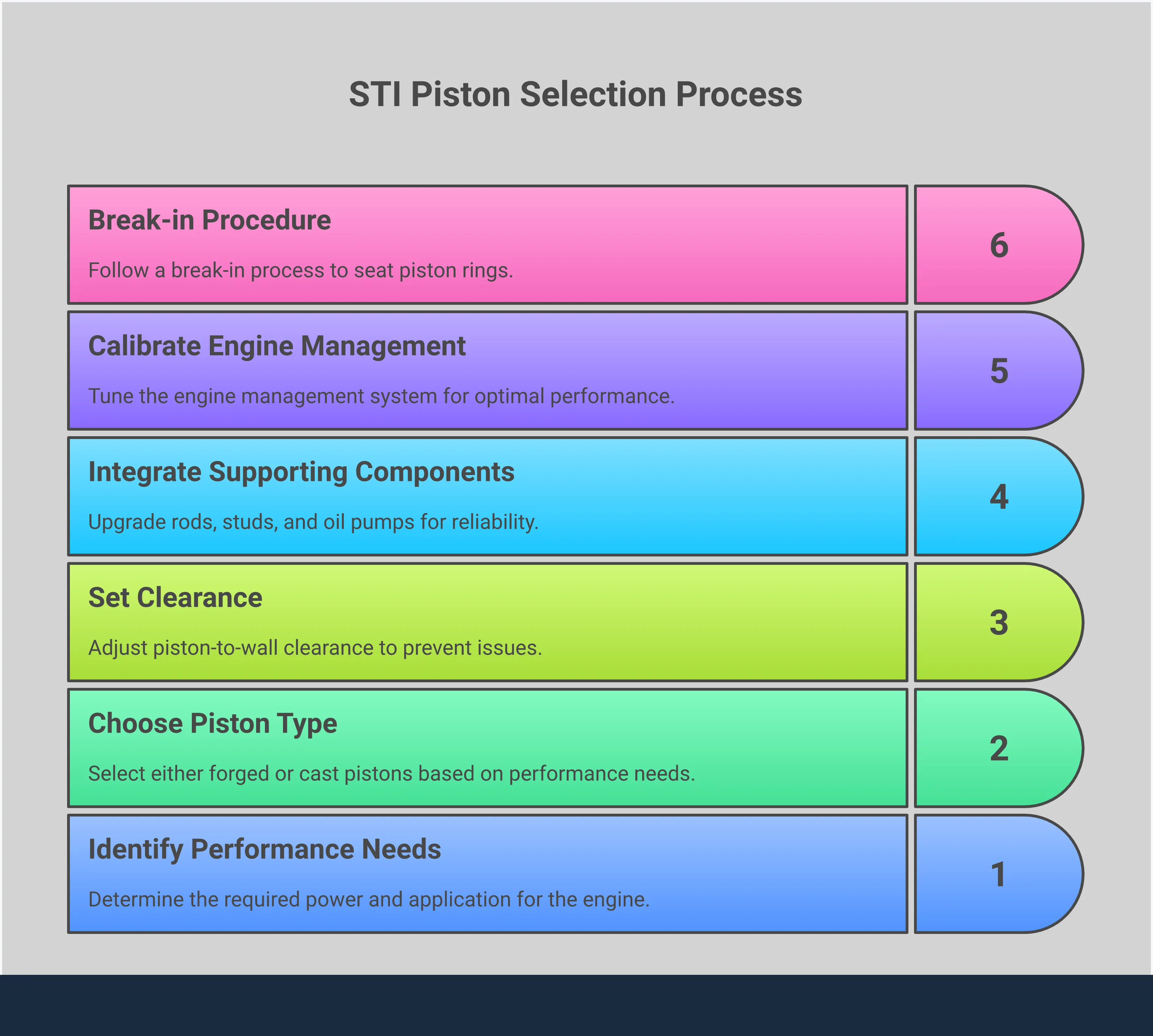

How to Choose the Right Piston for Your STI

Picking the right pistons isn't just about buying the most expensive part; it's about matching the component to your car and how you plan to use it. Your goals, driving habits, and budget all play a huge role in making the right choice. Let's walk through the key factors to consider so you can build an engine that’s reliable, powerful, and perfectly suited to you.

What Are Your Performance Goals?

First, be honest about what you want from your STI. Are you building a weekend track monster or a spirited daily driver? If you’re aiming for a significant power increase and plan on pushing your car hard, forged pistons are the clear winner. They are designed to handle the intense heat and pressure that come with high-performance Subaru STI upgrades. For those sticking close to stock power levels or making only minor modifications, the factory cast pistons are often sufficient for reliable everyday use. The key is to choose a piston that can support your ultimate power target.

How Do You Actually Drive Your Car?

How you drive every day matters. Factory cast pistons are perfectly fine for daily commuting and occasional spirited driving, but they can become brittle over time with repeated heat cycles. If your driving style involves frequent track days or aggressive runs, you need a piston that can keep up. Forged pistons are built for that abuse. They expand more as they heat up, which is why they require more clearance. This can sometimes cause a light knocking sound, known as piston slap, when the engine is cold. However, this is a small trade-off for the strength they provide under demanding conditions.

What's Your Total Project Budget?

There’s a significant price difference between cast and forged pistons, and it’s important to factor that into your build budget. Forged pistons are a bigger upfront investment, but they are essential for protecting your engine if you're adding serious power. Think of it as insurance for your motor. Cutting corners here could lead to a catastrophic engine failure down the road, which will cost far more to fix. When planning your build, remember to account for the cost of pistons alongside other performance parts and labor to get a complete picture of the total investment.

Are More Upgrades in Your Future?

Always build for the power you want, not just the power you have. If you know you’ll be adding a bigger turbo or chasing higher horsepower numbers in the future, install forged pistons now. Tearing down the engine a second time to upgrade pistons is expensive and time-consuming. While some believe forged pistons don't last as long in a daily driver, many modern performance cars come with them from the factory. With a proper installation and a professional engine tune, a forged piston setup can be perfectly reliable for years of enjoyment, giving you a strong foundation for any future modifications.

Related Articles

Frequently Asked Questions

I've heard forged pistons are noisy. Will my daily driver sound like a race car? That "noise" you're referring to is called piston slap, and it's a known characteristic of some performance builds. It happens because forged pistons require more room to expand as they heat up, so they have a bit more space in the cylinder when the engine is cold. This can create a light ticking sound that usually fades away completely once the car is warmed up. Modern piston designs have greatly reduced this, but it's a small trade-off for the incredible strength needed to handle serious power.

At what power level do I absolutely need to switch to forged pistons? There isn't a single horsepower number that acts as a hard-and-fast rule, as the engine's tune and how you drive are just as important. Generally, once you start planning for major upgrades like a larger turbo or a significant increase in boost, you're entering forged piston territory. The factory cast pistons are reliable for stock power and light modifications, but they weren't designed for the intense cylinder pressures of a high-output build. It's better to build the foundation for the power you want, rather than waiting for a failure to force your hand.

Can I just upgrade my pistons and leave the rest of the engine stock? Upgrading your pistons without strengthening the surrounding components is not a good idea. A high-performance engine is a balanced system. When you install pistons capable of handling more power, you also need to consider parts like connecting rods, bearings, and head studs, which will be subjected to the same increased stress. A strong piston in an otherwise stock bottom end just moves the weak point to the next component, setting you up for a different kind of failure down the road.

Is the expensive installation and professional tune really necessary for forged pistons? Absolutely. Proper installation by an experienced engine builder is critical to getting the piston-to-wall clearances exactly right, which is essential for both performance and longevity. After the build, a professional tune is what ties everything together. It adjusts your engine's fuel and timing parameters to work with the new, stronger components, ensuring you make power safely. Skipping these steps is the quickest way to ruin your new investment.

If forged pistons are so strong, why don't all cars come with them from the factory? The main reasons are cost and application. Cast pistons are much cheaper and faster to produce, making them ideal for mass-produced vehicles intended for daily driving. They are also designed for tighter clearances, which results in a quieter engine on cold starts—a priority for most consumers. Forged pistons are reserved for high-performance applications where their strength is necessary to handle the demands of more power, and the higher manufacturing cost is justified.