The Ultimate Subaru Cylinder Head Rebuild Guide

Share

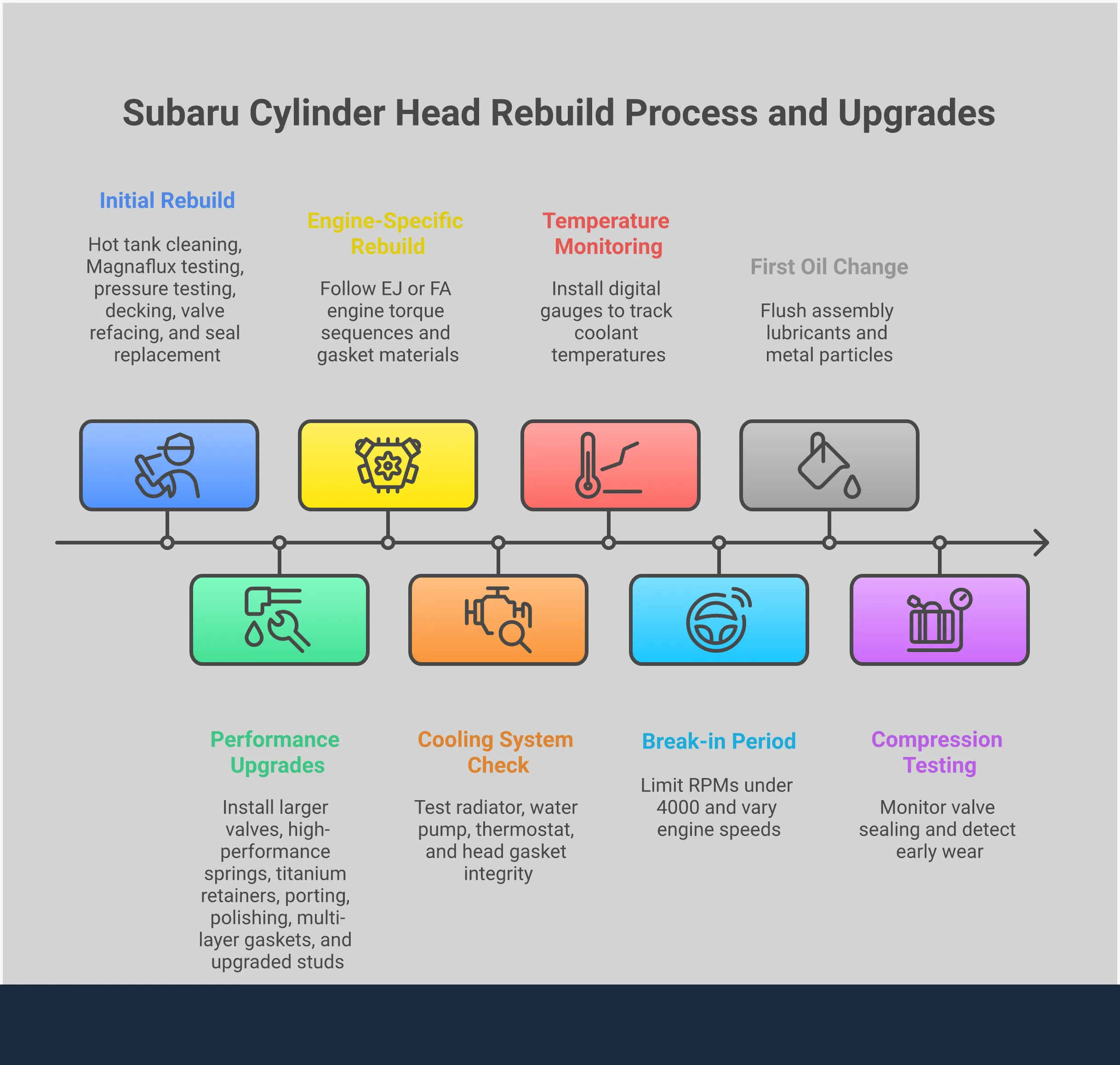

Hearing that your engine needs major work can feel like a setback, but it’s also a golden opportunity. If you’re facing a blown head gasket or other top-end issues, a Subaru cylinder head rebuild is the perfect time to build the engine you’ve always wanted. With the engine already disassembled, the labor-intensive part is done, making it the most cost-effective moment to install performance upgrades. Instead of just returning to factory specs, you can build a stronger, more reliable foundation for future power. This article will explain how to turn a necessary repair into a strategic investment in your car’s performance.

Key Takeaways

- A rebuild is a precision process, not a simple parts swap: It's a comprehensive overhaul that corrects the core reasons for failure, like overheating or head gasket issues, by restoring the cylinder head to exact specifications for long-term reliability.

- Build a stronger engine while you fix it: A cylinder head rebuild offers the most cost-effective chance to add performance components, transforming a standard repair into a foundational upgrade for more power and durability.

- Success depends on the right partner and proper aftercare: Selecting a shop with proven Subaru expertise is critical for a quality rebuild. Afterward, following a strict break-in procedure and maintaining a consistent oil change schedule is essential to protect your investment.

What is a Subaru Cylinder Head Rebuild?

A Subaru cylinder head rebuild is a meticulous process of restoring your engine's top-end to factory or better-than-factory condition. It involves completely disassembling the cylinder heads, thoroughly cleaning every component, inspecting for damage, and replacing any worn parts like valves, seals, and guides. Once everything is serviced and measured, the head is carefully reassembled. This isn't just a repair; it's a reset for a critical part of your Boxer engine. Think of it as the difference between patching a problem and giving your engine a new lease on life.

This process is essential for maintaining engine efficiency, power, and reliability. Whether you're dealing with a blown head gasket or simply refreshing a high-mileage engine, a proper rebuild ensures everything seals correctly and operates smoothly. At Crawford Performance, our approach to a rebuild involves motorsport-grade precision, guaranteeing that your engine is ready for the street, track, or trail. It’s also the perfect opportunity to install performance upgrades that can handle more power and abuse, turning a necessary repair into a strategic enhancement for your vehicle.

Signs You Need a Rebuild

Your Subaru is usually pretty good at telling you when something is wrong. The most common sign of a failing head gasket or cylinder head issue is chronic overheating, even with a healthy cooling system. You might also notice thick white smoke billowing from the exhaust, which indicates coolant is burning in the combustion chamber. Other tell-tale symptoms include a persistently rough idle, engine misfires, or visible oil and coolant leaks around the cylinder head. If you find a milky, frothy substance on your oil cap, it’s a classic sign that oil and coolant are mixing—a problem that needs immediate attention to prevent catastrophic engine damage.

EJ vs. FA: Key Engine Differences

Not all Subaru engines are created equal, and understanding the distinction between the EJ and FA series is crucial when considering a rebuild. The EJ engine, found in models like the 2002–2014 WRX and STIs up to 2021, has a long history in performance circles. The newer FA engine, used in the latest WRX and BRZ models, features modern technology like direct injection. These architectural differences mean the rebuild process, required tools, and potential weak points are unique to each. A shop that applies a one-size-fits-all approach can miss critical details. That’s why it’s vital to work with specialists who understand the specific needs and tolerances of your engine when selecting performance parts and services.

Why Do Subaru Cylinder Heads Fail?

Subaru cylinder heads are tough, but they aren't invincible. When they fail, it's rarely a spontaneous event. Instead, failure is usually the final symptom of an underlying problem that has been brewing for a while. The unique "boxer" engine design, with its horizontally opposed cylinders, places specific stresses on components, making certain issues more common than in other engine layouts. Understanding the root cause is the most important step in any repair, as simply fixing the cylinder head without addressing the initial problem is a recipe for a repeat failure down the road.

Most issues trace back to two main culprits: head gasket failure and overheating. These two problems are often linked in a destructive cycle. A failing head gasket can cause the engine to overheat, and an overheating engine can cause the head gasket to fail. Other times, mechanical issues like problems with the valvetrain can lead to poor performance that points toward a necessary rebuild. Identifying the specific cause helps you and your mechanic create a solid plan for not just repairing the damage, but also preventing it from happening again, often through strategic performance parts that strengthen the engine's weak points.

Common Culprit: Head Gasket Failure

If you’ve been in the Subaru community for any length of time, you’ve heard the term "head gasket failure." It’s the most frequent cause of major engine work. The head gasket is a critical seal between the cylinder head and the engine block, responsible for containing combustion pressure and keeping coolant and oil from mixing. When it fails, chaos ensues. The most common sign is an engine that chronically overheats. You might also notice white, sweet-smelling smoke from the exhaust (burning coolant), a milky residue on your oil cap (oil and coolant contamination), or persistent engine misfires. A failing gasket can allow hot combustion gases to damage the cylinder head, making a rebuild essential.

The Impact of Overheating

Overheating is your engine’s worst enemy, and for aluminum cylinder heads, it’s particularly destructive. When your temperature gauge consistently creeps into the red, it’s a serious warning sign. Extreme heat causes the aluminum head to expand and warp, destroying the perfectly flat surface needed to seal against the engine block. This warping is a direct cause of head gasket failure. Even if the gasket was fine before, a single severe overheating event can be enough to compromise the seal. That’s why addressing the source of the overheating—whether it's a bad radiator, a failing water pump, or a coolant leak—is just as important as repairing the head itself. Proper engine tuning services can also help manage temperatures, especially in modified vehicles.

Understanding Valve-Related Issues

While head gaskets get most of the attention, problems within the valvetrain can also necessitate a cylinder head rebuild. Issues like burnt or bent valves, worn valve guides, or failing valve stem seals can cause a range of symptoms. You might experience a noticeable decrease in engine power, a rough idle, or difficulty starting the car. Engine misfires are also common when a valve isn't sealing properly. A compression test is a great diagnostic tool to confirm if poor compression in one or more cylinders is the source of your trouble. If you have a timing issue or a valve problem, a rebuild is the perfect opportunity to install upgraded Subaru WRX upgrades like stronger valves and springs to handle more power and RPM.

What's in a Professional Cylinder Head Rebuild?

A professional cylinder head rebuild is far more than just swapping out a few old parts for new ones. It’s a meticulous, multi-stage process designed to restore your engine’s heart to factory-fresh—or even better-than-new—condition. Each step is critical for ensuring reliability, performance, and longevity, whether you're building a daily driver or a track-ready Subaru WRX. Think of it as a complete health check and restoration, where every component is cleaned, inspected, and serviced with precision. This detailed approach guarantees that the head is free of hidden flaws and ready to handle the power you expect from your Subaru.

The Disassembly and Cleaning Process

The first step in any professional rebuild is a complete and careful disassembly. Every single component—from the camshafts and valves to the springs and retainers—is systematically removed and organized. Once stripped down, the bare cylinder head is submerged in a hot tank. This industrial-strength cleaning bath uses a combination of heat and specialized chemical agents to dissolve and strip away all the built-up carbon, oil, and grime. This isn't just about making it look clean; it's about creating a perfectly bare surface. A thoroughly cleaned head is essential for the next stage, as even the smallest bit of debris could hide a critical flaw like a hairline crack.

Inspecting for Cracks and Leaks

With the cylinder head sparkling clean, the real diagnostic work begins. You can't spot every potential issue with the naked eye, so technicians rely on specialized tools. A Magnaflux test, which uses magnetic particles and ultraviolet light, is often performed to reveal any microscopic cracks on the surface that could lead to catastrophic failure under pressure. Next, the head undergoes a pressure test to check for internal leaks between coolant and oil passages. The head is sealed off and pressurized with air while submerged in water. Any bubbles that appear signal an internal breach. This rigorous inspection ensures the head is a solid, reliable foundation before any machining or reassembly begins.

Servicing Valves and Replacing Seals

The valves and their seats are critical for proper compression and engine performance. During a rebuild, each valve is inspected, cleaned, and refaced. The valve seats in the head are also cut to ensure a perfect angle for sealing. The valves are then "lapped" into their seats—a process of grinding them together with a special compound to create an airtight seal. A vacuum test confirms that the seal is perfect. At this stage, old, brittle valve stem seals are always replaced with new ones to prevent oil from leaking into the combustion chamber. This is also the perfect time to consider upgrading to higher-quality performance parts for better flow and durability.

Checking for Warpage and Machining

Overheating can cause the flat surface of the cylinder head—the part that mates with the engine block—to warp. Even a tiny, invisible distortion can prevent the head gasket from sealing correctly, leading to leaks and repeat failures. Technicians use a precision straight edge and feeler gauges to check the head for any warpage. If it’s not perfectly flat, the head is resurfaced through a process called decking or milling. This involves carefully machining a very thin layer of metal off the surface to restore a true, flat plane. This step is non-negotiable for a lasting repair and is a core part of our Subaru machine shop services.

How Much Does a Subaru Cylinder Head Rebuild Cost?

Let's talk about one of the biggest questions on every owner's mind: the cost. A cylinder head rebuild is a significant investment in your Subaru's health and performance, and the final price tag can vary quite a bit. The total cost depends on your specific engine, the extent of the damage, and the quality of the parts you choose for the job.

Think of it less as a fixed price and more as a range determined by a few key factors. A straightforward rebuild on a stock engine will cost less than a comprehensive overhaul that includes high-performance upgrades. The shop's labor rate and the specific machine work required will also play a major role. Below, we’ll break down the main components of the cost so you can get a clearer picture of what to expect and where your money is going. This will help you make an informed decision that aligns with both your budget and your performance goals for your vehicle.

Cost Breakdown by Engine Type

Not all Subaru engines are created equal, and their architecture directly impacts rebuild costs. For example, servicing the cylinder heads on an older EJ series engine found in many WRX and STI models can differ in price from working on a newer FA series engine. Generally, you can expect the total cost for a professional head gasket repair, which is the core of most rebuilds, to fall somewhere between $2,000 and $2,600. This range accounts for both parts and labor. The complexity of the engine, parts availability, and the specific procedures required for each engine family contribute to this variation.

What Affects the Final Price?

Several variables can influence the final invoice for your cylinder head rebuild. The labor rate of the shop is a primary factor, as this is a time-intensive job. Beyond that, the condition of the heads themselves is critical. If they only need to be cleaned and resurfaced, the machine shop bill will be relatively low—often between $125 and $300. However, if the inspection reveals cracks, warped surfaces beyond repair, or damaged valve guides, the cost for machining and parts will increase accordingly. The price of replacement components like gaskets, seals, and head studs will also be a significant part of the total.

Performance vs. OEM Parts: A Cost Comparison

When you’re rebuilding your cylinder heads, you have a choice between standard Original Equipment Manufacturer (OEM) parts and aftermarket performance parts. While OEM components might have a lower upfront cost, investing in performance-grade parts is often the smarter long-term decision, especially if you plan to push your Subaru on the track or trail. Upgraded head studs, multi-layer steel gaskets, and higher-quality valves are designed to withstand greater stress and heat. This added durability not only supports higher power levels but also provides a stronger defense against future failures, saving you from more costly repairs down the road.

Rebuild or Replace: Which is Right for You?

Deciding between rebuilding your cylinder heads and replacing them entirely is a major crossroads for any Subaru owner. A replacement might seem like a quicker fix, but it often means settling for a used component with an unknown history. A rebuild, on the other hand, allows you to restore your engine to precise specifications and, more importantly, opens the door to significant performance gains. It’s not just about fixing what’s broken; it’s about building something better and more reliable for the road or track ahead.

Your decision will hinge on the extent of the damage and your long-term goals for the vehicle. If you're dealing with common issues like a blown head gasket, a rebuild is almost always the superior choice. It gives a skilled technician the chance to thoroughly inspect every component, catch underlying problems, and ensure your Boxer engine is assembled with motorsport-grade precision. This process transforms a necessary repair into a strategic investment in your Subaru’s health and power.

When to Choose a Rebuild

A rebuild is the right call when you spot the classic signs of head gasket failure. The most common red flag is an engine that consistently overheats, even during normal driving. This happens when the gasket fails to seal the combustion chamber, allowing hot exhaust gases to leak into the cooling system.

Pay close attention to other tell-tale symptoms that point to internal Subaru cylinder head problems. Are you seeing clouds of sweet-smelling white smoke from your exhaust? That’s likely coolant burning off. Does your engine idle roughly or misfire? This could be due to coolant contaminating the cylinders. Also, check for external oil or coolant leaks around the head gasket seam. If you notice any of these issues, a rebuild is necessary to fix the root cause and prevent catastrophic engine damage.

The Perfect Time for Performance Upgrades

Think of a mandatory cylinder head rebuild as a golden opportunity. With the engine already taken apart, the labor-intensive work is done, making it the most cost-effective time to install performance upgrades. While a standard rebuild restores your engine to factory condition, a performance-focused rebuild can transform your vehicle’s character. This is your chance to go beyond a simple fix and build the engine you’ve always wanted.

Instead of just cleaning and resurfacing, you can opt for professional Subaru machine shop services that include porting and polishing for better airflow, installing stronger valve springs, or adding high-performance camshafts. These modifications work together to increase horsepower, torque, and overall engine efficiency. By bundling these upgrades with the rebuild, you save significantly on future labor costs and get back on the road with a stronger, more capable engine.

How to Choose the Right Rebuild Shop

Finding the right shop for your cylinder head rebuild is just as important as the parts you choose. The precision and expertise of the technicians will directly impact your engine's performance and longevity. Not all shops have the specialized knowledge required for Subaru's unique Boxer engines, especially when performance is the goal. You need a team that understands the specific challenges and opportunities these engines present, from the nuances of the classic EJ series to the direct-injection complexities of the newer FA engines. A general auto shop might be able to handle a basic repair, but for a performance-focused rebuild, you need a specialist who lives and breathes Subaru. This isn't just about fixing a problem; it's about investing in your vehicle's future. The right partner will work with you to understand your goals, whether you're building a reliable daily driver or a track-ready monster, and guide you toward the best solutions. They will ensure every component is meticulously inspected, cleaned, and machined to exacting standards, laying the foundation for reliable power.

The Crawford Performance Difference

When you're looking for more than just a standard fix, you need a shop that operates at a higher level. At Crawford Performance, we go beyond basic service—our Subaru Cylinder Head Disassembly & Cleaning delivers motorsport-grade precision to keep your Boxer engine performing at its best. This means we treat every engine with the same attention to detail as our race-winning builds. Our process involves a complete teardown, meticulous cleaning of every component, and a thorough inspection that identifies potential issues before they become major problems. This level of care ensures your rebuilt heads are ready to handle the increased demands of performance parts and aggressive driving, giving you confidence every time you turn the key.

What to Look For in a Professional Shop

A professional shop should be transparent, knowledgeable, and, most importantly, specialized. Look for a shop that focuses specifically on Subaru engines and offers a range of services tailored to your needs. A true specialist will understand the distinct requirements of EJ and FA series engines. Check their website for detailed descriptions of their Subaru machine shop services and look for galleries of past projects or customer testimonials. A shop that is proud of its work will have plenty to show you. They should also be able to discuss your goals, whether you're building a reliable daily driver or a track-ready monster, and recommend the right path forward.

Key Questions to Ask Your Mechanic

Before you hand over your keys, make sure you're asking the right questions to gauge a shop's expertise and professionalism. Start by inquiring about their rebuild packages to ensure you get a clear, itemized quote. Don't hesitate to ask about their warranty on parts and labor; a confident shop will stand behind its work. You should also ask about their experience with your specific model, like the Subaru WRX or STI. Finally, discuss their process for inspection, cleaning, and machining. A quality shop will be happy to walk you through their methods and explain why they do things a certain way, ensuring you feel confident in their ability to deliver exceptional results.

What Performance Upgrades Can You Add During a Rebuild?

A cylinder head rebuild is the perfect opportunity to go beyond simple repairs. With the engine already disassembled, you have direct access to its core components, making it the most efficient and cost-effective time to install upgrades. Choosing the right performance parts during this process can transform your Subaru’s power, responsiveness, and reliability, whether you’re building a daily driver or a dedicated track machine. This is your chance to move past stock limitations and build an engine that truly matches your performance ambitions.

Instead of just restoring your engine to factory specs, you can build it to be stronger and more capable than ever. This is the ideal time to address known weak points in the valvetrain and tailor the engine’s character to your driving style. From improving airflow with upgraded valves and porting to ensuring high-RPM stability with better springs and retainers, the right combination of components will prepare your engine for higher horsepower and more demanding conditions. Think of it as a foundational investment that pays off every time you turn the key, giving you the confidence to push your car harder on the street, trail, or track.

Upgraded Valves and Porting

Upgrading your valves and porting the cylinder heads are two of the most effective ways to help your engine breathe better. Performance valves are often made from stronger, lighter materials and can have larger diameters to allow more air and fuel into the combustion chamber. This directly translates to more power.

Porting involves smoothing and reshaping the intake and exhaust ports to remove casting imperfections and improve airflow velocity. A professional port and polish job ensures an unobstructed path for the air-fuel mixture to enter and exhaust gases to exit, which is critical for making serious horsepower. This is a highly skilled task, so it’s essential to have it done by a machine shop with experience in Subaru engines.

High-Performance Springs and Retainers

Your engine’s valve springs control how quickly the valves open and close. At high RPMs, stock springs can struggle to keep up, leading to a condition called "valve float," where the valve doesn't fully close before the next combustion cycle. This causes a loss of power and can lead to catastrophic engine damage.

High-performance valve springs are stiffer to prevent float and provide precise valve control, even at redline. Pairing them with lightweight titanium retainers reduces valvetrain mass, allowing the engine to rev more freely and reliably. This upgrade is a must for anyone planning to install aggressive camshafts or push their Subaru WRX or STI on the track.

Choosing Compatible Camshafts

Camshafts are the brain of your valvetrain, dictating when your valves open, how far they lift, and how long they stay open. Swapping to performance camshafts can dramatically alter your engine’s powerband, shifting torque and horsepower to a higher RPM range for better track performance.

However, it’s crucial to choose cams that are compatible with your entire setup. An aggressive cam profile requires matching valve springs and retainers to function correctly. More importantly, new camshafts demand professional engine tuning services to adjust fuel and ignition timing. Without a proper tune, you won’t see the full benefits and could even harm your engine. Always consult with your engine builder to select a camshaft that aligns with your power goals and driving needs.

How Long Does a Cylinder Head Rebuild Take?

One of the first questions on every driver's mind is, "How long will my car be out of commission?" A cylinder head rebuild is a meticulous process, not a quick fix, and the timeline can vary significantly. The total time depends on the extent of the damage, the specific services required, and the shop's current workload. A straightforward job involving cleaning, inspection, and resurfacing will be on the shorter end of the spectrum. However, if you're adding extensive performance upgrades or if the heads have significant damage, you should plan for a longer turnaround.

Understanding the process helps set realistic expectations. The rebuild involves completely disassembling the heads, thoroughly cleaning every component, inspecting for any signs of damage like cracks or warpage, machining surfaces, servicing valves, and finally, reassembling everything to precise specifications. Each step requires careful attention to detail. We’ll walk through the standard timeline you can expect and discuss common delays that can pop up, so you can be fully prepared.

The Standard Rebuild Timeline

A standard cylinder head rebuild typically takes anywhere from four to 20 days. This window accounts for the initial teardown and detailed inspection, sending the heads to a machine shop for services like decking and valve jobs, and waiting for any necessary performance parts to arrive. The lower end of this range, about a week, is realistic for a basic refresh with readily available components. If your rebuild includes more complex work like porting, polishing, or installing a full set of upgraded valvetrain components, it’s wise to expect the process to take closer to the two or three-week mark. A professional shop will provide a more accurate estimate after they’ve had a chance to inspect the heads firsthand.

Potential Delays and How to Handle Them

Even with the best planning, delays can happen. Common hold-ups include backlogs at the machine shop, shipping delays for specific parts, or the discovery of unexpected damage, like a hidden crack that requires specialized repair or a full replacement. The complexity of your engine can also play a role; some models simply take longer to work on than others.

The best way to manage this is to maintain open communication with your shop. Ask for a realistic timeline upfront and check in for periodic updates. Understanding that the initial estimate is just that—an estimate—can help manage your expectations. If a delay occurs, your mechanic should be able to explain exactly what’s causing it and provide a revised completion date.

Which Subaru Models Benefit Most?

While any Subaru can gain from a well-executed cylinder head rebuild, certain models and situations make it an especially smart move. It’s a solution that addresses specific weaknesses and unlocks new potential, whether you're chasing faster lap times or just want to keep your daily driver running smoothly for another 100,000 miles. The key is to tailor the approach to your car and your goals, ensuring you get the reliability and performance you expect from your Subaru. From track-focused builds to high-mileage workhorses, a rebuild can be the difference between an engine that just runs and one that runs right.

High-Performance Applications: WRX & STI

If you own a WRX or STI, you know these cars are built to be pushed. As you add power through tuning and bolt-ons, the cylinder heads become a critical component that must handle increased stress. A rebuild isn't just a repair—it's a foundational step for any serious build. This is your opportunity to install stronger valves, springs, and retainers that can manage higher RPMs and increased cylinder pressures without failing. By reinforcing the heads, you create a durable platform for aggressive engine tuning services and ensure your engine can reliably support your power goals. Explore our Subaru STI Upgrades to see how we can prepare your engine for the track or the street.

Benefits for High-Mileage Engines

For high-mileage Subarus, especially models like the Forester, Crosstrek, and Impreza with EJ engines, a cylinder head rebuild is all about restoring reliability. The notorious Subaru head gasket leak, often seen as a slow coolant "seep," is a common issue that can lead to overheating and catastrophic engine damage if ignored. Addressing this with a rebuild is a proactive investment in your vehicle's longevity. While the engine is apart, performing a valve job and replacing worn seals restores lost compression and efficiency. This isn't just a fix; it breathes new life into your engine, ensuring many more years of dependable service. We offer a range of performance parts that can improve durability for these workhorse models.

How to Maintain Your Rebuilt Cylinder Head

You’ve invested in a professional cylinder head rebuild, and now it’s time to protect that investment. Proper care after a rebuild is just as critical as the work itself, ensuring your engine performs reliably for years to come. The process isn’t complicated, but it does require attention to detail, especially in the beginning. Think of it in two key phases: a careful break-in period to let all the new components settle in, followed by a consistent long-term maintenance routine. Following these steps will help you get the most out of your rebuilt engine and any new performance parts that were installed. Taking the time to do this right ensures your Subaru runs smoothly, whether you’re on the track or heading out for an adventure.

Following the Proper Break-In Procedure

The first few hundred miles on a rebuilt engine are the most important. This break-in period allows the new piston rings, bearings, and gaskets to seat correctly against the freshly machined surfaces. Your mechanic will provide specific instructions, but the general idea is to be gentle. For the first 500 miles, avoid high RPMs—a common rule of thumb is to keep it under 4,000 RPM. You should also avoid hard acceleration, heavy engine loads, and prolonged idling. It’s best to vary your engine speed by driving on roads that require you to shift gears and change your speed, rather than setting cruise control on the highway for a long trip. This helps the components wear in evenly and creates a strong seal for optimal compression.

Long-Term Care: Oil Changes and Monitoring

Once the break-in period is over, your focus shifts to consistent, long-term care. The first oil change is crucial and should be done much earlier than usual, typically around 500 miles. This initial change flushes out any microscopic metal particles and assembly lube from the break-in process. After that, stick to a regular schedule using high-quality oil and filters. This routine maintenance is essential for preserving the engine's health and complements professional engine tuning services by keeping everything in top condition. Beyond oil changes, make it a habit to regularly check your oil level, watch for any signs of leaks, and listen for unusual noises. Catching a small issue early is always better than dealing with a major repair down the road.

Related Articles

Frequently Asked Questions

Can I just replace the head gasket without rebuilding the cylinder head? While it might seem like a tempting shortcut, simply swapping the head gasket is rarely a lasting solution. The head gasket usually fails because of an underlying issue, most often an overheated and warped cylinder head. If you put a new gasket on a surface that isn't perfectly flat, it will fail again in short order. A professional rebuild addresses the root cause by inspecting the head for damage and resurfacing it to create a perfect seal, ensuring the repair is done right the first time.

Is a rebuild really worth the cost on an older, high-mileage Subaru? Absolutely. For a high-mileage Subaru, a cylinder head rebuild is one of the best investments you can make in its long-term health. It's a proactive measure that addresses the most common major failure point—the head gaskets—before they can cause catastrophic engine damage. By restoring the engine's top end, you're not just fixing a leak; you're renewing its reliability and efficiency, ensuring you get many more years and miles out of a car you already know and love.

Will a cylinder head rebuild permanently fix my engine's overheating issue? A rebuild will fix the damage caused by overheating, such as a warped head or a failed head gasket. However, it won't fix the original source of the problem. Overheating is often a symptom of a separate issue in the cooling system, like a failing radiator, water pump, or thermostat. A reputable shop will diagnose and repair the root cause of the overheating in addition to rebuilding the cylinder heads to ensure the problem doesn't come back.

How do I decide between standard OEM parts and performance upgrades for my rebuild? The right choice depends entirely on your goals for the car. If you have a stock daily driver and simply want to restore its factory reliability, high-quality OEM parts are a perfectly suitable option. However, if you plan to add more power, drive your car on the track, or simply want to build a more durable engine, this is the ideal time to invest in performance parts. Upgraded head studs and multi-layer steel gaskets provide a much stronger defense against future failures, especially under stress.

What's the difference between resurfacing the head and porting it? These are two very different machine shop services. Resurfacing, also called decking, is a necessary step in almost every rebuild. It involves machining a very thin layer of metal off the head's mating surface to make it perfectly flat, which is essential for the head gasket to seal properly. Porting, on the other hand, is a performance modification where a technician smooths and reshapes the intake and exhaust ports to improve airflow, which helps the engine make more power.