Der ultimative Leitfaden zum Bau von EJ25-Shortblocks

Share

Bei jedem Subaru-Umbau kommt der Punkt, an dem eine ernsthafte Entscheidung ansteht. Entweder man lässt den Serienmotor weiterlaufen und hofft auf das Beste, oder man investiert in ein Fundament, das einem ein gutes Gefühl gibt. Ein gebauter EJ25 Shortblock ist mehr als nur eine Ansammlung von Hochleistungsteilen; er ist eine Versicherung gegen katastrophale Motorschäden. Er gibt Ihnen das Vertrauen, auf der Rennstrecke Vollgas zu geben oder sich tief in eine Overlanding-Tour zu wagen, ohne sich Sorgen machen zu müssen, ob der Motor heute den Geist aufgibt. Dieser Artikel ist Ihr umfassender Leitfaden für diese Investition und deckt alles ab, von der Wahl des Herstellers bis hin zu den wichtigen Tuning- und Wartungsarbeiten, die zum Schutz des Motors erforderlich sind.

Die wichtigsten Erkenntnisse

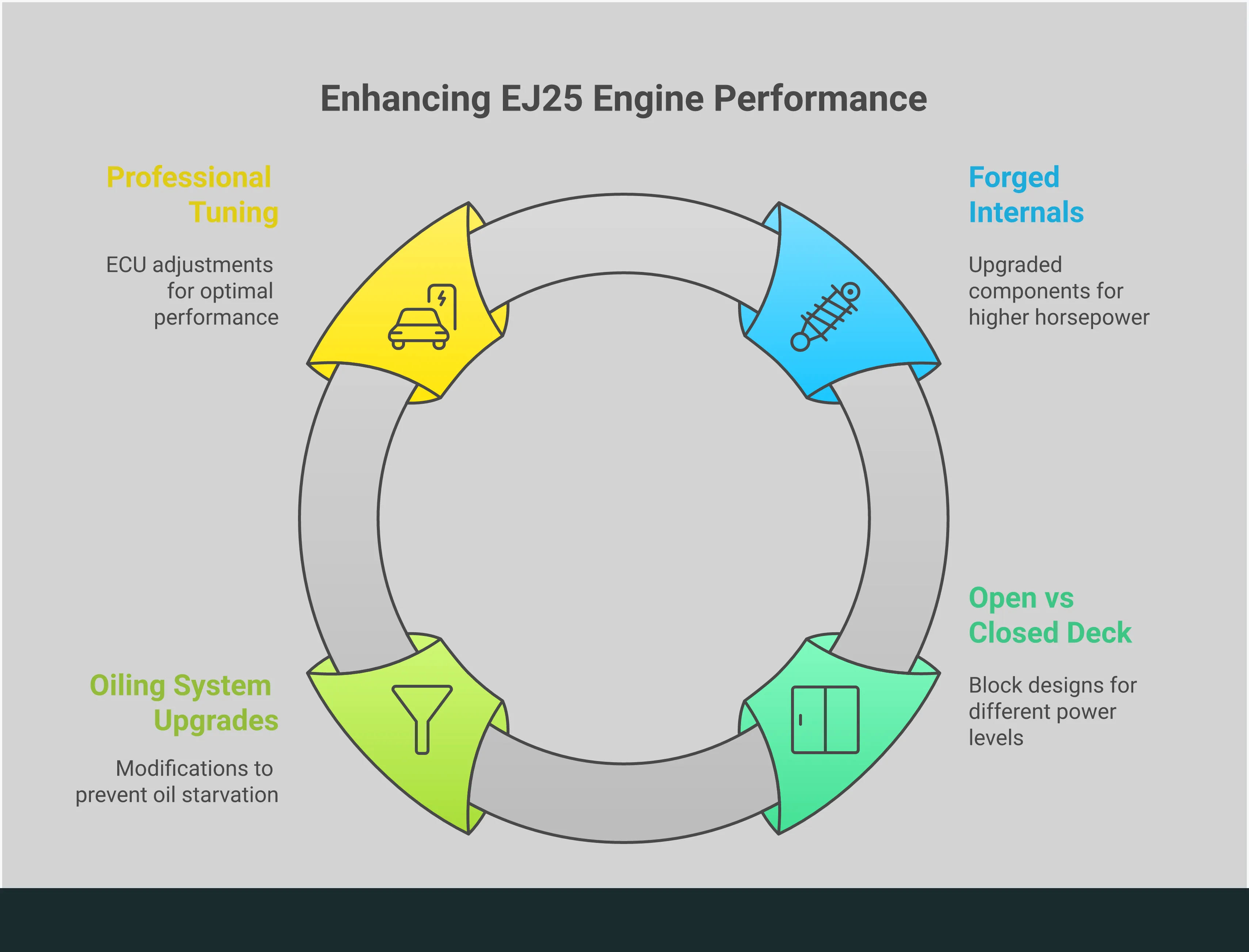

- Bauen Sie Ihren Motor für zuverlässige Leistung : Der serienmäßige EJ25 hat seine Grenzen, insbesondere die Gusskolben. Die Aufrüstung auf einen gebauten Kurzblock mit geschmiedeten Innenteilen schafft eine langlebige Grundlage, die der Belastung durch deutlich höhere PS-Zahl und aggressives Tuning sicher standhält.

- Ein starker Motor braucht starke Unterstützung : Ein gebauter Block ist nur ein Teil des Puzzles. Um eine zuverlässige Leistung zu erzielen, benötigen Sie auch eine sorgfältige Installation und unterstützende Upgrades für Ihre Öl-, Kühl- und Kraftstoffsysteme, um die erhöhte Leistungsabgabe zu bewältigen.

- Schützen Sie Ihre Investition nach der Installation : Die Arbeit ist nicht getan, wenn der Motor erst einmal eingebaut ist. Eine professionelle ECU-Abstimmung zur Anpassung an die neue Hardware ist unerlässlich und die Einhaltung eines strengen Einfahrverfahrens und Wartungsplans ist für die langfristige Gesundheit und Leistung Ihres Motors unerlässlich.

Was ist der Unterschied bei einem eingebauten EJ25-Shortblock?

Wenn Sie Ihren Subaru über die Werksgrenzen hinaus treiben möchten, haben Sie wahrscheinlich schon den Begriff „gebauter Block“ gehört. Aber was bedeutet das eigentlich? Im Grunde ist ein gebauter EJ25-Shortblock eine verstärkte und verbesserte Version des Motors, der in Ihrem Auto verbaut war. Der Serienmotor ist für den täglichen Gebrauch und die von Subaru vorgesehenen Leistungsstufen ausgelegt. Wenn Sie einen größeren Turbo, mehr Ladedruck und eine aggressivere Abstimmung hinzufügen, stoßen Sie schnell an die Grenzen der Originalkomponenten.

Ein gebauter Shortblock ersetzt die Serienteile durch hochfeste, geschmiedete Innenteile, die deutlich mehr Leistung und Belastung zuverlässig bewältigen. Es geht nicht nur darum, auf dem Prüfstand eine Zahl zu erreichen; es geht darum, ein Fundament zu schaffen, das auch bei starker Beanspruchung auf der Rennstrecke oder einer abgelegenen Overlanding-Strecke nicht versagt. Vergleichen Sie es mit dem Unterschied zwischen einem Standardfundament für ein Haus und einem verstärkten Fundament für einen Wolkenkratzer. Beide funktionieren, aber nur eines ist auf das vorbereitet, was Sie darauf bauen werden.

Stock vs. Built: Was Sie wissen müssen

Der Hauptunterschied zwischen einem serienmäßigen und einem gebauten Shortblock liegt in den Materialien und der Konstruktion der internen Komponenten. Ihr EJ25 ab Werk wird mit Gusskolben geliefert, die für die Serienleistung völlig ausreichend sind, aber unter der hohen Hitze und dem Zylinderdruck eines modifizierten Motors bekanntermaßen spröde werden. Ein gebauter Block, wie wir ihn bei Crawford Performance montieren, verwendet Schmiedekolben. Diese bestehen aus einer stärkeren Aluminiumlegierung und werden unter enormem Druck hergestellt, wodurch sie wesentlich langlebiger und widerstandsfähiger gegen Detonation sind. Allein dieses Upgrade ist ein entscheidender Faktor für die Motorzuverlässigkeit, da Sie höhere Ladedruckstufen sicher fahren und eine bessere Gesamtleistung erzielen können.

Offenes Deck vs. geschlossenes Deck – Erklärung

Subaru EJ25-Motoren werden werkseitig mit einem „Open Deck“-Design geliefert. Das bedeutet, dass sich an den Oberseiten der Zylinderwände große Kühlmittelkanäle befinden, was ideal für die Kühlung während der täglichen Fahrt ist. Allerdings sind die Zylinderwände bei diesem Design oben frei von Stützen. Unter dem immensen Druck bei Hochleistungskonstruktionen können sich diese freitragenden Wände verbiegen, verziehen oder sogar reißen. Eine „Closed Deck“-Modifikation löst dieses Problem, indem eine Stützstruktur in die Kühlmittelkanäle eingesetzt wird, die die Zylinderwände effektiv stützt. Dies macht den gesamten Motorblock deutlich stabiler und ist ein Muss für jeden, der einen ernsthaften Hochleistungsaufbau plant.

Wie viel Leistung kann ein Block wirklich bewältigen?

Ein serienmäßiger EJ25-Block gilt im Allgemeinen bis zu etwa 300 PS als sicher. Mehr Leistung mit serienmäßigen Innenteilen zu erreichen, ist riskant und endet oft mit dem berüchtigten Ringland-Fehler. Ein professionell gebauter Shortblock ändert die Situation grundlegend. Ein Basisaufbau mit Schmiedekolben bewältigt 400 PS bequem und zuverlässig. Wer mehr erreichen möchte, kann mit einem umfangreicheren Aufbau mit stärkeren Pleueln und einem geschlossenen Deck 500, 600 oder sogar mehr PS erreichen. Die endgültige Leistungsgrenze hängt von der Qualität der gewählten Performance-Teile und der Qualität der unterstützenden Modifikationen und Abstimmungen ab.

Wichtige Upgrades in einem Performance-Shortblock

Was genau steckt also in einem Performance-Shortblock? Die Stars der Show sind die geschmiedeten Kolben und Pleuelstangen. Geschmiedete Kolben sind die erste Verteidigungslinie gegen die erhöhte Hitze und den Druck eines modifizierten Motors. Sie werden mit geschmiedeten Pleuelstangen (oft in H- oder I-Träger-Bauweise) kombiniert, die viel stabiler sind als die Serieneinheiten und ein Verbiegen oder Brechen bei hohem Drehmoment verhindern. Darüber hinaus umfasst eine hochwertige Konstruktion Hochleistungslager, die höheren Belastungen und Temperaturen standhalten, und oft eine präzise Auswuchtung der gesamten rotierenden Baugruppe (Kurbel, Stangen und Kolben) für einen reibungslosen, zuverlässigen Betrieb bei hohen Drehzahlen. Dies sind die wichtigsten Upgrades des Subaru STI, die einen wirklich robusten Motor ausmachen.

Wer baut den am besten gebauten EJ25 Short Block?

Wenn Sie bereit sind, in das Herzstück Ihres Subaru zu investieren, möchten Sie sicher sein, dass Sie einen Qualitätsmotor von Experten erhalten. Der richtige Shortblock kann die Leistung und Zuverlässigkeit Ihres Autos grundlegend verbessern. Mehrere renommierte Hersteller haben sich auf den EJ25 spezialisiert, und jeder bringt etwas anderes mit. Werfen wir einen Blick auf einige der Top-Hersteller – Crawford Performance, IAG Performance und Outfront Motorsports –, um sie im Vergleich zu vergleichen und Ihnen zu helfen, den perfekten Motor für Ihren Umbau zu finden.

Crawford-Leistung

Hier bei Crawford leben und atmen wir Subaru-Leistung. Unsere Subaru Short Blocks werden vor allem für einen Zweck konstruiert: Sie bieten eine solide Grundlage für enorme Leistung und langfristige Zuverlässigkeit. Wir konstruieren unsere Blöcke so, dass sie den Belastungen sowohl auf der Rennstrecke als auch im Alltag standhalten. Einige Modelle unterstützen bis zu 770 PS. Wir sind von der Qualität unserer Arbeit so überzeugt, dass wir auf jeden Short Block eine 12-monatige oder 19.000-km-Garantie gewähren. So können Sie Ihr Auto beruhigt an seine Grenzen bringen, da Sie wissen, dass jahrzehntelange Ingenieurserfahrung dahinter steckt.

IAG-Leistung

IAG Performance ist ein weiterer bekannter Name in der Subaru-Community und bietet eine große Auswahl an EJ25-Shortblocks für Modelle wie den WRX, STI und Forester XT. Das Sortiment deckt ein breites Leistungsspektrum ab, angefangen beim 550-PS-Motor für robuste Straßenfahrzeuge bis hin zum 1150-PS-Motor für Rennwagen. Diese Auswahl bietet Ihnen zahlreiche Optionen, die Ihren individuellen Leistungszielen und Ihrem Budget entsprechen. Der Shortblock „Typ RA“ ist besonders beliebt bei denjenigen, die ein solides und kostengünstiges Upgrade des Serienmotors suchen, und ist daher für viele Enthusiasten eine attraktive Wahl.

Outfront Motorsports

Outfront Motorsports bietet eine umfangreiche Auswahl an EJ25-Shortblocks für vielfältige Leistungsanforderungen. Mit über 20 verschiedenen Konfigurationen finden Sie den passenden Motor für nahezu jeden Einsatzzweck, vom Straßenrennen bis zum Offroad-Einsatz. Viele Blöcke sind serienmäßig mit einem „Closed Deck“-Design für verbesserte Zylinderwandfestigkeit ausgestattet und verfügen über hochwertige Komponenten wie Schmiedekolben und Lauflager. Dieser Fokus auf Langlebigkeit und Vielfalt ermöglicht Ihnen die Auswahl eines Shortblocks mit genau den Komponenten und Spezifikationen, die Sie für Ihr individuelles Projekt benötigen. So erhalten Sie die perfekte Lösung für Ihre Leistungsanforderungen.

Vergleich von Leistung, Preis und Garantien

Wie entscheiden Sie sich also für den richtigen Hersteller? IAG bietet die größte Auswahl an Leistungsoptionen, während Outfront einen umfangreichen Katalog spezifischer Konfigurationen bietet. Crawford Performance konzentriert sich auf eine kuratierte Palette von Blöcken, die für bewährte, zuverlässige Leistung von bis zu 770 PS ausgelegt sind. Die Preise liegen in der Regel zwischen 4.999 und 5.999 US-Dollar. Im Vergleich dazu liegen die Preise von IAG zwischen etwa 4.000 und über 9.500 US-Dollar und die von Outfront zwischen 3.400 und 8.100 US-Dollar.

Ein entscheidendes Unterscheidungsmerkmal ist jedoch die Garantie. Zwar können die Garantiebedingungen anderswo variieren, Crawford Performance steht jedoch mit einer umfassenden 12-Monats- bzw. 12.000-Meilen-Garantie für jeden Motor voll hinter dem Produkt. Diese Zusage gibt Ihnen zusätzliches Vertrauen in Ihre Investition.

Anatomie eines hochwertig gebauten Blocks

Ein wirklich hochwertiger Motorblock ist mehr als nur eine Ansammlung glänzender, teurer Teile. Es ist ein komplettes System, bei dem jede Komponente so ausgewählt ist, dass sie die inhärenten Schwächen des EJ25 behebt und harmonisch zusammenwirkt, um ein zuverlässiges Kraftpaket zu schaffen. Betrachten Sie es als eine solide Grundlage für Ihre Leistungsziele. Statt nur auf PS-Zahlen zu zielen, konzentriert sich ein gut gebauter Motor auf Langlebigkeit, effiziente Ölung und gleichmäßige Kühlung. Dieser durchdachte Ansatz stellt sicher, dass Ihr Motor die zusätzliche Leistung, die Sie ihm zuführen, bewältigen kann, egal ob auf der Rennstrecke, im Gelände oder auf der Straße.

Warum gefälschte Innenteile nicht verhandelbar sind

Wenn Sie mehr Leistung wollen, sind die serienmäßigen Gusskolben und Pleuel oft die ersten Komponenten, die versagen. Sie sind einfach nicht für den erhöhten Zylinderdruck und die Belastung ausgelegt, die mit einem höheren Ladedruck einhergehen. Hier kommen geschmiedete Innenteile ins Spiel. Beim Schmieden wird Metall unter extremem Druck geformt, wodurch ein viel dichteres und festeres Bauteil entsteht als beim Gießen. Hochwertige Teile wie robuste geschmiedete Kolben und Pleuel sind für maximale Leistung und Performance unerlässlich. Sie bieten die nötige Haltbarkeit für aggressives Tuning und höhere Drehzahlen und geben Ihnen die Gewissheit, Ihren Motor zu fordern, ohne sich um einen Totalausfall sorgen zu müssen. Es ist das wichtigste Upgrade für einen zuverlässigen, leistungsstarken Motor.

Aufrüsten Ihres Ölsystems

Der EJ25 hat eine lange Geschichte von Problemen mit dem Ölsystem. Bei Kurvenfahrten mit hoher Schwerkraft oder anhaltend hohen Drehzahlen kann die serienmäßige Ölwanne reißen, und die Wannenkonstruktion kann zu Ölmangel führen, der die Pleuellager schnell zerstört. Ein qualitativ hochwertiger Motorblock berücksichtigt dieses Problem immer. Eine verbesserte Ölwanne ist ein Muss, und viele Hersteller verwenden zusätzlich eine Ölwanne mit großem Fassungsvermögen und Leitblechen, um das Öl dort zu halten, wo es hingehört. Ein Luft-/Ölabscheider (AOS) ist eine weitere wichtige Ergänzung, die verhindert, dass Öl in den Ansaugtrakt gelangt und die Oktanzahl des Kraftstoffs senkt. Die Reparatur des Ölsystems ist entscheidend für eine lange Lebensdauer Ihres neuen Motors.

Wesentliche Kühllösungen

Hitze ist der Feind jedes Hochleistungsmotors, und der EJ bildet da keine Ausnahme. Eine seiner bekannten Macken ist die schlechte Kühlung des vierten Zylinders. Bei höherer Leistung entsteht mehr Wärme, und das werkseitige Kühlsystem kann schnell überlastet sein. Ein gebauter Shortblock ist zwar widerstandsfähiger, benötigt aber ein effizientes Kühlsystem, um sichere Betriebstemperaturen aufrechtzuerhalten. Ein Aluminiumkühler, verbesserte Kühlmittelschläuche und sogar eine Wasserpumpe mit höherem Durchfluss sind sinnvolle unterstützende Modifikationen. Experten weisen darauf hin, dass ein werkseitiger EJ erhebliche Leistungen bewältigen kann, aber nur mit der richtigen Motorsteuerung und effektiven Kühllösungen, um Überhitzung zu vermeiden und die Zuverlässigkeit im Alltag zu gewährleisten.

Behebung der gemeinsamen Schwachstellen des EJ25

Ein erstklassiger Motorblock zeichnet sich dadurch aus, wie gut er die klassischen Probleme des EJ25 löst. Ein sorgfältiger Konstrukteur behebt nicht nur geschmiedete Innenteile, sondern auch alle bekannten Schwachstellen. Dazu gehören die Verwendung stärkerer Gehäuseschrauben, präzise Lagerabstände zur Vermeidung von Pleuellagerschlägen und manchmal auch Modifikationen zur Verbesserung des Kühlmittelflusses zum problematischen vierten Zylinder. Ziel ist es, einen zuverlässigen und leistungsstarken Motor zu schaffen, indem die werksseitigen Fehler, die zu Ausfällen führen, systematisch beseitigt werden. Wenn Sie in einen Motorblock investieren, zahlen Sie nicht nur für stärkere Teile, sondern auch für das Know-how und die Ingenieurskunst, die in die Schaffung einer ausgewogenen, langlebigen und zuverlässigen Grundlage für Ihre gesamte Konstruktion einfließen.

Ihr Leitfaden zur Installation und Kompatibilität

Die Wahl des richtigen Shortblocks ist ein großer Schritt, aber damit ist die Reise noch nicht zu Ende. Ein perfekter Motor kann durch eine fehlerhafte Installation ruiniert werden. Daher ist die richtige Wahl dieses Teils genauso wichtig wie die Wahl der Komponenten. Hier wird das Projekt konkret, und Ihre Liebe zum Detail entscheidet über den Erfolg Ihres Baus. Bevor Sie überhaupt einen Schraubenschlüssel in die Hand nehmen, benötigen Sie einen soliden Plan.

Zunächst müssen Sie absolut sicher sein, dass der neue Block zu Ihrem Subaru passt. EJ25 sind zwar für ihre Austauschbarkeit bekannt, es gibt jedoch feine Unterschiede zwischen den Modelljahren und Ausstattungen, die Sie ins Stolpern bringen können. Als Nächstes stehen Sie vor der großen Entscheidung: Nehmen Sie die Sache selbst in Angriff oder geben Sie die Schlüssel einem Fachmann? Es gibt nicht die eine richtige Antwort, aber wenn Sie ehrlich sind, was Ihre Fähigkeiten, Werkzeuge und Zeit angeht, ersparen Sie sich eine Menge Kopfzerbrechen. Wir gehen einige der häufigsten Installationsfehler durch, die uns im Laufe der Jahre aufgefallen sind – kleine Versehen, die zu großen Problemen führen können. Abschließend gehen wir auf die Bedeutung von Präzision ein, insbesondere bei den Drehmomentangaben. Die richtigen Details unterscheiden einen zuverlässigen, leistungsstarken Motor von einem, der zum Versagen verurteilt ist.

Passt es? Überprüfen Sie die Kompatibilität Ihres Fahrzeugs

Eine der ersten Fragen, die sich jeder stellt, ist: „Passt dieser Block tatsächlich in mein Auto?“ Die gute Nachricht ist, dass EJ25-Shortblocks grundsätzlich zwischen verschiedenen Subaru-Modellen von 2002 bis heute austauschbar sind. Das bedeutet, dass ein für einen STI gebauter Block oft die Grundlage für einen leistungsstarken WRX- oder Forester-Umbau bilden kann. „Austauschbar“ bedeutet jedoch nicht immer „Plug-and-Play“. Sie müssen dennoch Unterschiede bei Zylinderköpfen, Sensoren und Zubehör zwischen den Modellen berücksichtigen. Am besten lassen Sie sich die Kompatibilität immer von Ihrem Teilelieferanten bestätigen. Er kann Ihnen dabei helfen, sicherzustellen, dass alle Ihre vorhandenen Komponenten mit dem neuen Block funktionieren, und Sie auf zusätzliche Leistungsteile hinweisen, die Sie für eine reibungslose Installation benötigen.

Professionelle Installation oder DIY: Was ist das Richtige für Sie?

Die Entscheidung zwischen einem professionellen Einbau oder einem Eigenbauprojekt ist eine persönliche Entscheidung, die von Ihrer Erfahrung, Ihren Werkzeugen und Ihrem Selbstvertrauen abhängt. Unsere Short Blocks sind sowohl für ernsthafte Autoliebhaber als auch für Leute konzipiert, die einfach nur einen starken, zuverlässigen Ersatzmotor für ihren Subaru benötigen. Wenn Sie ein erfahrener Mechaniker mit einem sauberen Arbeitsplatz und den richtigen Werkzeugen sind, kann ein Eigenbauprojekt eine unglaublich lohnende Erfahrung sein. Wenn Sie jedoch neu im Motorenbau sind, bietet ein professioneller Einbau ein beruhigendes Gefühl. Eine seriöse Werkstatt verfügt über das Fachwissen, um mit allen Überraschungen umzugehen, und gewährt oft eine Garantie auf ihre Arbeit. Dies ist eine große Investition. Wenn ein Experte den Einbau und die anschließenden Motoroptimierungen durchführt, stellt er sicher, dass Ihr neuer Motor vom ersten Tag an seine beste Leistung bringt.

So vermeiden Sie häufige Installationsfehler

Der kleinste Fehler kann beim Bau eines Motors zu Fehlfunktionen führen. Wir haben schon erlebt, dass einfache Fehler, wie eine defekte Kupplung zwischen Ölpumpe und Lüfter, innerhalb weniger tausend Kilometer zum Totalausfall des Motors führen können. Um dies zu vermeiden, ist Akribie geboten. Überprüfen Sie jede Verbindung doppelt und dreifach. Stellen Sie sicher, dass alle Passflächen vor dem Anbringen von Dichtungen absolut sauber sind. Einer der wichtigsten Schritte ist das ordnungsgemäße Vorfüllen des Ölsystems vor dem ersten Starten des Motors, um sicherzustellen, dass alle Komponenten geschmiert sind. Überstürztes Vorgehen ist der schnellste Weg, Ihre Investition zu ruinieren. Nehmen Sie sich Zeit, folgen Sie einer Checkliste, und wenn Sie bei einem Schritt unsicher sind, halten Sie inne und bitten Sie um Hilfe oder konsultieren Sie das Servicehandbuch des Herstellers.

Die richtigen Drehmomentangaben finden

Das Erraten von Drehmomentangaben ist ein Rezept für eine Katastrophe. Jede Schraube an Ihrem Motor hat aus gutem Grund ein bestimmtes Drehmoment – es gewährleistet die richtige Klemmkraft, ohne die Schraube zu dehnen oder die Komponenten zu beschädigen. Um beispielsweise Auspufflecks zu vermeiden, ist es wichtig zu wissen, dass die Halterungen zwischen Aufwärtsrohr und Motorblock mit genau 24,6 lb/ft angezogen werden müssen. Die absolut beste Quelle für diese Informationen ist das Factory Service Manual (FSM) für das jeweilige Baujahr und Modell Ihres Subaru. Die Verwendung eines hochwertigen Drehmomentschlüssels und die Einhaltung der Spezifikationen und Anzugsreihenfolgen des FSM sind unerlässlich. Diese Präzision stellt sicher, dass Ihr Motor richtig abgedichtet ist und zusammenhält, wenn Sie ihn auf der Rennstrecke oder im Gelände stark beanspruchen.

Tuning und Wartung Ihres neuen Motors

Der Einbau eines EJ25-Shortblocks ist ein wichtiger Meilenstein, doch die Arbeit endet hier nicht. Um die zuverlässige Leistung zu erhalten, in die Sie investiert haben, müssen Sie sich auf das konzentrieren, was als Nächstes kommt: eine präzise Abstimmung und eine sorgfältige Wartungsroutine. Stellen Sie sich das so vor: Sie haben einen Weltklasse-Athleten aufgebaut, und jetzt ist es Zeit für den richtigen Trainings- und Ernährungsplan, um ihm zu Höchstleistungen zu verhelfen. Diese letzte Phase zu vernachlässigen, ist der schnellste Weg, all Ihre harte Arbeit zunichte zu machen.

Die richtige Pflege stellt sicher, dass Ihr neuer Motor nicht nur unglaubliche Leistung liefert, sondern auch viele Jahre hält. Von der ersten ECU-Kalibrierung bis zum ersten Ölwechsel und darüber hinaus ist jeder Schritt entscheidend. So schützen Sie Ihre Investition und machen Ihren Subaru fit für langfristigen Erfolg – egal, ob Sie auf der Rennstrecke, im Gelände oder einfach nur im Alltag unterwegs sind. Wir erklären Ihnen, was Ihr neuer Motor braucht, um erfolgreich zu sein.

Was Sie für das Motormanagement benötigen

Sobald Ihr eingebauter Motorblock installiert ist, können Sie nicht einfach den Schlüssel umdrehen und losfahren. Das Gehirn Ihres Subaru, die Motorsteuerung (ECU), ist noch auf den Serienmotor programmiert. Ein eingebauter Motor mit geschmiedeten Innenteilen und anderen Abständen arbeitet unter völlig anderen Parametern. Ihn mit der Serieneinstellung zu betreiben, kann innerhalb weniger Minuten zu einem katastrophalen Ausfall führen.

Deshalb ist eine professionelle Motoroptimierung unerlässlich. Ein erfahrener Tuner passt die Kraftstoffkennfelder, die Zündzeitpunkte und die Ladedruckstufen perfekt an Ihre neue Hardware an. Wie MotorTrend anmerkt, sollten Sie den Motorcomputer immer von einem Experten tunen lassen, der sich wirklich damit auskennt. Hier sollten Sie nicht sparen. Professionelle Motoroptimierungen sorgen dafür, dass alle Komponenten harmonisch zusammenarbeiten, was Ihnen sichere und zuverlässige Leistung bietet und Ihren neuen Motor gleichzeitig vor Schäden schützt.

Die entscheidende Einlaufzeit: Eine Schritt-für-Schritt-Anleitung

Geduld ist eine Tugend, insbesondere nach dem Einbau eines neuen Motors. Die Einfahrzeit ist eine kritische Phase, in der die neuen Kolbenringe richtig an den Zylinderwänden anliegen und eine dichte Abdichtung für optimale Kompression bilden. Ein Enthusiast auf Reddit drückte es treffend aus: „Wenn ein Motor überholt oder ausgetauscht wird, muss er eine Zeit lang sanft gefahren werden, um richtig einzufahren. Wenn man ihn gleich hart antreibt, kann er ausfallen.“

Hier ist eine einfache Anleitung für die ersten 1.000 Meilen:

- Die ersten 800 Kilometer: Halten Sie die Drehzahl unter 4.000 U/min und vermeiden Sie konstante Geschwindigkeiten. Variieren Sie die Motordrehzahl, indem Sie auf Straßen mit unterschiedlichen Geschwindigkeitsbegrenzungen fahren. Dies trägt dazu bei, dass die Ringe richtig sitzen. Vermeiden Sie starkes Beschleunigen und hohen Ladedruck.

- 500–1.000 Meilen: Sie können die Drehzahl schrittweise erhöhen, vermeiden Sie jedoch weiterhin Vollgas und das Überschreiten des roten Bereichs.

- Nach 1.000 Meilen: Führen Sie Ihren ersten Öl- und Filterwechsel durch, um alle Metallpartikel aus dem Einfahrprozess zu entfernen. Danach können Sie das volle Potenzial Ihres Aufbaus nutzen.

Ihre neue Wartungscheckliste

Ein eingebauter Motor ist eine Hochleistungsmaschine und erfordert einen strengeren Wartungsplan als ein Serienmotor. Die Einhaltung einer Routine ist der beste Weg, um seine Langlebigkeit und einen reibungslosen Betrieb zu gewährleisten. Die wichtigste Aufgabe auf Ihrer neuen Checkliste ist der regelmäßige Ölwechsel. Laut Experten von MotorTrend: „Regelmäßige Wartung: Wechseln Sie Ihr Öl häufig mit hochwertigem synthetischem Öl.“ Bei einem eingebauten EJ25 bedeutet dies in der Regel alle 3.000 Meilen oder je nach Fahrweise sogar früher.

Machen Sie es sich zur Gewohnheit, neben dem Ölwechsel regelmäßig alle Flüssigkeitsstände zu überprüfen, einschließlich Kühlmittel und Servolenkungsflüssigkeit. Achten Sie auf neue oder ungewöhnliche Geräusche im Motorraum. Ein konsequenter Wartungsplan mit hochwertigen Performance-Teilen hilft Ihnen, kleine Probleme zu erkennen, bevor sie zu größeren werden, und schützt Ihre Investition langfristig.

Welche anderen Mods benötigen Sie zur Unterstützung Ihres Builds?

Ein gebauter Shortblock ist das Herzstück Ihres Hochleistungsmotors, kann die Aufgabe jedoch nicht allein bewältigen. Um die erhöhte Leistung sicher und zuverlässig zu bewältigen, müssen Sie die unterstützenden Systeme verbessern. Viele Motorbauer haben gelernt: „Um zuverlässig mehr Leistung zu erzielen, müssen Sie möglicherweise bestimmte Motoränderungen vornehmen, z. B. das Ölsystem verbessern und den Motor gut abstimmen.“ Das ist absolut richtig. Eine verbesserte Ölpumpe, ein Kühler oder ein Ölabscheider sind entscheidend, damit Ihr Motor auch unter Belastung gut geschmiert bleibt.

Weitere wichtige unterstützende Modifikationen sind ein verbessertes Kraftstoffsystem (Pumpe, Einspritzdüsen und Verteilerrohre) für ausreichend Kraftstoff, eine stärkere Kupplung für das zusätzliche Drehmoment und ein verbessertes Kühlsystem (Kühler und Schläuche) zur Wärmeregulierung. Durch die Optimierung dieser Bereiche ist Ihr gesamtes Setup ausgewogen und bereit für die Leistung, die die Upgrades Ihres neuen Subaru WRX liefern.

Verwandte Artikel

Häufig gestellte Fragen

Brauche ich wirklich einen Shortblock, wenn ich meinen Subaru nur täglich fahre? Ehrlich gesagt: Wenn Ihr Auto serienmäßig ist oder nur ein paar leichte Modifikationen aufweist, ist der Werksmotor durchaus geeignet. Ein Shortblock ist eine Investition in die Zuverlässigkeit für alle, die deutlich mehr PS wollen. Wenn Sie planen, einen größeren Turbo einzubauen, einen höheren Ladedruck zu fahren oder Ihr Auto häufig auf der Rennstrecke zu fahren, ist ein Shortblock eine intelligente, vorbeugende Maßnahme zur Motorsicherheit.

Was versagt als Erstes, wenn man einen serienmäßigen EJ25 überfordert? Die häufigste Fehlerquelle sind die werkseitig gegossenen Kolben, insbesondere die Ringfelder, die kleinen Metallfelder zwischen den Kolbenringen. Durch die erhöhte Hitze und den Druck durch höhere Leistung können diese Gussteile spröde werden und reißen. Genau deshalb sind Schmiedekolben die grundlegende Verbesserung in jedem Performance-Shortblock; sie sind so konstruiert, dass sie dieser zusätzlichen Belastung problemlos standhalten.

Ist ein Closed-Deck-Block für jeden Hochleistungsaufbau notwendig? Keineswegs. Eine Closed-Deck-Modifikation ist eigentlich nur für extremste Aufbauten gedacht, typischerweise für solche mit deutlich über 500 oder 600 PS. Für ein leistungsstarkes und zuverlässiges Straßenfahrzeug kann ein gut montierter Open-Deck-Block mit hochwertigen geschmiedeten Innenteilen viel Leistung bewältigen. Das Closed-Deck sorgt lediglich für zusätzliche Festigkeit, indem es die Zylinderwände für Szenarien mit enormem Zylinderdruck verstärkt.

Warum kann ich nicht einfach selbst geschmiedete Kolben und Pleuel in meinen Originalblock einbauen? Obwohl es technisch möglich ist, erfordert ein professionell gefertigter Block viel mehr als nur den Austausch robusterer Teile. Er erfordert sorgfältige Reinigung, präzise Bearbeitung des Blocks, Messung der Abstände auf den Tausendstel Zoll genau und Auswuchten der gesamten rotierenden Baugruppe. Dieses Fachwissen stellt sicher, dass alle Komponenten perfekt zusammenarbeiten, was für einen reibungslosen, zuverlässigen und langlebigen Motor entscheidend ist. Sie investieren in die Montage und Qualitätskontrolle genauso viel wie in die Einzelteile.

Was ist wichtiger für die Zuverlässigkeit: der Motorblock oder die Motorabstimmung? Das eine geht nicht ohne das andere. Betrachten Sie beide als Team. Der Motorblock bildet die solide Grundlage für die Leistung, die Motorabstimmung hingegen ist das Gehirn, das dem Motor sagt, wie er diese Kraft sicher einsetzen kann. Ein perfekter Motor kann durch eine schlechte Abstimmung innerhalb von Minuten zerstört werden, während eine hervorragende Abstimmung den Ausfall eines schwachen mechanischen Teils nicht verhindern kann. Beides ist für einen erfolgreichen und langlebigen Motorbau unerlässlich.